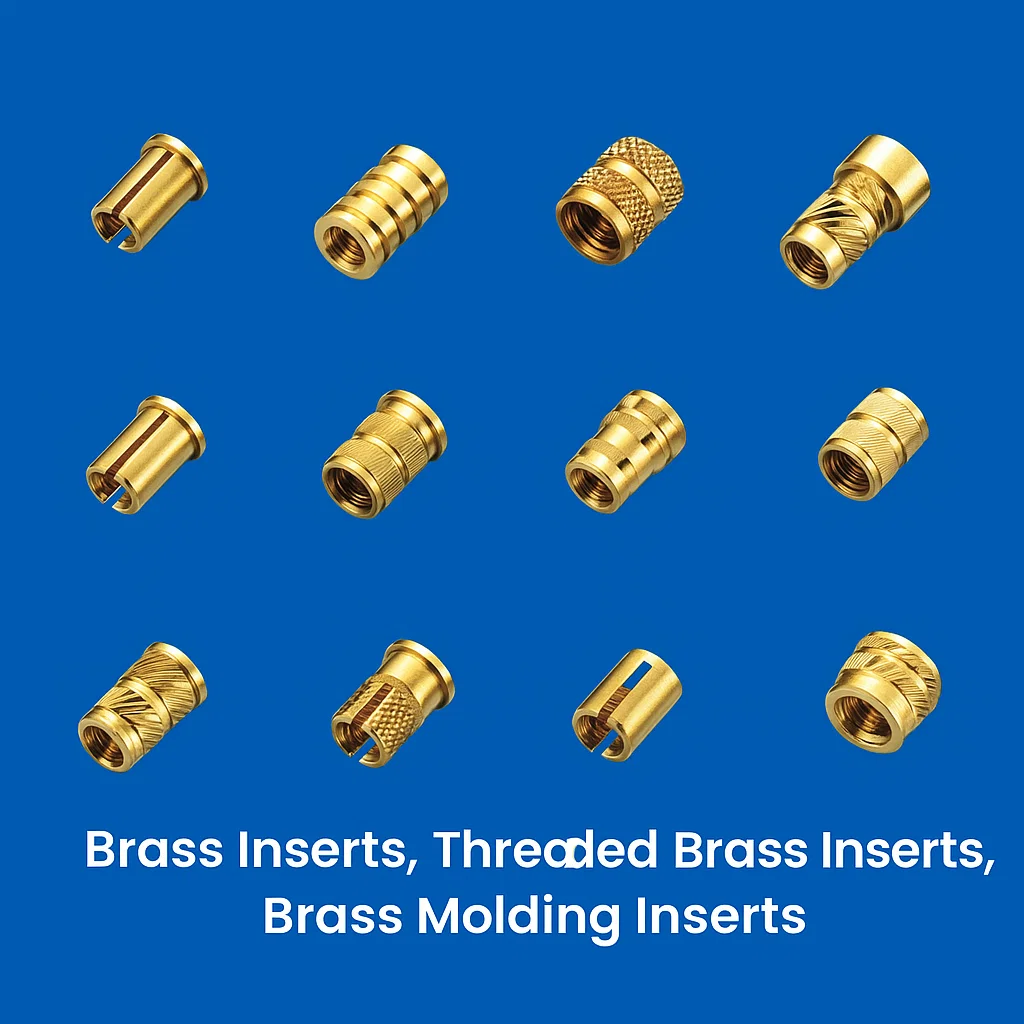

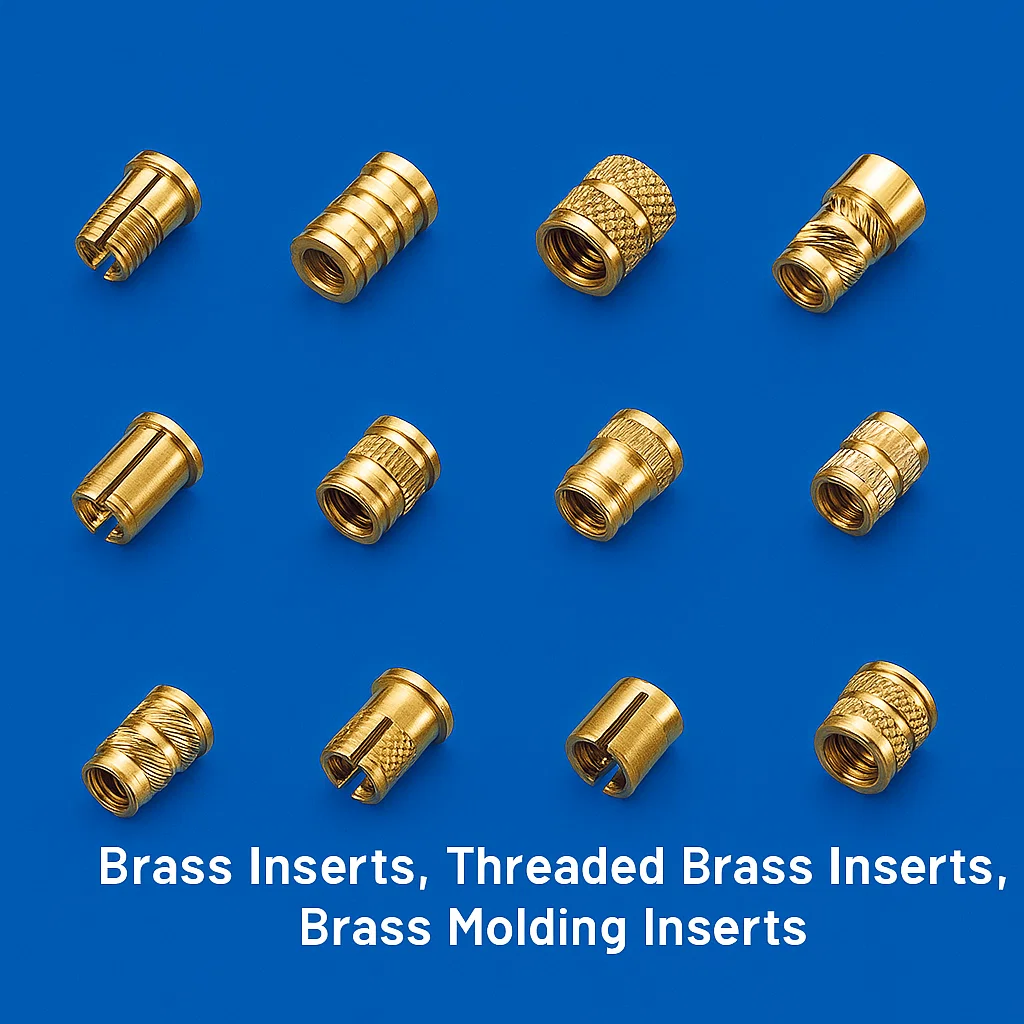

BRASS INSERTS, BRASS MOLDING INSERTS, PLASTIC MOLDING BRASS INSERTS

We are one of the leading manufacturers and exporters of Brass Inserts from India. We have been supplying Brass Inserts to the world market for many decades. Based in Jamnagar, Gujarat, our facility specializes in both blind and through Brass Inserts with no minimum order quantity, ensuring deep‐groove knurling and precision threads that comply with international Go / No‑Go standards. Whether you require Diamond, Straight, or Unidirectional Knurling, our inserts deliver maximum pull‑out resistance, tight inner‑diameter tolerances, and flawless fit in plastics, composites, and soft metals.

Product Overview

Brass Inserts are threaded bushings pressed or molded into softer materials to provide durable, reusable screw threads. Manufactured from high‑conductivity Brass alloys, these inserts offer excellent corrosion resistance, electrical conductivity, and mechanical strength. Our Inserts prevent thread stripping, improve product longevity, and are ideal for applications in electronics, automotive interiors, furniture, medical devices, and consumer goods.

