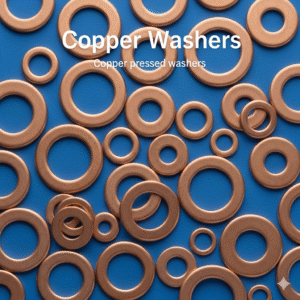

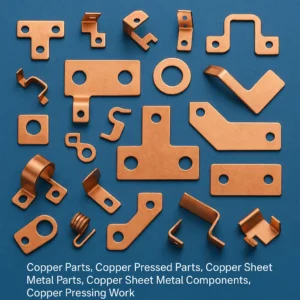

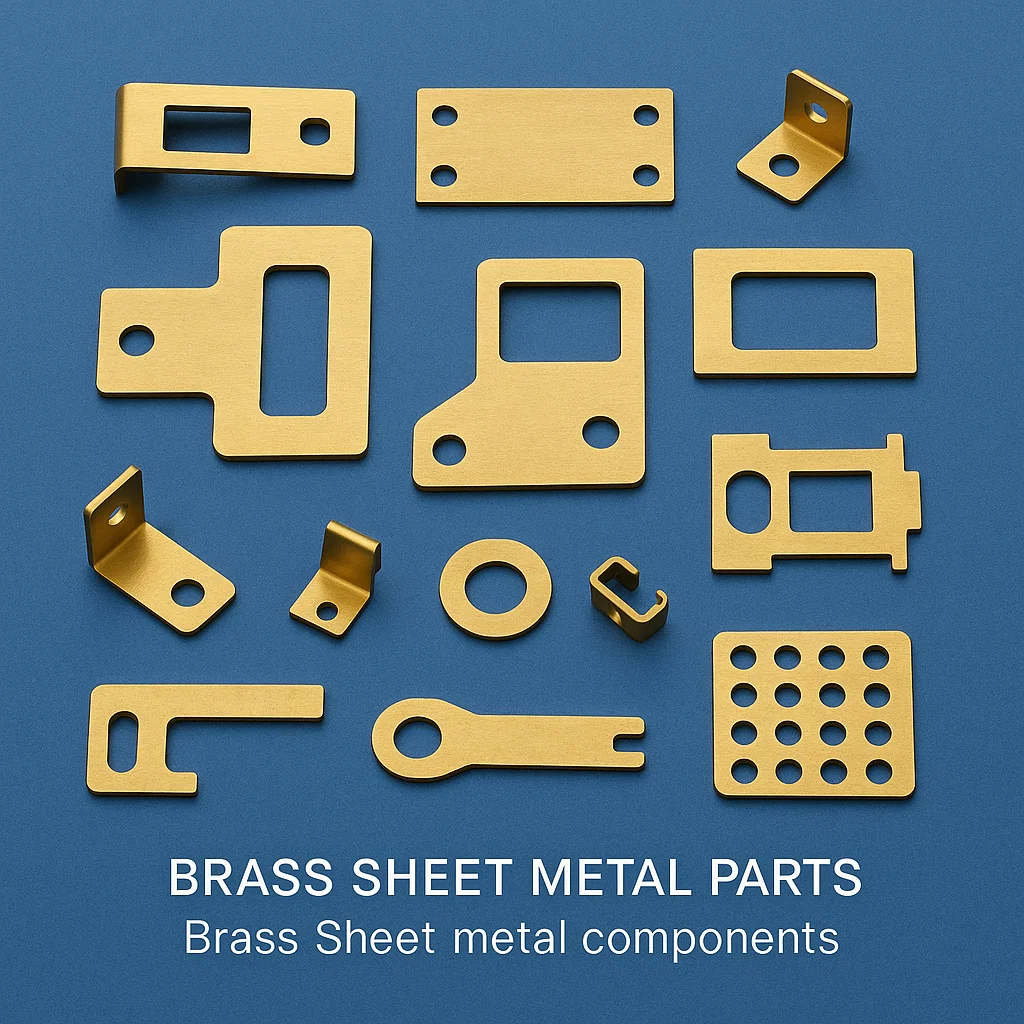

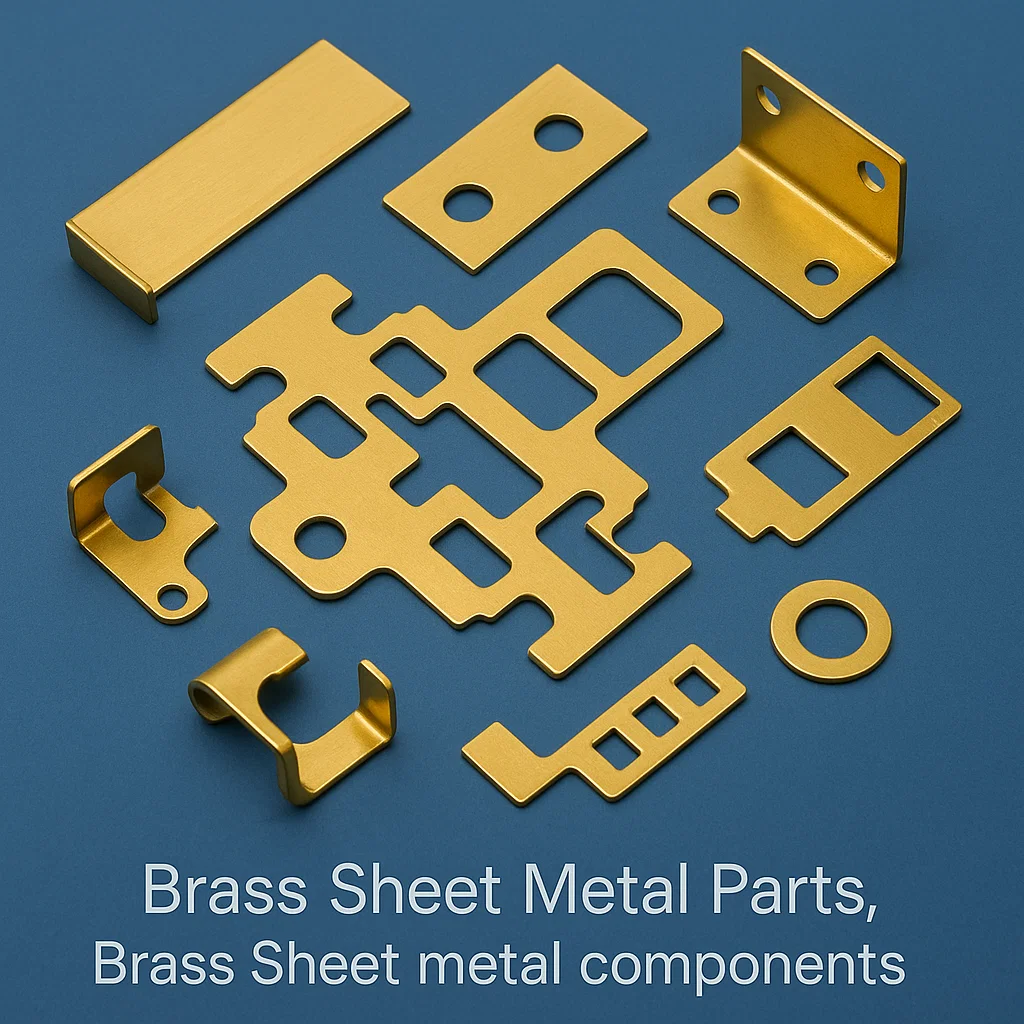

Brass Sheet Metal Parts, Brass Sheet metal Components & Deep Drawn Manufacturing

Premium Brass Sheet Metal Parts and Components Manufacturing from India

Price: US$ 10.30/kilogram

We are one of the leading manufacturers and exporters of precision Brass Sheet Metal Parts and Brass Sheet Metal Components from India. We have been supplying high-quality brass fabricated components to the world market for many decades. Our state-of-the-art manufacturing facility specializes in producing custom brass sheet metal parts, deep drawn components, precision stamped parts, and complex formed brass components for diverse industrial applications. With over three decades of experience in brass fabrication and sheet metal engineering, we have established ourselves as a trusted partner for businesses worldwide requiring superior quality brass components. Our comprehensive range includes everything from simple flat brass parts to complex three-dimensional deep drawn components, all manufactured to the highest international standards. We serve industries ranging from electronics and automotive to marine and architectural applications, delivering precision-engineered brass solutions that meet the most demanding specifications and quality requirements.

Overview of Brass Sheet Metal Manufacturing

Brass sheet metal manufacturing encompasses a comprehensive range of fabrication processes designed to transform flat brass sheets into functional components and parts. Our advanced manufacturing capabilities include precision cutting, forming, stamping, deep drawing, bending, and finishing operations. Brass Sheet Metal Parts are manufactured using various Brass alloys, each selected for specific mechanical