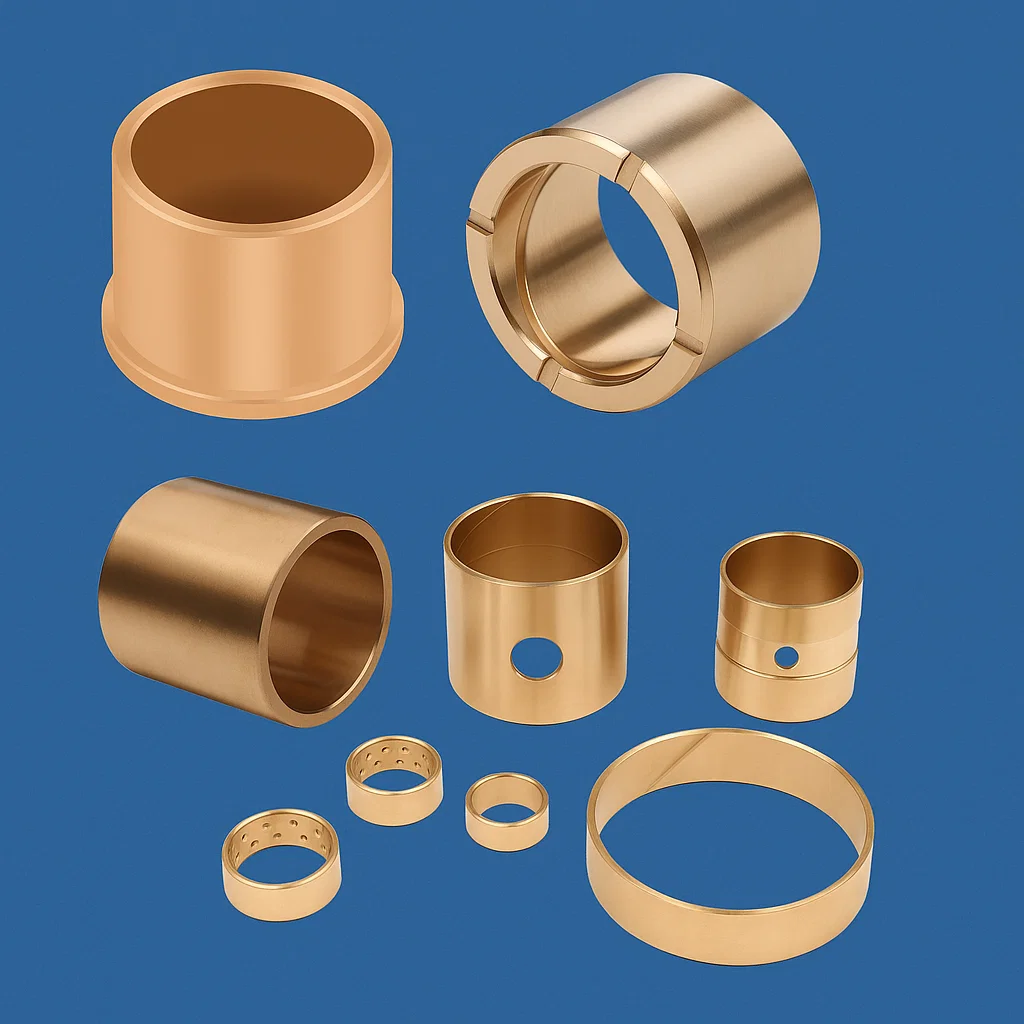

Bronze Bushings, Bronze Bearing Bushes & Bronze Bushes

The Ultimate Comprehensive source for Bronze Bushing, Bronze Bearing Bushes, Bronze general cast and CNC machined bushes s for Industrial Applications

Expert insights on bronze bearing bushes, selection criteria, installation, and maintenance

1. Introduction to Bronze Bushings and Bronze Bearing Bushes

Bronze bushings, also known as bronze bearing bushes or bronze bushes, represent one of the most reliable and versatile solutions in modern mechanical engineering. These cylindrical components serve as critical interfaces between moving parts, providing smooth operation, reduced friction, and extended equipment life across countless industrial applications.

Key Point: Bronze bushings are precision-engineered components made from various bronze alloys, designed to support rotational or sliding motion while minimizing wear and friction between mechanical parts. They serve as the backbone of countless industrial systems, from automotive transmissions to heavy mining equipment.

The history of bronze bearing bushes dates back centuries, with bronze alloys being among the first materials used for bearing applications due to their excellent combination of strength, corrosion resistance, and self-lubricating properties. Today’s bronze bushings have evolved significantly, incorporating advanced metallurgy, precision manufacturing techniques, and innovative design features that make them indispensable in modern industry.

Understanding the intricacies of bronze bushes is essential for engineers, maintenance professionals, and procurement specialists who need to select the right components for their specific applications. This comprehensive guide covers everything from basic principles to advanced selection criteria, ensuring you have the knowledge needed to make informed decisions about bronze bushing applications.

