Stainless Steel Hose Barbs – Premium Quality Fittings for Industrial Applications

We are one of the leading manufacturers and exporters of Stainless Steel Hose Barbs from India. We have been supplying precision-engineered hose barb fittings to the world market for many decades. Our comprehensive range of Stainless Steel Hose Barbs includes SS 304, SS 316, NPT threaded, BSP, NPTF, and sanitary grade fittings designed for diverse industrial applications. With over three decades of manufacturing excellence, we specialize in producing high-quality hose barb connections that meet international standards including ASTM, DIN, BS, IS, and JIS specifications. Our state-of-the-art manufacturing facility in India employs advanced CNC machining, precision turning, and quality control processes to ensure consistent product quality. We serve industries ranging from pharmaceutical and food processing to chemical, petrochemical, marine, and automotive sectors worldwide. Our expertise in custom manufacturing, flexible production schedules, and comprehensive technical support has made us a trusted partner for businesses across North America, Europe, Middle East, and Asia-Pacific regions.

Price: US$ 11.10/Kilogram

Product Overview and Manufacturing Excellence

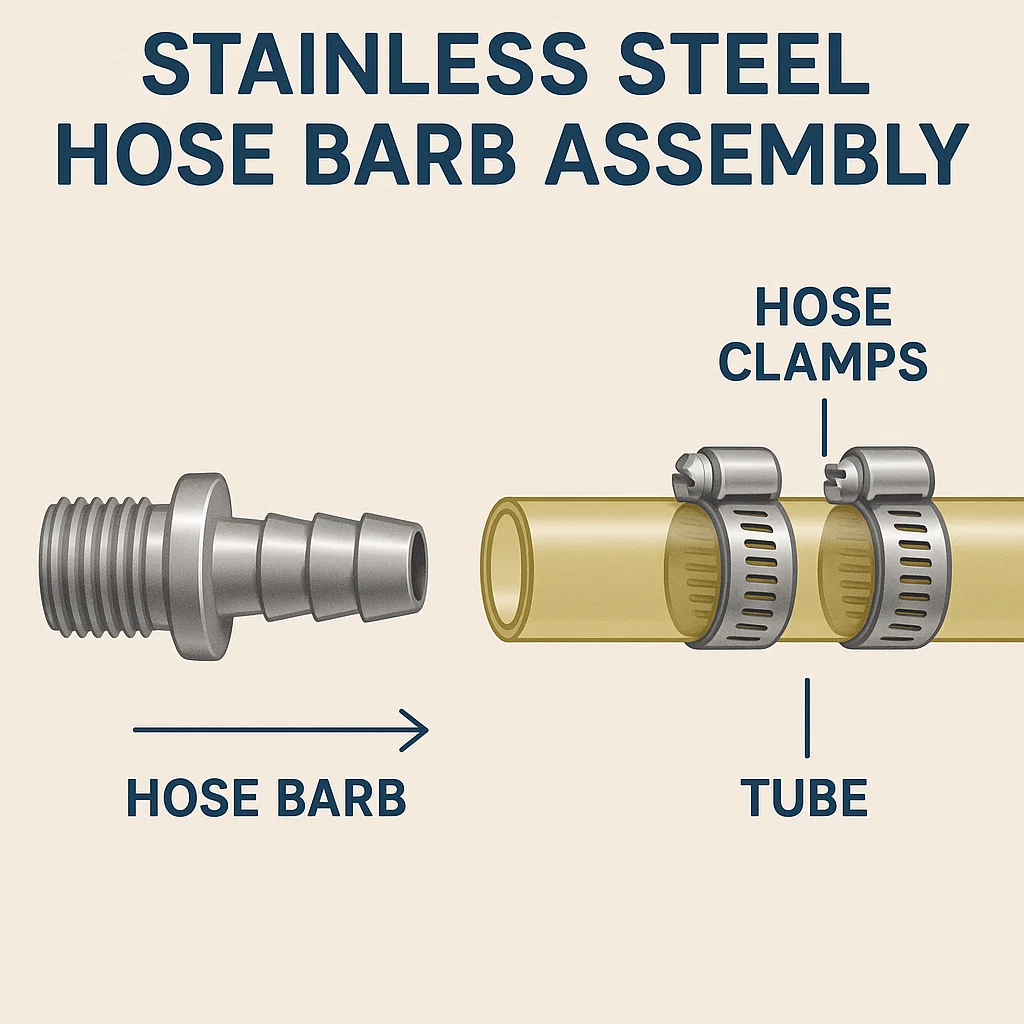

Our Stainless Steel Hose Barbs are precision-machined components designed to provide secure, leak-proof connections between hoses and piping systems. These fittings feature graduated barbed ends that grip the interior of flexible hoses while providing threaded connections compatible with various pipe thread standards. Manufacturing excellence is achieved through advanced CNC turning operations, precision threading, and comprehensive quality assurance protocols that ensure dimensional accuracy within ±0.05mm tolerances.

