BRASS FERRULES, BRASS PRECISION FERRULES, HOSE PIPE FERRULES, CRIMP FERRULES

Brass Ferrules – Premium Quality Brass Ferrules and Crimping Sleeves

Precision Engineered | ISO Certified | 30+ Years Excellence

Brass Ferrules – Comprehensive Overview

We are one of the leading manufacturers and exporters of Brass Ferrules, Brass Crimp Ferrules, Brass Hose Ferrules, Brass Machined Ferrules, and Brass Compression Ferrules from India. We have been supplying precision-engineered Brass Ferrules to the world market for many decades. Our extensive manufacturing capabilities encompass the complete range of ferrule types including threaded ferrules, compression ferrules, swage ferrules, and custom-designed ferrule solutions for diverse industrial applications. With state-of-the-art CNC machining centers, advanced hot forging facilities, and precision cold heading equipment, we produce Brass Ferrules that meet the most stringent international quality standards including ASTM, DIN, BS, JIS, and IS specifications. Our Brass Ferrules are manufactured from premium quality free-cutting Brass alloys, predominantly C36000 (Free Cutting Brass), which offers exceptional machinability, superior corrosion resistance, and excellent mechanical properties suitable for hydraulic systems, pneumatic applications, plumbing installations, automotive assemblies, electrical cable terminations, and fluid transfer systems. The ferrules serve as critical compression components that provide leak-proof connections, strain relief, and mechanical reinforcement when installed over hoses, pipes, tubes, or electrical cables. We offer Brass ferrules, Brass crimp ferrules, Brass olives, Brass pipe ferrules, Brass tube ferrules, Brass compression ferrules, Brass Compression olives, Brass pipe crimping ferrules from high quality Brass.

Our manufacturing facility is equipped with multi-spindle automatic lathes, Swiss-type CNC machines, progressive die stamping presses, and automated crimping machines that enable us to produce Brass Ferrules in high volumes while maintaining dimensional accuracy within ±0.02mm tolerance levels. Each ferrule undergoes rigorous quality inspection using coordinate measuring machines (CMM), optical comparators, and hardness testing equipment to ensure conformance to customer specifications and international standards. The surface finish of our Brass Ferrules ranges from 0.8 to 3.2 Ra (micrometers) depending on application requirements, and we offer various plating options including Nickel plating, Chrome plating, Tin plating, and Silver plating to enhance corrosion resistance and aesthetic appeal. Our engineering team possesses extensive expertise in custom ferrule design, prototyping, and technical consultation, enabling us to develop application-specific solutions for unique customer requirements across industries such as hydraulics, pneumatics, automotive, marine, oil and gas, chemical processing, water treatment, HVAC systems, and industrial automation.

