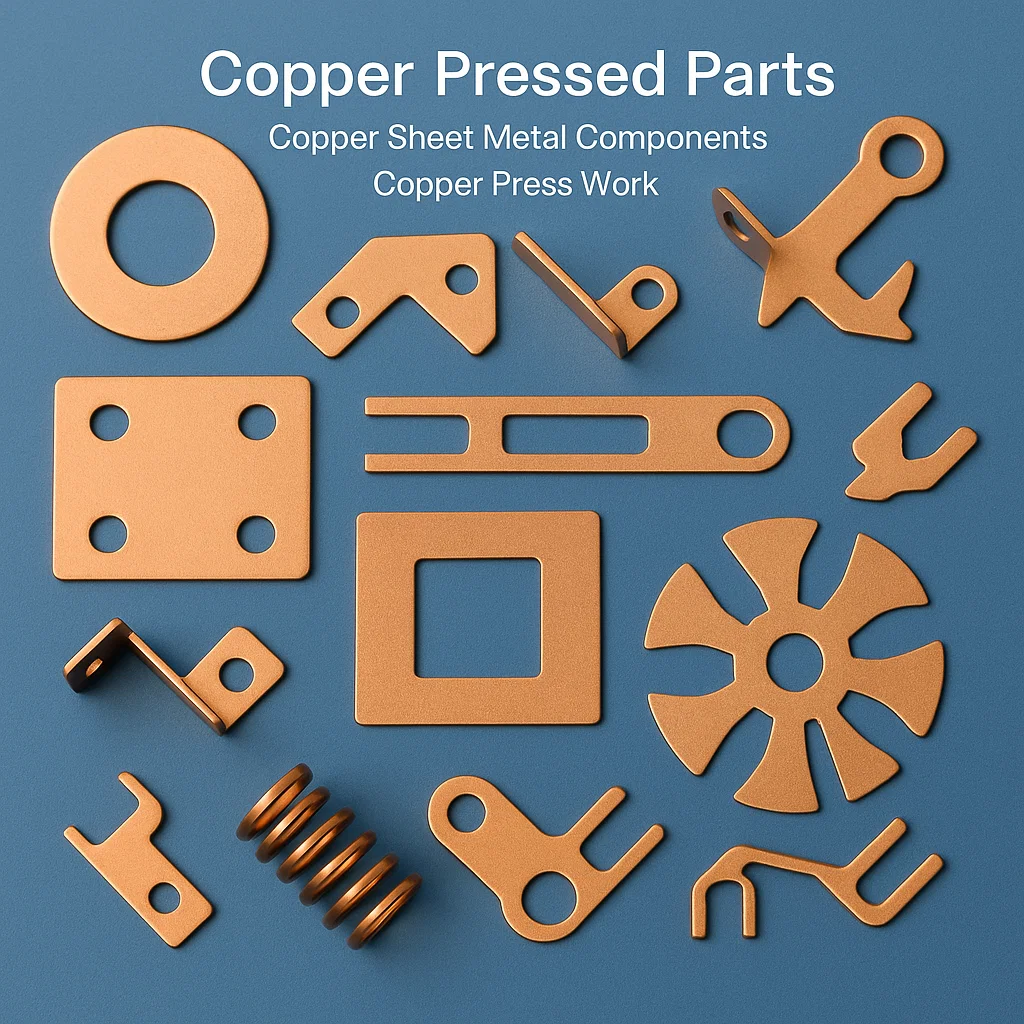

Copper Pressed Parts, Copper Sheet Metal Parts, Copper Pressed Components

Copper Pressed Parts, Copper Pressed Clips, Copper Clamps, Copper Sheet Metal Parts & Copper Pressed Components

We are one of the leading manufacturers and exporters of Copper pressed parts, Copper sheet metal parts, and Copper pressed components from India. We have been supplying precision Copper components to the world market for many decades. Our state-of-the-art manufacturing facility specializes in producing high-quality Copper pressed parts using advanced pressing technologies, deep drawing processes, and precision sheet metal fabrication techniques. With over three decades of experience in Copper component manufacturing, we have established ourselves as a trusted partner for industries requiring superior quality Copper pressed parts, electrical terminals, cable lugs, and custom Copper components. Our expertise spans across various Copper alloys and grades, ensuring optimal performance and durability for demanding applications in electrical, automotive, telecommunications, and industrial sectors. We maintain stringent quality control measures and adhere to international standards including ASTM, DIN, JIS, and IS specifications throughout our manufacturing processes.

