Copper Nuts & Copper Hex Nuts – Premium Quality Fasteners

Overview – Leading Copper Nuts Manufacturer from India

We are one of the leading manufacturers and exporters of Copper nuts, Copper hex nuts, and specialized Copper fasteners from India. We have been supplying precision-engineered Copper nuts and Copper hex nuts to the world market for many decades. Our comprehensive range includes Copper hex nuts, Copper square nuts, Copper lock nuts, Copper wing nuts, and custom-machined Copper threaded fasteners manufactured using advanced cold forging and precision machining techniques. With over three decades of experience in Copper alloy fastener production, we maintain strict adherence to international quality standards including ISO 4032, DIN 934, ASTM B194, and JIS B1181. Our state-of-the-art manufacturing facility in India produces millions of Copper nuts annually, serving diverse industries including marine engineering, electrical components, plumbing systems, architectural hardware, and specialized industrial applications. Each Copper nut undergoes rigorous quality control testing to ensure dimensional accuracy, thread integrity, and corrosion resistance properties that meet or exceed customer specifications. Our technical expertise in Copper metallurgy combined with modern manufacturing processes enables us to deliver consistent quality Copper nuts with superior performance characteristics for demanding applications worldwide.

📊 COPPER NUTS MANUFACTURING PROCESS INFOGRAPHIC

Raw Material Selection → Cold Forging/Machining → Thread Cutting → Quality Testing → Surface Treatment → Final Inspection → Packaging

Types of Copper Nuts – Comprehensive Product Range

Copper Nuts (Standard Range)

Our standard Copper nuts represent the foundation of our product line, manufactured from high-purity Copper alloys conforming to international specifications. These Copper threaded fasteners are produced using precision cold forging and machining processes to achieve optimal mechanical properties and dimensional accuracy. Standard Copper nuts are available in thread sizes ranging from M3 to M48 in metric specifications and #4-40 to 2″-8 in imperial threads. The manufacturing process involves careful material selection of Copper grades including C11000 (electrolytic tough pitch), C10100 (oxygen-free electronic), and C12200 (phosphorus deoxidized) to ensure superior electrical conductivity and corrosion resistance. Our Copper nuts feature precisely cut internal threads with Class 6H tolerance grades according to ISO 965-1 standards, ensuring reliable mating with corresponding bolts and threaded rods.

Copper Hex Nuts (Premium Hexagonal Design)

Copper hex nuts constitute our most popular fastener category, engineered with six-sided hexagonal geometry for optimal torque application and wrench engagement. These Copper hex nuts are manufactured according to ISO 4032, DIN 934, and ASTM F467 specifications, featuring standard hex dimensions that ensure compatibility with international tooling systems. Our Copper hex nuts undergo precision machining or cold forging processes to achieve consistent wall thickness, accurate thread pitch, and uniform hexagonal dimensions. The hexagonal design of these Copper hex nuts provides superior grip characteristics and prevents rotation during installation, making them ideal for high-stress applications in marine hardware, electrical panels, and architectural installations where Copper’s natural antimicrobial properties are beneficial.

Copper Square Nuts (Four-Sided Design)

Copper square nuts feature a distinctive four-sided geometry that provides excellent anti-rotation characteristics in specialized applications. These Copper square nuts are particularly valuable in wood construction, furniture manufacturing, and decorative hardware applications where the square profile prevents spinning during assembly. Manufacturing of Copper square nuts involves precision machining from Copper bar stock or specialized square-die cold forging to maintain accurate corner dimensions and thread concentricity. Our Copper square nuts comply with ASME B18.2.2 and DIN 557 standards, available in standard thread sizes with Class 2B thread fit for general applications and Class 3B for precision assemblies requiring tighter tolerances.

Copper Lock Nuts (Self-Locking Design)

Copper lock nuts incorporate advanced self-locking mechanisms to prevent loosening under vibration and dynamic loading conditions. These specialized Copper lock nuts feature either nylon insert technology, prevailing torque elements, or deformed thread designs that create resistance against reverse rotation. Manufacturing of Copper lock nuts requires precise control of insert placement and thread deformation to achieve consistent prevailing torque values according to ASTM F467 and DIN 985 specifications. Our Copper lock nuts are extensively used in marine applications, electrical equipment, and transportation systems where joint integrity is critical and regular maintenance access is limited.