Material Grades and International Standards

Our hose barb fittings are manufactured using premium grade Stainless Steel alloys conforming to multiple international standards:

| Standard | Grade | Composition | Applications |

|---|---|---|---|

| ASTM A276/A479 | SS 304/SS 316 | Cr 18-20%, Ni 8-10% | General purpose, corrosion resistant |

| DIN 1.4301/1.4404 | SS 304/SS 316 | Cr 17-19.5%, Ni 8-10.5% | European automotive, marine |

| BS 316S31/316S33 | SS 316/SS 316L | Mo 2-3%, Low Carbon | Chemical processing, marine |

| JIS SUS304/SUS316 | SS 304/SS 316 | Japanese standard composition | Asian automotive, electronics |

| IS 6911 | SS 304/SS 316 | Indian standard specification | Domestic industrial applications |

| GB/T 1220 | 0Cr18Ni9/00Cr17Ni14Mo2 | Chinese standard grades | Chinese industrial sector |

Manufacturing Processes and Machinery

Our advanced manufacturing facility employs state-of-the-art machinery and precision processes to ensure consistent quality and dimensional accuracy:

| Process | Machinery | Tolerance Achievement | Quality Control |

|---|---|---|---|

| CNC Turning | Multi-spindle CNC Lathes | ±0.025mm | CMM Inspection |

| Thread Cutting | Precision Threading Machines | ISO 2768-f | Thread Gauging |

| Barb Machining | CNC Turning Centers | ±0.05mm | Optical Measurement |

| Surface Finishing | Electropolishing Units | Ra 0.5μm | Surface Roughness Testing |

| Heat Treatment | Controlled Atmosphere Furnaces | ±5°C Temperature | Hardness Testing |

Typical Parts Produced and Dimensional Specifications

| Part Type | Size Range | Thread Options | Pressure Rating | Applications |

|---|---|---|---|---|

| Straight Hose Barbs | 1/8″ – 2″ | NPT, BSP, Metric | 150-3000 PSI | General plumbing, HVAC |

| Elbow Hose Barbs | 1/4″ – 1-1/2″ | NPT, BSP | 150-1500 PSI | Tight space connections |

| Reducing Hose Barbs | 1/4″ – 1″ | NPT, BSP | 150-1000 PSI | Size transition systems |

| Tee Hose Barbs | 1/4″ – 1″ | NPT, BSP | 150-800 PSI | Branch connections |

| Sanitary Hose Barbs | 1/2″ – 2″ | Tri-clamp, DIN | 150-300 PSI | Food, pharmaceutical |

Hose Size and Thread Size Compatibility Chart

The following table provides standard size correlations between hose inner diameter (ID), outer diameter (OD), and corresponding thread sizes for different international thread standards. This comprehensive sizing guide ensures proper fitting selection for optimal performance and leak-proof connections.

| Hose ID | Hose OD | NPT Thread | BSPT Thread | BSP Parallel | Barb Length | Hex Size |

|---|---|---|---|---|---|---|

| 1/4″ (6mm) | 9-11mm | 1/8″ NPT | 1/8″ BSPT | G1/8″ | 12mm | 7/16″ |

| 5/16″ (8mm) | 11-13mm | 1/4″ NPT | 1/4″ BSPT | G1/4″ | 15mm | 9/16″ |

| 3/8″ (10mm) | 13-16mm | 1/4″ NPT | 1/4″ BSPT | G1/4″ | 18mm | 9/16″ |

| 1/2″ (12mm) | 16-19mm | 3/8″ NPT | 3/8″ BSPT | G3/8″ | 20mm | 5/8″ |

| 5/8″ (16mm) | 19-22mm | 1/2″ NPT | 1/2″ BSPT | G1/2″ | 25mm | 3/4″ |

| 3/4″ (19mm) | 22-25mm | 1/2″ NPT | 1/2″ BSPT | G1/2″ | 28mm | 3/4″ |

| 7/8″ (22mm) | 25-28mm | 3/4″ NPT | 3/4″ BSPT | G3/4″ | 30mm | 1″ |

| 1″ (25mm) | 28-32mm | 3/4″ NPT | 3/4″ BSPT | G3/4″ | 32mm | 1″ |

| 1-1/4″ (32mm) | 35-38mm | 1″ NPT | 1″ BSPT | G1″ | 35mm | 1-1/4″ |

| 1-1/2″ (38mm) | 41-44mm | 1-1/4″ NPT | 1-1/4″ BSPT | G1-1/4″ | 40mm | 1-1/2″ |

| 2″ (50mm) | 54-57mm | 1-1/2″ NPT | 1-1/2″ BSPT | G1-1/2″ | 45mm | 1-3/4″ |

| 2-1/2″ (63mm) | 67-70mm | 2″ NPT | 2″ BSPT | G2″ | 50mm | 2-1/4″ |

Note: Custom size combinations available upon request. Thread engagement length: minimum 4-5 full threads for pressure-tight sealing. Hose selection should consider working pressure, temperature, and chemical compatibility with fitting materials.