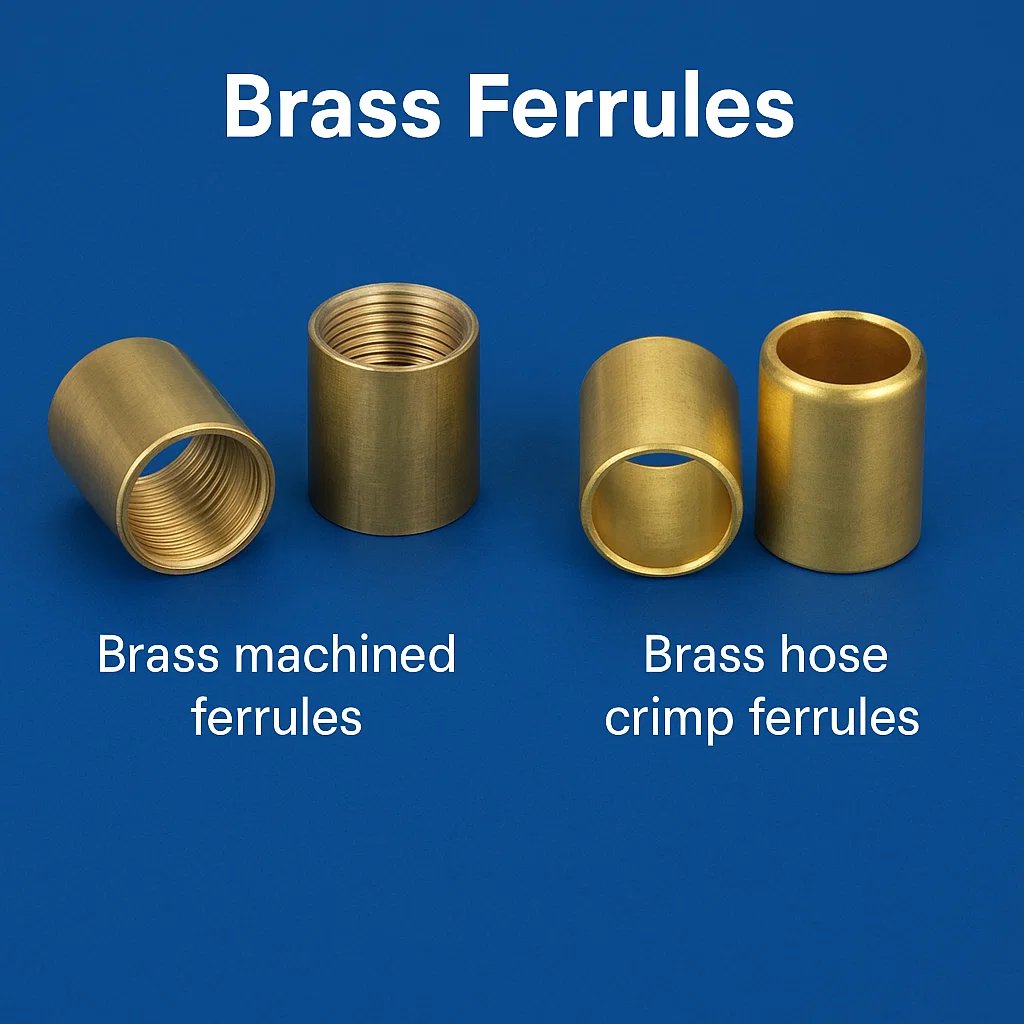

Types of Brass Ferrules We Manufacture

Brass Ferrules (Standard Compression Type): Our standard Brass Ferrules are precision-manufactured compression fittings designed to create permanent or semi-permanent mechanical connections in piping and tubing systems. These ferrules function by compressing around the outer diameter of tubes or pipes when tightened with compression nuts and body assemblies, creating a metal-to-metal seal that prevents fluid leakage under high pressure conditions. Manufactured from C36000 Free Cutting Brass, C27400 Yellow Brass, or C26000 Cartridge Brass alloys, these ferrules exhibit excellent cold working properties and can withstand operating pressures up to 3000 PSI depending on size and wall thickness. The manufacturing process involves precision CNC turning operations where Brass rod stock is automatically fed through computer-controlled lathes that perform multiple machining operations including facing, turning, grooving, chamfering, and parting-off in a single setup, ensuring concentricity within 0.01mm and maintaining consistent dimensional accuracy across production batches. These standard compression ferrules are available in imperial sizes ranging from 1/8 inch to 2 inches and metric sizes from 4mm to 50mm outer diameter, with various wall thicknesses to accommodate different pressure ratings and tube specifications.

Brass Crimp Ferrules: Brass Crimp Ferrules represent a specialized category of ferrule fittings specifically engineered for permanent crimping applications in hydraulic hose assemblies, industrial hoses, and high-pressure fluid transfer systems. Unlike compression-type ferrules, crimp ferrules are mechanically deformed using hydraulic crimping machines that apply radial compressive forces to permanently attach the ferrule to the hose outer diameter and inner reinforcement layers. Our Brass Crimp Ferrules are manufactured through a combination of hot forging and precision machining processes, where the initial ferrule shape is forged from Brass billets to achieve optimal grain structure and mechanical strength, followed by CNC machining operations to achieve final dimensional specifications and surface finish requirements. The crimp ferrule design incorporates internal serrations or gripping features that bite into the hose cover during the crimping process, creating a mechanical interlock that prevents hose blowoff under extreme pressure and temperature conditions. These ferrules are extensively used in automotive hydraulic brake lines, power steering systems, agricultural machinery hydraulic circuits, construction equipment, and industrial hydraulic power units where reliable, vibration-resistant connections are essential for safety and operational reliability.

Brass Hose Ferrules: Brass Hose Ferrules are specifically designed compression sleeves that provide reinforcement and sealing capability when connecting flexible hoses to rigid pipe fittings, barb fittings, or quick-connect couplings in fluid transfer applications. These ferrules serve the dual purpose of preventing hose collapse under vacuum conditions and providing radial compression to maintain leak-tight seals in pressurized systems. Our Brass Hose Ferrules feature precisely machined internal diameters that match standard hose outside diameters with clearances optimized for specific hose durometer hardness and wall thickness specifications. The manufacturing process utilizes high-speed Swiss-type CNC lathes capable of maintaining tight tolerances on both internal and external diameters while producing smooth surface finishes that prevent hose abrasion and premature failure. The ferrule geometry typically includes a tapered lead-in section that facilitates easy hose insertion, a parallel gripping section with optimized length-to-diameter ratio for maximum holding force, and a trailing chamfer that prevents sharp edges from cutting into hose materials. Brass Hose Ferrules find extensive application in pneumatic air tool connections, water supply lines, gas distribution systems, beverage dispensing equipment, laboratory fluid handling systems, medical gas delivery systems, and automotive cooling system hoses.

Brass Machined Ferrules: Brass Machined Ferrules represent the highest precision category of ferrule products, manufactured exclusively through CNC machining operations without any forming or forging processes, resulting in superior dimensional accuracy, excellent surface finish, and the ability to produce complex geometries with tight tolerance requirements. These ferrules are typically produced from solid Brass bar stock using multi-axis CNC turning centers equipped with live tooling capabilities that enable drilling, cross-hole machining, thread cutting, and profile turning operations in a single machine setup. The precision machining approach allows us to manufacture ferrules with internal threads (female ferrules), external threads (male ferrules), multiple diameter steps, custom groove configurations, and special features such as hex flats for wrench tightening or knurled surfaces for manual grip. Brass Machined Ferrules are manufactured to tolerances as tight as ±0.01mm on critical dimensions, with surface finishes achievable down to 0.4 Ra micrometers through precision turning with polycrystalline diamond (PCD) cutting tools or post-machining polishing operations. These high-precision ferrules are essential in applications demanding exceptional dimensional repeatability such as hydraulic manifold connections, precision instrumentation tubing, analytical equipment fluid connections, semiconductor processing gas delivery systems, pharmaceutical production equipment, and aerospace fluid control systems.