Overview of Copper Pressed Parts Manufacturing

Copper pressed parts manufacturing involves sophisticated metal forming processes that transform raw Copper sheets and strips into precise, functional components. Our comprehensive manufacturing capabilities encompass progressive die stamping, deep drawing, hydroforming, and precision punching operations. The versatility of Copper as a material, combined with our advanced pressing technologies, enables us to produce complex geometries with exceptional dimensional accuracy and surface finish quality.

Our manufacturing facility utilizes computer-controlled hydraulic presses ranging from 25 tons to 500 tons capacity, equipped with precision die sets designed for optimal material utilization and component quality. The Copper pressing process involves careful consideration of material properties, grain structure, work hardening characteristics, and spring-back compensation to achieve consistent results across production runs.

🏭 COPPER PRESSING MANUFACTURING PROCESS FLOW

Material Selection → Design Validation → Tool Development → Press Setup → Quality Control → Finishing → Packaging → Shipping

30+ Years Experience | ISO Certified | Global Supply Chain

Material Grades and Specifications

| Standard | Grade/Designation | Composition | Applications |

|---|---|---|---|

| ASTM B152 | C11000 (ETP Copper) | 99.90% Cu min | Electrical components, terminals |

| ASTM B152 | C10200 (OF Copper) | 99.95% Cu min | High conductivity applications |

| DIN 17672 | Cu-ETP (E-Cu58) | 99.90% Cu | European electrical standards |

| JIS H3100 | C1020 (Tough Pitch Copper) | 99.90% Cu | Japanese industrial applications |

| IS 191 | Grade A Copper | 99.90% Cu min | Indian standard electrical grade |

| BS EN 13599 | Cu-ETP1 | 99.90% Cu | British/European applications |

| GB/T 5231 | T2 (Chinese Standard) | 99.90% Cu | Chinese market specifications |

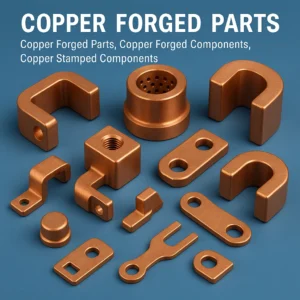

Copper Pressed Parts

Copper pressed parts represent our core manufacturing expertise, encompassing a wide range of components produced through precision metal forming processes. These parts are manufactured using high-grade Copper materials processed through hydraulic pressing, mechanical pressing, and specialized forming techniques. Our Copper pressed parts feature exceptional dimensional accuracy, superior surface finish, and consistent mechanical properties essential for critical applications in electrical, automotive, and industrial sectors.

The manufacturing process involves careful selection of appropriate Copper grades, precise tool design, and optimized pressing parameters to achieve desired component characteristics. Our quality control systems ensure each pressed part meets stringent specifications for dimensional tolerance, surface quality, and mechanical properties. Common applications include electrical enclosures, heat sinks, decorative components, and structural elements requiring Copper’s inherent corrosion resistance and thermal conductivity properties.

Copper Sheet Metal Parts

Copper sheet metal parts manufacturing combines traditional metalworking techniques with modern precision fabrication technologies. Our comprehensive capabilities include laser cutting, CNC punching, forming, bending, and welding operations performed on various Copper sheet thicknesses ranging from 0.1mm to 10mm. These parts are essential components in HVAC systems, architectural applications, electrical panels, and industrial equipment where Copper’s antimicrobial properties and excellent conductivity are paramount.

Our sheet metal fabrication processes utilize advanced CAD/CAM systems for precise nesting and cutting optimization, minimizing material waste while maximizing productivity. The combination of Copper’s malleability and our skilled craftsmanship enables production of complex geometries including channels, brackets, enclosures, and custom profiles. Each component undergoes rigorous quality inspection using coordinate measuring machines and surface finish analysis to ensure compliance with customer specifications and international standards.

