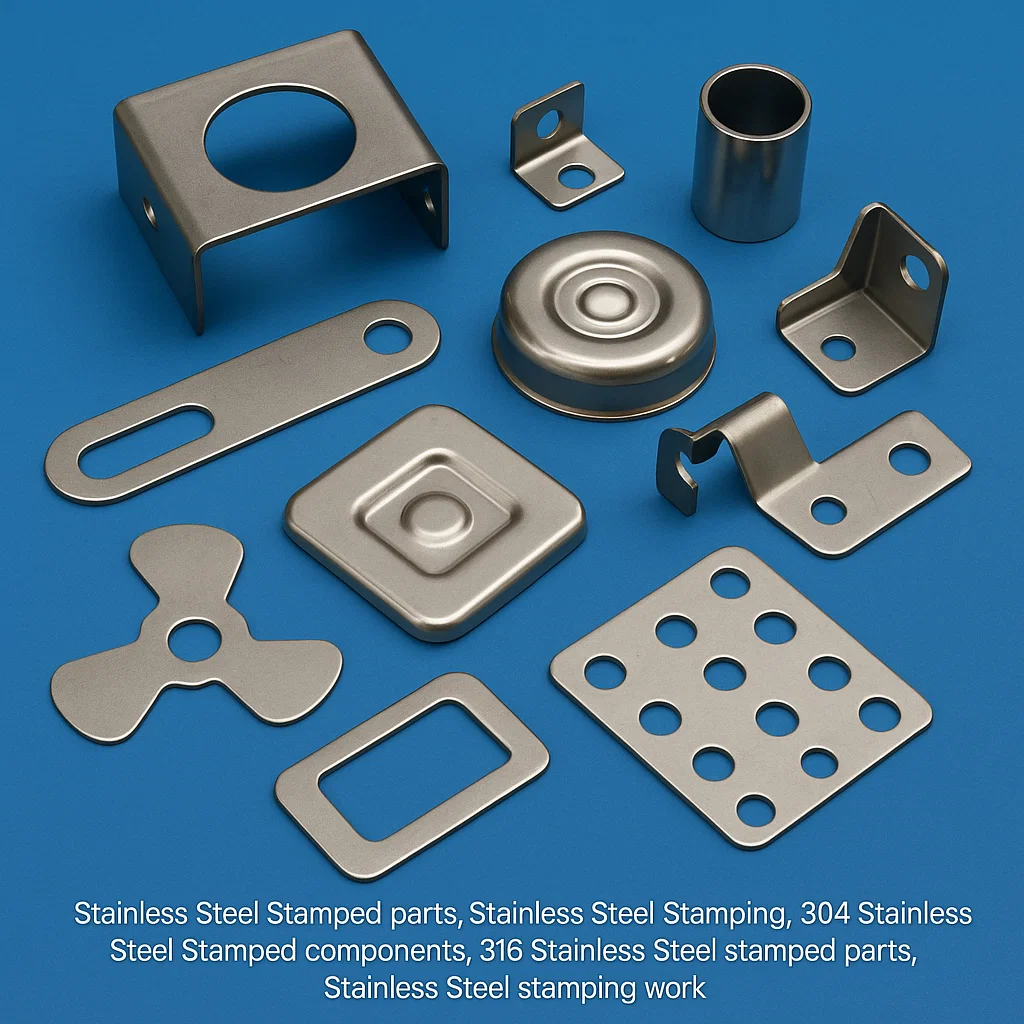

Stainless Steel Stamping, Stainless Steel Stamped parts and Components, AISI 304 and 316 Stainless Steel Stamping

Precision Stainless Steel Stamped Parts & Components

Price: US$ 8.10/Kilogram

We are one of the leading manufacturers and exporters of precision Stainless Steel stamped parts from India. We have been supplying high-quality Stainless Steel stamping solutions to the world market for many decades. Our comprehensive range of Stainless Steel stamped components encompasses various grades including SS 304, SS 316, SS 316L, SS 321, and SS 410, manufactured using state-of-the-art progressive stamping technology and precision press operations. With over three decades of expertise in metal stamping and sheet metal fabrication, we deliver custom Stainless Steel pressed parts that meet stringent international quality standards including ASTM, DIN, JIS, and BS specifications. Our advanced manufacturing facility utilizes high-tonnage progressive stamping presses, deep drawing equipment, and precision CNC machining centers to produce complex Stainless Steel components with exceptional dimensional accuracy and surface finish. We serve diverse industries including automotive, aerospace, electronics, medical devices, food processing, and industrial equipment, providing tailored solutions for both prototype development and high-volume production requirements.