C36000 Brass Ferrules: C36000 Brass Ferrules are manufactured from the most popular free-cutting Brass alloy composition containing approximately 61.5% Copper, 35.5% Zinc, and 3% Lead, which provides optimal machinability characteristics while maintaining good mechanical strength and excellent corrosion resistance in most industrial environments. The C36000 alloy designation conforms to the Unified Numbering System (UNS) standard and is equivalent to CuZn36Pb3 (EN designation), CW614N (European standard), and JIS C3604 (Japanese standard). This alloy’s superior machinability results from the presence of Lead, which acts as a chip breaker during cutting operations, enabling high-speed machining with extended tool life and excellent surface finish without secondary operations. Our C36000 Brass Ferrules exhibit tensile strength ranging from 340 to 470 MPa, yield strength of approximately 125-310 MPa, and elongation at break of 18-30%, making them suitable for applications requiring moderate mechanical loads combined with good ductility for cold forming operations during installation. The Lead content in C36000 also provides self-lubricating properties that reduce friction during compression and assembly operations, while the high Copper content ensures good thermal conductivity and electrical conductivity for applications in electrical cable terminations and grounding systems. These ferrules are extensively used across plumbing installations, automotive fuel lines, industrial compressed air systems, hydraulic brake assemblies, and general-purpose fluid transfer applications where cost-effective, reliable performance is required.

Material Grades and International Standards

Our Brass Ferrules are manufactured from premium quality Brass alloys conforming to multiple international material specifications and standards. The material selection depends on specific application requirements including mechanical strength, corrosion resistance, machinability, and compatibility with operating fluids and environmental conditions.

| Material Grade | USA Standard (UNS/ASTM) | European Standard (EN) | British Standard (BS) | German Standard (DIN) | Japanese Standard (JIS) | Indian Standard (IS) | Composition (%) |

|---|---|---|---|---|---|---|---|

| Free Cutting Brass | C36000 / ASTM B16 | CW614N / CuZn36Pb3 | BS CZ121 | DIN 2.0401 | JIS C3604 | IS 319 Type 1 | Cu 61.5, Zn 35.5, Pb 3.0 |

| High Tensile Brass | C37700 / ASTM B124 | CW617N / CuZn40Pb2 | BS CZ122 | DIN 2.0402 | JIS C3771 | IS 319 Type 2 | Cu 58-60, Zn 38-40, Pb 2.0 |

| Yellow Brass | C27400 / ASTM B36 | CW508L / CuZn37 | BS CZ106 | DIN 2.0321 | JIS C2700 | IS 410 | Cu 63-68, Zn 32-37 |

| Cartridge Brass | C26000 / ASTM B36 | CW505L / CuZn30 | BS CZ108 | DIN 2.0265 | JIS C2600 | IS 410 | Cu 68.5-71.5, Zn 28.5-31.5 |

| Lead-Free Brass | C69300 / ASTM B283 | CW724R / CuZn21Si3P | BS CW724R | DIN 2.0920 | JIS C6932 | IS 318 | Cu 76, Zn 21, Si 3, P 0.05 |

| Naval Brass | C46400 / ASTM B21 | CW719R / CuZn39Sn1 | BS CZ112 | DIN 2.0460 | JIS C4640 | IS 4417 | Cu 60, Zn 39.2, Sn 0.8 |

| Property | Value | Unit | Test Standard |

|---|---|---|---|

| Tensile Strength | 340-470 | MPa | ASTM E8 |

| Yield Strength (0.2% offset) | 125-310 | MPa | ASTM E8 |

| Elongation at Break | 18-30 | % | ASTM E8 |

| Hardness (Brinell) | 80-120 | HB | ASTM E10 |

| Modulus of Elasticity | 97-110 | GPa | ASTM E111 |

| Density | 8.50 | g/cm³ | ASTM B311 |

| Thermal Conductivity | 115 | W/m·K | ASTM E1461 |

| Electrical Conductivity | 26 | % IACS | ASTM B193 |

| Melting Point Range | 885-905 | °C | DSC Analysis |

| Coefficient of Thermal Expansion | 20.5 | μm/m·K | ASTM E228 |

Manufacturing Processes and Machinery

Our advanced manufacturing facility employs multiple precision manufacturing processes and state-of-the-art machinery to produce Brass Ferrules with exceptional dimensional accuracy, superior surface finish, and consistent quality. The selection of manufacturing process depends on ferrule complexity, production volume requirements, dimensional tolerances, and specific customer specifications.

CNC Precision Turning: Our primary manufacturing process utilizes computer numerical control (CNC) turning centers equipped with multi-spindle capabilities and automatic bar feeding systems. These machines include Swiss-type CNC lathes with sliding headstock design that provides exceptional rigidity during machining operations, enabling us to maintain tolerances within ±0.01mm on critical dimensions while achieving surface finishes of 0.4 to 1.6 Ra micrometers. The CNC turning process begins with precision-ground Brass bar stock automatically fed through the spindle collet, where multiple carbide cutting tools perform simultaneous machining operations including rough turning, finish turning, grooving, threading, chamfering, and cut-off operations. Our CNC machines are equipped with high-pressure coolant systems that flush chips away from the cutting zone and provide lubrication to extend tool life and improve surface finish. The automated bar feeding systems enable continuous production runs with minimal operator intervention, while integrated quality monitoring systems use laser micrometers and in-process gauging to verify dimensional accuracy throughout production.

Hot Forging and Cold Heading: For high-volume production of Brass Crimp Ferrules and standard compression ferrules, we employ hot forging and cold heading processes that offer superior mechanical properties and material efficiency compared to machining operations. The hot forging process involves heating Brass billets to temperatures between 650-750°C in controlled atmosphere furnaces, then transferring them to closed-die forging presses where pneumatic or hydraulic hammers force the softened metal to flow into precision-machined die cavities that form the basic ferrule shape. This process creates favorable grain flow patterns that enhance mechanical strength and fatigue resistance, particularly important for crimp ferrules subjected to high radial compression forces during assembly. After forging, the ferrules undergo annealing heat treatment to relieve residual stresses, followed by precision machining operations to achieve final dimensional specifications and surface finish requirements. Cold heading operations are performed on multi-station progressive headers that progressively form ferrule shapes from Brass wire or rod stock through a series of dies and punches, creating net-shape or near-net-shape components that require minimal secondary machining.

