CDA 360 Brass Parts | C36000 Brass Machined Components | UNS 36000 Brass Alloy

Price: US$ 11.20/Kilogram

We are one of the leading manufacturers and exporters of CDA 360 Brass Parts, C36000 Brass Machined Components, and UNS 36000 Brass Alloy from India. We have been supplying precision Brass components to the world market for many decades. Our state-of-the-art manufacturing facility specializes in producing high-quality free-cutting Brass parts that meet stringent international standards including ASTM, DIN, JIS, IS, and BS specifications. With over three decades of global experience in Brass machining and component manufacturing, we have established ourselves as a trusted partner for industries worldwide requiring precision-engineered Brass solutions. Our comprehensive range includes free-machining Brass parts, 360 Brass screw machine parts, and custom Alloy 360 Brass turned components designed to meet diverse industrial applications. We combine advanced CNC machining technology with traditional craftsmanship to deliver superior quality products with exceptional dimensional accuracy and surface finish. Our commitment to excellence, coupled with competitive pricing and reliable delivery schedules, has made us the preferred choice for customers across automotive, electrical, plumbing, marine, and aerospace industries globally.

CDA 360 / C36000 Brass composition:

| Element | Composition (Range / Typical) |

|---|---|

| Copper (Cu) | 60.0 – 63.0 % (nominal ~61.5%) |

| Zinc (Zn) | Balance (~35 – 37%) |

| Lead (Pb) | 2.5 – 3.0 % (nominal ~3%) |

| Iron (Fe) | ≤ 0.35 % |

| Residuals | ≤ 0.5 % |

CDA 360 Brass Material Overview

CDA 360 Brass, also known as Free-Cutting Brass or Half-Hard Brass, represents the pinnacle of machinability in Copper-Zinc alloys. This leaded Brass alloy contains approximately 61.5% Copper, 35.5% Zinc, and 3% Lead, making it the most widely used free-machining Brass alloy in industrial applications. The strategic addition of Lead particles creates natural chip-breaking properties, resulting in superior surface finishes and reduced tool wear during machining operations. CDA 360 Brass demonstrates excellent cold working characteristics, moderate hot forming capabilities, and outstanding performance in automatic screw machine operations. The alloy exhibits good corrosion resistance in atmospheric conditions and mild chemical environments, while maintaining adequate strength for structural applications requiring precise dimensional tolerances.

C36000 Brass Machined Components

C36000 Brass Machined Components represent the industry standard for precision-engineered parts requiring exceptional machinability and dimensional accuracy. Our advanced CNC machining capabilities enable the production of complex geometries, intricate threads, and tight tolerances typically ranging from ±0.001″ to ±0.005″ depending on component size and complexity. The inherent free-cutting properties of C36000 Brass allow for high-speed machining operations, resulting in superior surface finishes with Ra values consistently achieving 32 microinches or better. These machined components find extensive applications in automotive fuel systems, hydraulic fittings, electrical connectors, and precision instruments where reliability and performance are paramount. The uniform grain structure and consistent mechanical properties of C36000 Brass ensure predictable machining behavior and repeatable dimensional accuracy across large production runs.

UNS 36000 Brass Alloy Specifications

UNS 36000 Brass Alloy designation under the Unified Numbering System provides standardized identification for this critical engineering material across international markets. This specification ensures consistent chemical composition, mechanical properties, and performance characteristics that meet or exceed global industry standards. UNS 36000 offers excellent machinability rating of 100% when compared to standard free-cutting steel, making it the benchmark for automatic screw machine operations. The alloy demonstrates superior chip formation characteristics, minimal work hardening during machining, and exceptional tool life extension properties. Our UNS 36000 Brass components undergo rigorous quality control testing including chemical analysis, mechanical property verification, and dimensional inspection to ensure compliance with customer specifications and international standards including ASTM B16, ASTM B121, and relevant DIN, JIS, and IS specifications.