properties, corrosion resistance, and application requirements. The manufacturing process begins with careful material selection, followed by precision machining operations that ensure dimensional accuracy and surface finish quality. Our facility utilizes computer-controlled equipment and advanced quality management systems to maintain consistent production standards across all brass fabrication operations.

Brass Sheet Metal Parts represent a diverse category of components manufactured through various metalworking processes including stamping, forming, cutting, and machining. These parts are engineered to provide exceptional durability, corrosion resistance, and aesthetic appeal in demanding applications. Our brass sheet metal parts manufacturing process incorporates advanced metallurgical techniques and precision engineering to deliver components that meet stringent tolerance requirements. The inherent properties of Brass, including its excellent machinability, thermal conductivity, and antimicrobial characteristics, make it an ideal material for applications in electrical, plumbing, marine, and decorative industries. We specialize in producing both standard and custom brass sheet metal parts, ranging from simple brackets and plates to complex geometrical shapes requiring multi-stage forming operations.

Brass Sheet Metal Components encompass a broader range of assembled or semi-assembled parts that incorporate multiple brass elements or combine brass with other materials. These components often require secondary operations such as welding, brazing, threading, or surface treatment to achieve final specifications. Our manufacturing expertise extends to producing complex brass assemblies that integrate seamlessly into larger systems and equipment. The design and manufacturing of brass sheet metal components requires comprehensive understanding of material behavior, joining techniques, and application-specific requirements. We work closely with engineering teams to optimize component designs for manufacturability while maintaining performance specifications and cost-effectiveness.