Precision Stamping and Deep Drawing: For thin-walled Brass Hose Ferrules and sleeve-type ferrules, we utilize precision stamping and deep drawing processes on progressive die stamping presses with tonnage capacities ranging from 50 to 500 tons. The stamping process begins with Brass strip or sheet material fed through a series of progressive die stations that perform blanking, piercing, forming, and trimming operations in a synchronized sequence. Deep drawing operations utilize specialized tooling to convert flat Brass blanks into cylindrical ferrule shapes through controlled material flow, where the punch forces the blank through a die cavity while blank holder forces prevent wrinkling and maintain uniform wall thickness. Our stamping operations achieve dimensional tolerances of ±0.05mm and can produce ferrules with wall thicknesses ranging from 0.3mm to 3.0mm depending on material grade and ferrule diameter. The stamped ferrules undergo secondary operations including deburring, tumbling, and surface treatment to remove sharp edges and achieve specified surface finish.

| Machine Type | Specifications | Capacity | Application |

|---|---|---|---|

| Swiss-Type CNC Lathe | 8-Axis, Live Tooling, Bar Capacity 42mm | 15 Machines | Precision Machined Ferrules |

| Multi-Spindle Automatic Lathe | 6-Spindle, 32mm Bar Capacity | 10 Machines | High Volume Standard Ferrules |

| CNC Turning Center | 2-Axis, Chuck Size 200mm, Bar Feeder | 12 Machines | Large Diameter Ferrules |

| Hot Forging Press | 200-500 Ton Capacity, Closed Die | 5 Units | Crimp Ferrules, High Strength Parts |

| Cold Header | 4-Station Progressive, 16mm Wire | 8 Machines | Net-Shape Ferrule Formation |

| Progressive Stamping Press | 50-200 Ton, High-Speed Operation | 6 Presses | Thin-Wall Hose Ferrules |

| Thread Rolling Machine | Flat Die, M3-M24 Capacity | 4 Machines | External Thread Generation |

| Hydraulic Crimping Machine | 200-600 Bar Pressure, Die Sets | 3 Units | Sample Testing, Validation |

| Size (Tube OD) | Ferrule ID (mm) | Ferrule OD (mm) | Length L (mm) | Wall Thickness (mm) | Weight (g) |

|---|---|---|---|---|---|

| 1/8″ (3.18mm) | 3.20 ± 0.05 | 6.35 ± 0.05 | 8.0 ± 0.2 | 1.55 | 1.2 |

| 1/4″ (6.35mm) | 6.40 ± 0.05 | 9.53 ± 0.05 | 10.0 ± 0.2 | 1.55 | 2.8 |

| 3/8″ (9.53mm) | 9.58 ± 0.05 | 12.70 ± 0.08 | 12.0 ± 0.2 | 1.55 | 5.2 |

| 1/2″ (12.70mm) | 12.75 ± 0.08 | 15.88 ± 0.08 | 14.0 ± 0.2 | 1.55 | 8.5 |

| 5/8″ (15.88mm) | 15.93 ± 0.08 | 19.05 ± 0.10 | 16.0 ± 0.3 | 1.55 | 12.5 |

| 3/4″ (19.05mm) | 19.10 ± 0.10 | 22.23 ± 0.10 | 18.0 ± 0.3 | 1.55 | 17.2 |

| 1″ (25.40mm) | 25.45 ± 0.10 | 28.58 ± 0.10 | 22.0 ± 0.3 | 1.55 | 28.5 |

Plating Finishes and Surface Treatments

To enhance corrosion resistance, improve aesthetic appearance, and provide additional functional properties, our Brass Ferrules are available with various electroplating and surface treatment options. The selection of plating finish depends on application environment, compatibility with mating materials, electrical conductivity requirements, and customer preferences.

Nickel Plating: Electroless Nickel plating or electrolytic Nickel plating provides excellent corrosion protection and uniform coating thickness even on complex ferrule geometries. The typical Nickel plating thickness ranges from 5 to 15 micrometers, conforming to ASTM B733 specifications. Nickel-plated Brass Ferrules exhibit superior resistance to atmospheric corrosion, moisture, and mild chemical environments while maintaining good electrical conductivity and solderability. The bright Nickel finish also provides an attractive silvery appearance preferred in visible plumbing installations and decorative applications.

Chrome Plating: Decorative Chrome plating over a Nickel undercoat provides the highest level of corrosion resistance and an extremely hard, wear-resistant surface with brilliant reflective appearance. The multi-layer plating system typically consists of 8-12 micrometers Nickel undercoat followed by 0.25-0.5 micrometers Chromium top coat, meeting ASTM B456 requirements. Chrome-plated ferrules are specified for marine applications, outdoor installations, and high-humidity environments where maximum corrosion protection is essential.

Tin Plating: Tin plating offers excellent solderability, good corrosion resistance, and non-toxic properties making it ideal for potable water applications and food-grade fluid systems. The Tin coating thickness ranges from 2 to 8 micrometers conforming to ASTM B545 specifications. Tin-plated Brass Ferrules provide superior protection against dezincification corrosion in chlorinated water systems while maintaining compliance with NSF/ANSI 61 drinking water system components standard and European Drinking Water Directive requirements.