Free-Cutting Brass Components

Free-Cutting Brass Components manufactured from CDA 360 alloy offer unparalleled machinability characteristics that significantly reduce manufacturing costs while improving product quality. The Lead content in free-cutting Brass creates natural lubrication during machining operations, resulting in cleaner chip evacuation, reduced cutting forces, and extended tool life. These components exhibit excellent dimensional stability, minimal residual stress, and superior surface finish quality directly from the machining process, often eliminating secondary finishing operations. Our free-cutting Brass components are engineered to meet demanding applications in automotive brake systems, pneumatic fittings, electrical terminals, and marine hardware where corrosion resistance, strength, and precision are essential. The consistent metallurgical structure ensures uniform machining characteristics and predictable performance across diverse operating conditions and environmental exposures.

Free-Machining Brass Parts

Free-Machining Brass Parts from our facility demonstrate superior manufacturing efficiency through optimized Lead distribution and controlled grain structure. These parts benefit from advanced metallurgical processing techniques that enhance machinability while maintaining structural integrity and corrosion resistance properties. The free-machining characteristics enable complex threading operations, intricate boring processes, and precision turning applications with minimal tool deflection and excellent surface quality. Our manufacturing process incorporates statistical process control methods to ensure consistent part-to-part quality and dimensional repeatability. Free-machining Brass parts find critical applications in hydraulic systems, compressed air equipment, water meter components, and precision gauges where leak-proof performance and long-term reliability are essential requirements.

360 Brass Screw Machine Parts

360 Brass Screw Machine Parts represent the optimal choice for high-volume automatic screw machine production due to exceptional chip-breaking properties and superior machinability characteristics. The Lead content in 360 Brass creates short, manageable chips that facilitate continuous automated production without chip interference or machine stoppages. These parts benefit from reduced cycle times, improved tool life, and consistent dimensional accuracy across extended production runs. Our screw machine parts are produced on state-of-the-art multi-spindle automatic lathes capable of achieving tolerances within ±0.0005″ on critical dimensions. The inherent properties of 360 Brass enable the production of complex parts with multiple machined features including threads, knurls, grooves, and precision bores in single-pass operations, significantly reducing manufacturing costs and lead times.

Alloy 360 Brass Turned Components

Alloy 360 Brass Turned Components showcase precision engineering through advanced CNC turning operations that maximize the material’s exceptional machinability characteristics. These components undergo precision turning processes utilizing modern CNC lathes equipped with live tooling capabilities, enabling the production of complex geometries and multiple machined features without part repositioning. The uniform Lead distribution in Alloy 360 ensures consistent cutting forces and predictable tool wear patterns, resulting in exceptional surface finishes and dimensional accuracy. Our turned components meet stringent quality standards for automotive fuel injection systems, electronic connector assemblies, plumbing valve components, and aerospace applications where precision, reliability, and performance are non-negotiable requirements. Advanced quality control systems monitor critical dimensions throughout the production process to ensure compliance with customer specifications and international standards.