🏭 Stainless Steel Stamping Excellence

Stainless Steel Stamped Parts Overview

Stainless Steel stamped parts represent a critical category of precision-engineered components manufactured through advanced metal forming processes. These components are produced by subjecting Stainless Steel sheets to controlled deformation using specialized stamping dies and high-pressure mechanical or hydraulic presses. Our Stainless Steel stamped parts exhibit superior corrosion resistance, exceptional strength-to-weight ratios, and outstanding durability characteristics that make them indispensable across numerous industrial applications. The inherent properties of Stainless Steel, including its resistance to oxidation, chemical corrosion, and temperature extremes, combined with precise stamping techniques, result in components that maintain dimensional stability and performance integrity under demanding operational conditions.

The manufacturing process involves careful selection of appropriate Stainless Steel grades based on specific application requirements, followed by precision cutting, progressive stamping, secondary operations such as bending and piercing, and comprehensive quality control measures. Our stamped parts range from simple brackets and clips to complex multi-form components with intricate geometries, deep-drawn features, and precise dimensional specifications. Each component undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness analyzers to ensure compliance with customer specifications and international quality standards.

Stainless Steel Stamping Process Technology

Stainless Steel stamping encompasses a comprehensive suite of metal forming technologies designed to transform flat Stainless Steel sheets into three-dimensional components with precise geometrical specifications. Our stamping operations utilize progressive die systems that enable multiple forming operations in a single press stroke, significantly enhancing productivity while maintaining exceptional dimensional accuracy. The stamping process begins with material preparation, including surface cleaning, lubrication application, and precise blank cutting to optimize material utilization and minimize waste generation.

Progressive Stamping Process Flow

Sheet Feed → Blanking → Piercing → Forming → Bending → Deep Drawing → Trimming → Quality Inspection

Advanced servo-driven feed systems ensure precise material positioning throughout the stamping cycle

Our stamping technology incorporates advanced features including servo-controlled press drives, real-time tonnage monitoring, die protection systems, and automated material handling equipment. The integration of Industry 4.0 technologies enables continuous process monitoring, predictive maintenance scheduling, and statistical process control implementation. Temperature-controlled die systems and specialized Stainless Steel forming lubricants optimize material flow characteristics and minimize tool wear, resulting in extended die life and consistent part quality across extended production runs.

Stainless Steel 316 Stamped Parts

Stainless Steel 316 stamped parts represent the pinnacle of corrosion-resistant components, specifically engineered for applications requiring superior performance in harsh environmental conditions. The addition of molybdenum to the SS 316 alloy composition provides exceptional resistance to chloride-induced corrosion, making these components ideal for marine environments, chemical processing equipment, and pharmaceutical manufacturing applications. Our SS 316 stamping capabilities encompass complex geometries including deep-drawn housings, precision brackets, filtering components, and intricate assemblies that maintain structural integrity under extreme temperature and pressure conditions.

The enhanced mechanical properties of SS 316, including improved tensile strength and fatigue resistance, enable the production of lightweight components without compromising performance characteristics. Our specialized forming techniques for SS 316 include controlled work hardening processes that optimize strength distribution throughout the component, resulting in parts that exceed standard performance specifications. Advanced heat treatment protocols and passivation procedures ensure optimal surface characteristics and maximum corrosion resistance for critical applications in food processing, medical devices, and offshore equipment.

| Property | Value | Test Standard | Application Benefits |

|---|---|---|---|

| Tensile Strength | 515-620 MPa | ASTM A240 | High load bearing capacity |

| Yield Strength | 205-310 MPa | ASTM A240 | Excellent formability |

| Elongation | 40% min | ASTM A240 | Superior ductility |

| Corrosion Resistance | Excellent | ASTM G48 | Marine environment suitability |

| Operating Temperature | -196°C to +800°C | ASTM A240 | Wide temperature range |