2. What Are Bronze Bushings, Bronze Bushes, and Bronze Bearing Bushes?

Definition and Core Functions

Bronze bushings are cylindrical bearing components manufactured from bronze alloys, designed to reduce friction and wear between rotating or sliding mechanical parts. These components function as plain bearings, providing a smooth, low-friction surface that allows shafts, pins, or other moving elements to operate efficiently within their housings.

Primary Functions

- Friction reduction between moving parts

- Load distribution and support

- Vibration dampening

- Wear protection for expensive components

- Alignment maintenance

- Self-lubrication in many designs

Key Characteristics

- Excellent corrosion resistance

- High load-bearing capacity

- Good thermal conductivity

- Dimensional stability

- Long service life

- Minimal maintenance requirements

Terminology Clarification

While the terms bronze bushings, bronze bushes, and bronze bearing bushes are often used interchangeably, there are subtle distinctions in their usage across different industries and regions:

| Term | Primary Usage | Typical Applications | Regional Preference |

|---|---|---|---|

| Bronze Bushings | North American standard | General industrial applications | USA, Canada |

| Bronze Bushes | European/British standard | Mechanical engineering | UK, Europe, Australia |

| Bronze Bearing Bushes | Technical/engineering contexts | Precision applications | International technical documentation |

Fundamental Design Principles

The effectiveness of bronze bearing bushes relies on several key design principles that have been refined over decades of engineering development. These principles ensure optimal performance across a wide range of operating conditions and applications.

Design Philosophy: Bronze bushings operate on the principle of sliding friction, where the bronze alloy provides a sacrificial wearing surface that protects more expensive components while maintaining smooth operation. The inherent properties of bronze alloys, including their ability to embed debris and provide some degree of self-lubrication, make them ideal for this application.

3. Types and Categories of Bronze Bushings

Classification by Design Configuration

Cylindrical Bronze Bushings (Sleeve Bearings)

Cylindrical bronze bushings, also known as sleeve bearings, represent the most common and versatile type of bronze bearing bushes. These simple yet effective components consist of a bronze cylinder with precise inner and outer diameters designed to fit specific shaft and housing requirements.

Cylindrical Bronze Bushing Features:

- Simple installation and replacement

- Cost-effective manufacturing

- Available in standard and custom sizes

- Suitable for radial load applications

- Easy to machine and modify

- Excellent for high-speed applications

Flanged Bronze Bushings

Flanged bronze bushings feature an integral flange at one end, providing axial positioning and preventing the bushing from moving within its housing. This design is particularly valuable in applications where precise positioning is critical.

Thrust Bronze Bushings (Thrust Washers)

Thrust bronze bushings, often called thrust washers, are designed specifically to handle axial loads. These flat, ring-shaped components are essential in applications involving rotating shafts that experience thrust forces.

Classification by Manufacturing Method

Sintered Bronze Bushings

Sintered bronze bushings are manufactured using powder metallurgy techniques, where bronze powders are compressed and heated to form a porous structure. This porosity is key to their self-lubricating properties.

Sintering Process Advantages: The sintering process creates a network of interconnected pores throughout the bronze matrix, allowing for oil impregnation and creating excellent self-lubricating properties. Sintered bronze bushings can contain up to 20-30% porosity by volume.

Cast Bronze Bushings

Cast bronze bushings are produced through traditional casting methods, resulting in a dense, solid structure. These bushings offer excellent strength and dimensional stability, making them ideal for high-load applications.

Machined Bronze Bushings

Machined from solid bronze bar stock, these bushings offer the highest precision and surface finish quality. They are typically used in applications requiring tight tolerances and superior surface characteristics.

Classification by Lubrication Method

Oil-Impregnated Bronze Bushings

Oil-impregnated bronze bushings combine the benefits of sintered bronze with pre-loaded lubricant. These bushings are vacuum-impregnated with oil, providing continuous lubrication throughout their service life.

Oil Impregnation Benefits:

- Reduced maintenance requirements

- Extended service life

- Self-lubricating operation

- Suitable for hard-to-reach locations

- Consistent lubrication delivery

Typical Oil Types Used:

- SAE 20 mineral oil

- SAE 30 mineral oil

- Synthetic lubricants

- High-temperature oils

- Food-grade lubricants

Graphite-Plugged Bronze Bushings

These specialized bronze bearing bushes feature graphite plugs or inserts that provide solid lubrication, particularly useful in high-temperature applications or where traditional liquid lubricants are not suitable.

Grease-Lubricated Bronze Bushings

Designed with integral grease fittings or lubrication grooves, these bushings allow for periodic relubrication, making them suitable for applications requiring extended service intervals with maintenance accessibility.

4. Bronze Bushing Materials and Alloy Compositions

Understanding Bronze Alloy Systems

The performance characteristics of bronze bushings are fundamentally determined by their alloy composition. Bronze, as a family of copper-based alloys, offers a wide range of properties depending on the alloying elements and their proportions.