| Element | Percentage (%) | ASTM B16 Range |

|---|---|---|

| Copper (Cu) | 61.0 – 63.0 | 61.5 Nominal |

| Zinc (Zn) | 35.0 – 37.0 | 35.5 Nominal |

| Lead (Pb) | 2.5 – 3.7 | 3.0 Nominal |

| Iron (Fe) | 0.35 Max | 0.35 Max |

| Other Elements | 0.50 Max Total | 0.50 Max Total |

International Material Grade Standards

| Standard | Grade Designation | Specification | Region |

|---|---|---|---|

| ASTM | C36000 | ASTM B16, B121, B124 | USA |

| UNS | UNS 36000 | Unified Numbering System | North America |

| DIN | CuZn36Pb3 | DIN EN 12164, DIN EN 12167 | Germany/Europe |

| BS | CZ121 | BS EN 12164, BS EN 12167 | United Kingdom |

| JIS | C3604 | JIS H 3250, JIS H 3300 | Japan |

| IS | BS 249 Type 1 | IS 319, IS 6912 | India |

| GB | HPb63-3 | GB/T 4423, GB/T 5231 | China |

Mechanical Properties and Performance Characteristics

| Property | Value | Unit | Test Standard |

|---|---|---|---|

| Tensile Strength | 45,000 – 55,000 | PSI | ASTM B557 |

| Yield Strength (0.2%) | 20,000 – 25,000 | PSI | ASTM B557 |

| Elongation | 20 – 25 | % | ASTM B557 |

| Hardness (Rockwell B) | 60 – 70 | HRB | ASTM E18 |

| Density | 8.50 | g/cm³ | ASTM B311 |

| Electrical Conductivity | 26 | %IACS | ASTM E1004 |

| Thermal Conductivity | 115 | W/m·K | ASTM E1461 |

| Coefficient of Expansion | 20.3 | µm/m·°C | ASTM E831 |

Advanced Manufacturing Processes and Machinery

Our state-of-the-art manufacturing facility utilizes cutting-edge technology and precision machinery to produce superior quality CDA 360 Brass components. CNC Multi-Axis Turning Centers equipped with live tooling capabilities enable complex part geometries and multiple machined features in single setups, significantly reducing cycle times and improving dimensional accuracy. Swiss-Type CNC Lathes provide exceptional precision for small diameter parts and components requiring tight tolerances, with capabilities for simultaneous front and back operations.

Multi-Spindle Automatic Screw Machines deliver high-volume production efficiency for standard components, while CNC Machining Centers with 4th and 5th axis capabilities handle complex milled features and compound angle operations. Our Centerless Grinding Equipment achieves precise dimensional control and superior surface finishes on cylindrical components. Thread Rolling Machines produce high-strength threaded components with improved fatigue resistance compared to cut threads.

🔧 CDA 360 BRASS MANUFACTURING FLOW 🔧

RAW MATERIAL → INSPECTION → CNC MACHINING → QUALITY CONTROL → FINISHING → PACKAGING → SHIPPING

✓ 3 DECADES EXPERIENCE ✓ GLOBAL STANDARDS ✓ PRECISION ENGINEERING ✓ CUSTOM SOLUTIONS

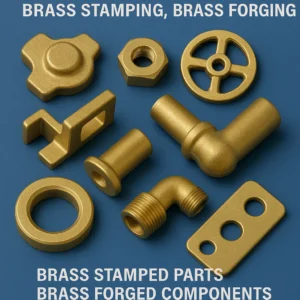

Typical Parts Produced and Applications

Our comprehensive manufacturing capabilities enable the production of diverse CDA 360 Brass components across multiple industries. Automotive Applications include fuel injection components, brake system fittings, transmission parts, and carburetor components where corrosion resistance and precision are critical. Electrical and Electronic Parts encompass connector pins, terminal blocks, switch components, and grounding hardware requiring excellent electrical conductivity and dimensional stability.

Plumbing and HVAC Components feature valve stems, faucet cartridges, pipe fittings, and pressure regulator parts that benefit from Brass’s natural antimicrobial properties and corrosion resistance. Marine Hardware includes propeller shafts, through-hull fittings, and navigation equipment components designed to withstand harsh saltwater environments. Precision Instruments utilize CDA 360 Brass for gauge components, measurement devices, and calibration standards requiring exceptional dimensional accuracy and stability.

Standard Dimensional Capabilities Chart

| Component Type | Diameter Range | Length Range | Tolerance Capability |

|---|---|---|---|

| Turned Components | 0.5mm – 150mm | 5mm – 500mm | ±0.01mm |

| Threaded Parts | M2 – M50 | 10mm – 300mm | ±0.02mm |

| Complex Machined Parts | 5mm – 200mm | 10mm – 400mm | ±0.005mm |

| Screw Machine Parts | 1mm – 25mm | 5mm – 150mm | ±0.008mm |

Surface Finishes and Quality Standards

We offer comprehensive surface finishing options to meet specific application requirements and enhance component performance. As-Machined Finish provides excellent surface quality directly from CNC operations, typically achieving Ra 32 microinches or better. Precision Grinding delivers superior dimensional accuracy and surface finish for critical applications requiring Ra 16 microinches or finer.