Copper Machined Nuts (Precision CNC Manufacturing)

Copper machined nuts represent the pinnacle of precision fastener manufacturing, produced using advanced CNC machining centers capable of achieving tight dimensional tolerances and complex geometries. These Copper machined nuts are manufactured from certified Copper bar stock through multi-axis machining operations that ensure perfect thread concentricity, accurate hex dimensions, and superior surface finish. Our Copper machined nuts are ideal for high-precision applications in aerospace components, scientific instruments, and medical devices where dimensional accuracy and material purity are paramount. The machining process allows for custom modifications including special thread pitches, non-standard sizes, and unique geometric features tailored to specific customer requirements.

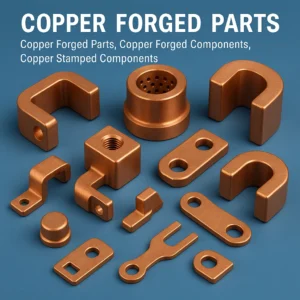

Copper Cold Forged Nuts (High-Strength Manufacturing)

Copper cold forged nuts are produced using advanced cold forming technology that enhances material properties through controlled deformation processes. This Copper cold forging method increases material density, improves grain structure, and enhances mechanical strength compared to machined alternatives. Our Copper cold forged nuts undergo multi-stage forming operations using precision dies to achieve accurate hexagonal geometry and consistent wall thickness. The cold forging process for Copper nuts requires specialized equipment including mechanical presses, progressive dies, and automated feeding systems that ensure consistent quality and high production efficiency. These Copper cold forged nuts offer superior fatigue resistance and dimensional stability for demanding industrial applications.

Copper Metric Nuts (International Standard Threading)

Copper metric nuts are manufactured according to ISO metric thread standards, featuring standard pitch dimensions from M1.6 x 0.35 to M100 x 6.0 for comprehensive application coverage. These Copper metric nuts conform to ISO 4032 dimensional specifications and ISO 898-2 mechanical property requirements, ensuring global compatibility and reliable performance. Our Copper metric nuts are produced with Class 6H internal thread tolerance according to ISO 965-1, providing optimal balance between assembly ease and thread engagement strength. Manufacturing processes for Copper metric nuts include precision thread rolling, CNC threading, and quality verification using specialized thread gauges and coordinate measuring machines.

Copper UNC Nuts (Unified National Coarse Threading)

Copper UNC nuts feature Unified National Coarse thread profiles according to ASME B1.1 specifications, designed for general-purpose applications requiring rapid assembly and disassembly. These Copper UNC nuts are available in standard sizes from #4-40 to 4″-8, manufactured with Class 2B thread fit for normal applications and Class 3B for precision assemblies. Our Copper UNC nuts are particularly popular in North American markets for electrical grounding applications, plumbing systems, and marine hardware where Copper’s excellent conductivity and corrosion resistance properties are essential. Manufacturing includes precision thread cutting operations and dimensional verification according to ASME B18.2.2 standards.

Material Grades & International Standards

| Standard | Grade/Designation | Composition | Key Properties | Applications |

|---|---|---|---|---|

| ASTM B194 | C11000 (ETP) | 99.90% Cu min | High conductivity, excellent formability | Electrical, plumbing |

| ASTM B152 | C10100 (OF) | 99.99% Cu min, oxygen-free | Superior electrical properties | Electronic components |

| DIN EN 1412 | Cu-ETP (CW004A) | ≥99.90% Cu | General purpose, good conductivity | General fasteners |

| JIS H3100 | C1100 | 99.90% Cu min | Excellent workability | Industrial applications |

| BS EN 1172 | Cu-PHC (CW024A) | Cu + 0.015-0.040% P | Enhanced strength, corrosion resistance | Marine, architectural |

| IS 1897 | Cu-1 | 99.90% Cu min | High purity, good conductivity | Electrical installations |

| GB/T 5231 | T2 | 99.90% Cu min | General purpose grade | Standard fasteners |

Manufacturing Processes & Advanced Machinery

Our Copper nuts manufacturing facility employs cutting-edge technology and precision machinery to ensure consistent quality and high production efficiency. The primary manufacturing processes include cold forging, precision machining, thread rolling, and CNC turning, each selected based on specific product requirements and volume considerations.

Cold Forging Process for Copper Nuts

Our cold forging operations utilize high-capacity mechanical presses ranging from 250 tons to 1600 tons, equipped with progressive dies designed specifically for Copper alloy forming. The cold forging process enhances material properties through work hardening, increases production efficiency, and reduces material waste compared to traditional machining methods. Key machinery includes Hatebur multi-station cold formers, Sacma transfer presses, and specialized trimming equipment for flash removal and dimensional finishing.

