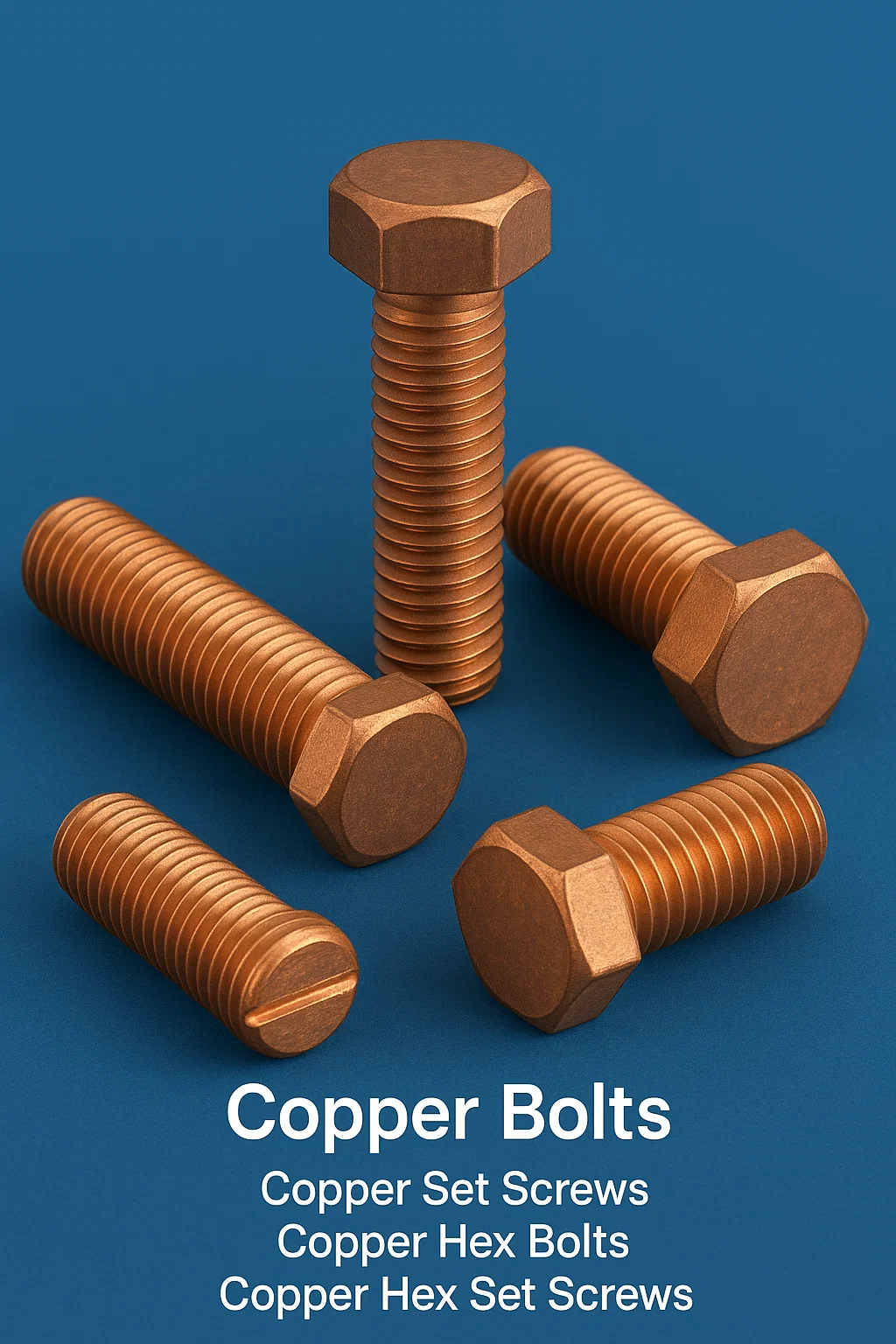

Copper Hex Bolts, Copper Bolts, Copper Hex Cap Screws, Copper Hex Set Screws

Copper Hex Bolts, Copper Bolts – Premium Quality Fasteners

Pricel US$ 13/kilogram

We are one of the leading manufacturers and exporters of Copper Hex Bolts and Copper Bolts from India. We have been supplying high-quality Copper fasteners to the world market for many decades. Our extensive range of Copper Hex Bolts encompasses various specifications including DIN 933 Copper hex bolts, ISO 4017 hex Copper bolts, Copper hex head cap screws, and full threaded Copper bolts. With advanced manufacturing facilities and stringent quality control measures, we ensure each Copper bolt meets international standards and customer specifications. Our expertise in producing Copper metric bolts and Copper hex set screws has made us a trusted partner for industries worldwide. We specialize in custom manufacturing with flexibility in production schedules, offering comprehensive solutions for marine, electrical, architectural, and industrial applications. Our commitment to excellence, combined with three decades of global experience, positions us as your preferred supplier for all Copper fastener requirements.

Product Overview

Copper Hex Bolts and Copper Bolts represent premium fastening solutions renowned for their exceptional corrosion resistance, electrical conductivity, and antimicrobial properties. These Copper fasteners are manufactured using high-grade Copper alloys that comply with international standards including ASTM B152, DIN 933, and ISO 4017. Our comprehensive product range caters to diverse industrial applications where traditional Steel fasteners would fail due to environmental conditions or specific functional requirements.

🔧 Copper Bolts Manufacturing Process Flow

Raw Material → Cold Forging → Thread Rolling → Heat Treatment → Surface Finishing → Quality Testing → Packaging

Advanced CNC machinery ensures precision threading and dimensional accuracy

Copper Hex Bolts

