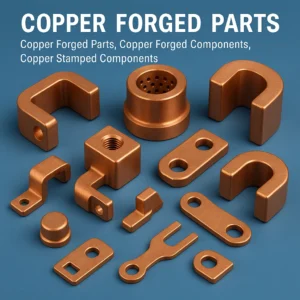

Copper CNC Components: Copper CNC Machined Parts, Copper Turned parts, & Copper CNC Milled Parts

We are one of the leading manufacturers and exporters of high-precision Copper Turned Parts, Copper CNC machined parts, and bespoke Copper Components from India. We have been supplying superior quality, precision-engineered Copper parts to the world market for many decades, establishing ourselves as a trusted partner for industries demanding excellence and reliability. Our expertise spans a vast array of manufacturing processes, including precision turning, CNC milling, and advanced Swiss machining, all dedicated to shaping pure Copper and its versatile alloys into critical components that power innovation globally. Our commitment to stringent quality control, adherence to international standards like ASTM, DIN, and JIS, and a customer-centric approach ensures that every component we produce meets the most exacting specifications. Whether you require a simple Copper electrical component or a complex, multi-axis machined assembly, our engineering prowess and state-of-the-art machinery are equipped to deliver.

In-Depth Look at Our Copper Manufacturing Capabilities

Copper Turned Parts

Copper Turned Parts are produced on sophisticated automatic lathes and CNC turning centers. This process is ideal for creating axially symmetric parts where material is removed from a rotating workpiece using stationary cutting tools. We specialize in high-volume production runs of precision Copper components like connectors, terminals, bushings, and sleeves. The process ensures excellent concentricity and surface finish straight off the machine. We utilize bar stock from internationally sourced Copper material grades such as C10100 (Oxygen-Free Electronic), C11000 (Electrolytic Tough Pitch), and the excellent free-machining alloy C36000 (Free-Cutting Brass). Standard tolerances held are within ISO 2768-mK, with even tighter tolerances achievable for critical dimensions.

Copper CNC Machined Parts

CNC Machining offers unparalleled flexibility for producing complex, non-rotationally symmetric Copper parts that cannot be made on a lathe. Our multi-axis CNC machining centers (3-axis, 4-axis, and 5-axis) allow us to machine intricate features, deep cavities, precise contours, and angled holes from a solid block of Copper. This is the go-to process for prototypes, low-volume batches, and highly complex components like waveguide components, heat sink bases, and custom actuator bodies. We machine a wide spectrum of materials including C10100, C10200 (Oxygen-Free), C11000, C14500 (Tellurium Copper) for improved machinability, and C17200 (Beryllium Copper) for high strength. We routinely work to tolerances as tight as ±0.01mm.

Copper Components (General)

The term Copper Components encompasses a vast range of finished parts utilized across every major industry. These components leverage the inherent benefits of Copper and its alloys: superior electrical conductivity, exceptional thermal conductivity, excellent corrosion resistance, inherent anti-microbial properties, and good mechanical strength. Our role is to transform raw material into a final, functional part that meets a specific application’s needs, often involving a combination of processes like machining, milling, turning, and finishing.

Copper Milled Parts

Copper Milled Parts are a specific subset of CNC machined parts where the primary material removal operation is performed by a rotating multi-point cutter. Milling is optimal for creating flat surfaces, slots, grooves, gears, and profiled edges. The rigidity of our CNC milling machines ensures precision and repeatability even when working with the somewhat gummy nature of pure copper alloys. We produce intricate Copper electrical components like busbars, switchgear parts, and motor laminations through precision milling, often achieving surface finishes better than Ra 0.8 µm.

Copper Swiss Machined Parts

For ultra-high-precision, long, and slender Copper turned parts, Swiss machining is the superior process. Our Swiss-type CNC lathes provide exceptional accuracy for parts with complex geometries and tight diameter tolerances over their entire length. The guide bushing provides immense support to the bar stock, minimizing deflection and allowing for intricate live tooling operations (milling, drilling, cross-holes) to be performed simultaneously with turning. This process is essential for producing medical device components, miniature connectors, and precision shafts from grades like C11000 and C36000, often holding diameters to tolerances of ±0.005mm.