Brass Deep Drawn Sheet Metal Parts represent the pinnacle of brass forming technology, where flat brass sheets are transformed into three-dimensional shapes through progressive forming operations. Deep drawing processes enable the production of seamless brass components with complex geometries, including cups, cylinders, boxes, and irregular shapes that would be impossible to achieve through conventional machining. Our deep drawing capabilities include single-stage and multi-stage operations, allowing for the production of parts with high depth-to-diameter ratios. The deep drawing process preserves material integrity while achieving exceptional dimensional accuracy and surface finish quality. These parts find applications in industries requiring hermetic sealing, pressure containment, or aesthetic appeal combined with functional performance.

Material Grades and Specifications

| Standard | Grade/Designation | Composition (Cu-Zn) | Applications | Properties |

|---|---|---|---|---|

| ASTM B36 | C26000 (Cartridge Brass) | 70% Cu, 30% Zn | Deep drawing, stamping | Excellent formability |

| ASTM B36 | C26800 (Yellow Brass) | 65% Cu, 35% Zn | Hardware, fittings | Good strength, machinability |

| BS EN 12163 | CW508L (CZ108) | 70% Cu, 30% Zn | Electrical components | High conductivity |

| DIN 17660 | CuZn30 (Ms70) | 70% Cu, 30% Zn | Marine applications | Corrosion resistant |

| JIS H3100 | C2600 (68 Brass) | 68% Cu, 32% Zn | Architectural trim | Decorative finish |

| IS 407 | Grade 1 Brass | 70% Cu, 30% Zn | General purpose | Standard properties |

| Chinese GB | H68 (HPb59-1) | 68% Cu, 31% Zn | Precision parts | Free machining |