Copper Hex Bolts feature a hexagonal head design that provides superior grip and torque transmission during installation. These bolts are manufactured using C10100 Oxygen-Free Electronic Copper and C11000 Electrolytic Tough Pitch Copper, ensuring maximum electrical conductivity and corrosion resistance. Our Copper hex bolts are available in thread specifications ranging from M3 to M64 in metric dimensions and #4 to 4 inches in imperial sizes. The hexagonal head configuration allows for efficient installation using standard hex keys and provides reliable fastening strength in demanding applications.

Copper Bolts

Copper Bolts encompass our complete range of threaded fasteners manufactured from premium Copper alloys. These bolts exhibit excellent thermal conductivity, making them ideal for heat exchange applications and electrical grounding systems. Our Copper bolt manufacturing process involves precision cold heading followed by thread rolling to achieve superior surface finish and dimensional accuracy. Available in various head styles including hex, socket head cap, and button head configurations, these bolts serve critical applications in marine hardware, electrical panels, and architectural installations.

Copper Hex Head Cap Screws

Copper Hex Head Cap Screws combine the functionality of traditional cap screws with the superior properties of Copper. These screws feature a cylindrical head with internal hex socket, enabling flush mounting and high torque applications. Manufactured according to DIN 912 and ISO 4762 standards, our Copper hex head cap screws offer precise dimensional control and consistent thread engagement. The internal hex drive system prevents cam-out and provides reliable torque transmission, making these screws perfect for precision assemblies in electronic equipment and marine applications.

Copper Hex Set Screws

Copper Hex Set Screws are specialized fasteners designed for securing components without protruding heads. These screws feature various point styles including cup point, cone point, and flat point configurations to accommodate different application requirements. Our Copper set screws are manufactured from C12200 Phosphorus Deoxidized Copper to ensure optimal strength and corrosion resistance. Available in both metric and imperial thread specifications, these screws provide reliable positioning and locking mechanisms in electrical assemblies and precision machinery.

