Bronze Transformer Spade Connectors , NEMA Spaced Bronze Transformer Spades, Transformer Spade terminals

Bronze Transformer Spade Terminals: The Ultimate Guide to Reliable Electrical Connections

When it comes to electrical transformer installations and maintenance, bronze transformer spade terminals and transformer spade connectors stand out as premium solutions for ensuring secure, long-lasting electrical connections. These specialized electrical components play a crucial role in power distribution systems, offering superior performance and reliability compared to standard alternatives.

What Are Bronze Transformer Spade Terminals?

Bronze transformer spade terminals are electrical connectors specifically designed for transformer applications, featuring a distinctive spade-shaped design that allows for quick insertion and removal from terminal blocks. Made from high-quality bronze alloy, these transformer spade connectors provide exceptional electrical conductivity while resisting corrosion in demanding industrial environments. We are a leading manufacturers of Transformer spade terminals, Transformer spades, Transformer spade connectors from India.

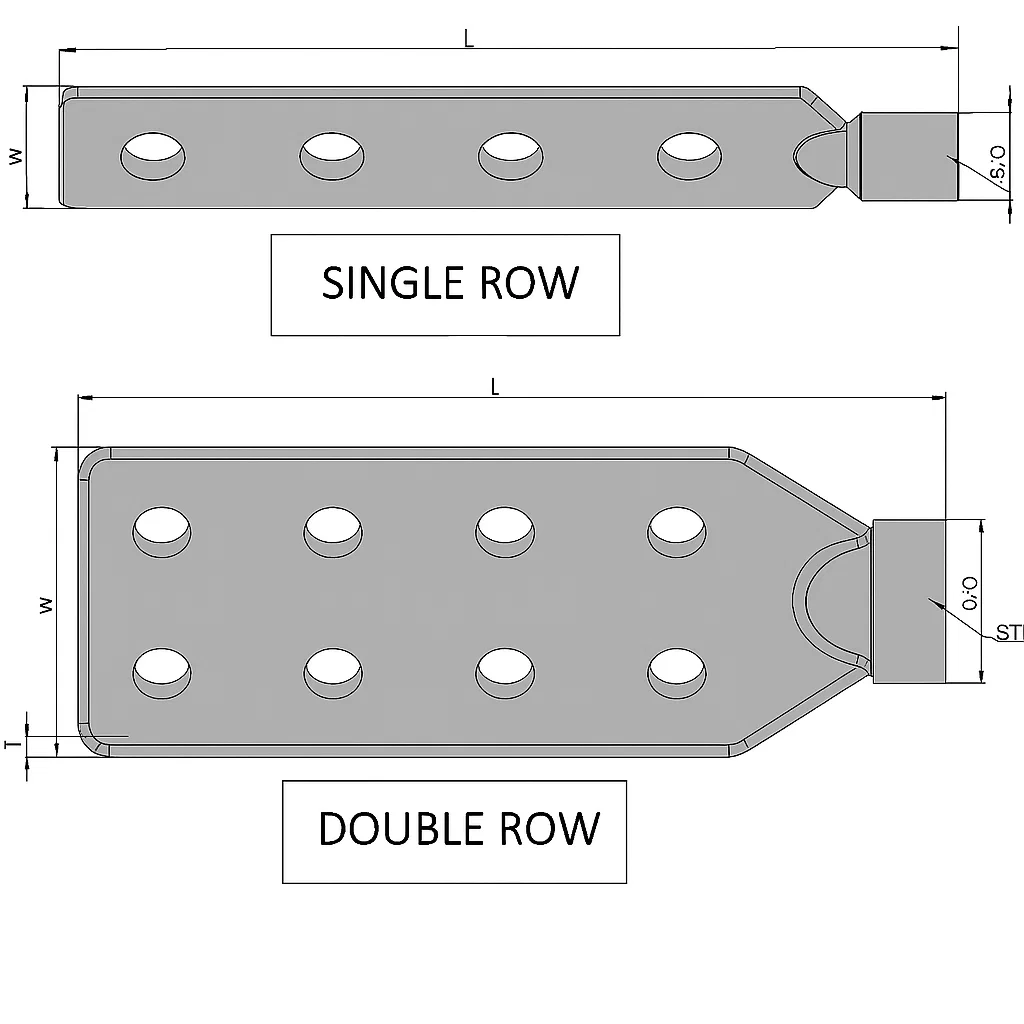

The spade terminal design features a flat, fork-like end that slides onto terminal studs, creating a secure mechanical and electrical connection. This design makes bronze spade terminals ideal for applications where frequent maintenance or component replacement is required.

