Brass is one of the most widely used engineering materials across industries—from plumbing and electrical to automotive, construction, and renewable energy. But what exactly makes Brass such a preferred choice over other metals like Steel, Aluminium, or even Plastic? In this blog, we explore the top five advantages of using Brass Components in industrial applications, especially for manufacturers, engineers, and procurement specialists looking for reliable, long-lasting solutions.

1. Exceptional Corrosion Resistance

One of Brass’s most celebrated properties is its natural resistance to corrosion and rust, especially in moisture-rich or chemical environments.

Ideal for plumbing and marine applications

Withstands oxidizing agents, water, and certain acids

Forms a protective patina that increases longevity

Brass Components outperform many other metals in outdoor or chemical environments without the need for costly coatings or maintenance.

2. Superior Machinability & Formability

Brass, especially grades like CZ121/C36000, offers excellent machinability. This results in:

Faster production on CNC and automatic lathes

Clean threads and precise tolerances

Lower tool wear and higher dimensional accuracy

Brass is also easily forged, cast, and pressed—making it highly adaptable for components of various sizes and complexity.

3. Electrical and Thermal Conductivity

While not as conductive as pure Copper, Brass still retains a high level of electrical and thermal conductivity, making it ideal for:

Electrical terminals and contacts

Heat exchangers and radiator parts

Earthing and grounding systems

Unlike coated Steel or Aluminium, Brass doesn’t lose conductivity due to surface oxidation or corrosion.

4. Aesthetic & Professional Appearance

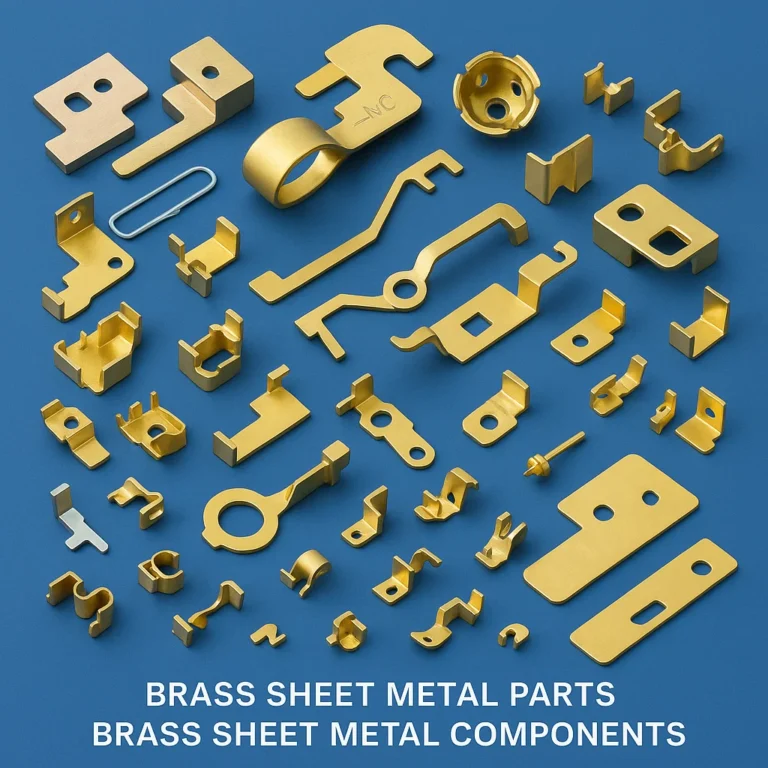

Brass Components offer a visually appealing golden finish that is suitable for:

Architectural fittings

Decorative hardware

Premium plumbing or valve products

The natural finish can be enhanced through Nickel, Chrome, or Tin plating, offering both aesthetic and functional benefits.

5. Long-Term Value and Sustainability

Brass is 100% recyclable without loss in performance, making it both cost-effective and eco-friendly. Additional benefits include:

Low lifecycle cost due to minimal maintenance

Resistance to dezincification with proper alloy selection

Compliance with RoHS, REACH, and other environmental standards

In industries where downtime is expensive, Brass Components offer longevity and reliability that translate directly into cost savings.

Real-World Use Cases

| Industry | Brass Component Examples |

|---|---|

| Plumbing | Pipe fittings, valves, couplers, nipples |

| Electrical | Terminals, grounding screws, earthing accessories |

| Automotive | Battery terminals, fuel system fittings, sensors |

| Aerospace | Instrument panels, connectors, mechanical linkages |

| Industrial | Bushings, sleeves, anchors, inserts |

Why Choose Us for Your Brass Component Needs?

At Brass-Copper-Parts.com, we specialize in manufacturing precision Brass Components for over 29 years, supplying to 74+ countries worldwide. Our in-house facilities include:

ISO 9001:2015 certified quality systems

Advanced CNC turning, casting, and forging

In-house brass rod plant for consistent alloy quality

Full documentation (RoHS, REACH, MTCs, etc.)

Whether you need custom-designed parts or standard catalog items, we deliver high-quality Brass Components at competitive prices.

📞 Need Help Choosing the Right Brass Component?

Contact our technical team for expert guidance, custom quotes, and fast delivery:

📧 sales@brass-copper-parts.com

📞 +91-22-43449300 | WhatsApp Available