Silver Plating: Silver plating provides the highest electrical and thermal conductivity among all plating options, making it essential for electrical cable ferrules and grounding applications. The Silver coating thickness typically ranges from 3 to 10 micrometers meeting ASTM B700 specifications. Silver-plated ferrules offer excellent oxidation resistance, maintain low contact resistance over extended service periods, and provide superior current-carrying capacity in electrical termination applications.

| Plating Type | Thickness (μm) | Standard | Hardness | Corrosion Resistance | Primary Applications |

|---|---|---|---|---|---|

| Bright Nickel | 5-15 | ASTM B733, ISO 1458 | 450-600 HV | Excellent | General Industrial, Automotive |

| Electroless Nickel | 8-20 | ASTM B733, MIL-C-26074 | 500-700 HV | Superior | Uniform Coating, Complex Shapes |

| Decorative Chrome | 0.25-0.5 (over Ni) | ASTM B456, ISO 1456 | 800-1000 HV | Outstanding | Marine, Outdoor, Decorative |

| Tin (Matte) | 2-8 | ASTM B545, EN 12540 | 20-40 HV | Good | Potable Water, Food Grade |

| Silver | 3-10 | ASTM B700, MIL-DTL-13508 | 80-120 HV | Very Good | Electrical, High Conductivity |

| Zinc (Yellow Chromate) | 5-12 | ASTM B633, ISO 2081 | 90-120 HV | Moderate | Low-Cost Protection |

| Passivation (Natural) | < 0.1 | AMS 2700, ASTM B858 | N/A | Good | Maintains Brass Appearance |

Industries and Applications

Our Brass Ferrules serve critical functions across numerous industries worldwide, providing reliable compression fittings, cable terminations, and hose connections in diverse operating environments ranging from cryogenic temperatures to elevated temperature conditions up to 150°C.

Hydraulic and Pneumatic Systems: Brass Ferrules are extensively used in industrial hydraulic power units, mobile hydraulic equipment, pneumatic control systems, and compressed air distribution networks where they provide leak-tight connections capable of withstanding system pressures up to 3000 PSI and vibration-induced fatigue loads. The ferrules connect hydraulic hoses to pumps, valves, actuators, and manifolds in construction machinery, agricultural equipment, material handling systems, and manufacturing automation.

Plumbing and Water Supply: In residential and commercial plumbing installations, Brass Ferrules create secure connections in water supply lines, shutoff valves, faucet assemblies, toilet supply lines, and water heater connections. The ferrules’ resistance to dezincification corrosion and compatibility with potable water regulations make them ideal for municipal water distribution systems, building plumbing networks, and water treatment facilities.

Automotive and Transportation: Automotive applications include brake line ferrules, fuel line connections, power steering hose assemblies, air conditioning refrigerant lines, and engine coolant system connections where the ferrules withstand temperature cycling, vibration exposure, and aggressive fluid environments throughout vehicle operating life. Heavy-duty truck hydraulic brake systems, railway air brake circuits, and marine vessel hydraulic steering systems rely on precision Brass Ferrules for safety-critical connections.

Oil and Gas Industry: Upstream oil and gas operations utilize Brass Ferrules in instrumentation tubing, hydraulic control lines, chemical injection systems, and wellhead connections where corrosion resistance and pressure integrity are essential for safe operation in harsh offshore and onshore production environments. Midstream pipeline facilities employ ferrules in meter runs, sampling systems, and process analyzers.

Chemical Processing and Pharmaceutical: Chemical plants and pharmaceutical manufacturing facilities specify Brass Ferrules for process piping connections, dosing pump installations, analytical sampling lines, and clean utility systems where the Brass material’s compatibility with process chemicals and ability to maintain sterile conditions are critical requirements. The smooth internal surface finish prevents bacterial growth and facilitates cleaning validation protocols.

HVAC and Refrigeration: Heating, ventilation, air conditioning, and refrigeration systems incorporate Brass Ferrules in refrigerant line connections, condensate drain lines, hot water heating piping, and chilled water distribution systems. The ferrules provide vibration-resistant connections that maintain seal integrity throughout seasonal temperature variations and continuous thermal cycling experienced in building climate control systems.

Marine and Offshore: Maritime applications demand Brass Ferrules with enhanced corrosion resistance through specialized plating finishes to withstand saltwater spray, high humidity, and corrosive marine atmospheres. Naval Brass ferrules containing Tin addition provide superior resistance to dezincification in seawater cooling systems, ballast lines, and deck washing systems aboard commercial vessels and military ships.

Electrical and Electronics: Wire rope ferrules and cable end ferrules manufactured from Brass provide secure mechanical terminations for multi-strand electrical cables, control wiring, grounding conductors, and communication cables. The crimped Brass Ferrules ensure reliable electrical continuity, prevent wire fraying, and facilitate insertion into terminal blocks and connectors in control panels, switchgear assemblies, and industrial automation systems.

Tolerances and Quality Standards

Our Brass Ferrules are manufactured to meet stringent dimensional tolerances and quality specifications conforming to international standards including ISO 9001:2015 quality management system, ISO 14001:2015 environmental management, and IATF 16949:2016 automotive quality management for ferrules supplied to automotive manufacturers.

Dimensional Tolerances: Standard production tolerances for Brass Ferrules maintain external diameter dimensions within ±0.05mm for sizes up to 25mm OD and ±0.08mm for larger sizes up to 50mm OD. Internal diameter tolerances are held to ±0.05mm for precision-fit applications requiring minimal clearance with mating tubes. Length dimensions are maintained within ±0.2mm for ferrules up to 25mm length and ±0.3mm for longer ferrules. Wall thickness uniformity is controlled to ±0.10mm to ensure consistent compression characteristics and pressure ratings. For critical applications requiring tighter tolerances, we offer precision-grade ferrules manufactured to ±0.02mm on critical dimensions using Swiss-type CNC lathes with in-process gauging systems.

Surface Finish Requirements: The external surface finish of machined Brass Ferrules typically ranges from 1.6 to 3.2 Ra micrometers for standard commercial grade ferrules, while precision-grade ferrules achieve 0.8 to 1.6 Ra surface finish through fine turning with polycrystalline diamond tooling or post-machining polishing operations. Internal bore surface finish is maintained between 1.6 to 2.5 Ra micrometers to facilitate smooth tube insertion and prevent damage to soft tubing materials such as nylon, polyethylene, and fluoropolymer tubes. The surface finish is verified using portable surface roughness testers calibrated to ISO 4287 standards.

