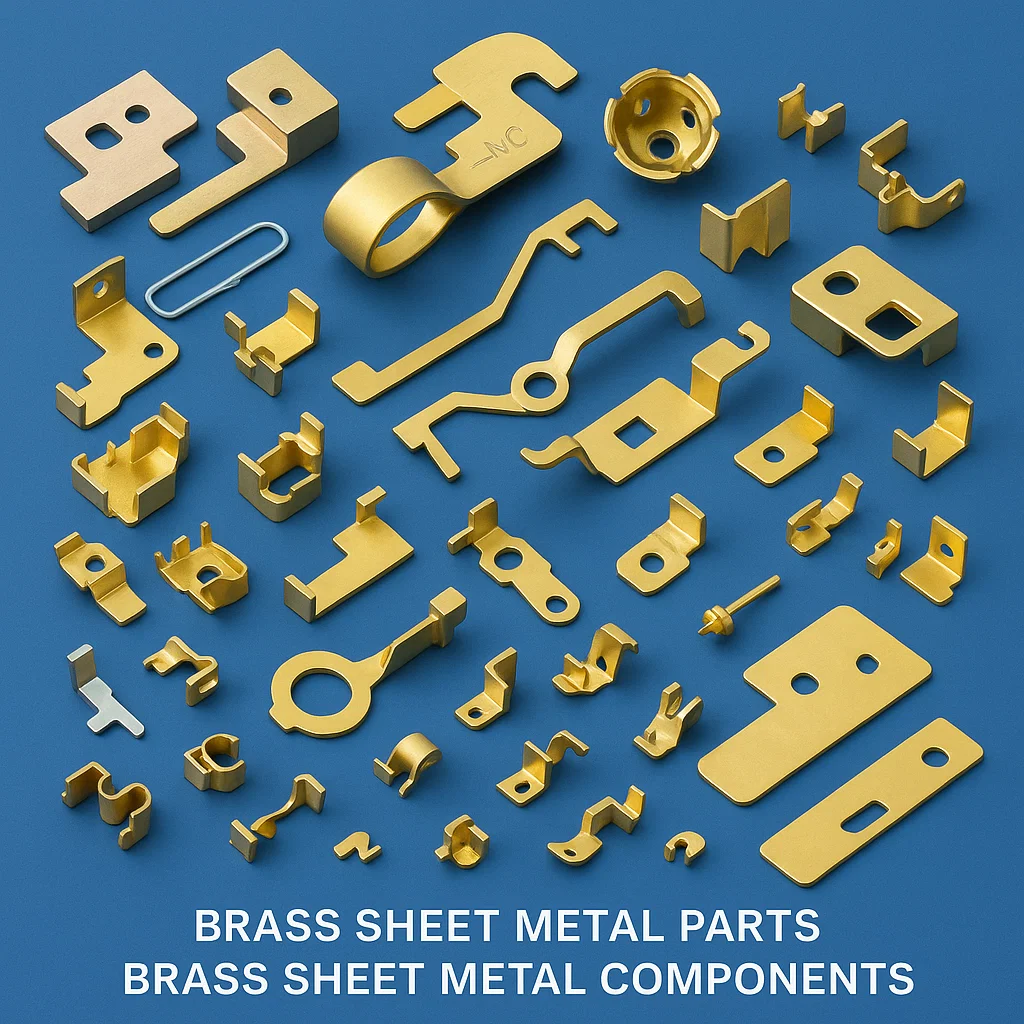

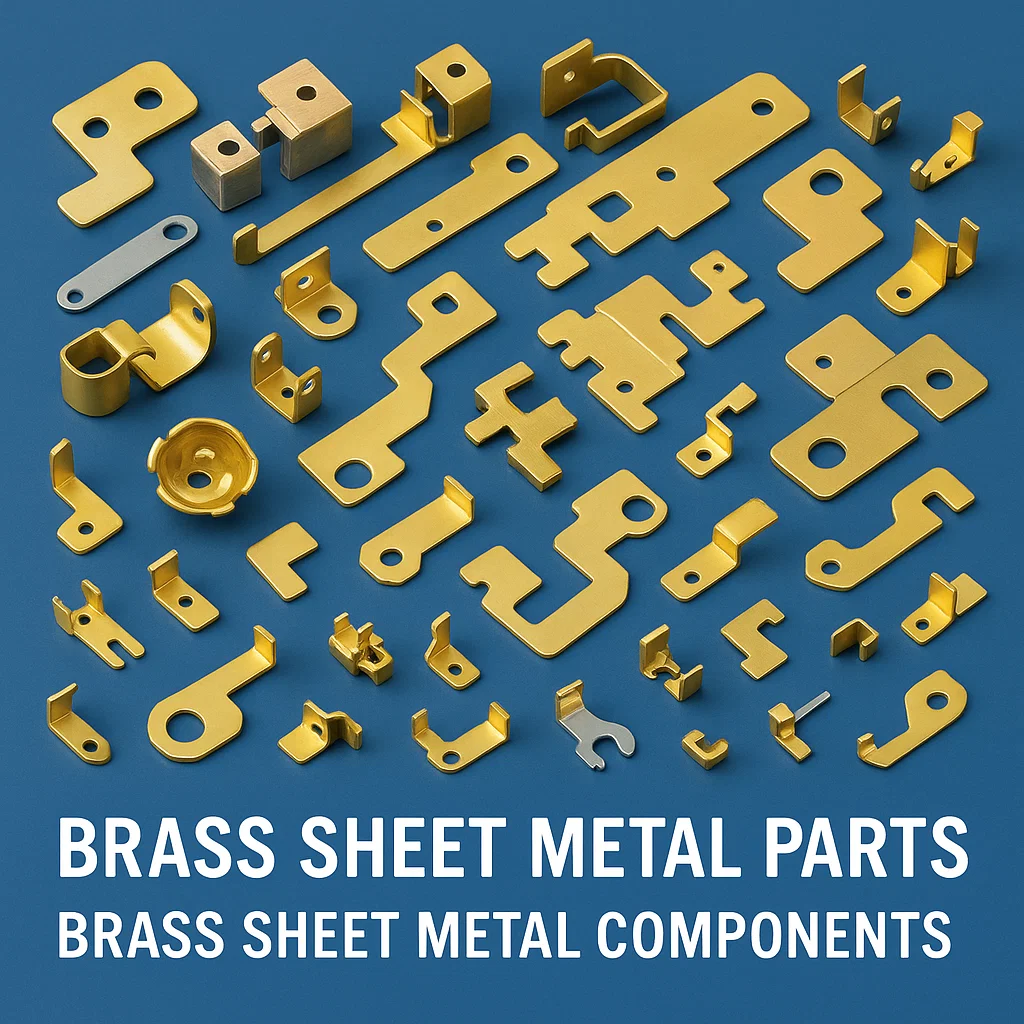

Brass Sheet Metal Parts and Brass Sheet Metal Components

Brass sheet metal parts and brass sheet metal components represent some of the most versatile and reliable solutions in modern manufacturing. With their exceptional combination of durability, corrosion resistance, and aesthetic appeal, brass sheet metal fabrications continue to play crucial roles across numerous industries worldwide.

Understanding Brass Sheet Metal Parts

Brass sheet metal parts are precision-manufactured components created from flat brass sheets through various forming, cutting, and finishing processes. These brass sheet metal components offer superior mechanical properties, making them ideal for applications requiring both functional performance and visual appeal. The malleability of brass allows manufacturers to create complex geometries while maintaining structural integrity.

Common Types of Brass Sheet Metal Parts

Architectural Hardware Components

- Decorative panels and cladding systems

- Door handles, hinges, and lock components

- Window hardware and frame elements

- Balustrade components and handrails

- Ornamental brackets and fixtures

Electrical and Electronic Components

- Electrical terminals and connectors

- Circuit board components and shields

- Switchgear housings and panels

- Grounding straps and bus bars

- Precision electronic enclosures

Industrial Brass Components

- Heat exchanger plates and fins

- Valve bodies and actuator components

- Bearing housings and mechanical assemblies

- Pump components and impellers

- Filter screens and perforated panels

Marine and Plumbing Applications

- Pipe fittings and flanges

- Marine hardware and deck fittings

- Plumbing fixtures and valve components

- Propeller components and shaft housings

- Corrosion-resistant fasteners

Manufacturing Processes for Brass Sheet Metal Components

Precision Cutting Methods

Laser Cutting: Provides exceptional accuracy for intricate brass sheet metal parts, enabling tight tolerances and smooth edge finishes without heat-affected zones.