Copper Electrical Components

Copper’s unmatched electrical conductivity makes it the material of choice for a myriad of electrical components. We manufacture critical parts that form the backbone of electrical systems worldwide. This includes heavy-duty busbars, electrical contacts, Copper terminals, Copper connectors, Copper switchgear components, Copper transformer spades, Copper studs for Transformers and rotor bars. For these applications, high-conductivity grades like C10100 (OFE), C10200 (OF), and C11000 (ETP) are preferred. Performance is often measured by conductivity (% IACS), and we guarantee material traceability to ensure electrical properties meet specified standards like ASTM B187.

Copper Parts (Comprehensive Overview)

Ultimately, every item we produce is a precision Copper part. Our comprehensive manufacturing ecosystem allows us to be a single-source solution for all your Copper needs. From the initial material selection—guiding you to choose between C10100, C11000, C14500, C17200, C36000, or European standards like Cu-ETP (CW004A) and Cu-OF (CW008A)—to final packaging, we manage the entire process. Our capabilities cover all standard Copper material grades and international specifications, ensuring global compliance and performance.

Technical Specifications & Data

Typical Copper Material Grades & Properties

Table: Common Copper Alloys for Machining

| Grade (ASTM) | Common Name | UNS | DIN | JIS | Key Properties | Typical Applications |

|---|---|---|---|---|---|---|

| C10100 | Oxygen-Free Electronic | C10100 | OF-Cu | C1011 | Highest conductivity (101% IACS), excellent ductility | High-frequency waveguides, vacuum electronics |

| C11000 | Electrolytic Tough Pitch | C11000 | Cu-ETP (CW004A) | C1100 | High conductivity (100% IACS), good formability | Electrical busbars, connectors, roofing |

| C14500 | Tellurium Copper | C14500 | Cu-TeP (CW118C) | C1450 | Excellent machinability, good conductivity | Machined electrical contacts, fittings |

| C17200 | Beryllium Copper | C17200 | CuBe2 (CW101C) | C1720 | Very high strength, good conductivity | Springs, bearings, explosion-proof tools |

| C36000 | Free-Cutting Brass | C36000 | CuZn36Pb3 (CW603N) | C3604 | Best machinability, good strength | Valves, fittings, gears, nuts |

Standard Tolerances

Table: Standard Machining Tolerances We Achieve

| Process | Standard Tolerance | Fine Tolerance (On Request) |

|---|---|---|

| CNC Turning | ±0.05 mm | ±0.012 mm |

| CNC Milling | ±0.05 mm | ±0.01 mm |

| Swiss Machining | ±0.013 mm | ±0.005 mm |

| Hole Diameters | ISO IT7 | ISO IT6 |

| Surface Finish | Ra 1.6 – 3.2 µm | Ra 0.4 – 0.8 µm |

Dimensional Capacity

Our machinery can accommodate a wide range of part sizes:

Turning: Bar Stock up to 60mm diameter, 300mm length

Milling: 600mm x 400mm x 400mm (X, Y, Z)

Swiss Machining: Bar Stock from 0.5mm to 32mm diameter

Industries Served

Our precision Copper components are critical in sectors where performance and reliability cannot be compromised:

Aerospace & Defense: Waveguides, connectors, bushings

Automotive: Sensor bodies, valve seats, electrical components

Electronics & Telecommunications: Heat sinks, RF shields, connectors

Electrical Power Generation & Distribution: Busbars, contacts, switchgear parts

Medical Devices: Surgical instrument components, MRI parts

Industrial Machinery: Bearings, bushings, hydraulic components

Why Choose Us as Your Copper Parts Manufacturer?

Three Decades of Global Expertise: Our 30+ years of experience supplying to markets in the USA, Europe, and Asia mean we understand diverse technical standards and quality expectations.

Unmatched Flexibility: From prototype batches to high-volume production runs, we adapt our processes to your schedule and needs.

Superior Customer Support & Communication: We assign a dedicated project engineer to every client, ensuring clear, timely communication and technical support from inquiry to delivery.

Faster, Reliable Turnaround: Our optimized production flow and extensive in-house capabilities allow us to consistently offer a competitive turnaround time of 4-6 weeks, even for complex orders.

Total Customization: We don’t just make parts; we provide solutions. This includes custom material sourcing, specialized finishes, and customized packaging with your labels and logos.