Full Threaded Copper Bolts

Full Threaded Copper Bolts feature continuous threading along the entire shank length, providing maximum thread engagement and holding power. These bolts are particularly effective in applications requiring extended thread engagement or where the bolt length needs to be adjusted during assembly. Our full threaded Copper bolts are manufactured using precision thread rolling techniques that enhance thread strength and surface finish. Available in lengths up to 300mm, these bolts serve critical applications in structural assemblies, marine hardware, and electrical grounding systems.

Copper Metric Bolts

Copper Metric Bolts are manufactured according to European and international metric standards, featuring precise dimensional control and standardized thread specifications. Our metric bolt range covers thread sizes from M3 to M64 with coarse and fine pitch options. These bolts comply with DIN 933, ISO 4017, and EN 24017 standards, ensuring compatibility with global metric fastening systems. The metric threading provides superior load distribution and thread engagement compared to imperial alternatives, making these bolts ideal for precision engineering applications.

DIN 933 Copper Hex Bolts

DIN 933 Copper Hex Bolts represent the German industrial standard for partially threaded hexagonal bolts. These bolts feature a distinct shoulder between the head and threaded portion, providing optimal shear strength and precise positioning. Our DIN 933 compliant Copper bolts are manufactured with strict adherence to dimensional tolerances and material specifications outlined in the standard. The partially threaded design ensures maximum clamping force while maintaining thread integrity under dynamic loading conditions.

ISO 4017 Hex Copper Bolts

ISO 4017 Hex Copper Bolts conform to the international standard for partially threaded hexagonal bolts, ensuring global compatibility and standardization. These bolts feature identical specifications to DIN 933 but carry the international ISO designation for broader market acceptance. Our ISO 4017 Copper hex bolts undergo rigorous quality testing to ensure compliance with dimensional accuracy, thread specifications, and material properties. The international standard certification facilitates seamless integration into global supply chains and engineering specifications.

Thread Charts and Dimensional Specifications

ASTM Standard Thread Chart (UNC/UNF)

| Size | TPI (UNC) | TPI (UNF) | Major Diameter (inches) | Pitch Diameter (inches) | Minor Diameter (inches) |

|---|---|---|---|---|---|

| #4-40 | 40 | 48 | 0.1120 | 0.0958 | 0.0795 |

| #6-32 | 32 | 40 | 0.1380 | 0.1177 | 0.0974 |

| #8-32 | 32 | 36 | 0.1640 | 0.1437 | 0.1234 |

| #10-24 | 24 | 32 | 0.1900 | 0.1629 | 0.1359 |

| 1/4-20 | 20 | 28 | 0.2500 | 0.2175 | 0.1850 |

| 5/16-18 | 18 | 24 | 0.3125 | 0.2764 | 0.2403 |

| 3/8-16 | 16 | 24 | 0.3750 | 0.3344 | 0.2938 |

| 1/2-13 | 13 | 20 | 0.5000 | 0.4500 | 0.4000 |

Metric Thread Chart (ISO/DIN)

| Size | Pitch (mm) | Major Diameter (mm) | Pitch Diameter (mm) | Minor Diameter (mm) |

|---|---|---|---|---|

| M3 | 0.5 | 3.000 | 2.675 | 2.459 |

| M4 | 0.7 | 4.000 | 3.545 | 3.242 |

| M5 | 0.8 | 5.000 | 4.480 | 4.134 |

| M6 | 1.0 | 6.000 | 5.350 | 4.918 |

| M8 | 1.25 | 8.000 | 7.188 | 6.647 |

| M10 | 1.5 | 10.000 | 9.026 | 8.376 |

| M12 | 1.75 | 12.000 | 10.863 | 10.106 |

| M16 | 2.0 | 16.000 | 14.701 | 13.835 |

Material Grades and Specifications

International Material Standards

C10100 – Oxygen-Free Electronic (OFE) Copper: Minimum 99.99% Copper content, ultra-low oxygen content (<0.0005%), exceptional electrical conductivity (101% IACS). Complies with ASTM B152, BS 6017, and JIS H3100 C1011.