Precision CNC Machining

For precision Copper nuts requiring tight tolerances and complex geometries, we employ state-of-the-art CNC machining centers including Mazak Quick Turn series, DMG Mori turning centers, and specialized multi-spindle automatic lathes. These machines achieve positional accuracy of ±0.005mm and surface finish requirements down to Ra 0.8μm, essential for high-precision applications in aerospace and medical industries.

Thread Manufacturing Technology

Internal threading operations utilize both cutting and forming methods depending on material grade and application requirements. Our facility includes thread rolling machines for enhanced thread strength, CNC threading lathes for precision applications, and specialized tapping equipment for small diameter nuts. Quality control includes real-time thread monitoring using laser measurement systems and go/no-go gauge verification.

| Manufacturing Process | Machinery Used | Capacity/Specifications | Typical Products | Quality Standards |

|---|---|---|---|---|

| Cold Forging | Hatebur HOT, Sacma Transfer Press | 250-1600 tons, 120 parts/min | Standard hex nuts M6-M48 | ISO 4032, DIN 934 |

| CNC Machining | Mazak Quick Turn, DMG Mori | ±0.005mm accuracy | Precision nuts, custom sizes | ISO 898-2, ASTM F467 |

| Thread Rolling | Profiroll THR series | M3-M64 capacity | High-strength lock nuts | ISO 965-1, ASME B1.1 |

| Progressive Stamping | Aida servo press | 400 tons, 80 spm | Square nuts, specialty shapes | ASME B18.2.2 |

Technical Specifications & Dimensional Standards

Copper Hex Nuts – Standard Dimensions (ISO 4032)

| Thread Size | Pitch (mm) | Width Across Flats (mm) | Thickness (mm) | Width Across Corners (mm) | Chamfer (mm) |

|---|---|---|---|---|---|

| M3 | 0.5 | 5.5 | 2.4 | 6.35 | 0.2 |

| M4 | 0.7 | 7 | 3.2 | 8.08 | 0.2 |

| M5 | 0.8 | 8 | 4.7 | 9.24 | 0.3 |

| M6 | 1.0 | 10 | 5.2 | 11.55 | 0.3 |

| M8 | 1.25 | 13 | 6.8 | 15.01 | 0.4 |

| M10 | 1.5 | 17 | 8.4 | 19.64 | 0.4 |

| M12 | 1.75 | 19 | 10.8 | 21.94 | 0.6 |

| M16 | 2.0 | 24 | 14.8 | 27.71 | 0.8 |

| M20 | 2.5 | 30 | 18.0 | 34.64 | 1.0 |

| M24 | 3.0 | 36 | 21.5 | 41.57 | 1.2 |

Material Properties of Copper Nuts

| Property | C11000 (ETP) | C10100 (OF) | C12200 (DHP) | Test Method | Units |

|---|---|---|---|---|---|

| Tensile Strength | 220-290 | 200-245 | 275-380 | ASTM E8 | MPa |

| Yield Strength (0.2%) | 70-260 | 60-200 | 140-310 | ASTM E8 | MPa |

| Elongation | 45-60 | 45-55 | 30-45 | ASTM E8 | % |

| Hardness | 40-90 | 40-65 | 50-95 | ASTM E18 | HRB |

| Electrical Conductivity | 101 | 103 | 85 | ASTM B193 | %IACS |

| Thermal Conductivity | 391 | 401 | 330 | ASTM E1461 | W/m·K |

| Density | 8.94 | 8.94 | 8.94 | ASTM B311 | g/cm³ |

Quality Standards & Tolerances

Precision Manufacturing Tolerances: Our Copper nuts are manufactured to exacting tolerances according to international standards. Standard dimensional tolerances include ±0.13mm for hex width across flats, ±0.05mm for thickness dimensions, and Class 6H thread tolerance for internal threads according to ISO 965-1. For precision applications, we can achieve tighter tolerances of ±0.05mm on critical dimensions and Class 5H thread fits when specified.