Manufacturing Processes and Machinery

Our comprehensive manufacturing facility incorporates advanced metalworking equipment and precision manufacturing processes specifically designed for brass sheet metal fabrication. The manufacturing process chain includes CNC punching machines for precise hole patterns and cutouts, hydraulic press brakes for accurate bending operations, and progressive stamping presses for high-volume production runs. Deep drawing operations utilize specialized hydraulic deep draw presses with cushion systems to ensure uniform material flow and prevent defects. Laser cutting systems provide precise edge quality and complex geometrical cutting capabilities, while CNC machining centers handle secondary operations requiring tight tolerances.

| Process | Machinery Used | Capacity Range | Tolerance Achievable | Applications |

|---|---|---|---|---|

| Precision Stamping | Progressive Die Stamping Press | 10-200 Tons | ±0.05mm | High volume parts |

| Deep Drawing | Hydraulic Deep Draw Press | 25-150 Tons | ±0.08mm | Seamless containers |

| CNC Punching | Turret Punch Press | 0.5-6mm thickness | ±0.1mm | Perforated components |

| Laser Cutting | Fiber Laser System | 0.5-10mm thickness | ±0.02mm | Complex geometries |

| Press Brake Forming | CNC Press Brake | 50-120 Tons | ±0.1mm | Bent components |

Typical Brass Sheet Metal Parts and Components

Our manufacturing expertise encompasses a comprehensive range of brass sheet metal parts and components designed to meet diverse industrial requirements. Electrical contact components including switch plates, terminal blocks, and connector housings benefit from brass’s excellent electrical conductivity and corrosion resistance. Plumbing and pipe fittings such as flanges, unions, and valve components utilize brass’s antimicrobial properties and pressure resistance capabilities. Architectural hardware including door handles, decorative panels, and trim components leverage brass’s aesthetic appeal and durability.

Technical Drawing – Brass Deep Drawn Component

Ø80 ±0.05100 ±0.150 ±0.08Material: Brass C26000Thickness: 1.5mm ±0.05

| Component Category | Typical Parts | Size Range | Thickness Range | Manufacturing Process |

|---|---|---|---|---|

| Electrical Components | Terminal blocks, Switch plates, Contact springs | 5-150mm | 0.3-3.0mm | Stamping, Forming |

| Plumbing Fittings | Flanges, Unions, Valve bodies | 15-300mm | 1.0-8.0mm | Deep Drawing, Machining |

| Architectural Hardware | Door handles, Decorative panels, Trim | 25-500mm | 0.8-5.0mm | Forming, Polishing |

| Marine Components | Porthole frames, Deck fittings, Cleats | 50-800mm | 2.0-12mm | Casting, Machining |

| Automotive Parts | Radiator components, Fuel line fittings | 10-200mm | 0.5-4.0mm | Stamping, Brazing |

BRASS FABRICATION PROCESS FLOW

Material Selection → Design Review → Tooling → Forming → Quality Control → Finishing → Packaging → Export

Material Properties and Performance Metrics

| Property | C26000 (70/30) | C26800 (65/35) | Test Method | Applications Impact |

|---|---|---|---|---|

| Tensile Strength (MPa) | 315-455 | 380-520 | ASTM E8 | Load bearing capacity |

| Yield Strength (MPa) | 105-380 | 140-450 | ASTM E8 | Permanent deformation resistance |

| Elongation (%) | 60-68 | 60-65 | ASTM E8 | Formability in deep drawing |

| Hardness (HB) | 55-85 | 75-110 | ASTM E10 | Wear resistance |

| Electrical Conductivity (%IACS) | 28 | 25 | ASTM B193 | Electrical applications |