Tin Bronze Alloys Bushes (Phosphor Bronze Bushes)

Tin bronze alloys represent the traditional and most widely used bronze compositions for bushing applications. These alloys typically contain 88-95% copper with tin as the primary alloying element.

| Alloy Designation | Composition | Key Properties | Primary Applications |

|---|---|---|---|

| C93200 (SAE 660) | 83% Cu, 7% Sn, 7% Pb, 3% Zn | Excellent machinability, good bearing properties | General purpose bushings |

| C90700 (Tin Bronze) | 89% Cu, 11% Sn | High strength, corrosion resistant | Marine applications |

| C51000 (Phosphor Bronze) | 95% Cu, 5% Sn, 0.2% P | Spring properties, fatigue resistance | Electrical contacts, springs |

Aluminum Bronze Alloys Bushes

Aluminum bronze bushings offer exceptional strength and corrosion resistance, making them ideal for demanding applications in marine, chemical, and heavy industrial environments.

Aluminum Bronze Advantages: These alloys can achieve tensile strengths exceeding 90,000 PSI while maintaining excellent corrosion resistance in seawater and many chemical environments. They are particularly valued in applications where both mechanical performance and environmental resistance are critical.

Bushes from Leaded Bronze Alloys

Leaded bronze alloys incorporate lead content ranging from 5% to 25%, significantly improving machinability and bearing performance through enhanced conformability and embedability.

Manganese Bronze Alloys Bushes

Despite the name, manganese bronze is actually a high-strength brass alloy that offers excellent mechanical properties and is often used in high-stress bushing applications.

Specialty Bronze Alloys

Nickel-Aluminum Bronze Bushes

These premium alloys offer superior strength, hardness, and corrosion resistance, making them suitable for the most demanding bronze bearing bush applications.

Silicon Bronze Bushes

Silicon bronze alloys provide excellent corrosion resistance and are often used in applications requiring resistance to stress corrosion cracking.

Material Selection Considerations

Mechanical Requirements

- Load capacity requirements

- Speed limitations

- Fatigue resistance needs

- Impact resistance

- Temperature stability

Environmental Factors

- Corrosion resistance needs

- Chemical compatibility

- Temperature range

- Lubrication availability

- Contamination levels

Economic Considerations

- Initial material cost

- Manufacturing complexity

- Maintenance requirements

- Service life expectations

- Replacement costs

5. Manufacturing Processes for Bronze Bushings

Powder Metallurgy and Sintering

The powder metallurgy process is fundamental to producing high-quality sintered bronze bushings. This sophisticated manufacturing technique allows for precise control of porosity, which is essential for creating self-lubricating properties.

Sintering Process Steps:

- Powder Preparation: Bronze powders are carefully blended to achieve desired composition

- Compaction: Powders are pressed in precision dies under high pressure

- Sintering: Compacts are heated to 750-850°C in controlled atmosphere

- Sizing: Final dimensions are achieved through cold pressing

- Oil Impregnation: Porous structure is filled with lubricant under vacuum

Advantages of Sintered Bronze Bushings

Sintered bronze bushes offer unique advantages that make them particularly suitable for many applications:

- Self-Lubrication: Controlled porosity allows for oil storage and gradual release

- Cost Efficiency: Near-net-shape manufacturing reduces machining requirements

- Consistency: Automated process ensures uniform properties

- Customization: Porosity and composition can be tailored to specific needs

Sand Casting and Centrifugal Casting

Traditional casting methods remain important for producing large or complex bronze bearing bushes, particularly when solid, dense structures are required for high-load applications.

Sand Casting Process

Sand casting is used for larger bushings and custom geometries where the flexibility of mold making is advantageous. This process is particularly suitable for low to medium volume production.

Centrifugal Casting

Centrifugal casting produces superior quality bushings with excellent mechanical properties and minimal defects. The centrifugal force eliminates porosity and ensures uniform density throughout the casting.

Machining and Finishing Operations

Precision machining is critical for achieving the tight tolerances required in high-performance bronze bushing applications. Modern CNC machining centers allow for consistent, repeatable production of complex geometries.

Typical Machining Operations

- Turning for cylindrical surfaces

- Boring for internal diameters

- Reaming for precision holes

- Facing for end surfaces

- Threading for special applications

Quality Control Measures

- Dimensional inspection

- Surface finish verification

- Hardness testing

- Porosity measurement

- Oil content analysis

Surface Treatments and Coatings

Advanced surface treatments can significantly enhance the performance of bronze bearing bushes in specialized applications:

Solid Film Lubrication

PTFE or molybdenum disulfide coatings can provide additional lubrication for extreme service conditions.

Plating and Surface Modification

Electroplating with tin, lead, or other materials can improve specific performance characteristics such as conformability or corrosion resistance.

