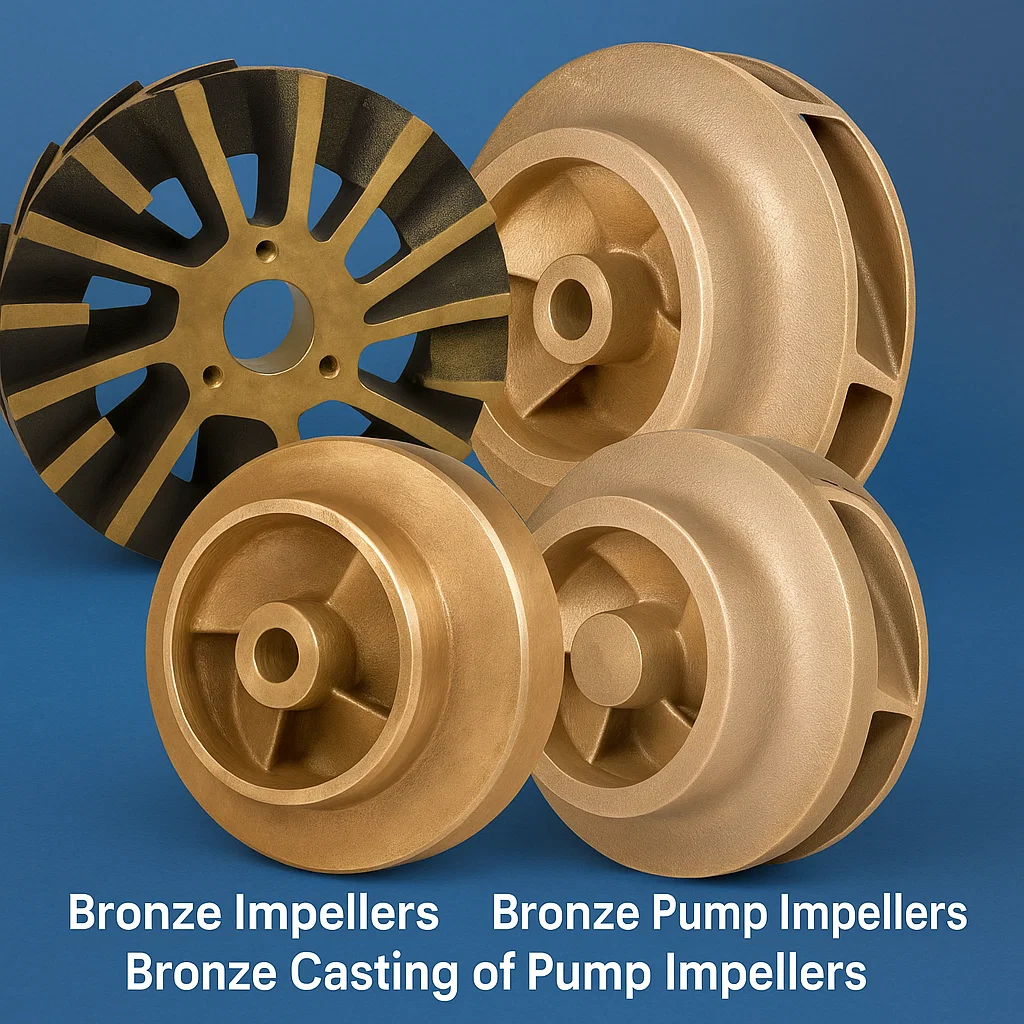

Bronze Pump Impellers, Bronze Casting Foundry for Pump Impellers

Bronze Pump Impellers & Bronze Casting Foundry for Pump Impellers and Bronze Pump Parts

We are one of the leading manufacturers and exporters of Bronze Pump Impellers and Bronze Casting foundry services from India. We have been supplying precision-engineered Bronze pump components to the world market for many decades. Our state-of-the-art foundry specializes in manufacturing high-quality Bronze Pump Impellers, LG2 Gunmetal Pump Impellers, and comprehensive Bronze pump parts using advanced casting techniques. With over three decades of experience in Bronze casting foundry operations, we serve diverse industries including marine, industrial, chemical processing, and water treatment sectors. Our expertise encompasses the complete range of Bronze alloys including CDA 836, LG2 Gunmetal, and various international grade specifications. We maintain stringent quality control standards and offer customized solutions with flexible production scheduling. Our global customer base relies on our consistent delivery performance, technical expertise, and comprehensive after-sales support. We combine traditional foundry craftsmanship with modern manufacturing technologies to deliver superior Bronze pump components that meet or exceed international quality standards.