| Dimension | Standard Tolerance | Precision Tolerance | Measurement Method | Inspection Frequency |

|---|---|---|---|---|

| Hex Width Across Flats | ±0.13mm | ±0.05mm | Caliper, CMM | Every 100 pieces |

| Thickness | ±0.15mm | ±0.08mm | Micrometer | Every 50 pieces |

| Thread Pitch | ±0.05mm | ±0.02mm | Thread pitch gauge | Every 25 pieces |

| Thread Class | 6H | 5H | Go/No-go gauges | Every 20 pieces |

| Surface Finish | Ra 3.2μm | Ra 1.6μm | Surface profilometer | Random sampling |

Industries & Applications

Our Copper nuts and Copper hex nuts serve diverse industries worldwide, leveraging Copper’s unique combination of electrical conductivity, corrosion resistance, antimicrobial properties, and aesthetic appeal. Key application sectors include marine engineering, electrical and electronics, plumbing and HVAC, architectural hardware, automotive components, and specialized industrial equipment.

Marine & Offshore Applications

Copper marine fasteners including hex nuts and lock nuts are extensively used in shipbuilding, offshore platforms, and yacht construction due to their exceptional resistance to seawater corrosion. The natural biofouling resistance of Copper prevents marine organism attachment, reducing maintenance requirements and extending service life in harsh marine environments.

Electrical & Electronics Industry

High-conductivity Copper nuts are essential components in electrical panels, grounding systems, transformer assemblies, and electronic equipment where superior electrical conductivity and reliable connections are critical. The non-magnetic properties of pure Copper make these nuts ideal for sensitive electronic applications.

Architectural & Decorative Hardware

Copper architectural fasteners including decorative hex nuts and specialty nuts are popular in high-end construction projects, historical restoration, and artistic installations. The natural patina development of Copper provides unique aesthetic appeal while maintaining structural integrity over decades of exposure.

Plumbing & HVAC Systems

Copper plumbing nuts and compression fittings are standard components in residential and commercial plumbing systems, offering reliable connections for Copper tubing and pipe assemblies. The antimicrobial properties of Copper contribute to improved water quality and reduced bacterial growth in plumbing systems.

Why Choose Our Copper Nuts – Unique Selling Propositions

Unmatched Experience: With over three decades of specialized experience in Copper fastener manufacturing, we bring deep technical expertise and proven reliability to every project. Our engineering team understands the unique challenges of Copper processing and has developed proprietary techniques for optimizing material properties and manufacturing efficiency.

Global Quality Standards: Our manufacturing processes are certified to ISO 9001:2015 quality management standards, and all products comply with international specifications including ASTM, DIN, JIS, and IS standards. We maintain full traceability from raw material sourcing through final inspection and packaging.

Customization Capabilities: We offer extensive customization options including non-standard sizes, special thread pitches, unique geometries, and custom packaging solutions. Our engineering team works closely with customers to develop application-specific solutions that meet exact requirements.

Rapid Turnaround: Despite our precision manufacturing processes, we maintain efficient production schedules with standard delivery times of 4-6 weeks for regular orders and expedited service available for urgent requirements. Our streamlined supply chain and inventory management ensure consistent availability.

Competitive Pricing: Our strategic location in India combined with advanced manufacturing technology enables us to offer highly competitive pricing without compromising quality. We provide transparent cost structures and volume discounts for large orders.

Comprehensive Support: Our technical support team includes metallurgical engineers, application specialists, and quality assurance experts who provide ongoing assistance throughout the product lifecycle. We offer detailed material certifications, application guidance, and troubleshooting support.

Performance Metrics & Testing

| Test Parameter | Standard Specification | Our Achievement | Test Method | Frequency |

|---|---|---|---|---|

| Tensile Strength | 220 MPa min | 250-290 MPa | ASTM E8/E8M | Per batch |

| Thread Engagement | ≥85% contact | ≥92% contact | Thread optical analysis | Statistical sampling |

| Corrosion Resistance | 500 hours salt spray | >1000 hours | ASTM B117 | Monthly validation |

| Dimensional Accuracy | ±0.15mm tolerance | ±0.08mm achieved | CMM measurement | Continuous monitoring |

| Electrical Conductivity | ≥95% IACS | 101-103% IACS | ASTM B193 | Per material lot |

Frequently Asked Questions (Q&A)

Q1: What are the main advantages of Copper nuts over other materials?

A1: Copper nuts offer superior electrical conductivity (up to 103% IACS), excellent corrosion resistance especially in marine environments, natural antimicrobial properties, non-magnetic characteristics, and aesthetic appeal with natural patina development. These properties make Copper nuts ideal for electrical grounding, marine applications, plumbing systems, and architectural hardware where these unique characteristics are essential.