Stainless Steel 304 Stamped Parts

Stainless Steel 304 stamped parts constitute our most versatile and widely specified product category, offering an optimal balance of mechanical properties, corrosion resistance, and cost-effectiveness. The austenitic microstructure of SS 304 provides exceptional formability characteristics that enable complex stamping operations including deep drawing, multi-stage bending, and precision piercing without compromising material integrity. Our SS 304 stamping expertise encompasses automotive components, household appliances, architectural hardware, and industrial equipment parts that require reliable performance across diverse operating conditions.

The non-magnetic properties of SS 304 in its annealed condition make it particularly suitable for electronic enclosures, medical instruments, and precision measurement devices where magnetic interference must be minimized. Our advanced stamping techniques for SS 304 include progressive die operations that achieve complex part geometries in single press cycles, reducing production costs while maintaining stringent quality standards. Specialized surface treatments including electropolishing, passivation, and decorative finishes enhance both aesthetic appeal and functional performance of finished components.

SS 304 vs SS 316 Comparative Analysis

| Characteristic | SS 304 | SS 316 | Advantage |

|---|---|---|---|

| Chromium Content | 18-20% | 16-18% | SS 304 – Higher chromium |

| Nickel Content | 8-10.5% | 10-14% | SS 316 – Enhanced corrosion resistance |

| Molybdenum | None | 2-3% | SS 316 – Superior marine resistance |

| Cost Factor | Standard | Premium (15-20% higher) | SS 304 – Cost effective |

| Formability | Excellent | Very Good | SS 304 – Easier stamping |

Press Work & Stamping Operations

Our comprehensive press work capabilities encompass both SS 304 and SS 316 stamping operations using state-of-the-art mechanical and hydraulic press systems ranging from 50 tons to 800 tons capacity. The integration of servo-driven press technology enables precise control over forming parameters including ram speed, pressure application, and dwell time, resulting in consistent part quality and extended die life. Our press work operations include blanking, piercing, bending, deep drawing, embossing, coining, and progressive stamping techniques that accommodate both simple and complex component geometries.

Advanced die design capabilities utilizing CAD/CAM software and finite element analysis (FEA) optimize material flow characteristics and minimize springback effects during forming operations. Our press work facilities incorporate real-time process monitoring systems that track tonnage requirements, stroke positions, and die temperatures to ensure optimal forming conditions throughout production runs. Automated material handling systems and robotic part transfer mechanisms enhance productivity while maintaining consistent part orientation and quality standards.

| Press Type | Capacity Range | Suitable Operations | Material Thickness | Typical Parts |

|---|---|---|---|---|

| Mechanical Single Action | 50-400 tons | Blanking, Piercing, Bending | 0.5-6.0 mm | Brackets, Clips, Plates |

| Hydraulic Deep Draw | 100-600 tons | Deep Drawing, Forming | 0.8-4.0 mm | Housings, Containers, Shells |

| Progressive Die | 200-800 tons | Multi-operation Stamping | 0.3-3.0 mm | Complex assemblies, Connectors |

| Transfer Press | 300-1000 tons | Multi-stage Forming | 1.0-8.0 mm | Automotive components, Large parts |

Pressed Stainless Steel Sheet Metal Components

Stainless Steel pressed sheet metal components encompass a broad spectrum of formed parts that leverage the superior mechanical properties and corrosion resistance of Stainless Steel alloys. Our pressed component manufacturing capabilities include single-operation forming, multi-stage progressive operations, and combination processes that integrate stamping with secondary machining operations. The precision forming of Stainless Steel sheet metal requires specialized expertise in material handling, lubrication systems, and tool design to achieve optimal results while minimizing work hardening and surface defects.