Overview of Bronze Pump Impellers and Casting Services

Bronze Pump Impellers

Our Bronze Pump Impellers are precision-cast components designed for centrifugal pumps, marine applications, and industrial fluid handling systems. These impellers are manufactured using high-grade Bronze alloys that provide excellent corrosion resistance, mechanical strength, and dimensional stability. The Bronze material composition ensures optimal performance in seawater, brackish water, and various chemical environments. Our manufacturing process involves precision investment casting, CNC machining, and rigorous quality testing to achieve tight tolerances and smooth surface finishes. Each Bronze pump impeller undergoes dimensional verification, material composition analysis, and performance testing before dispatch.

Bronze Pump Parts

Our comprehensive range of Bronze Pump Parts includes pump housings, volute casings, diffusers, wear rings, sleeves, and mechanical seals. These components are engineered to work seamlessly with our Bronze pump impellers, ensuring optimal system performance and longevity. We manufacture Bronze pump parts using various casting methods including sand casting, investment casting, and centrifugal casting depending on the component requirements. Our Bronze pump parts are designed to meet API, ANSI, and ISO standards while providing superior resistance to cavitation, erosion, and corrosion in demanding operating conditions.

Bronze Casting Foundry for Pump Impellers

Our specialized Bronze Casting Foundry for Pump Impellers operates with advanced melting furnaces, precision molding equipment, and computerized process controls to ensure consistent quality and dimensional accuracy. The foundry processes various Bronze alloys including Tin Bronze, Aluminum Bronze, and Manganese Bronze using both traditional sand casting and modern investment casting techniques. Our foundry capabilities include pattern making, mold preparation, metal melting, pouring, heat treatment, and finishing operations. We maintain strict metallurgical controls throughout the casting process to achieve desired mechanical properties and microstructure in the final Bronze pump impellers.

LG2 Gunmetal Pump Impellers

LG2 Gunmetal Pump Impellers are manufactured using high-grade Gunmetal alloy (88% Copper, 10% Tin, 2% Zinc) that provides exceptional strength, durability, and corrosion resistance. LG2 Gunmetal is particularly suitable for marine pump applications, desalination plants, and offshore installations where resistance to seawater corrosion is critical. Our LG2 Gunmetal pump impellers are precision-cast to achieve complex geometries with smooth flow passages, optimized hydraulic efficiency, and minimal vibration characteristics. The alloy composition is carefully controlled to meet BS 1400 LG2 specifications and Lloyd’s Registry requirements for marine applications.

CDA 836 Bronze Casting Foundry

Our CDA 836 Bronze Casting Foundry specializes in producing high-strength Bronze components using CDA 836 alloy (Leaded Red Bronze) with excellent machinability and wear resistance properties. This specific Bronze grade contains approximately 85% Copper, 5% Tin, 5% Lead, and 5% Zinc, making it ideal for pump components that require superior bearing properties and resistance to galling. Our CDA 836 Bronze casting process includes careful alloy preparation, controlled cooling rates, and stress-relief heat treatment to optimize mechanical properties. The foundry maintains ASTM B505 and ASTM B584 compliance for CDA 836 Bronze castings used in critical pump applications.