Packaging and Shipping

Every part is meticulously cleaned, degreased, and undergoes a final quality inspection before packaging. We use anti-tarnish papers and VCI (Vapor Corrosion Inhibitor) packaging to prevent oxidation during transit. Parts are securely packed in plywood boxes or cartons designed to withstand international shipping. We are experienced exporters and handle all necessary documentation for seamless delivery to your doorstep anywhere in the world.

Customer Testimonials

“John Matthews, Senior Procurement Manager, UK OEM: ‘We’ve been sourcing complex Copper waveguide components from this team for over five years. Their technical understanding of material properties and ability to hold incredibly tight tolerances on thin walls is exceptional. They are more than a supplier; they are a true engineering partner. Their communication is proactive, and their quality is consistently flawless, which is why they are our sole source for these critical parts.’“

Frequently Asked Questions (Q&A)

Q1: What is the main difference between Copper C10100 and C11000?

A: C10100 is Oxygen-Free Copper, offering the highest electrical and thermal conductivity, ideal for critical electronic applications. C11000, Electrolytic Tough Pitch Copper, has slightly lower conductivity but is more widely available and cost-effective for general electrical applications.

Q2: Can you machine parts from customer-supplied raw material?

A: Yes, we offer machining services for customer-supplied material, provided it meets the specifications for the intended part and process.

Q3: What information do I need to provide for an accurate quote?

A: Please provide a detailed drawing (PDF or STEP file), material specification, quantity, and any special requirements for plating or finishing.

Q4: What is the benefit of using Swiss machining for Copper parts?

A: Swiss machining is superior for long, slender parts as it provides exceptional support, minimizing deflection and allowing for ultra-precise diameters and complex secondary operations in a single setup.

Q5: Do you provide material certification?

A: Yes, we provide full material traceability and Certification of Conformance (Mill Certificate) with every batch, confirming the material grade and properties meet the specified standard.

Q6: What finishes can you apply to Copper parts?

A: We offer a range of finishes including plain (as-machined), polishing, buffing, tumbling, passivation (to prevent tarnishing), and we can also facilitate plating (e.g., Tin, Silver, Nickel, Gold) through vetted partners.

Q7: How do you ensure quality control?

A: Our quality control process includes First Article Inspection (FAI), in-process checks, and final inspection using calibrated equipment like CMMs, optical comparators, and micrometers.

Q8: What is your minimum order quantity (MOQ)?

A: We are flexible. While we are cost-effective for high-volume production, we also welcome prototype and low-volume orders to support your R&D and product development.

Q9: Which Copper alloy is best for machining?

A: C36000 Free-Cutting Brass offers the best machinability, rated at 100%. For parts requiring high conductivity, C14500 Tellurium Copper is an excellent machinable alternative.

Q10: Do you offer design for manufacturability (DFM) feedback?

A: Absolutely. Our engineering team will gladly review your designs and suggest modifications to optimize them for machining, reducing cost and improving manufacturability without compromising function.

Glossary of Terms

CNC (Computer Numerical Control): The automated control of machining tools by a computer, ensuring high precision and repeatability.

Swiss Machining: A specific type of precision turning where the guide bushing provides support very close to the cutting tool, allowing for the machining of small, complex, and slender parts.

IACS (% International Annealed Copper Standard): A measure of electrical conductivity where 100% IACS is defined by the standard conductivity of annealed Copper.

Tolerance: The permissible limit of variation in a physical dimension of a manufactured part.

Surface Finish (Ra): The average roughness of a surface, measured in micrometers (µm) or microinches (µin). A lower Ra value indicates a smoother surface.

Related Search Terms

Precision Copper components manufacturer, custom Copper turned parts India, export quality CNC milled Copper, small batch Copper machining, high conductivity Copper electrical contacts, Swiss precision Copper parts, OEM Copper parts supplier, Brass and Bronze machined components, Copper alloy machining services, ISO certified Copper parts manufacturer.

Ready to Get Started?

Unlock the potential of precision-engineered Copper components for your next project. Partner with a manufacturer that combines decades of experience with state-of-the-art technology and a unwavering commitment to quality.

Contact us today for a free, no-obligation quotation and design for manufacturability analysis.

Email: sales@brass- copper-parts.com