Waterjet Cutting: Ideal for thicker brass sheets, delivering precise cuts without thermal distortion, perfect for critical brass sheet metal components.

Plasma Cutting: Cost-effective solution for larger brass components requiring quick processing times.

Forming and Shaping Processes

Press Brake Forming: Creates precise bends and angles in brass sheet metal parts, essential for brackets, enclosures, and structural components.

Roll Forming: Continuous process for producing consistent cross-sectional profiles in brass components.

Deep Drawing: Transforms flat brass sheets into complex three-dimensional components like housings and containers.

Stamping and Punching: High-volume production method for creating repetitive brass sheet metal parts with consistent quality.

Finishing Operations

Polishing and Buffing: Enhances the natural luster of brass components for decorative applications.

Plating and Coating: Adds protective layers or aesthetic finishes to brass sheet metal parts.

Deburring and Edge Finishing: Ensures smooth, safe edges on all brass components.

Grades of Brass for Sheet Metal Applications

C26000 Cartridge Brass (70/30)

The most common brass alloy for sheet metal work, containing 70% copper and 30% zinc. This grade offers excellent cold working properties, making it ideal for deep drawing operations and complex brass sheet metal components. Applications include cartridge cases, lamp fixtures, and decorative hardware.

C36000 Free-Cutting Brass

Contains lead additives that improve machinability, perfect for brass components requiring secondary machining operations. Commonly used for precision fittings, valve components, and threaded brass parts.

C46400 Naval Brass

Enhanced with tin for superior corrosion resistance, particularly in marine environments. This grade is essential for brass sheet metal parts exposed to saltwater conditions, including marine hardware and offshore equipment components.

C28000 Muntz Metal

A 60/40 copper-zinc alloy offering increased strength and reduced cost compared to higher copper content brasses. Suitable for architectural applications and large brass sheet metal components where moderate corrosion resistance is acceptable.

C23000 Red Brass

With 85% copper content, this grade provides excellent corrosion resistance and thermal conductivity. Used in heat exchangers, plumbing components, and high-quality brass sheet metal parts requiring superior durability.

Key Applications Across Industries

Architectural and Construction

Brass sheet metal components enhance buildings with both functional and aesthetic value. Applications include curtain wall systems, decorative panels, roofing components, and architectural hardware. The natural antimicrobial properties of brass make it particularly valuable in high-touch applications like door handles and handrails.

Automotive Industry

Precision brass components serve critical functions in vehicles, including electrical connectors, radiator components, fuel system parts, and decorative trim elements. The excellent thermal and electrical conductivity of brass makes it indispensable for automotive electrical systems.

Electronics and Telecommunications

Brass sheet metal parts provide electromagnetic shielding, grounding, and structural support in electronic equipment. Components include RF shields, connector housings, heat sinks, and precision brackets for sensitive electronic assemblies.

Marine and Offshore

The corrosion resistance of brass components makes them essential for marine applications, including propeller hardware, deck fittings, navigation equipment housings, and underwater instrumentation components.

HVAC and Plumbing

Brass sheet metal components are crucial in heating, ventilation, and plumbing systems, offering reliable performance in demanding environments. Applications include valve bodies, pipe fittings, heat exchanger components, and control system housings.