Geometric Tolerances: Concentricity between internal and external diameters is maintained within 0.05mm total indicator reading (TIR) to ensure uniform wall thickness and prevent eccentric loading during compression. Perpendicularity of end faces relative to the ferrule axis is held within 0.05mm per 10mm of diameter to ensure proper seating in compression fittings and prevent cocking during assembly. Cylindricity of both internal and external surfaces is controlled to 0.03mm to maintain consistent compression behavior and seal integrity across the ferrule length.

Material Certification and Testing: Each production lot of Brass Ferrules is accompanied by material test certificates verifying chemical composition through optical emission spectrometry (OES) analysis conforming to ASTM E415 standards. Mechanical property testing includes tensile strength verification per ASTM E8, hardness testing per ASTM E18 (Rockwell) or ASTM E10 (Brinell), and elongation measurement to confirm material ductility requirements. For pressure-critical applications, representative samples undergo hydrostatic pressure testing to 1.5 times the rated working pressure to verify structural integrity and leak-tightness.

| Parameter | Standard Grade Tolerance | Precision Grade Tolerance | Measurement Method |

|---|---|---|---|

| External Diameter (≤25mm) | ± 0.05 mm | ± 0.02 mm | Micrometer, Optical Comparator |

| Internal Diameter | ± 0.05 mm | ± 0.02 mm | Pin Gauge, Air Gauge |

| Overall Length | ± 0.2 mm | ± 0.1 mm | Digital Caliper, Height Gauge |

| Wall Thickness | ± 0.10 mm | ± 0.05 mm | Ultrasonic Thickness Gauge |

| Concentricity (TIR) | 0.05 mm | 0.02 mm | CMM, Roundness Tester |

| Surface Finish (External) | 1.6-3.2 Ra μm | 0.8-1.6 Ra μm | Surface Roughness Tester |

| Perpendicularity | 0.05 mm per 10mm Ø | 0.03 mm per 10mm Ø | CMM, Angle Plate |

| Thread Accuracy (if applicable) | ISO 2768-mK | ISO 2768-fK | Thread Gauges, Profile Projector |

Turnaround Time and Production Capacity

Our manufacturing facility operates on efficient production scheduling systems that balance quick turnaround requirements with quality assurance protocols to deliver Brass Ferrules within 4 to 6 weeks from purchase order confirmation for standard product specifications and material grades. This lead time encompasses raw material procurement from certified Brass mill suppliers, production setup and machining operations, quality inspection procedures, surface treatment or plating operations when specified, final packaging, and preparation for shipment.

For urgent requirements or rapid prototype development, we offer expedited production services with turnaround times reduced to 2 to 3 weeks for limited quantity orders of standard ferrule configurations manufactured from in-stock raw materials. Rush orders receive priority scheduling on our CNC machining centers and bypass queue times in the normal production workflow, though expedited service may incur additional charges of 15-25% depending on order complexity and quantity requirements.

Large volume production runs exceeding 50,000 pieces benefit from economies of scale in raw material purchasing, dedicated machine setup allocation, and optimized production scheduling that can accommodate delivery schedules synchronized with customer assembly line requirements or just-in-time inventory management systems. Our annual production capacity exceeds 15 million Brass Ferrules across all size ranges and configurations, with flexible capacity allocation that can respond to seasonal demand fluctuations and urgent project requirements.

Custom-designed ferrules requiring engineering development, prototype fabrication, and tooling manufacture typically require 8 to 12 weeks for initial production orders, which includes 2-3 weeks for design finalization and technical drawing approval, 3-4 weeks for tooling manufacture and setup validation, 1-2 weeks for first article inspection and dimensional verification, and 2-3 weeks for production run completion. Subsequent repeat orders of approved custom designs revert to the standard 4 to 6 week turnaround time.

Performance Metrics and Technical Specifications

| Performance Parameter | Specification/Value | Test Standard |

|---|---|---|

| Maximum Working Pressure (Compression Type) | Up to 3000 PSI (207 Bar) | ASTM B117, ISO 4414 |

| Burst Pressure (Minimum) | 4 x Working Pressure | ISO 1402, SAE J343 |

| Operating Temperature Range | -40°C to +150°C (-40°F to +302°F) | ASTM D2837 |

| Crimp Force Required (6mm Ferrule) | 800-1200 kg | Manufacturer Test Protocol |

| Pull-Out Force (After Crimping) | > 2000 N for 1/4″ size | ISO 4640 |

| Leak Rate (Helium Test) | < 1 x 10⁻⁶ mbar·l/s | ISO 3601, ASTM E493 |

| Vibration Resistance | 50 Hz, 5g, 100 hours no failure | MIL-STD-810G, ISO 16750 |

| Corrosion Resistance (Salt Spray) | 200+ hours (Nickel plated) | ASTM B117, ISO 9227 |

| Pressure Cycle Life | 100,000+ cycles (0-2000 PSI) | ISO 6803 |

| Electrical Conductivity (Silver plated) | > 90% IACS | ASTM B193 |

Comprehensive Questions and Answers

Why Choose Our Brass Ferrules

Three Decades of Global Manufacturing Excellence: With over 30 years of continuous operation as a premier Brass Ferrule manufacturer and exporter from India, we have accumulated unparalleled expertise in precision machining, material science, and customer collaboration that translates directly into superior product quality and reliable delivery performance. Our long-standing relationships with international customers across North America, Europe, Australia, and Asia Pacific regions demonstrate our commitment to building partnerships based on trust, technical competence, and consistent quality delivery.