| Thermal Conductivity (W/m·K) | 120 | 110 | ASTM E1461 | Heat dissipation |

Industries Served and Applications

Our Brass Sheet Metal Components find extensive applications across multiple industries, each demanding specific performance characteristics and quality standards. The electronics industry relies on our precision brass components for electrical connectivity, electromagnetic shielding, and thermal management applications. Marine and offshore industries benefit from brass’s superior corrosion resistance in saltwater environments, utilizing our components in navigation equipment, port facilities, and vessel hardware. The automotive sector incorporates our brass parts in cooling systems, fuel delivery components, and decorative trim applications where both functionality and aesthetics are critical.

Architectural and construction industries specify our brass components for both structural and decorative applications, including door hardware, window fittings, and ornamental metalwork that requires long-term durability and visual appeal. Plumbing and HVAC applications utilize our deep drawn brass components for pressure vessels, fittings, and valve components where leak-tight performance and pressure resistance are essential. The medical and healthcare sector leverages brass’s antimicrobial properties in equipment components, surgical instruments, and hospital hardware applications.

TYPICAL PARTS:

| Industry | Typical Parts Made from Brass Sheet | Key Brass Properties Utilized |

|---|---|---|

| Plumbing & HVAC | • Brass Gaskets and Brass Seals (stamped washers, shims) • Valve Plates and Diaphragms • Brazing Brass Rings and Solder Pre-forms (stamped) • Heat Exchanger Fins (stamped and formed) • Faucet Internal Brass Discs (blanked and pierced) • Decorative Brass Escutcheons and CBrass over Plates Brass Ferrules, Brass Olives Brass Radiator keys Tommy Bar and Clock type Keys | • Corrosion Resistance • Machinability (for secondary ops) • Thermal Conductivity (fins) • Antimicrobial Properties • Aesthetic Finish |

| Electrical & Electronics | • Electrical Terminals & Connectors (stamped and formed) • Lead Frames for ICs (precision stamped) • RFI/EMI Shielding Cans (stamped and formed) • Battery Contacts & Spring Clips • Light Bulb Bases (E26, E27 – deep drawn) • Fuse Components (caps, end plates) | • Excellent Electrical Conductivity • Good Spring Properties • Corrosion Resistance • Ease of Soldering |

| Automotive & Transportation | • Radiator Header Tanks (formed and brazed) • Carburetor Jets & Gaskets (precision stamped) • Pneumatic Valve Diaphragms & Plates • Electrical Connector Housings • Decorative Badges, Emblems, and Grilles | • Corrosion Resistance • Heat and Electrical Conductivity • Aesthetic Appeal • Durability |

| Architecture & Hardware | • Door Knobs & Lever Handles (often deep drawn) • Kick Plates, Push Plates, Nameplates • Decorative Grilles and Vents • Light Fixture Bodies & Reflectors (spun or drawn) • Roofing Ornaments & Architectural Accents | • Antimicrobial Properties • Corrosion Resistance • Aesthetic Appeal & Prestige • Malleability for Forming |

| Marine & Naval | • Deck Light Covers & Housings • Instrument Panels and Faceplates • Electrical Junction Box Covers • Decorative Hatches and Trim | • Superior Saltwater Corrosion Resistance • Low Biofouling • Durability |

| Consumer Goods & Musical Instruments | • Bellows for Accordions & Concertinas • Reed Caps for Woodwind Instruments • Decorative Inlays for Instruments & Furniture • Zipper Sliders and Pulls • High-end Pen Housings & Clips (stamped/formed) | • Malleability for Deep Drawing • Acoustic Properties (instruments) • Aesthetic Finish and Luster • Durability |