| Usage Category | Typical Parts/Components | Key Properties of Brass Used | Examples of Use |

| Electrical & Electronics | Brass Terminals, Brass connectors, contacts, busbars, Brass switch components, Brass and Copper fuse end caps, shielding, battery caps. | Excellent electrical conductivity, good corrosion resistance, non-magnetic properties (in some alloys), easy formability. | Internal contacts for relays, electrical plugs and sockets, cable lugs for power distribution, EMI/RFI shielding in electronics. |

| Plumbing & Fluid Control | Stamped valve bodies, washers, gaskets, fittings, diaphragms, escutcheons. | High corrosion resistance to water and chemicals, durability, high formability for intricate designs. | Components for faucets, valves, and flow meters; decorative plates covering pipe openings. |

| Hardware & Fasteners | Washers, brackets, clips, eyelets, grommets, decorative rivets. | Aesthetic appeal, durability, corrosion resistance, non-sparking properties. | Stamped brackets for mounting, eyelets for shoes and tarps, rivets for luggage and leather goods. |

| Automotive & Aerospace | Stamped brackets, fluid system components, sensor parts, small electrical connector housings. | Corrosion resistance to fuels and oils, durability, good thermal conductivity. | Stamped connectors for vehicle wiring harnesses, components for braking systems, small parts in radiators. |

| Decorative & Consumer Goods | Nameplates, tags, buttons, snaps, buckles, clasps, jewelry components. | Visually appealing, easy to polish, excellent formability for intricate designs and embossing. | Embossed nameplates for furniture, buttons on high-end clothing, stamped components for watch faces and movements. |

Industries Utilizing Brass Sheet Metal Components

Manufacturing and Industrial Equipment

Heavy machinery, processing equipment, and automation systems rely on precision brass components for reliable operation in challenging industrial environments.

Energy and Power Generation

Power plants, renewable energy systems, and electrical distribution networks utilize brass components for their excellent electrical conductivity and corrosion resistance.

Aerospace and Defense

Critical applications requiring lightweight, durable, and reliable brass sheet metal parts, including avionics housings, connector assemblies, and precision instrumentation components.

Medical and Laboratory Equipment

The antimicrobial properties and precision manufacturing capabilities make brass ideal for medical device components, laboratory instruments, and healthcare facility hardware.

Food and Beverage Processing

Brass components meet strict hygiene requirements while providing excellent corrosion resistance in food processing equipment, brewing systems, and commercial kitchen applications.

Advantages of Brass Sheet Metal Parts

Superior Corrosion Resistance

Brass components resist corrosion from moisture, chemicals, and environmental factors, ensuring long service life in demanding applications.

Excellent Machinability

The favorable machining characteristics of brass allow for precision manufacturing of complex components with tight tolerances.

Antimicrobial Properties

Natural antimicrobial effects make brass components ideal for applications requiring hygiene and cleanliness.

Aesthetic Appeal

The golden appearance of brass adds visual value to architectural and decorative applications while maintaining functional performance.

Electrical and Thermal Conductivity

Superior conductivity properties make brass components essential for electrical and thermal management applications.

Recyclability

Brass components can be fully recycled, supporting sustainable manufacturing practices and environmental responsibility.

Quality Standards and Specifications

Professional brass sheet metal fabrication follows stringent quality standards, including ASTM specifications for material properties, dimensional tolerances according to industry standards, and surface finish requirements for specific applications. Quality control measures ensure consistent performance across all brass sheet metal components.

Future Trends in Brass Component Manufacturing

Advanced manufacturing technologies continue to expand the possibilities for brass sheet metal parts and components. Innovations in precision cutting, automated forming processes, and surface treatments are enabling new applications and improving performance characteristics. The growing emphasis on sustainable manufacturing is driving increased use of recycled brass materials and energy-efficient production methods.

Conclusion

Brass sheet metal parts and brass sheet metal components remain essential elements in modern manufacturing across diverse industries. Their unique combination of mechanical properties, corrosion resistance, and aesthetic appeal ensures continued relevance in applications ranging from architectural hardware to precision electronic components. As manufacturing technologies advance, the versatility and reliability of brass components position them as preferred solutions for demanding applications requiring both performance and longevity.

Whether you’re specifying components for marine applications, architectural projects, or precision electronics, brass sheet metal parts offer proven performance backed by decades of successful industrial use. The extensive range of available grades, manufacturing processes, and finishing options ensures that brass components can meet the specific requirements of virtually any application while delivering exceptional value and reliability.