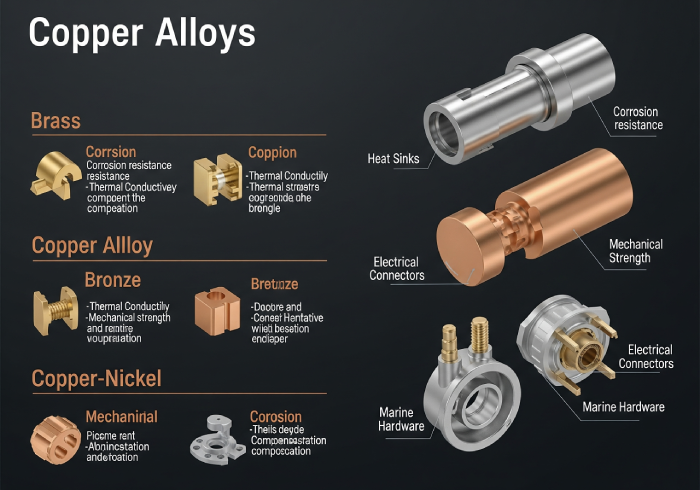

In today’s high-performance engineering and manufacturing environments, Copper Components play a vital role across industries—from power distribution to electronics and transportation. Thanks to their exceptional electrical, thermal, and mechanical properties, Copper has become an essential material for manufacturers seeking durability, conductivity, and corrosion resistance.

In this article, we’ll explore why Copper Components are indispensable, which industries benefit the most, and what makes them the preferred choice for many mission-critical systems.

🔧 What Makes Copper an Ideal Engineering Material?

Copper stands out for a few key reasons:

High Electrical Conductivity – Second only to Silver, Copper ensures minimal energy loss in power transmission systems.

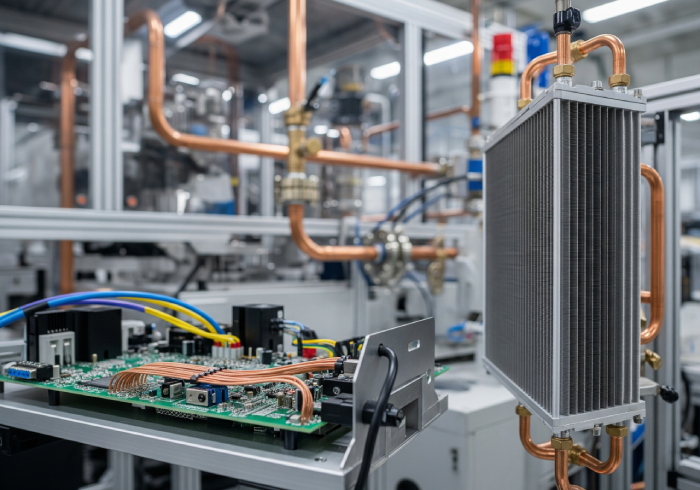

Excellent Thermal Conductivity – Perfect for heat sinks, radiators, and thermal management components.

Corrosion Resistance – Naturally forms a protective layer, increasing longevity in harsh environments.

Ductility and Workability – Easy to draw, bend, and shape without breaking, which helps in complex and custom part manufacturing.

These qualities make Copper an ideal choice for both high-precision and high-volume applications.

⚙️ Common Copper Components Used in Industry

| Component Type | Typical Application |

|---|---|

| Copper Busbars | Electrical panels, switchboards, transformers |

| Copper Terminals | Battery systems, wiring harnesses, auto-electrical |

| Copper Forgings & Castings | Pump parts, valves, electrical contacts |

| Copper Heat Sinks | Electronics, LED lighting, computer hardware |

| Copper Earthing Rods | Grounding systems in substations and telecom setups |

We manufacture custom and standard Copper Components in compliance with ASTM B62, IS 191, and DIN standards, among others.

🔋 Industries That Rely on Copper Components

Copper Components are extensively used in the following sectors:

Electrical & Power – For conductors, switchgear, earthing, terminals, and busbars.

Automotive – In battery terminals, connectors, and motor windings.

HVAC & Refrigeration – In coil systems, heat exchangers, fittings, and seals.

Electronics – As circuit connectors, PCB terminals, and EMI shielding parts.

Telecom & Renewable Energy – For grounding equipment and inverters.

The ability to withstand high temperatures, conduct electricity, and resist corrosion makes Copper ideal for these demanding environments.

🏭 Why Choose Our Copper Components?

At Brass-Copper-Parts.com, we offer:

Precision Casting & Forging of Copper Parts up to 20 kg

Machining with Tight Tolerances using advanced CNC equipment

Custom Design & Low MOQ Support

ISO 9001:2015 Certified Manufacturing Facility

RoHS and REACH Compliance

We work with alloys like C11000 (Electrolytic Tough Pitch Copper), C83600, and C92700 to deliver the exact mechanical and electrical performance your application demands.

🌍 Trusted by Global Customers

Our Copper Components are trusted by OEMs and system integrators in over 74 countries, including the USA, Germany, Australia, and the Middle East. Whether it’s a small batch or a high-volume production run, we maintain consistency in material quality, machining precision, and timely delivery.

💬 Customer Testimonial

David R., Electrical Systems Integrator (USA)

“We’ve worked with several global suppliers, but Brass-Copper-Parts.com consistently delivers top-tier copper terminals and custom components on time. Their quality and communication are unmatched.”

📞 Get a Free Consultation Today

Need custom Copper Castings, Terminals, or Machined Parts for your industry?

📧 Email us at sales@brass-copper-parts.com

📞 Call us at +91-22-43449300

💬 Or chat via WhatsApp for a quick quote!

Let’s build better, more efficient systems with high-precision Copper Components.