Comprehensive Customization Capabilities: Unlike suppliers limited to standard catalog products, we offer extensive customization flexibility encompassing custom dimensions, special thread configurations, unique internal features, proprietary material specifications, and application-specific design modifications. Our in-house design engineering team collaborates with customers from concept through production, providing technical consultation, design optimization recommendations, prototype fabrication, and manufacturing process development tailored to unique requirements.

Flexible Production Scheduling: We understand that project timelines and production requirements vary significantly across industries and applications. Our manufacturing planning system accommodates flexible production scheduling including phased deliveries synchronized with customer assembly schedules, blanket purchase orders with scheduled releases, just-in-time inventory management, and consignment stock arrangements that optimize customer working capital while ensuring material availability. Rush order capabilities and expedited production services provide solutions for urgent requirements without compromising quality standards.

Superior Communication and Responsive Service: Our multilingual sales and technical support team maintains proactive communication throughout order processing, production, and delivery stages ensuring customers remain informed about order status, production progress, and any technical considerations requiring attention. We respond to technical inquiries within 24 hours and provide prompt quotations typically within 48 hours of receiving detailed specifications. Our commitment to transparent communication eliminates uncertainty and builds confidence in our partnership.

Advanced Quality Assurance Systems: ISO 9001:2015 certified quality management systems govern every aspect of our operations from material procurement through final inspection and shipment. Statistical process control methodologies, calibrated inspection equipment traceable to national standards, comprehensive first article inspection protocols, and detailed material test certificates ensure customers receive Brass Ferrules conforming precisely to specifications. Our quality documentation includes dimensional inspection reports, material composition verification, mechanical property test results, and traceability records meeting the most stringent customer requirements.

Competitive Pricing with Consistent Value: Manufacturing operations based in India combined with strategic raw material sourcing relationships enable us to offer highly competitive pricing without compromising quality standards or delivery reliability. Volume purchase commitments benefit from progressive pricing discounts, and our transparent quotation structure clearly identifies material costs, processing charges, finishing operations, and packaging expenses eliminating hidden fees or unexpected charges. Long-term supply agreements can incorporate price stability provisions protecting customers from volatile raw material market fluctuations.

Comprehensive Technical Support: Beyond manufacturing excellence, we provide ongoing technical support including ferrule selection guidance, application engineering consultation, installation procedure recommendations, troubleshooting assistance for field performance issues, and failure analysis services when required. Our technical library includes detailed product specifications, material property data, installation instructions, and application guidelines freely available to customers supporting successful implementation of our Brass Ferrules in diverse applications.

Environmental and Social Responsibility: ISO 14001:2015 environmental management certification demonstrates our commitment to sustainable manufacturing practices including responsible raw material sourcing, energy-efficient production processes, waste minimization initiatives, and compliance with international environmental regulations including RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization of Chemicals) requirements. Our workplace safety programs and fair labor practices reflect our dedication to ethical business operations and positive social impact.

Packaging and Shipping

Our comprehensive packaging solutions ensure Brass Ferrules arrive at customer facilities in pristine condition regardless of transportation mode or distance traveled. Standard packaging utilizes heavy-duty corrugated carton boxes with internal foam cushioning or molded pulp inserts that prevent movement and protect ferrules from impact damage during handling and transit. Each carton is labeled with complete product identification including part number, quantity, material specification, and customer purchase order reference facilitating efficient receiving and inventory management.

For ferrules requiring extended storage periods or exposure to humid environments during ocean freight transit, we offer VCI (Volatile Corrosion Inhibitor) packaging incorporating specialized plastic bags or treated paper materials that release corrosion-inhibiting vapor molecules creating a protective atmosphere around Brass surfaces preventing oxidation and tarnishing without direct contact or residue. Export packaging conforms to ISPM 15 international standards for wood packaging materials using heat-treated lumber free from bark and insects.

Bulk quantity shipments utilize wooden pallets or plywood crates secured with industrial-grade plastic strapping and stretch wrap protecting contents from moisture and contamination. Pallet configurations are optimized for standard shipping container dimensions maximizing load efficiency and minimizing freight costs. For smaller orders or sample quantities, we utilize express courier services including DHL, FedEx, and UPS with door-to-door delivery and online shipment tracking capabilities ensuring rapid transit and delivery confirmation.

Custom packaging solutions accommodate specific customer requirements including custom-printed labels with barcodes for automated inventory scanning, divided packaging with multiple part numbers consolidated in single shipments reducing freight charges, returnable plastic totes for closed-loop packaging systems, and point-of-use packaging configured for automated assembly line feeding mechanisms. We maintain flexibility to adapt packaging specifications supporting customer-specific logistics systems and inventory management practices.

Customer Testimonials

Glossary of Technical Terms

Brass: A copper-zinc alloy typically containing 55-95% Copper and varying percentages of Zinc, exhibiting excellent machinability, corrosion resistance, and aesthetic appeal suitable for decorative and functional applications including plumbing fittings, electrical components, and musical instruments.

Compression Ferrule: A cylindrical ring or sleeve component used in compression-type tube fittings that compresses around the tube outer diameter when a compression nut is tightened, creating a mechanical seal preventing fluid leakage at the tube-fitting interface.

Crimp Ferrule: A tubular fitting component that is mechanically deformed using specialized crimping equipment to permanently attach to flexible hoses, creating a secure connection resistant to pressure and vibration loads typical in hydraulic and pneumatic applications.

C36000 Brass (Free Cutting Brass): A leaded Brass alloy containing approximately 61.5% Copper, 35.5% Zinc, and 3% Lead, providing exceptional machinability characteristics enabling high-speed production with excellent surface finish and extended cutting tool life.

