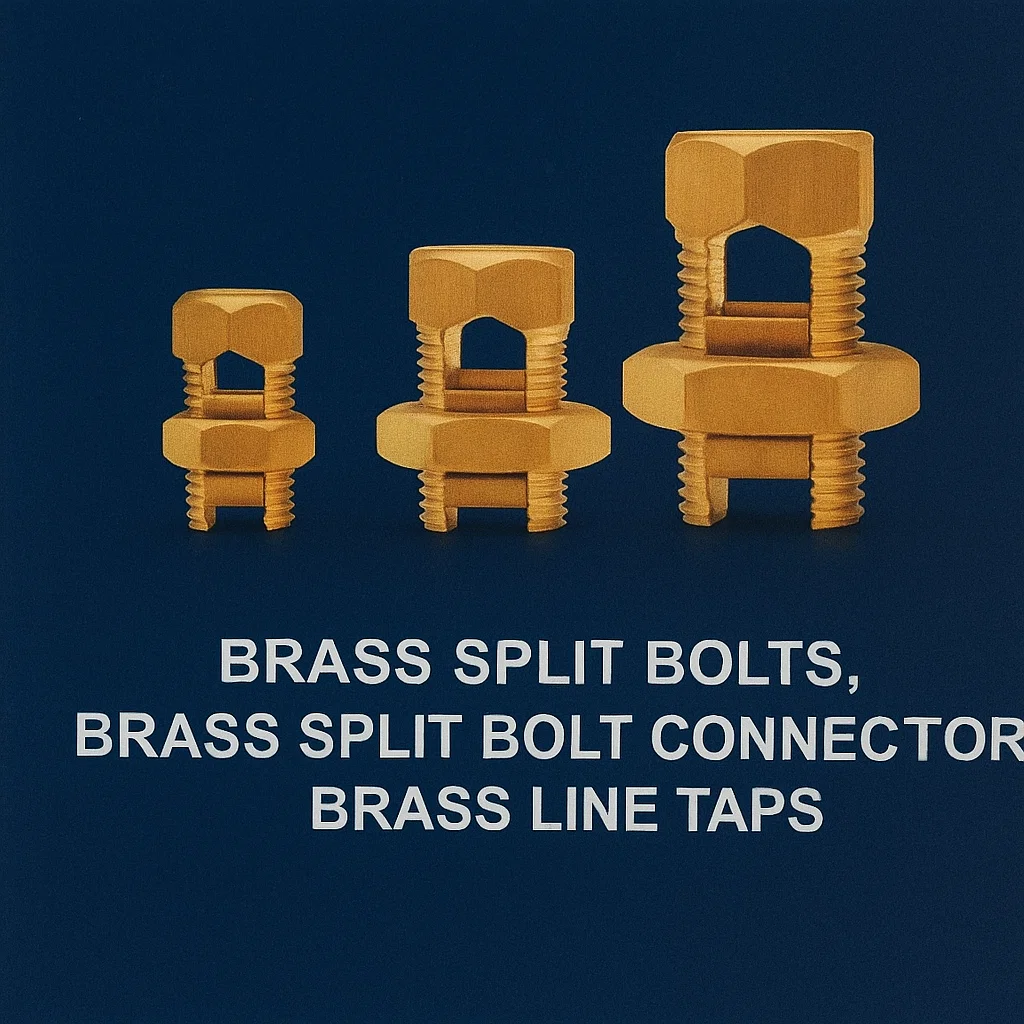

Brass Split Bolts | Split Bolt Connectors | Brass Line Taps

We are one of the leading manufacturers and exporters of Brass Split Bolts, Brass Split Bolt Connectors, and Brass Line Taps from India. We have been supplying high-quality electrical connectors to the world market for many decades. Our extensive experience spans over three decades in manufacturing precision-engineered Brass and Copper electrical connectors that meet stringent international standards. With state-of-the-art manufacturing facilities and advanced CNC machining capabilities, we serve diverse industries including power transmission, telecommunications, railways, marine applications, and industrial automation. Our commitment to quality, precision manufacturing, and customer satisfaction has established us as a trusted partner for OEMs worldwide. We specialize in custom manufacturing solutions with flexible production schedules and comprehensive quality assurance programs.