C11000 – Electrolytic Tough Pitch (ETP) Copper: 99.90% minimum Copper content, excellent formability and electrical properties (100% IACS). Conforms to ASTM B152, EN 13601 CW004A, and JIS H3100 C1100.

C12200 – Phosphorus Deoxidized Copper (DHP): 99.90% Copper with 0.015-0.040% Phosphorus, enhanced corrosion resistance and weldability. Meets ASTM B152, BS 6017 C106, and DIN 17670 SF-Cu specifications.

C14500 – Tellurium Copper: Free-machining grade with 99.5% Copper and 0.4-0.7% Tellurium, excellent machinability while maintaining conductivity. Complies with ASTM B152 and ISO 1337.

Chinese Standards (GB)

T2 (GB/T 5231): Equivalent to C11000, 99.90% Copper minimum, widely used in Chinese manufacturing. T1 (GB/T 5231): High purity Copper similar to C10100, 99.95% Copper content.

European Standards (EN)

CW004A (EN 13601): European designation for ETP Copper, identical to C11000 specifications. CW024A (EN 13601): Phosphorus deoxidized grade equivalent to C12200.

Japanese Standards (JIS)

C1011 (JIS H3100): Oxygen-free Copper with superior electrical properties. C1100 (JIS H3100): Tough pitch Copper for general electrical applications.

Manufacturing Process and Machinery

Our Copper bolt manufacturing process employs state-of-the-art cold heading technology using Sakamura multi-station headers and Hatebur precision forging machines. The process begins with wire drawing to achieve precise diameter control, followed by cold heading to form the bolt head and shank geometry. Thread rolling is performed using Profiroll thread rolling machines that enhance thread strength through cold working. Heat treatment is conducted in controlled atmosphere furnaces to achieve optimal mechanical properties while preventing oxidation. Secondary operations include CNC machining for special features and surface finishing using tumbling and polishing equipment.

Advanced Manufacturing Equipment

| Process | Equipment | Capability | Tolerance Achieved |

|---|---|---|---|

| Cold Heading | Sakamura 6-Station Headers | M3-M24 diameter range | ±0.05mm |

| Thread Rolling | Profiroll TR Series | Class 6g threads | ±0.02mm pitch diameter |

| CNC Machining | Mazak Integrex i-400 | Complex geometries | ±0.01mm |

| Heat Treatment | Ipsen Atmosphere Furnaces | Stress relief 200-300°C | ±5°C temperature control |

DIN 933 Dimensional Table

| Thread Size | Diameter (d) mm | Head Width (s) mm | Head Height (k) mm | Thread Length (b) mm |

|---|---|---|---|---|

| M6 | 6.0 | 10.0 | 4.0 | 18 |

| M8 | 8.0 | 13.0 | 5.3 | 22 |

| M10 | 10.0 | 16.0 | 6.4 | 26 |

| M12 | 12.0 | 18.0 | 7.5 | 30 |

| M16 | 16.0 | 24.0 | 10.0 | 38 |

| M20 | 20.0 | 30.0 | 12.5 | 46 |

Surface Finishes and Treatments

Our Copper bolt surface finishes are designed to enhance both aesthetic appeal and functional performance. Mill finish provides the natural Copper appearance with slight surface texture from manufacturing. Polished finish achieves mirror-like surface quality through progressive polishing stages using diamond compounds. Passivated finish involves chemical treatment to enhance corrosion resistance and prevent tarnishing. Antique patina creates controlled oxidation for architectural applications requiring aged appearance. All finishes comply with ASTM B370 standards for Copper alloy surface treatments.

Industries and Applications

Marine Industry: Copper hex bolts excel in saltwater environments due to their natural antimicrobial properties and corrosion resistance. Applications include propeller shaft assemblies, deck hardware, and underwater hull fittings.

Electrical Sector: High electrical conductivity makes Copper bolts essential for grounding systems, electrical panels, and power distribution equipment. They provide reliable electrical continuity while maintaining structural integrity.