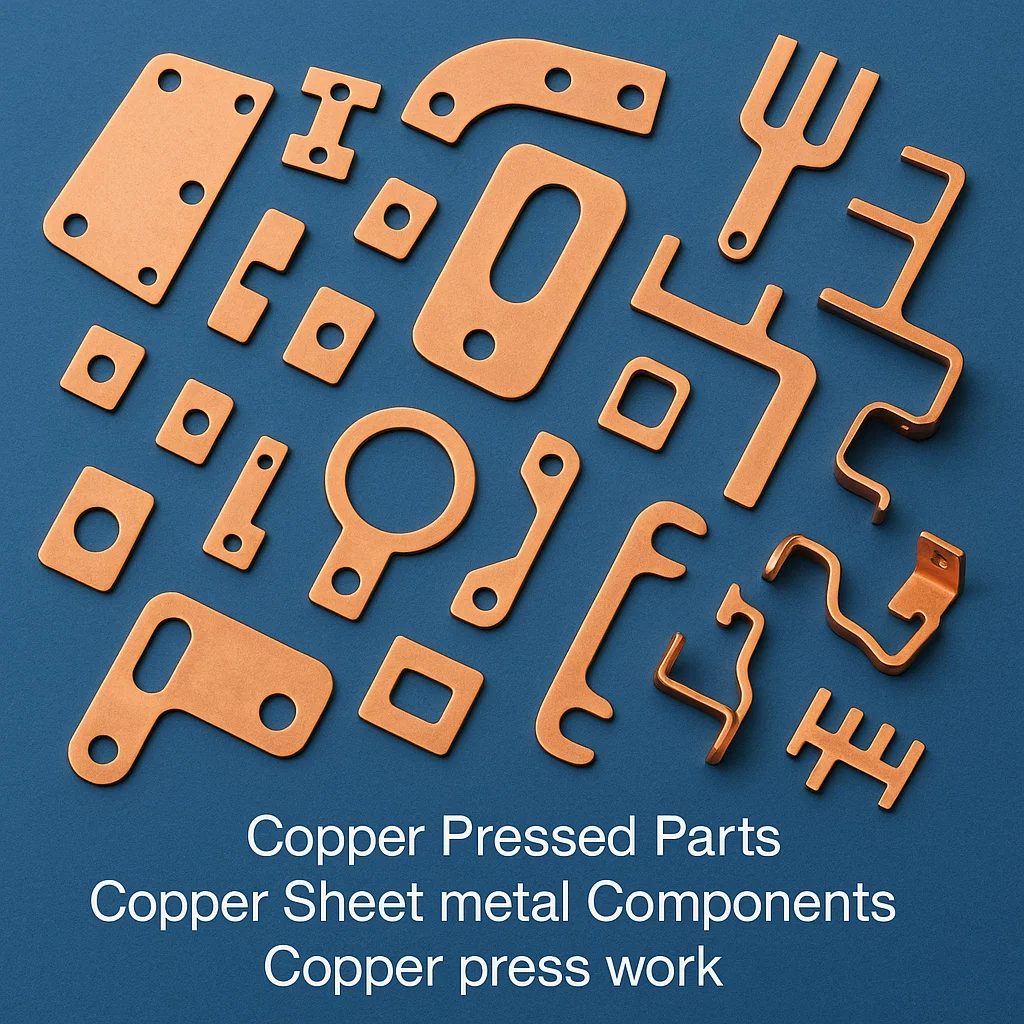

Copper Pressed Components

Copper pressed components encompass specialized parts produced through advanced metal forming techniques including deep drawing, progressive die stamping, and multi-stage pressing operations. These components serve critical functions in electrical systems, plumbing applications, and industrial machinery where reliability and performance are essential. Our manufacturing processes are optimized for high-volume production while maintaining consistent quality and dimensional accuracy across entire production runs.

The development of Copper pressed components involves comprehensive engineering analysis including material flow simulation, stress analysis, and tool design optimization. Our experienced engineering team works closely with customers to develop cost-effective solutions that meet specific performance requirements while minimizing manufacturing complexity. Quality assurance protocols include statistical process control, dimensional verification, and performance testing to ensure every component meets or exceeds customer expectations.

Copper Pressed Cable Lugs

Copper pressed cable lugs are precision-engineered electrical connection components manufactured through specialized pressing and forming operations. These critical components ensure reliable electrical connections in power distribution systems, industrial equipment, and automotive applications. Our cable lugs are produced using high-conductivity Copper grades conforming to international electrical standards including IEC, UL, and IS specifications.

Manufacturing involves precision punching, forming, and crimping operations designed to create optimal contact surfaces and mechanical strength. Each cable lug undergoes electrical conductivity testing, tensile strength verification, and dimensional inspection to ensure compliance with electrical safety standards. Available in various sizes from 1.5mm² to 1000mm² cable capacity with custom configurations available for specific application requirements.