Quality Standards and Tolerances

Our manufacturing processes maintain strict adherence to international quality standards including ISO 9001:2015 quality management systems, ISO 14001:2015 environmental management, and industry-specific standards such as ASTM B36 for brass sheet and strip specifications. Dimensional tolerances are maintained according to ISO 2768 general tolerances for linear and angular dimensions, with tighter tolerances achievable through precision machining operations. Surface finish specifications conform to ISO 4287 standards, with Ra values ranging from 0.8 to 3.2 μm depending on application requirements.

| Tolerance Class | Linear Dimensions | Angular Dimensions | Flatness/Straightness | Applications |

|---|---|---|---|---|

| Precision (Fine) | ±0.05 to ±0.1mm | ±0.5° | 0.05mm/100mm | Electrical contacts, precision instruments |

| Medium | ±0.1 to ±0.2mm | ±1° | 0.1mm/100mm | General engineering components |

| Coarse | ±0.2 to ±0.5mm | ±2° | 0.2mm/100mm | Architectural hardware, decorative parts |

| Very Coarse | ±0.5 to ±1.0mm | ±3° | 0.5mm/100mm | Rough fabrication, non-critical dimensions |

Turnaround Time and Production Capacity

Our optimized production processes ensure consistent delivery schedules with standard turnaround times of 4-6 weeks for custom brass sheet metal parts and components. This timeframe includes design review, tooling preparation, production setup, manufacturing operations, quality inspection, and packaging. Rush orders can be accommodated with expedited processing times of 2-3 weeks for urgent requirements, subject to production schedule availability and complexity of parts. High-volume production runs benefit from reduced per-unit processing times through optimized tooling and dedicated production lines.

Our production capacity encompasses both prototype and high-volume manufacturing capabilities, with flexibility to handle order quantities ranging from single prototypes to millions of pieces annually. Small batch production (1-100 pieces) typically requires 2-3 weeks including tooling setup, while medium volume orders (100-10,000 pieces) are completed within the standard 4-6 week timeframe. Large volume production (10,000+ pieces) may require extended lead times depending on component complexity and manufacturing requirements, with detailed production schedules provided during order confirmation.

Our Unique Selling Propositions (USPs)

Three Decades of Manufacturing Excellence: Our extensive experience in brass fabrication and sheet metal engineering ensures superior quality and reliability in every component we produce. We have successfully supplied brass components to over 50 countries worldwide, building long-term partnerships with leading manufacturers across diverse industries.

Customization Capabilities: We excel in developing custom brass sheet metal solutions tailored to specific application requirements. Our engineering team works closely with customers to optimize designs for manufacturability while maintaining performance specifications and cost-effectiveness. From initial concept to production, we provide comprehensive design support and prototyping services.

Flexible Production Scheduling: Understanding the dynamic nature of global supply chains, we offer flexible production scheduling and expedited delivery options to meet urgent requirements. Our production planning system accommodates changing order priorities while maintaining quality standards and delivery commitments.

Custom Packaging Solutions: We provide tailored packaging solutions including customer-branded labels, logos, and specialized packaging materials to ensure product protection during transit and enhance brand presentation. Our packaging capabilities include anti-corrosion treatments, moisture barriers, and secure packaging for international shipping.

Customer Testimonial

“We have been sourcing brass sheet metal components from this manufacturer for over 8 years, and their consistent quality and reliability have been exceptional. Their ability to meet our tight delivery schedules while maintaining precision tolerances has been crucial to our production success. The technical support team provides excellent communication throughout the entire process, from initial design review to final delivery. Their custom packaging with our company logos has greatly improved our inventory management system.”

– R. Mitchell, Procurement Manager, Canada

Frequently Asked Questions (Q&A)

Q1: What is the minimum order quantity for custom brass sheet metal parts?

A: We accommodate orders starting from single prototype pieces to high-volume production runs exceeding one million pieces annually. Our flexible manufacturing setup allows for economical production of small quantities while maintaining competitive pricing for large volume orders.

Q2: Can you provide material certificates and test reports for brass components?

A: Yes, we provide comprehensive material certificates including chemical composition analysis, mechanical property test reports, and dimensional inspection certificates. All documentation conforms to international standards such as ASTM, BS, DIN, and JIS specifications as required by customer specifications.