Architecture and Construction: Copper fasteners serve decorative and functional roles in roofing systems, gutters, and exterior cladding where weather resistance and aesthetic appeal are paramount.

Heat Exchanger Manufacturing: Thermal conductivity properties make Copper metric bolts ideal for tube sheet assemblies, header connections, and maintenance access points in heat exchangers.

Musical Instrument Industry: Precision Copper hex head cap screws are used in brass instrument manufacturing where tonal quality and corrosion resistance are critical factors.

Quality Standards and Tolerances

Dimensional Tolerances

| Parameter | Tolerance Class | Range (mm) | Standard |

|---|---|---|---|

| Thread Pitch Diameter | 6g | ±0.012 to ±0.032 | ISO 965-1 |

| Hex Head Width | Medium | ±0.08 to ±0.16 | DIN 933 |

| Head Height | Standard | ±0.05 to ±0.12 | ISO 4017 |

| Overall Length | Medium | ±0.5 to ±2.0 | ASTM F568M |

Manufacturing Lead Time: 4-6 Weeks

Our standard production schedule delivers custom Copper bolts within 4-6 weeks from order confirmation. This timeframe includes material procurement, manufacturing, quality inspection, and packaging. Express production options are available for urgent requirements with additional coordination. Large volume orders may require extended lead times based on material availability and production capacity allocation.

Performance Metrics and Material Properties

| Property | C10100 (OFE) | C11000 (ETP) | C12200 (DHP) | Test Method |

|---|---|---|---|---|

| Electrical Conductivity | 101% IACS | 100% IACS | 85% IACS | ASTM B193 |

| Thermal Conductivity | 391 W/m·K | 388 W/m·K | 339 W/m·K | ASTM E1461 |

| Tensile Strength | 220-290 MPa | 220-290 MPa | 210-250 MPa | ASTM E8M |

| Yield Strength | 70-200 MPa | 70-200 MPa | 70-170 MPa | ASTM E8M |

| Elongation | 45-55% | 45-55% | 35-45% | ASTM E8M |

| Hardness | 40-70 HRB | 40-70 HRB | 45-75 HRB | ASTM E18 |

Frequently Asked Questions

Q1: What are the key advantages of Copper hex bolts over Steel alternatives?

Copper hex bolts offer superior corrosion resistance in marine environments, excellent electrical and thermal conductivity, natural antimicrobial properties, and non-magnetic characteristics. Unlike Steel fasteners, Copper bolts do not rust and maintain their integrity in saltwater applications while providing reliable electrical grounding capabilities.

Q2: Can you manufacture custom Copper bolts according to specific drawings?

Yes, we specialize in custom Copper bolt manufacturing based on customer drawings and specifications. Our engineering team reviews technical requirements and provides feasibility analysis, material recommendations, and production timelines. We accommodate special head styles, thread specifications, and dimensional requirements beyond standard offerings.

Q3: What quality certifications do your Copper bolts carry?

Our Copper fasteners are manufactured under ISO 9001:2015 quality management system with material certifications including ASTM B152, EN 13601, and JIS H3100. Each batch includes material test certificates, dimensional inspection reports, and compliance documentation for relevant international standards.

Q4: Do you offer different thread standards for international markets?

We manufacture Copper bolts with various thread standards including ASTM UNC/UNF for North American markets, ISO metric for European applications, JIS metric for Japanese requirements, and BS Whitworth for British specifications. Our threading capabilities ensure global compatibility and seamless integration into diverse fastening systems.

Q5: What is the minimum order quantity for Copper hex bolts?

Our standard minimum order quantity is 100 pieces per size and specification for Copper hex bolts. For custom specifications or non-standard dimensions, the minimum quantity may vary based on tooling requirements and material optimization. We accommodate smaller quantities for prototyping and testing purposes with adjusted pricing structures.

Q6: How do you ensure consistent quality across large production batches?