Copper Electrical Pressed Terminals

Copper electrical pressed terminals are manufactured using precision stamping and forming processes designed to create reliable electrical connections in diverse applications. These components feature optimized contact geometries, superior surface finishes, and consistent electrical properties essential for automotive, telecommunications, and industrial electrical systems. Our terminals are produced from high-purity Copper alloys selected for optimal conductivity and mechanical performance.

The manufacturing process incorporates advanced tool design principles including progressive die technology, automated feeding systems, and integrated quality control measures. Each terminal design is validated through electrical testing, mechanical stress analysis, and environmental performance evaluation. Our comprehensive range includes ring terminals, spade terminals, pin terminals, and custom configurations designed to meet specific customer requirements and industry standards.

Copper Deep Drawn Parts

Copper deep drawn parts are manufactured through specialized metal forming processes that transform flat Copper blanks into complex three-dimensional components. This manufacturing technique is ideal for producing seamless cups, cylinders, cones, and irregular shapes requiring superior mechanical properties and surface finish quality. Our deep drawing capabilities encompass single-action, double-action, and multi-stage operations accommodating various complexity levels and production volumes.

The deep drawing process requires precise control of material flow, lubrication systems, and forming parameters to achieve optimal results without defects such as tearing, wrinkling, or dimensional distortion. Our engineering team utilizes finite element analysis and material simulation software to optimize tool design and process parameters. Applications include electrical housings, decorative components, pressure vessels, and specialized containers requiring Copper’s corrosion resistance and thermal properties.

Copper Automatic Sheet Metal Parts

Copper automatic sheet metal parts are produced using high-speed automated manufacturing systems designed for efficiency and consistency in high-volume production environments. Our automated fabrication cells integrate CNC punching, forming, and finishing operations to minimize handling and reduce production cycle times. These systems are particularly effective for producing standardized components such as electrical enclosures, brackets, and structural elements.

Automation capabilities include programmable tooling systems, automatic material handling, and integrated quality inspection stations. The combination of advanced machinery and skilled operators ensures consistent part quality while maximizing production efficiency. Our automated systems can process Copper sheets ranging from 0.5mm to 8mm thickness with positioning accuracy of ±0.025mm, making them ideal for precision applications requiring tight tolerances and repeatability.

Copper Pressed Fuse Holders – Fuse Contacts

Copper pressed fuse holders and fuse contacts are critical safety components in electrical systems, manufactured to exacting standards for reliable circuit protection. These components require precise dimensional control, superior electrical conductivity, and consistent mechanical properties to ensure proper fuse retention and electrical continuity. Our manufacturing processes incorporate specialized pressing techniques designed to create optimal contact surfaces and mechanical retention features.

Production involves precision blanking, forming, and finishing operations performed on high-conductivity Copper materials. Each component undergoes comprehensive testing including contact resistance measurement, retention force verification, and thermal cycling evaluation. Our fuse holders accommodate standard fuse sizes including blade-type, cartridge, and specialty configurations with custom designs available for specific application requirements.

Copper Pressed Clips

Copper pressed clips are versatile fastening components manufactured through precision stamping and forming operations designed to provide secure mechanical retention with excellent electrical conductivity properties. These components are essential in electrical assemblies, automotive applications, and industrial equipment where reliable connection and easy installation are required. Our clip designs incorporate spring characteristics optimized for consistent retention force and durability.

Manufacturing processes include progressive die stamping, heat treatment, and surface finishing operations tailored to specific application requirements. Design considerations include spring rate calculation, stress distribution analysis, and fatigue life evaluation to ensure long-term performance reliability. Available configurations include battery clips, terminal clips, grounding clips, and custom retention systems designed for specific customer applications.

Copper Earth Tags

Copper earth tags are essential electrical safety components manufactured through precision pressing and forming processes designed to provide reliable grounding connections in electrical installations and industrial equipment. These specialized Copper components ensure effective electrical earthing systems by providing low-resistance paths for fault currents and static discharge protection. Our earth tags are produced using high-conductivity Copper grades conforming to electrical safety standards including IS 3043, BS 951, and IEC 62561 specifications for earthing applications.

Manufacturing involves precision blanking, forming, drilling, and finishing operations designed to create optimal contact surfaces and mechanical strength for secure cable connections and panel mounting. Each earth tag undergoes electrical continuity testing, mechanical strength verification, and dimensional inspection to ensure compliance with earthing system requirements. Available in various sizes and configurations including bolt-on earth tags, welded earth tags, and custom designs for specific grounding applications in power distribution, telecommunications, and industrial installations where reliable earthing is critical for safety and equipment protection.