Surface Finish and Quality Specifications

Our Stainless Steel Hose Barbs are available with multiple surface finish options to meet specific application requirements. Standard finishes include mill finish with Ra 1.6μm surface roughness, precision machined finish achieving Ra 0.8μm, and electropolished finish providing Ra ≤0.5μm for sanitary applications. All fittings undergo passivation treatment per ASTM A967 to enhance corrosion resistance and remove free iron contamination from machining operations.

Industries and Applications

Our hose barb fittings serve diverse industrial sectors requiring reliable fluid transfer connections:

Performance Metrics and Technical Specifications

| Parameter | SS 304 Grade | SS 316 Grade | Test Method |

|---|---|---|---|

| Tensile Strength | 515-620 MPa | 520-670 MPa | ASTM A370 |

| Yield Strength | 205 MPa min | 210 MPa min | ASTM A370 |

| Elongation | 40% min | 40% min | ASTM A370 |

| Hardness | ≤200 HB | ≤200 HB | ASTM E18 |

| Operating Temperature | -196°C to +400°C | -196°C to +400°C | ASTM A276 |

Frequently Asked Questions (Technical Q&A)

Q1: What is the difference between SS 304 and SS 316 hose barbs for marine applications?

A1: SS 316 contains 2-3% molybdenum providing superior resistance to chloride-induced pitting and crevice corrosion, making it essential for saltwater and marine environments where SS 304 may experience localized corrosion.

Q2: Can your hose barbs handle cryogenic applications?

A2: Yes, our austenitic Stainless Steel hose barbs maintain excellent toughness and ductility at cryogenic temperatures down to -196°C (liquid nitrogen temperature), with no brittle transition temperature.

Q3: What thread sealants are compatible with Stainless Steel hose barbs?

A3: Compatible sealants include PTFE tape, anaerobic thread compounds, and pipe dope formulated for Stainless Steel. Avoid zinc-containing compounds that may cause galvanic corrosion.

Q4: How do you prevent galling during installation of Stainless Steel threaded fittings?

A4: Use appropriate anti-seize compounds, control installation torque, ensure proper thread engagement, and avoid cross-threading. Our fittings feature chamfered thread starts to minimize installation issues.

Q5: What is the maximum pressure rating for your high-pressure hose barbs?

A5: Our high-pressure series achieves working pressures up to 6000 PSI (414 bar) depending on size and configuration, with safety factors of 4:1 minimum and 100% pressure testing verification.

Q6: Are your sanitary hose barbs validated for pharmaceutical use?

A6: Yes, our sanitary grade fittings comply with FDA 21 CFR 177.2600, USP Class VI biocompatibility, cGMP requirements, and include material certifications with full traceability.

Q7: What quality certifications do you provide with shipments?

A7: Each shipment includes Material Test Certificates (MTC) per EN 10204 3.1, dimensional inspection reports, pressure test certificates, and chemical composition analysis from accredited laboratories.

Q8: Can you customize hose barb configurations for OEM applications?

A8: Absolutely. We specialize in custom configurations including non-standard thread specifications, unique geometries, special materials, and private labeling with customer logos and part numbers.

Q9: What is your typical turnaround time for standard vs. custom orders?

A9: Standard catalog items ship within 4-6 weeks. Custom configurations require 6-8 weeks depending on complexity. Rush orders can be accommodated with premium scheduling.

Q10: How do you ensure dimensional accuracy across production batches?

A10: We employ statistical process control (SPC), coordinate measuring machines (CMM) for inspection, calibrated tooling, and first-article inspection protocols to maintain consistent dimensional accuracy within specified tolerances.

Why Choose Our Stainless Steel Hose Barbs

Our competitive advantages stem from three decades of manufacturing excellence and continuous innovation in precision engineering. Faster turnaround times are achieved through optimized production scheduling, strategic inventory management, and streamlined quality processes that reduce lead times without compromising quality standards. Our superior customer support includes dedicated technical assistance, application engineering consultation, and responsive communication throughout the entire order lifecycle.

Exceptional communication skills ensure clear understanding of customer requirements, regular project updates, and proactive problem-solving before issues impact delivery schedules. Our global exposure and experience spanning over thirty years provides deep understanding of international standards, diverse application requirements, and cultural business practices across multiple continents.

Additional differentiators include flexible production capabilities accommodating both large-volume orders and small-batch specialty requirements, customized packaging solutions with customer labels and logos, comprehensive quality documentation meeting international certification requirements, and competitive pricing achieved through efficient manufacturing processes and strategic supplier relationships.