6. Mechanical Properties and Performance Characteristics

Load Carrying Capacity

The load carrying capacity of bronze bushings is one of their most critical performance characteristics. This capacity depends on multiple factors including alloy composition, operating conditions, and lubrication effectiveness.

| Alloy Type | Max PV Value (psi·fpm) | Max Load (psi) | Max Velocity (fpm) | Temperature Range (°F) |

|---|---|---|---|---|

| Oil-Impregnated Bronze | 50,000 | 4,000 | 1,000 | -65 to +300 |

| Tin Bronze (Solid) | 75,000 | 6,000 | 1,500 | -100 to +400 |

| Aluminum Bronze | 100,000 | 8,000 | 2,000 | -200 to +600 |

| Leaded Bronze | 40,000 | 3,000 | 800 | -50 to +250 |

PV Value Explained: The PV value (Pressure × Velocity) is a critical parameter in bushing selection. It represents the product of the bearing load in PSI and the sliding velocity in feet per minute. Exceeding the maximum PV value can lead to excessive heat generation and bearing failure.

Friction Characteristics

The friction coefficient of bronze bearing bushes varies significantly based on operating conditions, surface finish, and lubrication state. Understanding these characteristics is essential for proper application engineering.

Static vs. Dynamic Friction

Bronze bushings typically exhibit different friction coefficients for static (starting) and dynamic (running) conditions:

Lubricated Conditions

- Static friction: 0.15-0.25

- Dynamic friction: 0.05-0.15

- Boundary lubrication: 0.10-0.20

- Hydrodynamic lubrication: 0.002-0.010

Dry Running Conditions

- Static friction: 0.3-0.5

- Dynamic friction: 0.2-0.4

- Emergency operation: 0.4-0.6

- Temperature dependent variation

Thermal Properties

The thermal characteristics of bronze bushes significantly influence their performance in high-temperature applications or high-speed operations where heat generation is a concern.

Thermal Conductivity

Bronze alloys generally exhibit excellent thermal conductivity, ranging from 15-60 BTU/hr·ft·°F depending on composition. This property helps dissipate heat generated by friction, preventing thermal damage.

Thermal Expansion

Understanding thermal expansion is crucial for maintaining proper clearances across temperature ranges. Typical values range from 9-11 × 10⁻⁶ in/in/°F for most bronze alloys.

Fatigue and Wear Resistance

Long-term durability of bronze bearing bushes depends heavily on their resistance to fatigue and wear under cyclic loading conditions.

Wear Mechanisms: Bronze bushings can experience various wear modes including adhesive wear, abrasive wear, corrosive wear, and fatigue wear. The dominant mechanism depends on operating conditions, contamination levels, and lubrication effectiveness.

Surface Fatigue

Surface fatigue becomes critical in applications with cyclic loading or oscillatory motion. Proper surface finish and material selection can significantly extend fatigue life.

Wear Rate Factors

Several factors influence wear rates in bronze bushings:

- Load intensity and distribution

- Sliding velocity and acceleration

- Surface roughness and finish

- Lubrication effectiveness

- Contamination and debris

- Temperature and environmental conditions

7. Industrial Applications of Bronze Bearing Bushes

Automotive Industry Applications

The automotive industry represents one of the largest markets for bronze bushings, where they serve critical functions in various vehicle systems requiring reliable operation under demanding conditions.

Engine Components

Connecting rod bushings, wrist pin bushings, and camshaft bushings rely on bronze’s excellent bearing properties and thermal stability.

Transmission Systems

Gear shift mechanisms, clutch linkages, and transmission controls utilize bronze bushings for smooth, reliable operation.

Suspension Components

Control arm bushings, stabilizer bar links, and shock absorber mounts benefit from bronze’s vibration damping properties.

Steering Systems

Steering column bushings, tie rod ends, and power steering components require the precision and durability of bronze bearings.

Heavy Equipment and Construction Machinery

Bronze bearing bushes are essential components in heavy equipment where extreme loads, harsh environmental conditions, and extended service intervals are common requirements.

Excavators and Earth Moving Equipment

Hydraulic cylinder bushings, boom and arm pivot bushings, and track system components rely on bronze’s ability to handle high loads and resist contamination.

Critical Requirements for Heavy Equipment:

- High load capacity for lifting and digging operations

- Contamination resistance in dusty environments

- Long service intervals to minimize downtime

- Temperature stability for varying operating conditions

- Impact resistance for shock loading

- Corrosion resistance for outdoor operation

Mining Equipment

The mining industry presents some of the most challenging applications for bronze bushes, requiring exceptional durability and reliability in extreme conditions.

Marine and Offshore Applications

Marine environments demand superior corrosion resistance, making bronze alloys particularly valuable for propeller shaft bushings, rudder bushings, and deck machinery applications.

Marine Application Benefits: Bronze’s natural resistance to seawater corrosion, combined with its excellent bearing properties, makes it the material of choice for marine propulsion systems. Aluminum bronze and naval brass compositions are specifically formulated for these demanding applications.

Propulsion Systems

Propeller shaft bushings, stern tube bushings, and thrust bearing components utilize specialized marine bronze alloys designed for continuous submersion in seawater.

Deck and Cargo Handling Equipment

Winches, cranes, and anchor windlasses rely on bronze bushings for reliable operation in corrosive marine atmospheres.