Key Features & Specifications

| Feature | Specification |

|---|---|

| Thread Standard | ISO Metric (M2 – M12), UNF, UNC, BSP, NPT |

| Knurling Types | Diamond |

| Pull‑Out Resistance | ≥ 1,200 N (dependent on substrate) |

| I/D Tolerance (post‑thread) | ± 0.02 mm |

| Insert Lengths | 3 mm – 25 mm |

| Material Grades | ASTM C36000, EN CW614N, IS 319 Grade 1 & 2 |

Materials & International Standards

| Region | Standard | Brass Grade | Property Highlights |

|---|---|---|---|

| USA | ASTM | C36000 | High machinability, conductivity |

| Europe | EN/DIN | CW614N | Superior corrosion resistance |

| UK | BS | CZ121 | Free‑cutting brass |

| Japan | JIS | C3602 | Precision machining |

| India | IS | IS 319:2015 (LG2, LTB2) | Durable, electrical applications |

| China | GB | H62 | Industrial strength |

Manufacturing Process

Our multi‑stage process ensures consistent quality:

Cold Heading: Brass slugs are formed into pre‑shaped inserts.

Knurling: Diamond, Straight, or Unidirectional patterns are rolled for grip.

Thread Rolling: Threads are formed under pressure to achieve Go / No‑Go compliance.

Deburring & Cleaning: Ultrasonic cleaning removes swarf; parts are rinsed and dried.

Quality Inspection: SPC/SQC system records Cpk values, max/min measurements, and thread‑gage verification for every batch.

Typical Applications

| Industry | Use Case |

|---|---|

| Electronics | PCB standoffs, housing assemblies |

| Automotive | Dashboard panels, seat adjuster knobs |

| Furniture | Knock‑down fittings, modular assembly |

| Medical Devices | Instrument casings, ergonomic grips |

| Consumer Goods | Appliance panels, handheld tools |

| Telecommunications | Enclosures, connector housings |

Tolerances & Performance Metrics

| Parameter | Value |

|---|---|

| Inner‑Diameter Tolerance | ± 0.02 mm |

| Length Tolerance | ± 0.05 mm |

| Pull‑Out Force | ≥ 1,200 N (in polycarbonate) |

| Temperature Range | −40 °C to +120 °C |

Turnaround Time

Standard production takes 4–6 weeks from order confirmation. Expedited runs and sample quantities can often be delivered in 2–3 weeks, subject to capacity.

Frequently Asked Questions

Can I order inserts without minimum quantity?

Yes—both blind and through Brass Inserts are available with no MOQ.What materials can they be pressed into?

Suitable for thermoplastics (ABS, PC), composites, soft alloys, and wood.Do you support custom knurl patterns?

Yes—besides Diamond, Straight, and Unidirectional, bespoke patterns can be developed.Are inserts RoHS compliant?

All materials and processes meet RoHS and REACH regulations.How are inserts delivered?

Supplied in polybags or loose bulk cartons; custom packaging on request.Do you provide test reports?

Each lot ships with SPC/SQC reports, including Cpk and dimension data.Can you machine inserts after production?

We offer secondary operations such as plating, passivation, or polishing.What thread sizes are supported?

From M2 to M12 metric; UNF, UNC, BSP, and NPT also available.How do I install blind versus through inserts?

Blind inserts are set with a heat or ultrasonic press; through inserts use expansion or knurl grip.Can you ship globally?

Yes—we export via sea, air, and courier to over 50 countries.

Types of BRASS INSERTS

Brass Threaded Inserts: The most common general category.

Brass Press-Fit Inserts: Inserts designed to be pressed into a hole.

Brass Knurled Inserts: Feature a knurled outer diameter for better grip in the host material.

Brass Bushings: Often used when the insert provides a bearing surface rather than a thread, but sometimes used interchangeably.

Brass Inserts for Wood: Specifically describes their primary application material.

Brass Inserts for Plastic: Specifically describes their primary application material.

Embedded Nuts / Captive Nuts: Refers to their function of providing a permanent, internal thread.

Technical & Engineering Terms

These are terms used in design, engineering, and manufacturing specifications.

Helical Inserts / Wire Inserts (e.g., Heli-Coil®): A specific type of insert made of wound wire, often stainless steel, used to repair stripped threads or provide stronger threads in soft materials. Brass versions exist.

Key-Locking Inserts: A high-strength, vibration-resistant insert that locks into place with keys.

Brass Ultrasonic Inserts: Inserts designed to be installed using ultrasonic energy, which melts the surrounding plastic for a secure fit.

Thermal Inserts / Heat-Set Inserts: Inserts installed by applying heat to the insert, which then melts into the surrounding plastic.