Copper Pressed Pipe Straps

Copper pressed pipe straps are structural support components designed to secure plumbing and HVAC systems while providing corrosion resistance and antimicrobial properties inherent to Copper materials. These components are manufactured through precision forming processes that create optimal clamping geometry and mechanical strength characteristics. Our pipe straps accommodate standard pipe sizes from 15mm to 200mm diameter with custom configurations available.

The manufacturing process involves blanking, forming, and finishing operations designed to create smooth contact surfaces that prevent pipe damage while providing secure retention. Quality control measures include dimensional verification, load testing, and corrosion resistance evaluation. Applications include residential plumbing, commercial HVAC systems, and industrial piping installations where Copper’s natural properties provide long-term performance advantages.

Manufacturing Processes and Machinery

Primary Manufacturing Processes

Progressive Die Stamping: High-speed production of complex parts through sequential operations in a single press stroke, ideal for high-volume Copper terminal and connector production.

Deep Drawing: Multi-stage forming process for seamless Copper cups, housings, and cylindrical components requiring superior mechanical properties.

Hydroforming: Specialized process using hydraulic pressure to form complex Copper shapes with minimal material stress and superior surface finish.

Machinery and Equipment

Hydraulic Presses: 25-500 ton capacity with programmable controls and precision die positioning systems.

CNC Punch Presses: High-speed punching and forming operations with automatic tool changing capabilities.

Deep Drawing Presses: Specialized equipment for multi-stage forming operations with precise blank holding and material flow control.

Dimensional Specifications and Tolerances

| Parameter | Standard Range | Precision Range | Tolerance |

|---|---|---|---|

| Material Thickness | 0.1mm – 10mm | 0.05mm – 5mm | ±0.025mm |

| Overall Dimensions | 5mm – 500mm | 1mm – 300mm | ±0.1mm |

| Hole Diameter | 1mm – 50mm | 0.5mm – 25mm | ±0.05mm |

| Bend Angles | 15° – 180° | 30° – 150° | ±1° |

| Surface Finish | 1.6μm Ra | 0.8μm Ra | Per specification |

Material Properties and Performance Characteristics

| Property | ETP Copper (C11000) | OF Copper (C10200) | Test Method |

|---|---|---|---|

| Electrical Conductivity | 101% IACS | 103% IACS | ASTM B193 |

| Thermal Conductivity | 391 W/m·K | 398 W/m·K | ASTM E1225 |

| Tensile Strength | 220-290 MPa | 210-280 MPa | ASTM B152 |

| Yield Strength | 70-280 MPa | 60-270 MPa | ASTM B152 |

| Elongation | 30-45% | 35-50% | ASTM B152 |

| Hardness | 40-90 HRB | 35-85 HRB | ASTM E18 |

Industries and Applications

Our Copper pressed parts serve diverse industries requiring superior electrical conductivity, thermal management, and corrosion resistance properties. The electrical and electronics industry represents our largest market segment, utilizing Copper terminals, connectors, and bus bars in power distribution systems, control panels, and electronic devices. Automotive applications include electrical harnesses, battery terminals, heat exchangers, and decorative trim components where Copper’s durability and aesthetic appeal are valued.

Telecommunications infrastructure relies on our precision Copper components for signal transmission, grounding systems, and electromagnetic shielding applications. The HVAC industry utilizes Copper pipe fittings, heat exchanger components, and antimicrobial surfaces in air handling systems. Industrial machinery applications include electrical contacts, slip rings, bearings, and specialized fasteners requiring Copper’s unique combination of properties.

Quality Standards and Certifications

Our manufacturing operations maintain comprehensive quality management systems certified to ISO 9001:2015 standards with specialized certifications for automotive (IATF 16949) and aerospace (AS9100) applications. All Copper materials are sourced from certified suppliers providing mill certificates and chemical analysis documentation. Our quality control laboratory performs incoming material inspection, in-process monitoring, and final product verification using calibrated measuring equipment traceable to national standards.

International standards compliance includes ASTM specifications for material properties, DIN standards for European applications, JIS requirements for Japanese markets, and IS standards for Indian domestic supply. Environmental compliance includes RoHS certification, REACH regulation compliance, and conflict minerals reporting for responsible sourcing practices.