Electroplating Options include Nickel, Chrome, Zinc, and Tin coatings for enhanced corrosion resistance and wear protection. Passivation Treatments improve natural corrosion resistance while maintaining dimensional integrity. Anodizing Services provide decorative and protective finishes with color options for aesthetic applications. Heat Treatment Processes optimize mechanical properties and relieve machining stresses for improved dimensional stability and performance reliability.

Industries and Applications

| Industry | Applications | Key Requirements |

|---|---|---|

| Automotive | Fuel systems, brake components, transmission parts | Corrosion resistance, precision, durability |

| Electrical & Electronics | Connectors, terminals, switch components | Conductivity, dimensional accuracy, reliability |

| Plumbing & HVAC | Valves, fittings, pressure regulators | Leak-proof sealing, corrosion resistance |

| Marine | Propeller hardware, through-hulls, fittings | Saltwater corrosion resistance, strength |

| Aerospace | Fuel system components, electrical connections | High reliability, strict tolerances, traceability |

| Medical Devices | Surgical instruments, diagnostic equipment | Biocompatibility, sterilization resistance |

Precision Tolerances and Quality Control

Our advanced quality control systems ensure consistent dimensional accuracy and superior product quality through comprehensive inspection protocols. Statistical Process Control (SPC) monitoring tracks critical dimensions throughout production to maintain tight tolerances and prevent quality variations. Coordinate Measuring Machines (CMM) with probe accuracy of ±0.0001″ verify complex geometries and ensure compliance with customer specifications.

Surface Roughness Testing confirms finish quality requirements using calibrated profilometers and comparison standards. Material Testing Capabilities include chemical analysis, hardness testing, tensile strength verification, and metallographic examination to ensure material property compliance. First Article Inspection (FAI) protocols document complete dimensional and material property verification for new parts or production setup changes.

Our Unique Selling Propositions (USPs)

Customization Excellence: Our engineering team collaborates with customers to develop specialized CDA 360 Brass components tailored to unique application requirements, including modified chemical compositions, special heat treatments, and custom geometries not available from standard suppliers.

Production Flexibility: We accommodate varying production volumes from prototype quantities to high-volume production runs, with the ability to adjust delivery schedules based on customer requirements and market demands, ensuring optimal inventory management for our clients.

Custom Packaging Solutions: Our packaging services include customer-specific labeling, logo printing, custom part marking, and specialized packaging designs that meet specific shipping, storage, and identification requirements for global distribution networks.

Turnaround Time and Delivery

Standard Production Lead Time: 4-6 weeks from order confirmation to shipment, including material procurement, manufacturing, quality control, and packaging. Expedited Services available for urgent requirements with 2-3 week delivery possible for standard components and existing tooling setups. Prototype Development typically completed within 1-2 weeks for design verification and testing purposes.

Global Shipping Network ensures reliable delivery to international destinations through established logistics partnerships with major freight forwarders and shipping lines. Inventory Management Services include consignment stock arrangements and scheduled release programs to optimize customer inventory levels and reduce supply chain risks.

Customer Testimonial

Robert Mitchell, Senior Procurement Manager, AutoTech Components USA

“We have been sourcing CDA 360 Brass components from this Indian manufacturer for over 8 years, and their consistency in quality and delivery has been outstanding. Their technical expertise in free-machining Brass applications helped us resolve critical dimensional stability issues in our fuel injection systems. The precision of their CNC machining and attention to our specific tolerance requirements has made them our preferred supplier for all Brass components. Their customer service team is highly responsive, and they have never missed a delivery commitment. The cost savings compared to domestic suppliers, combined with superior quality, has significantly improved our product margins while maintaining the high standards our automotive customers demand.”