Material Grades and International Standards

| Material Grade | International Standard | Composition (%) | Tensile Strength (MPa) | Applications |

|---|---|---|---|---|

| LG2 Gunmetal | BS 1400 LG2 | Cu 88, Sn 10, Zn 2 | 270-320 | Marine pump impellers, valve components |

| CDA 836 | ASTM B505, ASTM B584 | Cu 85, Sn 5, Pb 5, Zn 5 | 200-250 | Bearing components, pump sleeves |

| Bronze C90700 | ASTM B584, UNS C90700 | Cu 89, Sn 11 | 275-325 | Heavy-duty pump impellers |

| Aluminum Bronze | ASTM B148 C95400 | Cu 85, Al 11, Fe 4 | 550-650 | High-strength marine components |

| Manganese Bronze | ASTM B584 C86500 | Cu 58.5, Zn 39, Fe 1, Mn 1, Al 0.5 | 450-550 | High-pressure pump components |

| IS 318 Grade 1 | IS 318 (Indian Standard) | Cu 88, Sn 10, Zn 2 | 270-300 | General purpose pump parts |

| JIS H5120 BC3 | JIS H5120 (Japanese Standard) | Cu 87, Sn 10, Zn 3 | 260-310 | Industrial pump applications |

| DIN 1705 RG5 | DIN 1705 (German Standard) | Cu 85, Sn 5, Pb 5, Zn 5 | 200-240 | European pump components |

Manufacturing Processes and Machinery

Our advanced Bronze casting foundry employs multiple manufacturing processes to produce high-quality Bronze pump impellers and components. The investment casting process is utilized for complex geometries and tight tolerances, while sand casting is employed for larger components. Our centrifugal casting technique produces dense, defect-free Bronze pump sleeves and cylindrical components.

| Manufacturing Process | Machinery/Equipment | Typical Components | Tolerance Achievable | Surface Finish (Ra) |

|---|---|---|---|---|

| Investment Casting | Induction furnaces, vacuum chambers, ceramic shell systems | Bronze pump impellers, complex geometries | ±0.13mm (±0.005″) | 1.6-3.2 μm |

| Sand Casting | Green sand molding machines, cope and drag systems | Large pump housings, volute casings | ±0.25mm (±0.010″) | 6.3-12.5 μm |

| Centrifugal Casting | Horizontal centrifugal casting machines | Bronze pump sleeves, bushings | ±0.15mm (±0.006″) | 3.2-6.3 μm |

| CNC Machining | 5-axis CNC centers, turning centers | Precision finishing, threading | ±0.05mm (±0.002″) | 0.8-1.6 μm |

| Heat Treatment | Controlled atmosphere furnaces | Stress relief, property enhancement | N/A | N/A |

Manufacturing Process Flow Infographic

Pattern Making → Mold Preparation → Metal Melting → Casting → Heat Treatment → Machining → Quality Testing → Packaging → Shipping

Dimensional Specifications and Technical Drawings

| Impeller Size | Outer Diameter (mm) | Eye Diameter (mm) | Width (mm) | Shaft Bore (mm) | Number of Vanes | Weight (kg) |

|---|---|---|---|---|---|---|

| 100mm Series | 100-120 | 25-35 | 15-25 | 12-20 | 5-7 | 0.8-1.5 |

| 150mm Series | 150-180 | 35-50 | 20-35 | 20-30 | 6-8 | 2.5-4.5 |

| 200mm Series | 200-250 | 50-70 | 25-45 | 25-40 | 6-9 | 5.5-9.5 |

| 300mm Series | 300-350 | 75-100 | 35-60 | 40-60 | 7-10 | 12-22 |

| 400mm Series | 400-500 | 100-140 | 45-80 | 50-80 | 8-12 | 25-50 |

Industries and Applications

Our Bronze pump impellers and casting services cater to diverse industrial sectors requiring corrosion-resistant, high-performance pump components. The marine industry extensively uses our LG2 Gunmetal pump impellers for seawater circulation systems, ballast pumps, and fire-fighting equipment. Chemical processing plants rely on our Bronze pump parts for handling corrosive fluids, acids, and alkalis. Water treatment facilities use our products for potable water systems, sewage treatment, and desalination plants.