Customer Testimonial

“We have been sourcing copper pressed terminals and cable lugs from this Indian manufacturer for over 8 years now. Their consistent quality, competitive pricing, and excellent communication have made them our preferred supplier. The technical expertise they bring to custom component development has helped us solve several design challenges. Their 4-6 week delivery schedule is reliable, and the packaging quality ensures our parts arrive in perfect condition. I highly recommend them to any company seeking high-quality copper components with professional service.”

– Robert K. Miller, Procurement Manager, UK

Comprehensive Technical Q&A Session

Q1: What are the typical lead times for custom Copper pressed parts?

A: Our standard lead time for custom Copper pressed parts is 4-6 weeks from order confirmation, which includes tool development, prototype approval, and production. Rush orders can be accommodated in 2-3 weeks with expedited processing charges. Lead times may vary based on part complexity, quantity requirements, and material availability.

Q2: What dimensional tolerances can you achieve on Copper pressed components?

A: We routinely achieve tolerances of ±0.1mm on overall dimensions and ±0.05mm on critical features such as hole locations and diameters. For specialized precision applications, we can achieve tolerances as tight as ±0.025mm using secondary machining operations and enhanced quality control procedures.

Q3: Do you provide material certificates and test reports with shipments?

A: Yes, we provide comprehensive documentation including material certificates showing chemical composition and mechanical properties, dimensional inspection reports, and performance test data as applicable. All certificates are traceable to original material sources and include batch identification for quality tracking purposes.

Q4: What surface finishes are available for Copper pressed parts?

A: Standard finishes include mill finish, bright annealed, and pickled surfaces. Specialized finishes include tin plating, nickel plating, and antioxidant coatings for enhanced corrosion resistance. We can also provide specific surface roughness requirements and decorative finishes for architectural applications.

Q5: Can you manufacture Copper parts to international electrical standards?

A: Absolutely. We manufacture Copper electrical components conforming to IEC, UL, CSA, VDE, and other international standards. Our quality systems include electrical testing capabilities for conductivity, insulation resistance, and high-potential testing as required by specific standards.

Q6: What is your minimum order quantity for custom Copper pressed parts?

A: Minimum order quantities vary based on part complexity and tooling requirements. For standard components, we can accommodate orders as small as 100 pieces. Custom parts typically require minimum quantities of 1,000-5,000 pieces to justify tooling costs, though we’re flexible based on customer needs.

Q7: Do you offer design assistance and engineering support?

A: Yes, our experienced engineering team provides comprehensive design support including manufacturability analysis, cost optimization recommendations, and alternative material suggestions. We utilize CAD software for design validation and can provide 3D models and technical drawings for customer approval.

Q8: What quality control measures are implemented during production?

A: Our quality control system includes incoming material inspection, first article inspection, statistical process control during production, and final inspection using coordinate measuring machines. We maintain detailed quality records and provide inspection reports with every shipment.

Q9: Can you handle high-volume production requirements?

A: Yes, our automated production capabilities can handle volumes exceeding 1 million pieces annually for standard components. We maintain dedicated production lines for high-volume customers and can implement vendor-managed inventory programs to ensure consistent supply.

Q10: What packaging options are available for international shipping?

A: We offer various packaging solutions including bulk packaging in corrugated boxes, individual component packaging in antistatic bags, and custom packaging with customer labels and logos. All packaging is designed for safe international transport with appropriate corrosion protection and handling instructions.

Q11: Do you provide prototyping services before full production?

A: Yes, we offer comprehensive prototyping services including rapid tooling for low-volume prototype runs. This allows customers to evaluate form, fit, and function before committing to production tooling. Prototype quantities typically range from 10-100 pieces with 1-2 week lead times.

Q12: What secondary operations can you perform on Copper pressed parts?

A: Our secondary operations include machining, threading, welding, plating, heat treatment, and assembly services. We maintain in-house capabilities for most secondary operations, ensuring quality control and delivery schedule consistency throughout the manufacturing process.

Why Choose Our Copper Pressed Parts?

Three Decades of Manufacturing Excellence: Our extensive experience in Copper component manufacturing has developed deep expertise in material processing, tool design, and quality control systems. This experience translates to superior product quality, reliable delivery schedules, and cost-effective solutions for our customers.

Advanced Manufacturing Technology: Our investment in state-of-the-art pressing equipment, computer-controlled systems, and automated quality inspection ensures consistent part quality and competitive manufacturing costs. Continuous technology upgrades maintain our competitive advantage in the global market.