Comprehensive FAQ Session

Q1: What makes CDA 360 Brass superior to other Brass alloys for machining applications?

A1: CDA 360 Brass contains optimized Lead content (3%) that creates natural chip-breaking properties, resulting in superior machinability, extended tool life, and excellent surface finishes. The Lead acts as a natural lubricant during machining, reducing cutting forces and enabling higher spindle speeds compared to other Brass alloys.

Q2: Can you provide CDA 360 Brass components with custom chemical compositions?

A2: Yes, we can modify the standard CDA 360 composition within ASTM limits to meet specific application requirements. Our metallurgical team works with customers to optimize Lead content, adjust Copper-Zinc ratios, or incorporate trace elements for enhanced properties while maintaining excellent machinability characteristics.

Q3: What surface finish quality can you achieve on CDA 360 Brass parts?

A3: Our CNC machining operations typically achieve Ra 32 microinches as-machined, with precision grinding capabilities reaching Ra 16 microinches or better. The free-cutting properties of CDA 360 Brass enable superior surface finishes directly from machining operations, often eliminating secondary finishing requirements.

Q4: How do you ensure dimensional accuracy for high-precision components?

A4: We utilize coordinate measuring machines (CMM) with ±0.0001″ probe accuracy, statistical process control monitoring, and temperature-controlled inspection environments. Our quality control protocols include first article inspection, in-process monitoring, and final dimensional verification to ensure consistent accuracy within ±0.001″ to ±0.005″ depending on component size and complexity.

Q5: What corrosion resistance properties does CDA 360 Brass offer?

A5: CDA 360 Brass provides excellent corrosion resistance in atmospheric conditions, mild chemical environments, and freshwater applications. While not recommended for direct seawater exposure, it performs well in marine atmospheric conditions and offers superior resistance to dezincification compared to standard yellow Brass alloys.

Q6: Can you produce CDA 360 Brass components with complex internal features?

A6: Our advanced CNC machining capabilities include 4th and 5th axis operations, enabling the production of complex internal geometries, compound angles, and intricate features. Swiss-type lathes handle complex small diameter parts, while machining centers accommodate larger components with multiple machined features.

Q7: What quality certifications and traceability do you provide?

A7: We provide comprehensive material certifications including chemical analysis reports, mechanical property test results, and dimensional inspection records. Full traceability documentation tracks material source, processing history, and inspection results throughout the manufacturing process, meeting aerospace and automotive industry requirements.

Q8: How do you handle large volume production requirements?

A8: Our multi-spindle automatic screw machines and CNC production lines accommodate high-volume requirements with consistent quality and competitive pricing. We implement dedicated production schedules, statistical process control monitoring, and automated inspection systems to maintain quality standards across extended production runs.

Q9: What secondary operations and finishing services do you offer?

A9: We provide comprehensive secondary operations including threading, knurling, heat treatment, electroplating (Nickel, Chrome, Zinc, Tin), anodizing, passivation, and precision grinding. Our integrated facility eliminates the need for multiple suppliers while maintaining strict quality control throughout all processing steps.

Q10: How do you ensure on-time delivery for international customers?

A10: Our established logistics network includes partnerships with major freight forwarders, comprehensive export documentation services, and proactive shipment tracking. We maintain buffer stock for critical components, implement advanced production planning systems, and provide regular delivery status updates to ensure reliable on-time performance.

Q11: What minimum order quantities do you accept?

A11: We accommodate varying order sizes from prototype quantities (as low as 10-50 pieces) to high-volume production runs exceeding 100,000 pieces. Our flexible manufacturing setup enables cost-effective production across diverse order volumes while maintaining consistent quality standards.

Q12: Can you provide design assistance for CDA 360 Brass component optimization?

A12: Our experienced engineering team offers comprehensive design support including machinability analysis, dimensional optimization, tolerance stack-up studies, and cost reduction recommendations. We collaborate with customers to optimize part designs for manufacturability while maintaining functional requirements and performance specifications.