Q2: Can you manufacture custom sizes and specifications for Copper hex nuts?

A2: Yes, we specialize in custom Copper hex nuts manufacturing including non-standard sizes, special thread pitches (metric and imperial), modified hex dimensions, and unique geometric features. Our CNC machining capabilities enable production of prototypes and small batches with tight tolerances. We work closely with customers to develop application-specific solutions that meet exact requirements.

Q3: What quality certifications and material traceability do you provide?

A3: All our Copper nuts come with complete material certifications including chemical composition analysis, mechanical property test results, dimensional inspection reports, and surface finish verification. We maintain full traceability from raw material sourcing through final inspection, with batch-specific documentation available for critical applications.

Q4: How do you ensure consistent thread quality in your Copper nuts?

A4: We employ multiple thread manufacturing methods including precision CNC threading, thread rolling, and specialized tapping depending on size and application requirements. Each batch undergoes comprehensive thread inspection using go/no-go gauges, optical thread analysis, and tensile testing to ensure Class 6H tolerance compliance and reliable mating with corresponding bolts.

Q5: What is the typical lead time for standard and custom Copper nut orders?

A5: Standard Copper nuts in regular sizes typically require 4-6 weeks for production and delivery. Custom orders may require 6-8 weeks depending on complexity and quantity. We maintain strategic inventory levels for common sizes to reduce delivery times and offer expedited service for urgent requirements with advance coordination.

Q6: Do your Copper nuts comply with international environmental and safety standards?

A6: Yes, all our Copper nuts comply with RoHS directives, REACH regulations, and various international environmental standards. We use high-purity Copper alloys without harmful additives, and our manufacturing processes incorporate environmental best practices. Material safety data sheets and compliance certificates are available for all products.

Q7: Can you provide surface treatments or special finishes for Copper nuts?

A7: We offer various surface treatments including passivation for enhanced corrosion resistance, antioxidant coatings to prevent tarnishing, and specialized finishes for decorative applications. Natural Copper patina development can be accelerated or controlled through chemical treatments, and we can apply protective clear coatings when specified.

Q8: What packaging options are available for bulk Copper nut orders?

A8: Standard packaging includes plastic bags with desiccant, cardboard boxes with foam inserts, and wooden crates for export shipments. We offer custom packaging solutions including customer-labeled boxes, specialized containers for automated assembly systems, and anti-corrosion packaging for long-term storage. Packaging can be tailored to specific handling and storage requirements.

Q9: How do you handle quality issues or warranty claims?

A9: We maintain comprehensive quality records for all Copper nuts and provide immediate support for any quality concerns. Our quality assurance team investigates all issues promptly, provides detailed failure analysis when required, and implements corrective actions to prevent recurrence. We stand behind our products with appropriate warranties based on application and service conditions.

Q10: Do you provide technical support for application-specific Copper nut selection?

A10: Our technical team includes metallurgical engineers and application specialists who provide comprehensive support for Copper nut selection, installation guidelines, compatibility assessments, and performance optimization. We offer material property data, application case studies, and ongoing technical consultation to ensure optimal performance in specific applications.

Q11: What are the minimum order quantities for different types of Copper nuts?

A11: Minimum order quantities vary by size and type: standard Copper hex nuts have MOQs of 1000-5000 pieces depending on size, while custom or precision nuts may have lower MOQs of 100-500 pieces. We accommodate both large production orders and smaller prototype quantities to support customer development needs.

Q12: Can you supply Copper nuts with third-party inspection certificates?

A12: Yes, we can arrange third-party inspection and certification through accredited agencies including Lloyd’s, SGS, Bureau Veritas, and others as specified by customers. Third-party inspection can cover dimensional verification, material testing, and quality system audits according to customer requirements and international standards.

Turnaround Time & Production Capacity

Standard Production Schedule: Our efficient manufacturing processes and strategic inventory management enable us to maintain consistent delivery schedules of 4-6 weeks for standard Copper nuts orders. This timeframe includes material procurement, production scheduling, manufacturing operations, quality control testing, and packaging preparation. For urgent requirements, we offer expedited service with delivery in 2-3 weeks subject to capacity availability and advance coordination.

Our production facility operates with multiple shifts to maximize capacity utilization and maintain consistent output. Current production capacity includes over 2 million pieces annually for standard Copper hex nuts, with the flexibility to adjust production schedules based on customer requirements and seasonal demand variations. Advanced planning and scheduling systems enable us to accommodate both large production orders and smaller specialized requirements efficiently.