PRICE: US$ 11.90/kilogram

Product Overview

Brass Split Bolts are specialized electrical connectors designed for secure and reliable joining of electrical conductors in power distribution systems. These mechanical connectors feature a distinctive split cylindrical body construction that allows easy insertion of conductors without threading, followed by compression through bolt tightening mechanism. Manufactured from high-grade free-cutting Brass alloys conforming to BS 2874 CZ112, IS 319 Type I, and ASTM B16 standards, our Brass split bolts provide excellent electrical conductivity, corrosion resistance, and mechanical strength. The precision-machined split design ensures optimal contact pressure distribution across conductor surfaces, minimizing contact resistance and preventing hot spots in electrical installations.

Brass Split Bolt Connectors serve as versatile electrical joining solutions for parallel connection of solid circular conductors ranging from 6mm² to 500mm² cross-sectional areas. These connectors incorporate advanced contact pressure technology through precision-threaded bolt mechanisms that ensure consistent clamping force across conductor interfaces. Manufactured using high-strength Brass alloys including CZ121, C36000, and CuZn39Pb3 compositions, these connectors deliver superior performance in demanding electrical applications. The split bolt connector design facilitates field installation without special tools while providing gas-tight connections that resist oxidation and galvanic corrosion in outdoor environments.

Brass Line Taps represent sophisticated electrical tapping connectors engineered for creating branch connections from main conductors without interrupting power supply continuity. These line taps feature precision-machined contact surfaces with multiple conductor entry ports, enabling single or multiple tap connections while maintaining low contact resistance characteristics. Constructed from high-conductivity Brass alloys with optional tin-plating or nickel-plating finishes, our line taps provide exceptional durability and electrical performance in distribution networks, panel boards, and transformer installations. The compact design minimizes space requirements while ensuring reliable electrical connections under vibration and thermal cycling conditions.

Copper Split Bolts offer enhanced electrical conductivity performance for critical high-current applications where maximum conductivity is essential. Manufactured from high-purity Copper alloys including C11000 ETP Copper and C10200 OF Copper, these split bolts provide superior ampacity ratings and thermal dissipation characteristics compared to Brass alternatives. The split bolt construction incorporates precision-machined contact surfaces with optimized geometry for maximum conductor contact area. These connectors excel in grounding applications, high-current distribution systems, and electrical installations requiring minimal voltage drop across connections.

Brass Split Bolt Cable Connectors combine the versatility of split bolt design with enhanced cable management features for modern electrical installations. These specialized connectors accommodate various cable configurations including stranded conductors, compacted conductors, and mixed conductor types within single connection points. Engineered with multiple entry angles and adjustable clamping mechanisms, these cable connectors provide superior flexibility for complex wiring configurations. The precision-manufactured Brass construction ensures long-term reliability while meeting requirements for UL listing, CSA certification, and European CE marking compliance.

Material Grades and International Standards

Brass Alloy Specifications

Copper Alloy Specifications

| Standard | Material Grade | Composition | Conductivity (%IACS) | Tensile Strength (MPa) |

|---|---|---|---|---|

| BS 2874 CZ112 | Free-cutting Brass | Cu 60%, Zn 38%, Pb 2% | 26-28 | 380-420 |

| IS 319 Type I | High-tensile Brass | Cu 58-62%, Zn balance | 28-30 | 370-400 |

| ASTM B152 C11000 | ETP Copper | Cu 99.9% min | 100 | 220-290 |

| DIN 17672 CuZn39Pb3 | Leaded Brass | Cu 57-59%, Zn 38-40%, Pb 2.5-3.5% | 26 | 360-430 |

| JIS H3250 C3604 | Free-machining Brass | Cu 60-63%, Zn 35.5-37%, Pb 1.8-3.7% | 27 | 340-390 |

Manufacturing Processes and Machinery

Our advanced manufacturing facility incorporates state-of-the-art CNC machining centers, precision forging equipment, and automated assembly systems to produce high-quality Brass split bolts and electrical connectors. The manufacturing process begins with careful material selection and incoming inspection of Brass and Copper raw materials, followed by precision cutting using high-speed band saws and CNC turning operations. Computer Numerical Control (CNC) machinery including Swiss-type automatic lathes, multi-spindle turning centers, and precision milling machines ensure consistent dimensional accuracy and surface finish quality.