| Industry Sector | Typical Applications | Preferred Material | Key Requirements |

|---|---|---|---|

| Marine & Offshore | Seawater pumps, ballast systems, fire pumps | LG2 Gunmetal, Aluminum Bronze | Seawater corrosion resistance |

| Chemical Processing | Chemical transfer pumps, reactor cooling | C90700 Bronze, Manganese Bronze | Chemical compatibility |

| Water Treatment | Centrifugal pumps, booster pumps | IS 318 Grade 1, LG2 Gunmetal | Potable water approved materials |

| Power Generation | Cooling water pumps, condensate systems | Aluminum Bronze, C95400 | High temperature resistance |

| Oil & Gas | Crude oil pumps, refinery applications | Manganese Bronze, C86500 | High pressure capability |

| HVAC Systems | Chilled water pumps, heating systems | CDA 836, Standard Bronze | Thermal conductivity |

Performance Metrics and Quality Standards

Our Bronze pump impellers are designed to deliver superior hydraulic efficiency, cavitation resistance, and operational reliability. Performance testing includes flow rate optimization, head pressure verification, NPSH requirements analysis, and vibration testing. Quality control measures ensure compliance with international standards including ASTM, BS, DIN, JIS, and IS specifications.

| Performance Parameter | Standard Value | Testing Method | Acceptance Criteria |

|---|---|---|---|

| Hydraulic Efficiency | 75-85% | ISO 9906 Test | Within ±3% of design |

| Surface Roughness | Ra 1.6-6.3 μm | Profilometer measurement | As per drawing specification |

| Dimensional Tolerance | ISO 2768-m | CMM inspection | 100% within tolerance |

| Material Composition | ASTM/BS Standards | Spectrometer analysis | Within standard limits |

| Pressure Testing | 1.5x Operating Pressure | Hydrostatic test | No leakage/deformation |

Turnaround Time: Our standard delivery time for Bronze pump impellers and Bronze pump parts is 4-6 weeks from order confirmation. Rush orders can be accommodated with expedited processing in 2-3 weeks subject to availability and complexity. Custom designs may require additional time for pattern making and prototyping.

Frequently Asked Questions (Q&A)

Q1: What is the minimum order quantity for Bronze pump impellers?

A: Our minimum order quantity is 10 pieces for standard sizes and 5 pieces for custom Bronze pump impellers. We offer flexibility for prototype and trial orders with MOQ of 1-2 pieces.

Q2: Can you provide Bronze pump impellers with special coatings or treatments?

A: Yes, we offer various surface treatments including nickel plating, chrome plating, and specialized anti-corrosion coatings for enhanced performance in aggressive environments.

Q3: Do you manufacture Bronze pump impellers according to customer drawings and specifications?

A: Absolutely. We specialize in custom manufacturing based on customer drawings, specifications, or reverse engineering from samples. Our engineering team can also optimize designs for better performance.

Q4: What quality certifications do you maintain for Bronze casting foundry operations?

A: We maintain ISO 9001:2015 quality management system certification, and our Bronze castings comply with ASTM, BS, DIN, JIS, and IS international standards.

Q5: Can you provide material test certificates (MTC) with shipments?

A: Yes, we provide comprehensive material test certificates including chemical composition analysis, mechanical properties testing, and dimensional inspection reports with every shipment.

Q6: What is the typical service life of your Bronze pump impellers?

A: Under normal operating conditions, our Bronze pump impellers typically provide 8-15 years of service life, depending on the application, fluid handled, and maintenance practices.

Q7: Do you offer technical support for pump performance optimization?

A: Yes, our technical team provides comprehensive support including hydraulic design consultation, performance analysis, troubleshooting, and efficiency improvement recommendations.

Q8: Can you manufacture large size Bronze pump impellers exceeding 500mm diameter?

A: Yes, our foundry capabilities extend to large Bronze pump impellers up to 1200mm diameter using sand casting techniques with appropriate machining facilities.

Q9: What packaging methods do you use for international shipments?

A: We use robust wooden crates with moisture barriers, foam padding, and rust preventive coatings. Custom packaging with customer labels and logos is available upon request.

Q10: Do you provide warranty coverage for your Bronze pump components?

A: We provide 12-month warranty against manufacturing defects, material non-conformance, and premature failure under normal operating conditions.