Packaging and Shipping Excellence

Custom Packaging Solutions designed to protect components during international shipping while meeting customer-specific requirements for identification, handling, and storage. Anti-Corrosion Packaging includes VCI (Vapor Corrosion Inhibitor) films and desiccant packets for long-term storage and overseas shipments. Customer Labeling Services provide custom part marking, logo printing, and identification systems integrated with customer inventory management systems.

Export Documentation includes comprehensive commercial invoices, packing lists, certificates of origin, and material certifications required for international trade. Shipping Insurance and tracking services ensure secure delivery with full documentation for customs clearance and receiving verification. Consignment Programs available for high-volume customers requiring flexible inventory management and scheduled release arrangements.

Why Choose Our CDA 360 Brass Components

Three Decades of Global Experience in precision Brass machining and component manufacturing has established us as a trusted partner for customers worldwide. Our extensive knowledge of international standards, customer requirements, and application-specific challenges enables us to deliver superior solutions that exceed expectations.

Advanced Manufacturing Capabilities utilizing state-of-the-art CNC equipment, quality control systems, and metallurgical expertise ensure consistent product quality and dimensional accuracy. Our integrated facility provides complete manufacturing solutions from raw material processing through final inspection and packaging, eliminating supply chain complexities.

Exceptional Customer Communication through dedicated project managers, technical support teams, and real-time production updates ensures transparent collaboration throughout the manufacturing process. Our multilingual customer service team provides comprehensive support across different time zones and cultural preferences.

Competitive Global Pricing leverages India’s manufacturing advantages while maintaining international quality standards and delivery reliability. Our efficient operations, optimized supply chain, and economies of scale provide significant cost benefits compared to alternative suppliers without compromising product quality or service excellence.

Glossary of Technical Terms

CDA (Copper Development Association): Industry organization that standardizes Copper alloy designations and specifications for North American markets, providing consistent identification and property requirements.

Free-Cutting Brass: Brass alloys containing Lead additions that improve machinability by creating natural chip-breaking properties and reducing cutting forces during machining operations.

UNS (Unified Numbering System): Standardized alloy designation system used in North America to provide consistent material identification across different specifications and applications.

Machinability Rating: Numerical assessment of material’s ease of machining, typically expressed as percentage relative to standard free-cutting steel (100%), with CDA 360 Brass achieving 100% rating.

Lead Content: Controlled addition of Lead particles in Brass alloys to improve machinability, chip formation, and surface finish quality during machining operations.

Swiss-Type Lathe: Specialized CNC turning machine designed for high-precision small diameter parts, featuring guide bushing support and simultaneous front/back machining capabilities.

Related parts:

CDA 360 Brass parts, C36000 Brass components, UNS 36000 Brass alloy, free-cutting Brass, free-machining Brass parts, 360 Brass screw machine parts, Alloy 360 Brass turned components

CDA 360 Brass precision machined components India, C36000 free-cutting Brass parts manufacturer, UNS 36000 Brass alloy custom manufacturing, automotive Brass components supplier India, precision CNC machined Brass parts, high-volume Brass screw machine parts production

Leaded Brass components, yellow Brass machined parts, Copper-Zinc-Lead alloy parts, automotive Brass fittings, electrical Brass connectors, marine Brass hardware, precision turned Brass components, custom Brass manufacturing India

ASTM B16 Brass specifications, DIN CuZn36Pb3 components, JIS C3604 Brass parts, multi-spindle screw machine parts, CNC precision Brass machining, Brass component dimensional accuracy, international Brass standards compliance

Get Your Custom CDA 360 Brass Components Today!

Ready to experience the precision and quality of our CDA 360 Brass manufacturing expertise?

📧 Email us at sales@brass-copper-parts. com

📞 Call us at 91 22 43449300 for immediate technical consultation

Request Your Custom Quote Today – Fast Response Guaranteed Within 24 Hours!

Join thousands of satisfied customers worldwide who trust our CDA 360 Brass components for their critical applications.