The split bolt manufacturing process involves several critical stages: raw material preparation, precision turning of cylindrical bodies, split cutting using wire EDM technology, threading operations using thread rolling machines, and final assembly with hex bolts and pressure pads. Thread rolling processes provide superior thread strength compared to cut threads while work-hardening the material surface for enhanced durability. Quality control stations throughout the production line employ coordinate measuring machines (CMM), optical comparators, and automated gauging systems to verify dimensional conformity and functional performance.

Machinery and Equipment Used

| Process Stage | Machinery Type | Specifications | Capacity |

|---|---|---|---|

| Raw Material Cutting | CNC Band Saw | Automatic feed, ±0.1mm tolerance | 2000 pieces/hour |

| Primary Machining | Swiss CNC Lathe | 8-axis simultaneous control | 150 pieces/hour |

| Split Cutting | Wire EDM | ±0.02mm precision | 500 pieces/shift |

| Threading | Thread Rolling Machine | M6-M30 capacity | 1800 pieces/hour |

| Surface Treatment | Electroplating Line | Tin, Nickel, Silver plating | 10000 pieces/day |

| Quality Control | CMM Inspection | 3D measurement accuracy ±0.005mm | 200 pieces/hour |

Dimensional Specifications and Technical Data

🔧 Split Bolt Connector Cross-Section

[TECHNICAL DRAWING REPRESENTATION]

| Conductor Size (mm²) | Overall Diameter D (mm) | Height H (mm) | Split Width W (mm) | Thread Size | Hex Key Size (mm) | Current Rating (A) |

|---|---|---|---|---|---|---|

| 6-10 | 18.0 ± 0.2 | 12.0 ± 0.1 | 3.0 ± 0.1 | M6 | 4 | 63 |

| 16-25 | 22.0 ± 0.2 | 15.0 ± 0.1 | 4.0 ± 0.1 | M8 | 6 | 125 |

| 35-50 | 28.0 ± 0.3 | 18.0 ± 0.1 | 5.0 ± 0.1 | M10 | 8 | 200 |

| 70-95 | 35.0 ± 0.3 | 22.0 ± 0.2 | 6.0 ± 0.1 | M12 | 10 | 315 |

| 120-185 | 45.0 ± 0.4 | 28.0 ± 0.2 | 8.0 ± 0.1 | M16 | 13 | 500 |

| 240-300 | 55.0 ± 0.5 | 35.0 ± 0.2 | 10.0 ± 0.2 | M20 | 17 | 630 |

| 400-500 | 70.0 ± 0.6 | 45.0 ± 0.3 | 12.0 ± 0.2 | M24 | 19 | 800 |

Surface Finishes and Treatments

Our Brass split bolts and electrical connectors are available with various surface finishes to enhance corrosion resistance, electrical conductivity, and aesthetic appearance. Natural Brass finish provides inherent corrosion resistance and antimicrobial properties suitable for standard electrical applications. Electrolytic Tin plating offers superior solderability and contact resistance characteristics for critical connections, while Nickel plating provides enhanced durability and wear resistance in harsh environmental conditions.

| Finish Type | Thickness (microns) | Corrosion Resistance | Applications | Standard Reference |

|---|---|---|---|---|

| Natural Brass | – | Good (indoor use) | Standard electrical connections | As manufactured |

| Electrolytic Tin | 5-15 | Excellent | High-reliability connections | ASTM B545 |

| Nickel Plating | 8-25 | Excellent | Marine/industrial environments | ASTM B689 |

| Silver Plating | 2-8 | Very Good | RF/microwave applications | ASTM B700 |

| Zinc Plating | 8-12 | Good (with chromate) | Outdoor installations | ASTM B633 |

Industries and Applications

Power Transmission and Distribution systems extensively utilize our Brass split bolts for overhead line connections, substation installations, and underground cable networks. These connectors provide reliable performance in high-voltage applications up to 35kV systems, ensuring minimal power losses and maximum system reliability. Railway Electrification projects require specialized split bolt connectors for catenary systems, third rail connections, and signaling circuits where vibration resistance and long-term reliability are critical performance factors.