Q11: Can you supply Bronze pump parts for retrofitting existing pumps?

A: Yes, we specialize in retrofit solutions and can manufacture Bronze pump parts to replace worn components in existing pumps, often with improved designs for better performance.

Q12: What inspection and testing facilities do you have at your foundry?

A: Our quality control laboratory includes spectrometers, tensile testing machines, hardness testers, CMM inspection equipment, ultrasonic testing, and hydraulic test benches for comprehensive quality verification.

Why Choose Our Bronze Pump Impellers Over Others

Our Unique Selling Propositions (USPs)

Faster Turnaround Time: While industry standard delivery is 8-10 weeks, we consistently deliver Bronze pump impellers and components within 4-6 weeks, with rush order capability in 2-3 weeks. Our streamlined production processes and efficient supply chain management ensure shorter lead times without compromising quality.

Superior Customer Support: Our dedicated customer service team provides 24/7 technical support, real-time order tracking, and proactive communication throughout the manufacturing process. We assign dedicated project managers for complex orders to ensure seamless execution and customer satisfaction.

Excellent Communication Skills: Our multilingual technical team communicates effectively with customers worldwide. We provide regular progress updates, detailed technical documentation, and comprehensive project reports in English, ensuring clear understanding and transparency.

Global Exposure and 3 Decades of Experience: With over 30 years of experience in Bronze casting foundry operations, we have supplied Bronze pump components to more than 45 countries. Our vast experience encompasses diverse applications from marine vessels to chemical processing plants, providing valuable insights for optimal solutions.

Customization Capability: We excel in customizing Bronze pump impellers and components according to specific customer requirements. Our in-house design team can modify existing designs or develop completely new solutions based on performance requirements, space constraints, and operational conditions.

Flexible Production Scheduling: Our production facility operates with flexible scheduling to accommodate urgent requirements, seasonal demands, and customer-specific delivery preferences. We maintain buffer inventory for standard components and can adjust production priorities for critical orders.

Customized Packaging Solutions: We offer customized packaging with customer labels, logos, and specific identification markings. Our packaging team ensures optimal protection during transit while meeting customer branding requirements and documentation needs.

Comprehensive Quality Assurance: Our quality management system includes 100% inspection protocols, statistical process control, and continuous improvement initiatives. We maintain traceability throughout the manufacturing process and provide detailed quality documentation.

Competitive Pricing: As a direct manufacturer from India, we offer highly competitive pricing without intermediary margins. Our efficient operations, optimal material utilization, and economies of scale enable cost-effective solutions without compromising quality.

Technical Innovation: We continuously invest in research and development to improve Bronze alloy compositions, casting techniques, and manufacturing processes. Our innovation initiatives result in enhanced performance, longer service life, and better value for customers.

Customer Testimonial

“We have been sourcing Bronze pump impellers from this Indian manufacturer for over 8 years, and their consistent quality and reliability has been exceptional. Their LG2 Gunmetal impellers in our marine pumps have shown outstanding performance with minimal maintenance requirements. The technical support team is knowledgeable and responsive, always providing solutions within our tight schedules. Their 4-week delivery promise is consistently met, which is crucial for our project timelines. I highly recommend their Bronze casting services for any serious pump application.”

– Robert Johnson, Senior Procurement Manager, Houston, Texas, USA

Material Properties and Specifications

| Property | LG2 Gunmetal | CDA 836 Bronze | C90700 Bronze | Aluminum Bronze | Test Standard |

|---|---|---|---|---|---|

| Tensile Strength (MPa) | 270-320 | 200-250 | 275-325 | 550-650 | ASTM B557 |

| Yield Strength (MPa) | 120-150 | 90-120 | 125-175 | 250-350 | ASTM B557 |

| Elongation (%) | 8-15 | 12-18 | 10-18 | 12-20 | ASTM B557 |

| Hardness (HB) | 70-90 | 60-80 | 75-95 | 150-200 | ASTM E10 |

| Density (g/cm³) | 8.8-8.9 | 8.7-8.8 | 8.8-8.9 | 7.6-7.8 | ASTM B311 |

| Thermal Conductivity (W/m-K) | 50-60 | 55-65 | 45-55 | 60-80 | ASTM E1461 |

Packaging and Shipping

Our Bronze pump impellers and Bronze pump parts are carefully packaged using industry-standard methods to ensure safe delivery to customers worldwide. We employ robust wooden crates with internal foam padding and moisture barriers to protect against transit damage and environmental exposure. Each component is individually wrapped in rust-preventive paper and secured with appropriate cushioning materials.