Our pressed sheet metal components serve critical functions across industries including HVAC systems, food processing equipment, pharmaceutical manufacturing, and architectural applications. Advanced forming techniques including hydroforming, explosive forming, and electromagnetic pulse forming enable the production of components with complex curvatures, deep recesses, and intricate surface features that would be difficult to achieve through conventional stamping methods. Quality assurance protocols include dimensional verification, surface finish analysis, and corrosion resistance testing to ensure component performance meets or exceeds specification requirements.

Manufacturing Processes & Technology

Advanced Manufacturing Capabilities

Progressive Die Stamping: Multi-station dies performing sequential operations in a single press stroke, ideal for high-volume production with complex geometries and tight tolerances.

Our manufacturing processes integrate cutting-edge technology with proven metalworking techniques to deliver superior Stainless Steel stamped components. The implementation of lean manufacturing principles and continuous improvement methodologies ensures optimal resource utilization and consistent quality outcomes. Advanced process control systems monitor critical parameters including material feed rates, press tonnage, die temperatures, and lubrication delivery to maintain optimal forming conditions throughout production cycles.

| Process | Capability | Tolerance | Surface Finish | Production Volume |

|---|---|---|---|---|

| Blanking | 0.3-12 mm thickness | ±0.1 mm | Ra 1.6 μm | 10,000-1,000,000 pcs |

| Deep Drawing | Draw ratio up to 2.5:1 | ±0.05 mm | Ra 0.8 μm | 5,000-500,000 pcs |

| Progressive Stamping | Up to 20 stations | ±0.02 mm | Ra 0.4 μm | 50,000-5,000,000 pcs |

| Fine Blanking | 0.5-8 mm thickness | ±0.01 mm | Ra 0.2 μm | 1,000-100,000 pcs |

Material Grades & International Standards

Comprehensive Material Grade Matrix

| Grade | ASTM | DIN/EN | JIS | BS | Chinese GB | Applications |

|---|---|---|---|---|---|---|

| SS 304 | A240/A276 | 1.4301 | SUS304 | 304S15 | 0Cr18Ni9 | General purpose, food equipment |

| SS 304L | A240/A276 | 1.4307 | SUS304L | 304S12 | 00Cr19Ni10 | Welded constructions, low carbon |

| SS 316 | A240/A276 | 1.4401 | SUS316 | 316S16 | 0Cr17Ni12Mo2 | Marine, chemical processing |

| SS 316L | A240/A276 | 1.4404 | SUS316L | 316S12 | 00Cr17Ni14Mo2 | Pharmaceutical, food processing |

| SS 321 | A240/A276 | 1.4541 | SUS321 | 321S12 | 0Cr18Ni10Ti | High temperature applications |

| SS 410 | A240/A276 | 1.4006 | SUS410 | 410S21 | 1Cr13 | Cutlery, turbine blades |

| SS 430 | A240/A276 | 1.4016 | SUS430 | 430S17 | 1Cr17 | Automotive trim, appliances |

Typical Parts & Applications of Stainless Steel Sheet metal parts, Stainless Steel stamping

Our extensive portfolio of Stainless Steel stamped parts encompasses diverse component categories serving multiple industries with varying performance requirements. Automotive applications include exhaust system components, fuel injection parts, sensor housings, and decorative trim elements that require exceptional corrosion resistance and thermal stability. Electronics industry components encompass EMI/RFI shielding enclosures, connector housings, heat dissipation elements, and precision mounting brackets that demand tight dimensional tolerances and surface conductivity characteristics.

Medical device applications leverage the biocompatibility and sterilization compatibility of Stainless Steel stamped parts including surgical instrument components, implantable device housings, diagnostic equipment parts, and pharmaceutical processing components. Food processing industry applications encompass conveyor components, mixing equipment parts, storage container elements, and sanitary fittings that must comply with FDA and USDA regulatory requirements for food contact surfaces.