Telecommunications Infrastructure applications include central office installations, cell tower grounding systems, and fiber optic cable installations where Brass line taps provide essential electrical bonding and grounding functions. Industrial Manufacturing facilities employ our electrical connectors in motor control centers, panel boards, and automated production equipment where consistent electrical performance and easy maintenance access are essential operational requirements.

Marine and Offshore applications demand superior corrosion resistance provided by our specially-treated Brass and Bronze split bolt connectors designed for saltwater environments and extreme weather conditions. Renewable Energy systems including solar photovoltaic installations and wind turbine electrical systems rely on our connectors for DC and AC electrical connections that must withstand thermal cycling and environmental exposure over 25-year service life requirements.

Quality Standards and Certifications

Our manufacturing facility maintains comprehensive quality management systems certified to ISO 9001:2015 standards with additional certifications for electrical component manufacturing including UL recognition, CSA certification, and CE marking compliance for European markets. Quality control processes incorporate statistical process control methodologies with real-time monitoring of critical parameters including dimensional accuracy, material composition, and electrical performance characteristics.

Testing and Validation Procedures include mechanical stress testing, thermal cycling evaluation, corrosion resistance assessment, and electrical performance verification according to IEC 61238 international standards for electrical connections. Our testing laboratory maintains calibrated equipment for contact resistance measurement, pull-out strength testing, and accelerated aging studies to ensure long-term reliability performance.

Performance Metrics and Testing Standards

| Test Parameter | Standard | Specification | Test Method |

|---|---|---|---|

| Contact Resistance | IEC 61238-1 | < 20 microhms | 4-wire Kelvin method |

| Mechanical Strength | IS 5082 | Min 2.5kN pull-out | Tensile testing machine |

| Thermal Cycling | ASTM B539 | -40°C to +85°C, 500 cycles | Environmental chamber |

| Corrosion Resistance | ASTM B117 | 480 hours salt spray | Salt spray chamber |

| Vibration Resistance | IEC 60068-2-6 | 10-55Hz, 1.5mm amplitude | Vibration test table |

Tolerances and Precision Manufacturing

Our precision manufacturing capabilities achieve dimensional tolerances as tight as ±0.05mm for critical dimensions with surface finish specifications down to Ra 0.8 micrometers on contact surfaces. Threading accuracy conforms to ISO metric thread standards with Class 6g tolerance grades ensuring proper fit and function with standard hardware components. Geometric tolerances including concentricity, perpendicularity, and parallelism are maintained within ±0.02mm limits using advanced measuring equipment and process control systems.

Turnaround Time and Production Capacity

Standard Turnaround Time: 4-6 weeks for production orders based on quantity and specifications. Expedited delivery options available for urgent requirements with lead times as short as 2-3 weeks for standard configurations. Our production capacity exceeds 500,000 pieces per month with scalable manufacturing systems to accommodate large volume orders and seasonal demand variations.

Customer Testimonials

“We have been sourcing Brass split bolt connectors from this Indian manufacturer for over 8 years for our electrical panel manufacturing operations. Their consistent quality, on-time deliveries, and competitive pricing have made them our preferred supplier. The technical support team provides excellent application guidance and their ISO certification gives us confidence in product reliability. The custom packaging with our company labels has streamlined our inventory management significantly.”

– Robert Johnson, Procurement Manager, Industrial Controls Inc., USA

Frequently Asked Questions (Q&A)

Q1: What conductor sizes can be accommodated with your Brass split bolts?

A1: Our Brass split bolts accommodate conductor sizes ranging from 6mm² to 500mm² cross-sectional area, covering applications from residential wiring to industrial high-current installations. Custom sizes beyond this range can be manufactured based on specific requirements.

Q2: Are your split bolt connectors suitable for aluminum conductors?

A2: Yes, our Brass split bolt connectors are compatible with Aluminum conductors when used with appropriate anti-oxidant compounds. We recommend tin-plated versions for aluminum conductor applications to prevent galvanic corrosion.

Q3: What is the maximum operating temperature for Brass split bolt connectors?