We implement statistical process control (SPC) throughout manufacturing with regular dimensional inspections, material property testing, and surface finish verification. Each production batch undergoes first-piece inspection, in-process monitoring, and final quality audits. Our quality laboratory performs tensile testing, conductivity measurement, and metallurgical analysis to ensure specification compliance.

Q7: Are your Copper bolts suitable for high-temperature applications?

Copper bolts maintain excellent thermal stability up to 200°C in standard atmospheric conditions. For higher temperature applications, we recommend phosphorus deoxidized Copper (C12200) which offers enhanced creep resistance and thermal cycling performance. Specific application engineering support is available for extreme temperature requirements.

Q8: Can you provide Copper bolts with specialized coatings or platings?

While Copper naturally resists corrosion, we offer specialized surface treatments including nickel plating for enhanced wear resistance, tin plating for improved solderability, and silver plating for maximum electrical conductivity. These treatments are applied according to relevant ASTM and MIL specifications with appropriate thickness control and adhesion testing.

Q9: What testing procedures do you follow for material verification?

Our quality control laboratory performs optical emission spectroscopy for chemical composition analysis, conductivity testing using eddy current methods, mechanical testing per ASTM E8M, and dimensional inspection using coordinate measuring machines. All testing follows documented procedures with calibrated equipment and certified reference standards.

Q10: Do you provide technical support for fastener selection and application engineering?

Our technical team offers comprehensive application engineering support including material selection guidance, torque specifications, joint design recommendations, and compatibility analysis. We provide technical data sheets, application notes, and installation guidelines to ensure optimal performance of Copper fasteners in specific applications.

Why Choose Our Copper Bolts

Unmatched Experience: With three decades of global manufacturing experience, we understand the nuances of Copper bolt production and international quality requirements. Our established supply chain relationships ensure consistent material quality and competitive pricing.

Advanced Manufacturing Capabilities: Our state-of-the-art production facility features the latest cold heading technology, precision thread rolling equipment, and automated quality control systems. This technological advantage enables us to produce Copper hex bolts with superior dimensional accuracy and surface finish.

Customization Flexibility: Unlike standard suppliers, we offer extensive customization options including special head styles, proprietary thread specifications, custom lengths, and unique surface treatments. Our engineering team collaborates with customers to develop optimal fastening solutions.

Superior Customer Service: Our dedicated customer service team provides multilingual support, technical assistance, and proactive communication throughout the order process. Regular project updates and shipment tracking ensure transparency and reliability.

Competitive Lead Times: Our optimized production planning and inventory management systems enable faster turnaround times compared to industry standards. Express manufacturing options are available for urgent requirements without compromising quality.

Global Logistics Network: Strategic partnerships with international freight forwarders enable efficient shipping to worldwide destinations with competitive rates and reliable delivery schedules. Our packaging expertise ensures product integrity during transit.

Packaging and Shipping

Our Copper bolt packaging system protects products during shipping while facilitating easy handling and identification. Small quantities are packed in poly bags with desiccant packets to prevent moisture exposure. Bulk orders utilize corrugated cartons with foam inserts for shock protection and organized arrangement. Each package includes detailed labeling with part numbers, quantities, material certifications, and handling instructions.

Custom Packaging Options: We accommodate specific packaging requirements including customer-branded labels, special box configurations, and retail-ready packaging formats. Automated packaging lines ensure consistent pack quality and efficient processing for large-volume orders.

International Shipping: Our logistics team manages comprehensive export documentation including commercial invoices, packing lists, certificates of origin, and material test reports. We utilize established shipping routes through major ports in Mumbai, Chennai, and Nhava Sheva for optimized transit times to global destinations.

Customer Testimonial

“We have been sourcing Copper hex bolts from this Indian manufacturer for over five years now, and their consistency in quality and delivery has been exceptional. The technical support team helped us optimize our fastener specifications, resulting in improved product performance and cost savings. Their ability to manufacture custom thread lengths and special head configurations has made them our preferred supplier for marine hardware applications. The communication is excellent, and they always keep us informed about production progress.”