Self-Tapping Inserts: Have a thread on the outside that cuts its own thread into the host material during installation.

Expansion Inserts: Inserts that expand during or after installation to grip the side of the hole tightly.

Brass Blind Hole Inserts: Inserts designed for use in a hole that doesn’t go all the way through the material.

Brass Through-Hole Inserts: Inserts designed for use in a hole that passes completely through the material.

Internal Thread: The primary feature the insert provides.

External Thread: The thread on the outside of the insert that grips the host material.

Knurl Pattern: The specific pattern on the OD (e.g., diamond knurl, straight knurl) for anti-rotation.

Drive Style: The method of installation (e.g., hex drive, slotted drive, phillips drive).

Related Hardware & Components

These are parts that are used with, instead of, or are similar to brass inserts.

T-Nuts (Tee Nuts): A pronged nut that presses into wood, often used as an alternative.

Rivet Nuts / Nutserts: Blind threaded inserts installed with a rivet-like tool, typically made of steel or aluminum.

Threaded Rod / All-Thread: A rod that is fully threaded, which can be cut and used as a custom insert.

Standoffs: Spacers with threaded ends, often made of brass.

Screws / Machine Screws / Bolts: The fasteners that are driven into the brass insert.

Washers: Often used in conjunction with the screw and insert.

Installation Methods & Tools

Terms related to how brass inserts are put in place.

Soldering / Brazing: A method of permanently fixing a brass insert into a metal part.

Press Fit: Installation using force to push the insert into a slightly undersized hole.

Heat Installation: Using a soldering iron or specialized heated tip to install inserts into plastic.

Ultrasonic Welding: Using high-frequency sound waves to install inserts into plastic.

Insertion Tool / Installation Tool: A specific tool, often a heated tip, designed to drive the insert.

Alignment Jig / Fixture: A tool to hold the part and ensure the insert is installed straight.

Applications & Industries

Terms related to where and why brass inserts are used.

Woodworking / Furniture Manufacturing: For creating strong, wear-resistant threads in wood.

Plastic Injection Molding: Often molded-in-place or installed post-molding.

3D Printing: A very common use case for adding strong threads to printed parts (PLA, ABS, etc.).

Fixtures & Jigs: For durable, reusable threaded points.

Electrical Connectors: Brass is conductive and corrosion-resistant, making it suitable for certain electrical fittings.

Corrosion Resistance: A key reason for choosing brass, especially in marine or moist environments.

Non-Sparking: Brass is non-sparking, a critical safety feature in flammable environments (compared to steel).

Material & Properties

Brass Alloy: Common types include C360 (Free-Machining Brass), C377, etc.

Zinc Alloy / Zamak: A common, cheaper alternative material for inserts.

Stainless Steel: A stronger, often more corrosion-resistant alternative.

Aluminum: A lighter-weight alternative.

Nylon / Plastic Inserts: Used for electrical insulation or in less demanding applications.

In short, “brass inserts” are most commonly threaded sleeves pressed or installed into a softer material (like wood, plastic, or a soft metal) to create a durable, wear-resistant, and reusable threaded hole. The related terms above branch out from this core concept into their types, uses, and installation methods.

Customer Testimonial

Emily Carter – USA

“These Brass Inserts have transformed our product assembly. The pull‑out strength and consistent thread fit have eliminated so many warranty issues. Fantastic service and no MOQ—just what we needed for our small runs.”

Glossary of Terms

| Term | Definition |

|---|---|

| Cold Heading | Forming metal at room temperature under high pressure. |

| Knurling | Rolling a pattern into the outer surface to improve grip. |

| SPC/SQC | Statistical Process/Quality Control—ongoing monitoring of production data. |

| Go / No‑Go Gauge | Pass/fail thread‑checking tool ensuring thread standards compliance. |

| Pull‑Out Resistance | Force required to extract the insert from its host material. |

Enhance your assemblies with precision Brass Inserts—no MOQ, ISO‐compliant, and ready to ship worldwide.

📧 Email: sales@brass-copper-parts.com

📞 Phone/WhatsApp: +91‑22‑43449300

Request a quote, sample, or technical brochure today!