Dezincification: A selective corrosion mechanism affecting Brass alloys in aggressive water environments where Zinc preferentially dissolves from the alloy structure leaving behind weak, porous Copper-rich material with significantly degraded mechanical strength.

CNC (Computer Numerical Control): Automated machining technology utilizing computer programming to control machine tool movements enabling precision manufacturing of complex geometries with tight tolerances and excellent repeatability across production quantities.

Swiss-Type Lathe: A specialized CNC turning machine featuring a sliding headstock design that supports workpieces near the cutting zone providing exceptional rigidity enabling production of small-diameter, high-precision components with tight tolerances and superior surface finish.

Hot Forging: A metalworking process involving heating metal above its recrystallization temperature and shaping it through compressive forces in dies or hammers, producing components with favorable grain flow patterns and enhanced mechanical properties.

Cold Heading: A high-speed metal forming process performed at room temperature where wire or rod material is progressively shaped through a series of dies and punches creating net-shape or near-net-shape components requiring minimal secondary machining.

Ra (Roughness Average): A numerical parameter expressing surface finish quality measured in micrometers representing the arithmetic average of surface profile deviations from the mean line, with lower values indicating smoother surfaces.

TIR (Total Indicator Reading): A measurement of geometric deviation such as concentricity or runout expressed as the total range of indicator movement when a part is rotated in a precision fixture, quantifying how far a surface varies from ideal geometric form.

Electroplating: An electrochemical process depositing metallic coatings onto component surfaces using electric current to reduce metal ions from solution onto the substrate, providing corrosion protection, wear resistance, or aesthetic enhancement.

Naval Brass: A corrosion-resistant Brass alloy containing approximately 60% Copper, 39% Zinc, and 1% Tin exhibiting superior resistance to dezincification and seawater corrosion making it ideal for marine applications and saltwater environments.

Compression Fitting: A mechanical pipe or tube connection system utilizing a compression nut, ferrule, and body assembly to create leak-tight seals through radial compression without requiring welding, soldering, or threading operations.

Hydraulic Crimping: A process using hydraulic-powered crimping machines to permanently deform ferrules or fittings onto hose assemblies by applying radial compressive forces through precision dies, creating connections capable of withstanding high operating pressures.

ASTM (American Society for Testing and Materials): An international standards organization developing and publishing technical standards for materials, products, systems, and services covering everything from material composition specifications to testing methodologies and performance requirements.

ISO (International Organization for Standardization): A worldwide federation of national standards bodies developing international standards covering manufacturing, technology, safety, quality management, and environmental management systems facilitating global trade and ensuring product quality.

CMM (Coordinate Measuring Machine): A precision measurement device utilizing electronic probes to determine three-dimensional coordinates of points on component surfaces enabling accurate verification of complex geometries and tight tolerances in manufactured parts.

Related Parts:

Product-Related Terms: Brass compression sleeve, Brass tube ferrules, Brass pipe ferrules, Brass cable ferrules, Brass wire rope ferrules, Brass hose sleeves, Brass swage ferrules, Brass crimping ferrules, Brass olives ), Brass compression rings, Brass tube end fittings, Brass ferrule fittings, Brass reducing ferrules, Brass threaded ferrules, Brass hex ferrules, Brass knurled ferrules.

Material-Specific Terms: Free Cutting Brass ferrules, C36000 ferrules, CW614N ferrules, Yellow Brass ferrules, Cartridge Brass ferrules, Naval Brass ferrules, Lead-Free Brass ferrules, Silicon Brass ferrules, High tensile Brass ferrules, CuZn36Pb3 ferrules.

Application-Specific Terms: Hydraulic ferrules, Pneumatic ferrules, Plumbing ferrules, Brake line ferrules, Fuel line ferrules, Water line ferrules, Gas line ferrules, Automotive ferrules, Marine ferrules, Industrial hose ferrules, Instrumentation ferrules, Tube fitting ferrules.

Process-Related Terms: CNC machined ferrules, Forged Brass ferrules, Cold headed ferrules, Precision turned ferrules, Swiss machined ferrules, Stamped Brass ferrules, Compression ferrule manufacturer, Crimp ferrule supplier.

Finish-Specific Terms: Nickel plated ferrules, Chrome plated ferrules, Tin plated ferrules, Silver plated ferrules, Zinc plated ferrules, Passivated Brass ferrules, Polished Brass ferrules.

Standard-Specific Terms: ASTM B16 ferrules, DIN 2353 ferrules, ISO 8434 ferrules, SAE J514 ferrules, BS 5200 ferrules, Metric ferrules, Imperial ferrules, Standard compression ferrules, Flared tube ferrules.

Geographic and Commercial:: Brass ferrule manufacturer India, Brass ferrule exporter, Custom Brass ferrules, OEM Brass ferrules, Brass ferrule supplier, Bulk Brass ferrules, Wholesale Brass ferrules, Precision Brass ferrules, Quality Brass ferrules, Certified Brass ferrules.

Ready to Order Premium Quality Brass Ferrules?

Experience the difference of working with a manufacturer that combines 30+ years of expertise with cutting-edge technology and customer-focused service.

Contact Us Today

📧 Email: sales@brass-copper-parts.com

📱 WhatsApp: +91-22-43449300

📞 Phone: +91-22-43449300

🏭 Manufacturing Facility: Jamnagar, India

We respond to all inquiries within 24 hours and provide detailed quotations within 48 hours.

Our multilingual team is ready to assist you in English, German, French, Spanish, and other languages.

© 2025 Brass & Copper Parts India. All Rights Reserved.

ISO 9001:2015 | ISO 14001:2015 | IATF 16949:2016 Certified

Premium Quality Brass Ferrules | Manufactured in India | Exported Worldwide