– Michael Thompson, Procurement Manager, Australia

Glossary of Terms

Cold Heading: Manufacturing process where Copper wire is formed into bolt heads and shanks at room temperature using high-pressure dies, enhancing material strength through work hardening.

Thread Rolling: Process of forming threads by displacing material using hardened steel dies, creating stronger threads compared to cutting methods while improving surface finish.

IACS (International Annealed Copper Standard): Measurement standard for electrical conductivity where pure annealed Copper at 20°C represents 100% conductivity reference.

Pitch Diameter: Effective diameter of threaded fastener measured at the point where thread width equals groove width, critical for proper thread engagement.

UNC/UNF: Unified National Coarse and Unified National Fine thread standards used in North American fastener applications with specific pitch specifications.

DIN 933: German industrial standard specifying dimensions, tolerances, and technical requirements for partially threaded hexagonal bolts.

Passivation: Chemical treatment process that removes surface contaminants and enhances natural corrosion resistance of Copper alloys.

Work Hardening: Strengthening mechanism in Copper alloys where plastic deformation increases material hardness and tensile strength.

Related Parts:

Copper hex bolts manufacturer, Copper bolts supplier India, DIN 933 Copper bolts, ISO 4017 Copper hex bolts, Copper metric bolts exporter, custom Copper fasteners

High conductivity Copper hex bolts for electrical applications, marine grade Copper bolts with corrosion resistance, precision manufactured Copper hex head cap screws, ASTM B152 compliant Copper fasteners India

Industry-specific Terms: Copper grounding bolts electrical panels, antimicrobial Copper fasteners marine hardware, thermal conductive Copper bolts heat exchangers, architectural Copper bolts exterior applications

Technical Specifications: M6 M8 M10 Copper hex bolts metric threading, UNC UNF threaded Copper bolts American standard, phosphorus deoxidized Copper bolts C12200 grade, oxygen free Copper bolts C10100 specification

International Standards: JIS H3100 Copper bolts Japanese standard, EN 13601 European Copper fasteners, BS 6017 British Copper bolt specifications, GB T5231 Chinese Copper grade standards

Some Other related grades:

1. Core Materials & Alloys

These are the specific metal compositions used for these bolts.

Pure Copper (C101, C110): For maximum electrical conductivity.

Beryllium Copper (BeCu, Alloy 172): Known for high strength and being non-sparking.

Silicon Bronze (C651, C655): The most common “workhorse” alloy for marine and architectural use.

Copper Nickel (CuNi, 90/10, 70/30): Excellent corrosion resistance in seawater.

Phosphor Bronze (Alloy 510, 544): Good fatigue resistance and wear resistance.

Brass: A copper-zinc alloy, often grouped with copper fasteners.

Aluminum Bronze: High strength and excellent wear resistance.

Cartridge Brass (Alloy 260): A common brass alloy for cold-headed fasteners.

📊 Copper Bolt Applications

| 🚢 Marine Saltwater Resistant Propeller Assemblies | ⚡ Electrical High Conductivity Grounding Systems | 🏗️ Architecture Weather Resistant Roofing Systems |

| 🔥 Heat Exchange Thermal Conductive Tube Assemblies | 🎵 Musical Tonal Quality Instrument Hardware | 🧪 Chemical Corrosion Resistant Process Equipment |

Request Your Custom Quote Today

Ready to source premium quality Copper Hex Bolts and Copper Bolts for your applications?

📧 Email us for detailed product brochure: sales@brass-copper-parts. com

📱Call or instant quotation: + 91 22- 43449300

💬 Submit your requirements online and receive:

• Technical data sheets and material certificates

• Competitive pricing with volume discounts

• Custom manufacturing feasibility analysis

• Delivery timeline and shipping options

Experience the difference of working with India’s leading Copper bolt manufacturer. Contact us now for your specialized fastening solutions!