Q3: What surface finishes are available for brass sheet metal parts?

A: We offer various surface finishes including natural brass finish, polished surfaces (mirror and satin), protective clear coatings, electroplated finishes (nickel, chrome, gold), and specialized treatments such as passivation for enhanced corrosion resistance. Custom finishes can be developed based on specific application requirements.

Q4: How do you ensure consistent quality across different production batches?

A: Our ISO 9001:2015 certified quality management system includes statistical process control, first article inspection, in-process quality checks, and final inspection procedures. Each production batch is tracked through our quality management system with complete traceability from raw material to finished product.

Q5: What design support services do you provide for custom brass components?

A: Our experienced engineering team provides comprehensive design support including Design for Manufacturing (DFM) analysis, cost optimization recommendations, prototype development, and technical drawings preparation. We utilize advanced CAD systems and finite element analysis to optimize designs for manufacturability and performance.

Q6: Can you handle secondary operations such as machining, threading, and assembly?

A: Yes, our integrated manufacturing facility includes CNC machining capabilities, threading operations, welding and brazing services, and assembly operations. This comprehensive capability allows us to deliver finished components ready for installation, reducing customer processing requirements and lead times.

Q7: What is your approach to handling urgent or rush orders?

A: We maintain dedicated production capacity for urgent requirements and offer expedited processing with 2-3 week turnaround times. Our production planning system prioritizes rush orders while maintaining quality standards. Rush order feasibility depends on component complexity and current production schedule.

Q8: How do you ensure proper packaging for international shipping?

A: Our packaging specialists design custom packaging solutions using moisture barriers, corrosion inhibitors, and shock-absorbing materials appropriate for international shipping. We comply with export packaging regulations and provide specialized packaging for sensitive components requiring environmental protection.

Q9: What quality standards and certifications do you maintain?

A: We maintain ISO 9001:2015 quality management certification, ISO 14001:2015 environmental management certification, and comply with industry-specific standards including ASTM, BS, DIN, and JIS specifications. Our facility undergoes regular third-party audits to ensure continued compliance with international quality standards.

Q10: Can you provide cost estimates and technical feasibility analysis for new projects?

A: We provide detailed cost estimates and technical feasibility analysis within 48-72 hours of receiving complete project specifications. Our quotations include tooling costs, per-piece pricing for different volume levels, and delivery schedules. Technical feasibility analysis includes manufacturing recommendations and design optimization suggestions.

Q11: What are your capabilities for producing complex geometries and deep drawn parts?

A: Our deep drawing capabilities include single-stage and multi-stage operations with draw ratios up to 2.5:1 for simple geometries and specialized tooling for complex shapes. We can produce seamless cylindrical, rectangular, and irregular shapes with wall thicknesses maintained within ±5% of original material thickness.

Q12: How do you handle intellectual property protection and confidentiality?

A: We maintain strict confidentiality protocols including non-disclosure agreements, secure data handling procedures, and restricted access to customer designs and specifications. Our quality management system includes provisions for intellectual property protection and confidential information management throughout the manufacturing process.

Size and Dimensional Specifications

| Component Type | Minimum Size | Maximum Size | Thickness Range | Typical Tolerance | Special Features |

|---|---|---|---|---|---|

| Flat Stamped Parts | 5mm x 5mm | 1200mm x 600mm | 0.3-10mm | ±0.1mm | Complex cutouts, holes |

| Deep Drawn Components | Ø10mm | Ø300mm | 0.5-5mm | ±0.08mm | Seamless construction |

| Bent/Formed Parts | 15mm x 10mm | 800mm x 400mm | 0.8-8mm | ±0.15mm | Multiple bends, angles |

| Threaded Components | M3 thread | M50 thread | 1-15mm | 6H/6g class | Internal/external threads |

| Perforated Sheets | 100mm x 100mm | 2000mm x 1000mm | 0.5-6mm | ±0.2mm | Custom hole patterns |

International Standards Compliance

Our manufacturing processes and quality systems comply with comprehensive international standards ensuring global acceptance and reliability of our brass sheet metal components. ASTM B36/B36M specifications govern brass sheet and strip dimensional and chemical composition requirements, while ASTM B103 covers temper designations for copper alloys. ISO 2768 general tolerances for linear and angular dimensions provide standardized tolerance classes for various precision requirements.