| Industry | Typical Parts | Material Grade | Key Requirements | Production Volume |

|---|---|---|---|---|

| Automotive | Exhaust manifolds, Fuel rails, Sensor brackets | SS 304, SS 321 | High temperature, Corrosion resistance | 100K-1M pieces |

| Aerospace | Engine components, Structural brackets, Fasteners | SS 316, SS 321 | Lightweight, High strength, FAA compliance | 1K-50K pieces |

| Food Processing | Conveyor parts, Mixing blades, Tank components | SS 316L, SS 304 | FDA compliance, Easy cleaning, Sanitary | 10K-100K pieces |

| Medical | Surgical instruments, Device housings, Sterilization trays | SS 316L, SS 304 | Biocompatibility, Sterilization resistance | 5K-200K pieces |

| Electronics | EMI shields, Heat sinks, Connector housings | SS 304, SS 316 | Dimensional precision, Surface conductivity | 50K-2M pieces |

Dimensional Capabilities & Tolerances of Stainless Steel stamping

| Parameter | Standard Tolerance | Precision Tolerance | Measurement Method | Quality Standard |

|---|---|---|---|---|

| Linear Dimensions | ±0.1 mm | ±0.02 mm | CMM, Caliper | ISO 9001:2015 |

| Angular Dimensions | ±1° | ±0.5° | Angle gauge, CMM | ASTM A240 |

| Hole Diameter | ±0.05 mm | ±0.01 mm | Pin gauge, CMM | ISO 286 |

| Bend Radius | ±0.2 mm | ±0.05 mm | Radius gauge, Profile | DIN 6935 |

| Flatness | 0.1 mm | 0.02 mm | Surface plate, Dial indicator | ISO 1101 |

| Surface Roughness | Ra 3.2 μm | Ra 0.8 μm | Surface roughness tester | ISO 4287 |

Surface Finishes & Treatment Options

Our comprehensive surface finishing capabilities enhance both the aesthetic appeal and functional performance of Stainless Steel stamped parts. Standard finishes include mill finish (2B), brushed finish (4), and mirror finish (8) that provide varying levels of reflectivity and texture characteristics suitable for different applications. Advanced finishing processes encompass electropolishing, which removes surface imperfections and enhances corrosion resistance through controlled electrochemical material removal, resulting in ultra-smooth surfaces with improved cleanability for pharmaceutical and food processing applications.

Specialized coating applications include PVD (Physical Vapor Deposition) coatings for enhanced wear resistance, ceramic coatings for thermal barrier properties, and decorative finishes for architectural applications. Passivation treatments utilizing nitric acid or citric acid solutions optimize the natural oxide layer formation, maximizing corrosion resistance and ensuring compliance with ASTM A380 specifications for passive layer integrity.

Quality Assurance & Testing Protocols for Stainless Steel stamping and Stainless Steel Stamped parts and Components

Our comprehensive quality assurance program encompasses incoming material inspection, in-process monitoring, and final product verification to ensure consistent compliance with customer specifications and international quality standards. Advanced testing equipment including X-ray fluorescence spectrometers verify material composition, tensile testing machines validate mechanical properties, and salt spray chambers assess corrosion resistance characteristics according to ASTM B117 standards.

Statistical process control implementation monitors key process variables and part characteristics, enabling early detection of process variations and proactive corrective actions. Certificate of compliance documentation accompanies all shipments, providing material traceability, test results, and manufacturing process verification for critical applications requiring regulatory compliance and quality documentation.

Frequently Asked Questions on Stainless Steel stamping and Stainless Steel Stamped parts and Components

Customer Testimonial

“Working with this Indian manufacturer for our Stainless Steel stamping requirements has been exceptional. Their technical expertise, competitive pricing, and reliable delivery schedules have made them our preferred supplier for critical aerospace components. The quality consistency and excellent communication throughout our 5-year partnership has exceeded expectations. Their ability to handle complex geometries with tight tolerances while maintaining cost-effectiveness is remarkable.”

– Linda G, Procurement Manager, ********* Components Inc., USA

Why Choose Our Stainless Steel Stamping Services

🏆 Competitive Advantages & Unique Selling Propositions

Three Decades of Global Experience: Our extensive expertise spanning 30+ years in precision metal stamping has enabled us to develop specialized techniques and quality systems that consistently exceed customer expectations. This deep knowledge base allows us to solve complex manufacturing challenges and optimize production processes for maximum efficiency and quality.