“We have been sourcing Stainless Steel hose barbs from this Indian manufacturer for over five years, and their consistency in quality and delivery performance has been outstanding. Their technical team’s ability to understand our specific requirements and provide customized solutions has made them an invaluable partner for our pharmaceutical equipment manufacturing. The SS 316 sanitary hose barbs meet all FDA requirements and have performed flawlessly in our clean room environments.”

– R. Chen, Procurement Manager, California, USA

Packaging and Shipping

Our customized packaging solutions protect product integrity during international shipping while providing professional presentation. Standard packaging includes individual poly bags for small fittings, foam-lined cartons for medium quantities, and wooden crates for large orders. Custom labeling with customer logos, part numbers, and specifications is available at no additional cost. All shipments include comprehensive documentation: commercial invoices, packing lists, Material Test Certificates, Certificate of Origin, and any required regulatory compliance certificates.

International shipping capabilities include air freight for urgent orders (3-5 days), sea freight for economical large shipments (15-25 days), and express courier services for samples and small quantities (2-3 days). Our logistics partners provide door-to-door delivery with shipment tracking, customs clearance assistance, and delivery confirmation for complete supply chain visibility.

International Standards Compliance

| Standard | Application | Compliance Level | Certification |

|---|---|---|---|

| ASTM A276/A479 | Material specifications | Full compliance | Third-party certified |

| ANSI B1.20.1 | NPT thread specifications | Class A threads | Thread gauge verified |

| ISO 228 | BSP thread specifications | Class A tolerance | ISO certified facility |

| DIN 2999 | European thread standards | Medium tolerance class | TÜV certified |

| FDA 21 CFR 177.2600 | Food contact materials | Full compliance | FDA registered |

| 3-A Sanitary Standards | Dairy/food equipment | Full compliance | 3-A certified |

Material Property Tables

| Property | SS 304 | SS 316 | SS 316L | Units |

|---|---|---|---|---|

| Density | 8.00 | 8.02 | 8.02 | g/cm³ |

| Melting Point | 1399-1454 | 1375-1400 | 1375-1400 | °C |

| Thermal Conductivity | 16.2 | 16.2 | 16.2 | W/m·K |

| Electrical Resistivity | 72 | 74 | 74 | μΩ·cm |

| Magnetic Permeability | 1.008 | 1.008 | 1.008 | μ/μ₀ |

Tolerances and Quality Standards

Our manufacturing processes achieve precision tolerances conforming to international standards. Dimensional tolerances for threaded features follow ISO 2768 medium tolerance class with thread pitch accuracy within ±0.025mm. Surface finish specifications range from Ra 1.6μm for standard applications to Ra 0.5μm for sanitary applications, verified using calibrated surface roughness measuring instruments.

Geometric tolerances include concentricity within 0.05mm TIR, perpendicularity within 0.1mm, and thread runout within 0.08mm TIR. All critical dimensions undergo statistical process control with capability studies demonstrating Cpk values exceeding 1.33 for key characteristics.

Related Terms

Related Terms:: Stainless steel tube fittings, hose nipples, barbed fittings, threaded hose adapters, SS pipe fittings, sanitary hose connections, high pressure fittings, corrosion resistant fittings, food grade hose barbs, pharmaceutical fittings, marine hose fittings, chemical resistant connectors, pneumatic hose fittings, hydraulic adapters, custom hose barbs, precision machined fittings, electropolished fittings, tri-clamp hose barbs, quick disconnect fittings, push-to-connect fittings

Contact Us for Your Stainless Steel Hose barb needs!

Ready to experience the superior quality and reliability of our Stainless Steel hose Barb solutions?

📧 Email us for a detailed brochure: sales@brass-copper-parts. com- Receive our comprehensive capabilities brochure with detailed specifications, case studies, and technical data sheets.

📞 Call us directly: +91-22-43449300 – Speak with our technical experts who can provide immediate assistance and project guidance.

💬 WhatsApp for quick response: +91-91-22-43449300- Get fast answers to your technical questions and preliminary quotations.

📋 Request a Quote: Submit your drawings, specifications, and requirements through our online quote system for a detailed proposal within 24 hours.

🏭 Schedule a Virtual Facility Tour: Experience our manufacturing capabilities through a virtual tour of our CNC machining facilities and quality control laboratories.

Request Catalog

Experience the difference that three decades of manufacturing excellence makes. Contact us today for samples, technical consultations, or volume quotations. Our team is ready to support your project success with superior Stainless Steel hose Barb and 316 Stainless Steel NPT hose barb solutions.

Standard Response Time: 24 Hours | Sample Availability: 3-5 Days | Production Lead Time: 4-6 Weeks