Aerospace and Defense Applications

The aerospace industry requires bronze bearing bushes that meet stringent performance, reliability, and weight requirements while operating in extreme temperature and pressure conditions.

Landing Gear Systems

Main landing gear bushings, nose gear bushings, and retraction mechanism components demand high strength-to-weight ratios and precise dimensional stability.

Control Surface Actuators

Flight control systems utilize bronze bushings in elevator, rudder, and aileron actuators where precision and reliability are critical for flight safety.

Industrial Manufacturing Equipment

Manufacturing equipment applications for bronze bushings span across numerous industries, from textiles to steel production, where continuous operation and minimal maintenance are essential.

Textile Machinery

Spinning frames, looms, and knitting machines require smooth, quiet operation provided by precision bronze bushings.

Paper and Pulp Equipment

Paper mill rolls, calendering equipment, and conveyor systems utilize bronze bushings for reliability in corrosive environments.

Steel Production

Rolling mill bushings, crane systems, and material handling equipment depend on bronze’s high-temperature performance.

Food Processing

Mixing equipment, conveyor systems, and packaging machinery use food-grade bronze bushings that resist contamination.

Power Generation Equipment

Power generation applications present unique challenges requiring bronze bearing bushes capable of operating reliably in high-temperature, high-vibration environments with minimal maintenance.

Hydroelectric Turbines

Wicket gate bushings, runner bushings, and generator guide bushings must operate submerged while handling massive water forces.

Wind Turbine Systems

Pitch control mechanisms, yaw systems, and generator components utilize bronze bushings designed for long-term outdoor exposure.

Steam and Gas Turbines

High-temperature applications in thermal power plants require specialized bronze alloys capable of maintaining properties at elevated temperatures.

8. Selection Criteria for Bronze Bushings

Load Analysis and Capacity Requirements

Proper selection of bronze bushings begins with thorough analysis of the load conditions, including magnitude, direction, and dynamic characteristics of the forces involved.

Load Analysis Steps:

- Static Load Calculation: Determine maximum static load in PSI

- Dynamic Load Assessment: Calculate varying loads during operation

- Impact Load Consideration: Account for shock and vibration effects

- Safety Factor Application: Apply appropriate design margins

- PV Value Calculation: Ensure load-velocity combination is acceptable

Radial vs. Thrust Load Considerations

Different types of bronze bearing bushes are optimized for different load directions:

| Load Type | Recommended Bushing Type | Design Considerations | Typical Applications |

|---|---|---|---|

| Pure Radial | Cylindrical sleeve bushings | Length-to-diameter ratio optimization | Rotating shafts, spindles |

| Pure Thrust | Thrust washers, flat bushings | Surface area maximization | Vertical shafts, thrust applications |

| Combined Loads | Flanged bushings | Both radial and thrust capacity | Multi-directional loading |

Speed and Motion Characteristics

Operating speed significantly influences the selection of bronze bushes, affecting lubrication requirements, heat generation, and wear patterns.

Continuous Rotation Applications

High-speed continuous rotation applications require careful consideration of:

- Surface velocity limits for the selected bronze alloy

- Heat dissipation capability of the housing design

- Lubrication system adequacy

- Dynamic balance and vibration characteristics

- Centrifugal force effects on oil-impregnated bushings

Oscillating and Reciprocating Motion

Oscillating applications present different challenges requiring specialized consideration of fretting wear, boundary lubrication conditions, and fatigue resistance.

Environmental Considerations

Environmental factors significantly impact the performance and longevity of bronze bearing bushes, requiring careful evaluation during the selection process.

Temperature Factors

- Operating temperature range

- Temperature cycling effects

- Thermal shock resistance

- Lubrication stability at temperature

- Dimensional stability requirements

Chemical Environment

- Corrosive media exposure

- pH levels and chemical compatibility

- Cleaning agent compatibility

- Galvanic corrosion potential

- Stress corrosion cracking resistance

Contamination Levels

- Particulate contamination types

- Filtration system effectiveness

- Seal design and effectiveness

- Washdown requirements

- Self-cleaning capability needs

Lubrication System Integration

The lubrication system design significantly influences bronze bushing selection, performance, and maintenance requirements.

Self-Lubricating vs. Externally Lubricated

The choice between self-lubricating and externally lubricated bronze bushings depends on several factors:

Self-Lubricating Advantages: Oil-impregnated bronze bushings eliminate the need for external lubrication systems, reducing complexity and maintenance. They are ideal for remote locations, sealed applications, or where contamination of the lubricant is a concern.