European standards including BS EN 12163 for copper and copper alloy sheet and strip, and DIN 17660 for brass sheet specifications ensure compliance with European manufacturing requirements. Japanese Industrial Standards (JIS H3100) provide specifications for copper and copper alloy sheets, strips, and plates used in precision applications.

Packaging and Shipping Solutions

Our comprehensive packaging solutions ensure product integrity during international transit while providing convenient handling and storage capabilities. Standard packaging includes moisture-resistant barriers, corrosion inhibitor papers, and protective foam inserts arranged in sturdy cardboard cartons or wooden crates depending on component size and weight. Custom packaging options accommodate specific customer requirements including branded labels, company logos, part number identification, and specialized protective materials for sensitive components.

Export packaging complies with international shipping regulations and includes proper documentation for customs clearance, country-specific marking requirements, and hazardous materials classification where applicable. Our packaging engineers design solutions optimized for container loading efficiency while ensuring adequate protection against shock, vibration, and environmental conditions during ocean and air freight transportation.

Glossary of Technical Terms

Brass Sheet Metal Parts: Components manufactured from brass alloy sheets through various metalworking processes including cutting, forming, stamping, and machining operations to achieve specific dimensional and functional requirements.

Deep Drawing: Metal forming process where flat brass sheet is formed into hollow shapes through progressive drawing operations using punch and die tooling, creating seamless components with high depth-to-diameter ratios.

Cartridge Brass (C26000): Brass alloy containing 70% Copper and 30% Zinc, known for excellent deep drawing characteristics, corrosion resistance, and electrical conductivity properties.

Progressive Die Stamping: Manufacturing process utilizing multi-station tooling to perform sequential operations including cutting, forming, bending, and piercing in a continuous production sequence.

Brass Sheet Metal Components: Assembled or semi-assembled parts incorporating multiple brass elements or combining brass with other materials through joining processes such as welding, brazing, or mechanical fastening.

Antimicrobial Properties: Inherent characteristic of brass alloys to inhibit bacterial growth and reduce microbial contamination, making brass suitable for medical and food service applications.

Electrical Conductivity (IACS): International Annealed Copper Standard measurement expressing electrical conductivity as percentage relative to pure copper, with typical brass alloys achieving 25-30% IACS values.

Corrosion Resistance: Material property describing brass’s ability to withstand deterioration from environmental exposure, chemical attack, and galvanic corrosion in various service conditions.

Related Parts

Precision brass fabrication, custom brass manufacturing, brass stamping services, sheet metal forming India, brass deep drawing components, electrical brass parts, marine brass fittings, architectural brass hardware, automotive brass components, brass sheet metal supplier, precision brass machining, brass component manufacturer, custom metal fabrication, brass alloy processing, sheet metal punching services, brass electrical contacts, plumbing brass fittings, decorative brass components, brass valve components, industrial brass parts, brass terminal blocks, copper-zinc alloy parts, brass switch components, marine grade brass, high conductivity brass,

Get Your Custom Brass Sheet Metal Solution Today

Ready to discuss your brass sheet metal requirements?

📧 Email us for detailed technical brochure: sales@brass-copper-parts. com

📞 Call our technical experts: +91- 22- 43449300

📱 WhatsApp for instant quotes: +91- 22- 43449300

💬 Request a comprehensive quote with your specifications

Experience the difference of three decades of brass sheet metal part and sheet metal component manufacturing excellence. Contact us today for superior quality brass sheet metal parts and components delivered with precision and reliability.