Customer Testimonial

“We have been sourcing Copper hex nuts from this Indian manufacturer for over five years, and their consistency in quality and delivery has been exceptional. The technical support team provided valuable guidance for our marine application requirements, and their ability to customize packaging with our company logos has enhanced our brand presentation. The competitive pricing combined with superior product quality makes them our preferred supplier for all Copper fastener requirements.”

– Angela Anderson, Procurement Manager, USA

Packaging & Shipping Solutions

Our comprehensive packaging solutions ensure optimal protection and presentation of Copper nuts throughout the supply chain. Standard packaging includes anti-corrosion materials, moisture barriers, and shock-absorbing elements to maintain product integrity during transportation and storage. We offer customized packaging options including customer branding, specialized containers, and automated handling compatibility.

| Package Type | Quantity Range | Protection Features | Customization Options | Typical Applications |

|---|---|---|---|---|

| Plastic Bags | 100-1000 pieces | Anti-static, moisture barrier | Customer labels, size marking | Small orders, samples |

| Cardboard Boxes | 1000-10000 pieces | Foam inserts, desiccant packs | Branding, handling instructions | Standard orders |

| Wooden Crates | 10000+ pieces | Export quality, fumigation cert | Size specifications, marking | Bulk export orders |

| Plastic Containers | 500-5000 pieces | Reusable, stackable design | Color coding, automation ready | Assembly line supply |

Glossary of Technical Terms

Cold Forging: A manufacturing process where Copper nuts are formed at room temperature through controlled deformation, enhancing material strength and grain structure while maintaining dimensional accuracy.

Thread Class: A standardized system (such as Class 6H for internal threads) that defines the tolerance and fit characteristics of threaded fasteners, ensuring proper mating between Copper nuts and bolts.

IACS (International Annealed Copper Standard): A measurement scale for electrical conductivity where pure annealed Copper is defined as 100% IACS, used to specify the conductivity of Copper alloys in electrical applications.

Prevailing Torque: The resistance to rotation exhibited by Copper lock nuts during installation, created by thread deformation or insert materials to prevent loosening under vibration.

Work Hardening: The strengthening of Copper material through plastic deformation during cold forming processes, resulting in increased strength and hardness compared to annealed conditions.

Thread Engagement: The percentage of theoretical thread contact between Copper nuts and mating bolts, typically specified as minimum 85% for reliable joint performance.

Patina: The natural oxidation layer that forms on Copper surfaces over time, providing enhanced corrosion resistance and distinctive aesthetic appearance in architectural applications.

DHP (Deoxidized High Phosphorus): A Copper alloy designation (C12200) containing phosphorus additions for improved machinability and enhanced corrosion resistance properties.

Related Parts:

Primary : Copper nuts, Copper hex nuts, Copper square nuts, Copper lock nuts, Copper fasteners, Copper threaded fasteners, Copper hardware, Copper alloy nuts

Manufacturing: Cold forged Copper nuts, machined Copper nuts, precision Copper nuts, CNC Copper nuts, Copper nut manufacturing, Copper fastener production

Technical Specifications Metric Copper nuts, UNC Copper nuts, ISO 4032 Copper nuts, DIN 934 Copper nuts, ASTM B194 Copper nuts, high conductivity Copper nuts, UNF Copper Nuts, UNC threaded Copper nuts

Application Areas: Marine Copper nuts, electrical Copper nuts, plumbing Copper nuts, architectural Copper nuts, electronic Copper nuts, grounding Copper nuts

Quality Terms: Premium Copper nuts, certified Copper nuts, tested Copper nuts, traceable Copper nuts, RoHS compliant Copper nuts, high purity Copper nuts

Get Your Custom Copper Nuts Quote Today!

Ready to experience the superior quality and reliability of our Copper nuts and Copper hex nuts? Our technical team is standing by to assist with your specific requirements and provide detailed quotations for your project needs.

📞 Call us: +91-22-43449300

📱 WhatsApp: +91-22-43449300

✉️ Email: sales@brass-copper-parts. com

Request our comprehensive product catalog and technical specification brochure! We’ll send detailed information about our complete range of Copper nuts, Copper hex nuts, and specialized fasteners along with application guidance and selection charts.

Contact us today for immediate assistance with your Copper fastener requirements and discover why customers worldwide choose us for their critical applications!