Comprehensive Customization Capabilities: We offer complete design flexibility from prototype development through high-volume production, with in-house tooling design, progressive die manufacturing, and secondary operations integration. Our engineering team collaborates closely with customers to optimize part designs for manufacturability, cost reduction, and performance enhancement.

Flexible Production Scheduling: Unlike rigid production systems, we accommodate urgent delivery requirements, seasonal demand fluctuations, and custom scheduling preferences. Our adaptive manufacturing approach includes expedited tooling, priority processing, and flexible capacity allocation to meet critical project timelines.

Custom Packaging Solutions: Professional packaging services include customer logo printing, specialized protective packaging, barcoding systems, and custom labeling for direct-to-line delivery. Our packaging engineers design optimal protection strategies for international shipping while minimizing costs and environmental impact.

Superior Communication Excellence: Dedicated project managers provide regular updates, technical support, and responsive communication throughout the project lifecycle. Our multilingual technical team ensures clear understanding of specifications, timely issue resolution, and proactive project management for international customers.

Advanced Technology Integration: State-of-the-art manufacturing equipment including servo presses, robotic automation, and Industry 4.0 monitoring systems ensure consistent quality, optimal efficiency, and predictive maintenance capabilities. This technology investment translates to superior part quality and competitive pricing for our customers.

Packaging & International Shipping

Our professional packaging and logistics services ensure secure delivery of Stainless Steel stamped parts to global destinations. Standard packaging includes anti-corrosion treatments, moisture protection, impact-resistant containers, and detailed labeling for customs clearance. Specialized packaging solutions encompass clean room packaging for medical components, ESD-protective packaging for electronics, and temperature-controlled shipping for sensitive applications.

International shipping capabilities include air freight for urgent deliveries, sea freight for cost-effective bulk shipments, and consolidated shipping for multiple part numbers. Our logistics partnership network provides door-to-door delivery services, customs brokerage assistance, and shipment tracking throughout the global supply chain. Documentation services include commercial invoices, packing lists, certificates of origin, and material compliance certificates for regulatory compliance.

Performance Metrics & Continuous Improvement

Our commitment to operational excellence is demonstrated through key performance indicators including 99.5% on-time delivery, 99.8% first-pass quality rate, and 95% customer satisfaction ratings. Continuous improvement initiatives focus on lead time reduction, quality enhancement, cost optimization, and customer service excellence through lean manufacturing implementation and employee training programs.

Regular customer feedback collection and analysis drives product development, process improvements, and service enhancements that align with evolving market requirements. Performance benchmarking against industry standards ensures competitive positioning while maintaining our commitment to superior customer value and long-term partnership development.

Technical Terms Glossary

Industry Terminology & Definitions

Progressive Stamping: Multi-station die process performing sequential operations in single press stroke

Deep Drawing: Metal forming process creating hollow shapes from flat sheet material

Blanking: Cutting operation separating desired shape from sheet material

Piercing: Creating holes or openings in sheet metal using punch and die

Springback: Material tendency to return toward original shape after forming

Work Hardening: Strengthening effect from plastic deformation during stamping

Passivation: Chemical treatment enhancing corrosion resistance of Stainless Steel

Austenitic: Stainless Steel crystal structure providing non-magnetic properties

Ferritic: Magnetic Stainless Steel structure with good corrosion resistance

Martensitic: Hardened Stainless Steel structure used in cutting applications

Related Terms

Stainless steel stamping, precision metal stamping, SS 304 stamping, SS 316 stamping, custom metal stamping, progressive die stamping

Ready to discuss your Stainless Steel stamping requirements? Our technical experts are standing by to provide comprehensive solutions tailored to your specific needs.

📧 Email Quote Request

Send your drawings and specifications for detailed technical quotation

sales@brass-copper-parts. com

📱 WhatsApp Support

Instant communication for urgent requirements and technical discussions

+91-22-43449300

📞 Technical Hotline

Direct connection to our engineering team for complex projects

+91-22-43449300

📋 Download Brochure

Comprehensive capability guide with technical specifications

Download PDF Catalog

Contact us today for your free consultation and discover why leading companies worldwide trust us for their critical Stainless Steel stamping requirements. Experience the difference that three decades of precision manufacturing expertise can make for your project success!