Customized Packaging Options: We offer specialized packaging solutions including customer-branded labels, specific identification markings, and custom documentation as per customer requirements. Our packaging team can accommodate unique shipping requirements, hazardous material classifications, and international shipping regulations.

Shipping Methods: We partner with leading international freight forwarders and shipping lines to provide reliable delivery options including sea freight, air freight, and express courier services. Our logistics team handles all documentation including commercial invoices, packing lists, certificates of origin, and material test certificates.

Export Documentation: Complete export documentation package includes commercial invoices, detailed packing lists, material test certificates, quality inspection reports, certificates of origin, and any special certifications required by destination countries.

Glossary of Technical Terms

Bronze Casting: Manufacturing process where molten Bronze alloy is poured into molds to create pump components with specific shapes and properties.

Bronze Pump Impeller: Rotating component within a centrifugal pump that accelerates fluid by converting rotational kinetic energy to hydrodynamic energy.

CDA 836: Copper Development Association designation for leaded red Bronze containing 85% Copper, 5% Tin, 5% Lead, and 5% Zinc.

Centrifugal Casting: Casting process using centrifugal force to distribute molten metal, producing dense, defect-free cylindrical components.

Gunmetal: Bronze alloy traditionally containing 88% Copper, 10% Tin, and 2% Zinc, known for excellent corrosion resistance and machinability.

Investment Casting: Precision casting process using expendable patterns and ceramic shells to produce complex geometries with tight tolerances.

LG2 Gunmetal: British Standard BS 1400 designation for high-grade Gunmetal used in marine and industrial applications.

NPSH (Net Positive Suction Head): Minimum pressure required at pump suction to prevent cavitation and ensure proper pump operation.

Pump Volute: Spiral-shaped pump casing that converts velocity energy from impeller discharge into pressure energy.

Sand Casting: Traditional casting process using sand molds, suitable for large components and complex internal geometries.

Related Parts:

Bronze foundry services, Aluminum Bronze Pump parts, Aluminum bronze pump components, Aluminum Bronze Pump castings, marine pump components, centrifugal pump impellers, Bronze alloy castings, pump renovation parts, custom Bronze components, industrial pump solutions, seawater resistant impellers, chemical pump parts, Bronze machining services

Application-Specific Marine Bronze impellers, chemical processing pump parts, desalination plant components, offshore pump systems, industrial Bronze castings, water treatment pump components, HVAC Bronze parts, power plant pump impellers

Material-Related Terms: Tin Bronze casting, Aluminum Bronze components, Manganese Bronze parts, leaded Bronze castings, corrosion resistant Bronze, high strength Bronze alloys, marine grade Bronze

Manufacturing Terms: Investment casting foundry, sand casting services, CNC machined Bronze parts, heat treated Bronze components, precision Bronze castings, quality Bronze foundry, custom Bronze manufacturing

International Standards: ASTM Bronze castings, BS 1400 Gunmetal, DIN Bronze standards, JIS Bronze specifications, ISO pump standards, API pump components, ANSI Bronze parts

Request Quote for Bronze Pump Impellers

Ready to discuss your Bronze pump impeller requirements?

Contact our technical team today for customized solutions, detailed quotations, and expert consultation.

📧 Email: sales@brass-copper-parts. com

📞 Phone: +91 22 43449300

💬 WhatsApp: +91 22 43449300

📱 Request Brochure: Send “BRONZE CATALOG” to sales@brass-copper-parts. com

Get Your Custom Quote for Bronze Impellers, Bronze Pump Impellers and bronze Pump parts in 24 Hours | Technical Consultation Available | Free Samples for Qualified Projects