Flexible Production Capabilities: We accommodate varying production volumes from prototype quantities to high-volume production runs. Our flexible manufacturing systems can adapt to changing customer requirements while maintaining quality standards and delivery commitments.

Global Supply Chain Expertise: Decades of international business experience have developed sophisticated logistics capabilities, export documentation expertise, and customer service systems designed for global markets. We understand international quality standards and regulatory requirements.

Custom Engineering Solutions: Our engineering team collaborates closely with customers to develop optimized component designs, recommend cost-effective materials, and provide technical support throughout the product development process. This partnership approach ensures successful project outcomes.

Competitive Pricing with Quality Assurance: Our manufacturing efficiency, strategic location in India, and volume purchasing power enable competitive pricing without compromising quality standards. We provide excellent value proposition for international customers seeking reliable Copper component suppliers.

Packaging and Shipping

Our comprehensive packaging systems are designed to ensure safe transportation of Copper pressed parts while maintaining component quality during international shipping. Standard packaging includes moisture-resistant materials, cushioning systems, and corrosion protection appropriate for marine transport environments. Each shipment includes detailed packing lists, handling instructions, and quality documentation.

Custom packaging solutions accommodate specific customer requirements including branded packaging, individual component protection, and automated unpacking compatibility. We maintain partnerships with international freight forwarders and logistics providers to ensure reliable delivery schedules and competitive shipping costs. All packaging materials comply with international environmental standards and customer sustainability requirements.

Turnaround Time and Production Scheduling

Our standard production turnaround time of 4-6 weeks includes comprehensive project planning, material procurement, tool preparation, production setup, manufacturing, quality inspection, and shipping preparation. This timeline allows for thorough quality control and ensures consistent delivery of components meeting customer specifications.

Expedited production schedules are available for urgent requirements, utilizing priority production slots and dedicated manufacturing resources. Our production planning systems optimize manufacturing sequences to maximize efficiency while maintaining quality standards. Regular progress updates keep customers informed throughout the production process.

International Standards Compliance

| Standard Organization | Applicable Standards | Compliance Areas |

|---|---|---|

| ASTM International | B152, B187, B193, B224 | Material specifications, testing methods |

| DIN (German Institute) | DIN 17672, DIN 40500 | European material and electrical standards |

| JIS (Japanese Standards) | JIS H3100, JIS H3110 | Japanese industrial specifications |

| IS (Indian Standards) | IS 191, IS 1897 | Indian national standards compliance |

| BS/EN (British/European) | BS EN 13599, BS EN 1652 | British and European material standards |

| IEC (International Electrotechnical) | IEC 60947, IEC 61984 | Electrical component specifications |

| UL (Underwriters Laboratories) | UL 486A, UL 486B | North American electrical safety |

Performance Metrics and Quality Indicators

| Quality Metric | Target Performance | Measurement Method | Frequency |

|---|---|---|---|

| Dimensional Accuracy | 99.8% within tolerance | CMM inspection, Statistical analysis | Every batch |

| Surface Finish Quality | Ra ≤ 1.6μm standard | Surface profilometer measurement | Daily sampling |

| Material Conductivity | ≥101% IACS (ETP Copper) | Eddy current testing | Material certification |

| Mechanical Properties | Per ASTM B152 specifications | Tensile testing, Hardness testing | Material lot basis |

| Delivery Performance | 98% on-time delivery | Shipment tracking analysis | Monthly review |

| Customer Satisfaction | ≥95% satisfaction rating | Customer feedback surveys | Quarterly assessment |

Unique Selling Propositions (USPs)

Customization Flexibility: Our engineering and manufacturing teams excel at developing custom Copper pressed parts tailored to specific application requirements. We work collaboratively with customers to optimize designs for manufacturability, cost-effectiveness, and performance. This includes material selection guidance, tolerance optimization, and alternative design suggestions that can reduce costs while maintaining functionality.

Production Scheduling Flexibility: Unlike many manufacturers with rigid production schedules, we offer flexible scheduling options to accommodate customer requirements. This includes expedited production for urgent orders, scheduled releases for inventory management, and vendor-managed inventory programs for high-volume customers. Our production planning systems can adapt to changing requirements while maintaining quality standards.

Custom Packaging Solutions: We provide comprehensive packaging customization including customer branding, specialized protection systems, and automated unpacking compatibility. Our packaging engineers work with customers to develop optimal solutions for their specific handling, storage, and distribution requirements. This includes anti-tarnish packaging for long-term storage and shock-resistant packaging for sensitive components.