Lubrication Schedule and Accessibility

Maintenance accessibility significantly impacts bushing selection:

- Maintenance interval requirements

- Accessibility for lubrication

- Contamination sensitivity

- Lubricant type restrictions

- Temperature effects on lubrication

Economic Factors and Life Cycle Costs

Total cost of ownership considerations extend far beyond initial purchase price, requiring comprehensive analysis of life cycle costs for bronze bearing bushes.

| Cost Factor | Initial Impact | Long-term Impact | Optimization Strategy |

|---|---|---|---|

| Material Cost | High | Low | Balance performance vs. cost |

| Manufacturing Cost | Medium | Low | Optimize for volume production |

| Installation Cost | Medium | Medium | Design for easy installation |

| Maintenance Cost | Low | High | Minimize maintenance requirements |

| Downtime Cost | Low | Very High | Maximize reliability and service life |

9. Installation and Maintenance of Bronze Bushes

Pre-Installation Considerations

Proper installation of bronze bushings is critical for achieving optimal performance and service life. Pre-installation planning and preparation significantly impact long-term success.

Dimensional Verification and Tolerances

Before installation, verify that both the bronze bushing and mating components meet specified tolerances:

Critical Measurements:

- Housing bore diameter and tolerance

- Shaft diameter and surface finish

- Bushing outer diameter and wall thickness

- Length and chamfer specifications

- Concentricity and roundness requirements

Surface Preparation

Proper surface preparation of mating components ensures optimal performance of bronze bearing bushes:

Housing Preparation

- Clean and degrease housing bore

- Verify surface finish (typically 32-63 µin RA)

- Check for scratches or damage

- Ensure proper bore straightness

- Apply appropriate press-fit compound if required

Shaft Preparation

- Achieve specified surface finish (16-32 µin RA)

- Verify hardness requirements (typically Rc 28-35)

- Check for straightness and concentricity

- Remove burrs and sharp edges

- Apply initial lubrication if specified

Installation Procedures

Press-Fit Installation

Most bronze bushes are installed using press-fit methods. Proper technique ensures consistent performance and prevents damage:

- Arbor Press Method: Use appropriate tooling to distribute installation force evenly

- Hydraulic Press Installation: Provides controlled force application for large bushings

- Thermal Installation: Heat housing or cool bushing for interference fit installation

- Mandrel Support: Use internal mandrels to prevent distortion during installation

Installation Best Practices: Always support the bushing properly during installation to prevent distortion. Use appropriate installation tools that contact the bushing at the correct locations. Monitor installation force to detect potential problems early.

Post-Installation Operations

After installation, several operations may be required to achieve final specifications:

- Reaming or honing to final inside diameter

- End facing to final length

- Deburring and chamfering

- Final dimensional verification

- Initial lubrication application

Maintenance Procedures

Lubrication Maintenance

Proper lubrication maintenance is essential for maximizing the service life of bronze bearing bushes:

| Bushing Type | Lubrication Method | Maintenance Frequency | Key Maintenance Points |

|---|---|---|---|

| Oil-Impregnated | Self-lubricating | Minimal | Monitor for oil depletion signs |

| Grease Lubricated | Periodic greasing | 500-2000 hours | Purge old grease, verify grease type |

| Oil Bath | Continuous oil supply | 1000-5000 hours | Oil level, contamination, filtration |

| Forced Lubrication | Pressurized oil system | Continuous monitoring | Pressure, flow rate, oil quality |

Inspection and Condition Monitoring

Regular inspection of bronze bushings helps detect potential problems before they lead to failure:

Visual Inspection Points

- Surface wear patterns

- Corrosion or discoloration

- Lubrication condition

- Contamination presence

- Alignment and positioning

Performance Monitoring

- Operating temperature trends

- Vibration levels and patterns

- Power consumption changes

- Noise level variations

- Clearance measurements

Troubleshooting Common Issues

Premature Wear

Excessive wear of bronze bearing bushes can result from various causes:

- Inadequate Lubrication: Most common cause of premature failure

- Contamination: Abrasive particles accelerate wear

- Misalignment: Creates uneven load distribution

- Overloading: Exceeds design capacity

- Incorrect Installation: Distortion or damage during installation

Seizure and Galling

Seizure represents catastrophic failure requiring immediate attention:

Seizure Prevention: Maintain adequate lubrication, monitor operating temperatures, ensure proper clearances, and avoid contamination. Early detection of warning signs such as increased temperature, vibration, or noise can prevent catastrophic failure.

Corrosion and Chemical Attack

Environmental corrosion can significantly impact bronze bushing performance:

- Identify corrosive agents in the environment

- Select appropriate alloy composition for conditions

- Implement protective measures such as coatings

- Monitor pH levels and chemical concentrations

- Establish appropriate maintenance intervals

10. Bronze Bushings vs. Other Bearing Types

Bronze Bushings vs. Steel Bushings

The comparison between bronze bushings and steel bushings reveals distinct advantages and limitations for each material type across different applications.

| Performance Factor | Bronze Bushings | Steel Bushings | Advantage |

|---|---|---|---|

| Corrosion Resistance | Excellent in most environments | Requires protective coatings | Bronze |

| Load Capacity | Good to very good | Excellent | Steel |

| Self-Lubrication | Available in oil-impregnated forms | Not available | Bronze |

| Cost | Higher initial cost | Lower initial cost | Steel |

| Machinability | Good to excellent | Variable, may require heat treatment | Bronze |

| Temperature Range | -65°F to +400°F typical | -100°F to +800°F+ | Steel |

Application Guidelines: Choose bronze bushings for corrosive environments, applications requiring self-lubrication, or where embedability is important. Select steel bushings for extreme temperature applications, maximum load capacity, or where cost is the primary consideration.