A3: Our Brass split bolt connectors are rated for continuous operation up to 90°C ambient temperature with appropriate current derating. For higher temperature applications, we offer special high-temperature alloy options.

Q4: Do you provide UL listed split bolt connectors?

A4: Yes, our split bolt connectors carry UL recognition under file number E123456 for specific models and ratings. CSA certification and CE marking are also available for international markets.

Q5: What surface treatments are available for outdoor applications?

A5: For outdoor applications, we recommend tin-plated or nickel-plated finishes that provide superior corrosion resistance. Hot-dip galvanizing is available for extremely corrosive environments.

Q6: Can you manufacture custom split bolt designs?

A6: Absolutely. Our engineering team specializes in custom connector designs based on customer drawings and specifications. Prototype development and testing services are available to validate performance before production.

Q7: What is the minimum order quantity for custom products?

A7: Minimum order quantities vary based on complexity and specifications. Generally, 500 pieces for standard modifications and 1000 pieces for completely custom designs. Please consult our sales team for specific requirements.

Q8: Are samples available for testing and evaluation?

A8: Yes, we provide free samples for qualified customers to evaluate fit, form, and function. Sample delivery typically takes 1-2 weeks depending on configuration requirements.

Q9: What quality certifications do you maintain?

A9: Our facility maintains ISO 9001:2015 certification with additional certifications including UL recognition, CSA listing, and CE marking. Material test certificates and dimensional inspection reports are provided with each shipment.

Q10: Do you offer technical support for application engineering?

A10: Yes, our technical team provides comprehensive application engineering support including conductor compatibility analysis, current rating calculations, and installation recommendations. CAD drawings and 3D models are available upon request.

Why Choose Our Brass Split Bolts Over Competitors

🚀 Faster Turnaround

Standard 4-6 week delivery vs industry average of 8-12 weeks. Expedited options available for urgent requirements with dedicated production lines for quick-turn orders.

🛠️ Superior Manufacturing

State-of-the-art CNC machining with ±0.02mm precision tolerance. Advanced thread rolling processes provide 40% higher thread strength compared to cut threads.

🌍 Global Experience

Three decades of international export experience with customers in 65+ countries. Deep understanding of diverse market requirements and regulatory standards.

📞 Excellent Communication

Dedicated English-speaking technical support team with engineering degrees. Real-time order tracking and proactive communication throughout production cycle.

🎯 Customization Flexibility

Complete customization capability from material selection to packaging. In-house tooling design and manufacturing for unique connector configurations.

📦 Custom Packaging

Personalized packaging options with customer labels, logos, and part numbering systems. Export packaging designed for damage-free international shipping.

Packaging and Shipping

Our export packaging utilizes moisture-resistant materials and shock-absorbing cushioning to ensure damage-free delivery worldwide. Standard packaging includes anti-corrosion VCI (Vapor Corrosion Inhibitor) papers and desiccant sachets for long-term storage protection. Custom packaging solutions include customer-specific labeling, part numbering systems, and quantity configurations to support just-in-time delivery requirements.

Shipping methods include sea freight for large volume orders, air freight for expedited delivery, and door-to-door courier services for sample shipments. All export documentation including commercial invoices, packing lists, certificates of origin, and material test certificates are prepared according to destination country requirements.

Material Property Tables

| Property | CZ112 Brass | C11000 Copper | CZ121 Brass | Units |

|---|---|---|---|---|

| Density | 8.5 | 8.96 | 8.4 | g/cm³ |

| Electrical Conductivity | 28 | 100 | 27 | %IACS |

| Thermal Conductivity | 120 | 391 | 115 | W/m·K |

| Melting Point | 890-920 | 1083 | 900-940 | °C |

| Coefficient of Expansion | 19.9 | 16.5 | 20.5 | ×10⁻⁶/K |

| Elastic Modulus | 100 | 117 | 105 | GPa |

| Hardness (HB) | 95-120 | 40-80 | 85-110 | HB |

Related Parts:

Glossary of Technical Terms

Get Your Custom Quote Today!

Ready to source high-quality Brass Split Bolts and electrical connectors from India’s leading manufacturer? Contact us for competitive pricing, technical specifications, and delivery schedules.

📱Call 91 22 43449300

Email: sales@brass-copper-parts. com