Technical Documentation Support: Our technical documentation capabilities include detailed engineering drawings, material certificates, inspection reports, and installation instructions. We can provide documentation in multiple languages and formats to support international customers and comply with various regulatory requirements.

Glossary of Technical Terms

Annealing: Heat treatment process used to soften Copper and improve formability by relieving internal stresses and refining grain structure. Critical for deep drawing operations and complex forming processes.

Conductivity (IACS): International Annealed Copper Standard, expressing electrical conductivity as a percentage relative to pure Copper at 20°C. Higher percentages indicate better electrical conductivity performance.

Deep Drawing: Metal forming process that uses tensile forces to stretch a blank into a desired shape. Particularly effective for creating seamless Copper cups, housings, and cylindrical components.

ETP Copper: Electrolytic Tough Pitch Copper containing approximately 99.90% Copper with controlled oxygen content. Most common grade for electrical applications requiring good conductivity and formability.

Grain Structure: Crystalline arrangement of atoms in Copper that affects mechanical properties, formability, and electrical characteristics. Controlled through annealing and processing parameters.

Hydraulic Pressing: Metal forming process using hydraulic pressure to shape components. Provides precise control of forming forces and is ideal for complex geometries and high-strength applications.

Progressive Die: Specialized tooling system that performs multiple operations on a workpiece as it advances through sequential stations. Highly efficient for high-volume production of complex parts.

Spring Back: Tendency of formed metal to partially return to its original shape after forming forces are removed. Compensated through tool design and process parameter optimization.

Work Hardening: Increase in material strength and hardness resulting from plastic deformation. Important consideration in Copper forming processes affecting subsequent operations.

Related Copper Parts:

Copper pressed parts manufacturer India, Copper sheet metal fabrication, custom Copper pressing services, precision Copper components, electrical Copper terminals, Copper cable lugs manufacturer, Copper deep drawn parts, industrial Copper pressing

High conductivity Copper pressed electrical terminals, custom Copper sheet metal parts India export, precision Copper pressing 4-6 weeks delivery, ASTM B152 Copper pressed components manufacturer, automotive Copper electrical parts supplier

Copper bus bars, Copper electrical connectors, Copper grounding components, Copper heat sinks, Copper electrical enclosures, Copper telecommunications parts, Copper automotive terminals

C11000 Copper pressing, ETP Copper fabrication, OF Copper components, close tolerance Copper parts, progressive die Copper stamping, hydraulic pressed Copper components

Environmental Compliance and Sustainability

Our manufacturing operations maintain strict environmental compliance standards including waste minimization, energy efficiency optimization, and responsible material sourcing practices. Copper’s inherent recyclability makes our products environmentally sustainable, with end-of-life components fully recyclable without performance degradation. Our facility operates under ISO 14001 environmental management systems with continuous improvement programs for reducing environmental impact.

Sustainability initiatives include energy-efficient manufacturing equipment, waste reduction programs, and partnership with certified Copper suppliers committed to responsible mining practices. We provide environmental compliance documentation including RoHS certification, REACH compliance statements, and conflict minerals reporting to support customer sustainability requirements.

Technical Support and Customer Service

Our comprehensive technical support services include application engineering assistance, material selection guidance, design optimization recommendations, and troubleshooting support throughout the product lifecycle. Our experienced engineers are available for on-site consultations, video conferences, and detailed technical discussions to ensure successful project outcomes.

Customer service capabilities include multilingual support, dedicated account management, real-time order tracking, and proactive communication throughout the manufacturing process. Our customer service team maintains detailed project histories and technical specifications to provide consistent support across multiple orders and long-term partnerships.

Research and Development Capabilities

Our R&D facility focuses on advanced Copper forming technologies, new alloy development, and innovative manufacturing processes to maintain competitive advantages in the global market. Current research areas include high-speed forming techniques, precision micro-components, and specialized surface treatments for enhanced performance characteristics.

Collaboration with customers on new product development includes feasibility studies, prototype development, testing and validation programs, and production optimization. Our engineering team utilizes advanced simulation software, material testing equipment, and prototype manufacturing capabilities to support innovation initiatives.

Ready to Get Started with Premium Copper Pressed Parts?

Contact our technical team today to discuss your specific requirements and receive a detailed quotation for your Copper pressing needs.

📧 Email us for a comprehensive technical brochure: sales@brass-copper-parts. com