Bronze Bushings vs. Plastic Bushings

Bronze bearing bushes offer several advantages over plastic alternatives, particularly in demanding industrial applications requiring durability and reliability.

Bronze Bushing Advantages

- Higher load capacity and strength

- Better thermal conductivity and heat dissipation

- Superior chemical resistance in many environments

- Dimensional stability across temperature ranges

- Longer service life in harsh conditions

- Better performance in high-speed applications

Plastic Bushing Advantages

- Lower weight and density

- Lower material cost

- Excellent chemical resistance to specific media

- Self-lubricating properties without oil

- Electrical insulation properties

- FDA approval for food applications

Bronze Bushings vs. Rolling Element Bearings

The choice between bronze bushes and rolling element bearings (ball or roller bearings) depends on specific application requirements and operating conditions.

Performance Comparison

| Characteristic | Bronze Bushings | Rolling Element Bearings | Best Application |

|---|---|---|---|

| Friction Coefficient | 0.05-0.15 (lubricated) | 0.001-0.005 (lubricated) | Rolling for lowest friction |

| Speed Capability | Moderate to high | Very high | Rolling for highest speeds |

| Load Capacity | High static, good dynamic | High dynamic, lower static | Bronze for static loads |

| Contamination Tolerance | Excellent | Poor to moderate | Bronze for dirty environments |

| Maintenance | Low to minimal | Regular lubrication required | Bronze for low maintenance |

| Noise Level | Very low | Moderate | Bronze for quiet operation |

Application Selection Guidelines

Choose Bronze Bushings When: Applications involve heavy static loads, contaminated environments, oscillating motion, requirement for quiet operation, minimal maintenance access, or where simplicity and reliability are paramount.

Choose Rolling Element Bearings When: High-speed rotation, lowest friction requirements, precise positioning, high dynamic loads, or where efficiency is critical to overall system performance.

Hybrid Solutions and Composite Bearings

Modern bearing technology has developed hybrid solutions that combine the benefits of different materials and technologies, including composite bearings that incorporate bronze elements.

Bronze-PTFE Composite Bushings

These advanced bronze bearing bushes combine a bronze backing with a PTFE lining, offering the structural strength of bronze with the low-friction properties of PTFE.

Tri-Metal Bearings

Three-layer construction incorporating steel backing, bronze intermediate layer, and polymer surface provides optimized performance characteristics for specific applications.

11. Troubleshooting and Problem Solutions

Common Failure Modes

Understanding common failure modes of bronze bushings enables proactive maintenance and proper root cause analysis when problems occur.

Adhesive Wear and Galling

Adhesive wear occurs when metal-to-metal contact causes material transfer between surfaces, leading to surface roughening and potential seizure.

Symptoms of Adhesive Wear

- Material transfer on shaft surface

- Rough or galled bearing surface

- Increased operating temperature

- Higher power consumption

- Metallic debris in lubricant

Root Causes

- Inadequate lubrication

- Excessive load or speed

- Poor surface finish

- Contaminated lubricant

- Improper material selection

Abrasive Wear

Abrasive wear results from hard particles cutting or gouging the bronze bearing bush surface, creating grooves and reducing load-bearing area.

Abrasive Wear Prevention: Implement effective filtration systems, maintain proper sealing, select appropriate bronze alloys with good embedability, and establish regular contamination monitoring procedures.

Corrosive Wear

Chemical attack combined with mechanical wear creates a synergistic effect that accelerates material loss from bronze bushing surfaces.

Diagnostic Techniques

Visual Inspection Methods

Systematic visual inspection of bronze bushes can reveal valuable information about operating conditions and potential problems:

- Wear Patterns: Uniform wear indicates normal operation, while uneven patterns suggest misalignment or uneven loading

- Color Changes: Blue or black discoloration indicates overheating, while green coloration may indicate corrosion

- Surface Texture: Smooth, polished surfaces are normal, while rough or pitted surfaces indicate problems

- Lubrication State: Dry or carbonized lubricant indicates inadequate lubrication or overheating

Dimensional Analysis

Precise measurement of bronze bushing dimensions can quantify wear rates and predict remaining service life:

| Measurement | Typical Tolerance | Wear Limit | Measurement Method |

|---|---|---|---|

| Inside Diameter | +0.001″ to +0.003″ | +0.010″ over new | Inside micrometer, bore gauge |

| Outside Diameter | -0.001″ to -0.003″ | -0.005″ under new | Outside micrometer |

| Length | ±0.005″ | -0.010″ under new | Calipers, height gauge |

| Wall Thickness | ±0.002″ | -20% of nominal | Ultrasonic thickness gauge |

Problem Resolution Strategies

Lubrication-Related Problems

Many bronze bushing failures relate to lubrication issues. Systematic approach to lubrication problems includes:

- Lubricant Analysis: Test oil or grease for contamination, degradation, and proper viscosity

- System Inspection: Verify lubrication system operation, flow rates, and distribution

- Application Method: Ensure proper lubricant application technique and frequency

- Environmental Factors: Consider temperature, contamination, and other environmental influences

Load and Alignment Issues

Overloading and misalignment are common causes of premature bronze bearing bush failure:

Alignment Verification Methods:

- Dial indicator measurements

- Laser alignment systems

- String line and optical methods

- Vibration analysis techniques

- Load distribution assessment

Material Selection Review

Sometimes bronze bushing problems stem from incorrect material selection for the specific application:

- Review actual operating conditions vs. design specifications

- Analyze failure patterns for material property limitations

- Consider alternative alloy compositions

- Evaluate surface treatments or coatings

- Assess compatibility with mating materials

Predictive Maintenance Strategies

Condition Monitoring Techniques

Implementing condition monitoring helps prevent unexpected failures of bronze bushings:

Key Monitoring Parameters:

- Temperature: Infrared thermography to detect hot spots

- Vibration: Accelerometer-based monitoring for wear patterns

- Oil Analysis: Particle counting and chemical analysis

- Acoustic Emission: High-frequency monitoring for crack initiation

- Performance: Power consumption and efficiency tracking

Trending and Analysis

Long-term trending of condition monitoring data enables prediction of bronze bushing service life and optimization of maintenance intervals.

New Trends in Bronze Bushing Technology

Advanced Alloy Development

The future of bronze bushings includes development of advanced alloy compositions tailored for specific applications and operating conditions.

Nanostructured Bronze Alloys

Research into nanostructured bronze materials promises significantly improved mechanical properties and wear resistance for bronze bearing bushes.

Nanostructured Alloy Benefits:

- Enhanced strength-to-weight ratios

- Improved wear resistance

- Better fatigue performance

- Superior thermal stability

- Enhanced self-lubricating properties

High-Entropy Bronze Alloys

Multi-principal element alloy systems offer the potential for bronze bushings with unprecedented property combinations.

Smart Bearing Technologies

Embedded Sensors

Integration of sensors directly into bronze bushes enables real-time monitoring of operating conditions:

- Temperature sensors for thermal monitoring

- Strain gauges for load measurement

- Accelerometers for vibration detection

- Chemical sensors for lubrication monitoring

- Wireless communication capabilities

Self-Healing Materials

Research into self-healing bronze alloys could revolutionize bearing maintenance by enabling automatic repair of minor surface damage.

Manufacturing Innovations

Additive Manufacturing

3D printing technologies are beginning to enable production of complex bronze bearing bushes with integrated features:

Additive Manufacturing Advantages: Complex internal cooling channels, gradient material properties, integrated lubrication systems, rapid prototyping capabilities, and customization for specific applications.

Advanced Powder Metallurgy

New powder processing techniques enable better control of microstructure and properties in sintered bronze bushings.

Environmental Considerations

Sustainable Manufacturing

Growing emphasis on sustainability drives development of more environmentally friendly bronze bushing manufacturing processes:

- Reduced energy consumption in production

- Increased recycled content in bronze alloys

- Bio-based lubricants for oil-impregnated bushings

- Improved material utilization efficiency

- End-of-life recycling optimization

Green Lubrication Systems

Development of environmentally friendly lubricants that maintain performance while reducing environmental impact.

13. Conclusion

Bronze bushings, bronze bearing bushes, and bronze bushes represent critical components in modern industrial applications, offering unique combinations of properties that make them indispensable across numerous industries. From automotive applications to heavy mining equipment, marine propulsion systems to precision manufacturing machinery, bronze bushings provide reliable, long-lasting solutions for reducing friction and wear between moving parts.

Key Takeaways

Material Advantages

- Excellent corrosion resistance

- Superior load-carrying capacity

- Self-lubricating capabilities

- Thermal stability

- Dimensional consistency

Application Benefits

- Reduced maintenance requirements

- Extended equipment life

- Improved reliability

- Cost-effective operation

- Versatile performance

Design Flexibility

- Multiple alloy compositions

- Various manufacturing methods

- Customizable dimensions

- Specialized surface treatments

- Integrated lubrication systems

Selection and Implementation Best Practices

Successful implementation of bronze bearing bushes requires careful consideration of operating conditions, proper material selection, correct installation procedures, and appropriate maintenance practices. The comprehensive information provided in this guide enables informed decision-making throughout the entire lifecycle of bronze bushing applications.

Critical Success Factors: Thorough application analysis, proper material selection, quality installation procedures, effective lubrication systems, regular condition monitoring, and proactive maintenance planning are essential for optimal bronze bushing performance.

Ready to Optimize Your Bearing Applications?

Apply the knowledge from this comprehensive guide to select, install, and maintain bronze bushings that deliver exceptional performance and reliability for your specific applications.