| CATALOG NUMBER | PRODUCT TYPE | NO. OF HOLES | STUD SIZE | D | L | W | T |

|---|---|---|---|---|---|---|---|

| BCP5811-2S | SINGLE ROW | 2 | 5/8-11 | 0.88″ | 5.06″ | 1.37″ | 0.31″ |

| BCP1014-2S | SINGLE ROW | 2 | 1-14 | 1.38″ | 5.12″ | 1.93″ | 0.34″ |

| BCP5811-4S | SINGLE ROW | 4 | 5/8-11 | 0.88″ | 8.50″ | 1.37″ | 0.31″ |

| BCP1014-4S | SINGLE ROW | 4 | 1-14 | 1.38″ | 8.56″ | 1.93″ | 0.34″ |

| BCP5811-2 | DOUBLE ROW | 2 | 5/8-11 | 0.88″ | 4.00″ | 3.50″ | 0.25″ |

| BCP1014-2 | DOUBLE ROW | 2 | 1-14 | 1.38″ | 4.00″ | 3.50″ | 0.37″ |

| BCP5811-4 | DOUBLE ROW | 4 | 5/8-11 | 0.88″ | 5.37″ | 3.50″ | 0.25″ |

| BCP1014-4 | DOUBLE ROW | 4 | 1-14 | 1.38″ | 5.87″ | 3.50″ | 0.37″ |

| BCP5811-6 | DOUBLE ROW | 6 | 5/8-11 | 0.88″ | 6.62″ | 3.50″ | 0.37″ |

| BCP1014-6 | DOUBLE ROW | 6 | 1-14 | 1.38″ | 6.70″ | 3.50″ | 0.37″ |

| BCP5811-8 | DOUBLE ROW | 8 | 5/8-11 | 0.88″ | 8.37″ | 3.50″ | 0.37 |

Why Choose Bronze for Transformer Spade Connectors?

Superior Electrical Properties

Bronze offers excellent electrical conductivity, making it an ideal material for transformer spade terminals. The copper-tin alloy composition provides:

- High conductivity: Ensuring minimal power loss during electrical transmission

- Low resistance: Reducing heat generation and improving system efficiency

- Stable performance: Maintaining consistent electrical properties over time

Exceptional Corrosion Resistance

Bronze transformer spade connectors excel in harsh environments due to their natural corrosion resistance. This makes them particularly valuable for:

- Outdoor transformer installations

- Marine electrical applications

- Industrial settings with high humidity

- Chemical processing facilities

Mechanical Durability

The robust nature of bronze ensures that transformer spade terminals can withstand:

- Repeated connection and disconnection cycles

- Vibration from transformer operation

- Thermal expansion and contraction

- Physical stress during installation

Applications of Bronze Transformer Spade Terminals

Power Distribution Transformers

Bronze spade connectors are commonly used in:

- Distribution transformers in electrical substations

- Pole-mounted transformer installations

- Underground vault transformer systems

- Industrial plant power distribution

Specialty Transformer Applications

Transformer spade terminals find extensive use in:

- Isolation transformers for sensitive equipment

- Auto-transformers in voltage regulation systems

- Instrument transformers for measurement and protection

- Audio transformers in professional sound systems

Technical Specifications and Standards

Current Rating Capabilities

Bronze transformer spade terminals are available in various current ratings:

- Low current applications: 15-30 amperes

- Medium current systems: 50-100 amperes

- High current installations: 200+ amperes

- Heavy-duty applications: 600+ amperes

Voltage Classifications

Transformer spade connectors are designed for different voltage levels:

- Low voltage systems (under 1kV)

- Medium voltage applications (1kV-35kV)

- High voltage installations (above 35kV)

Industry Standards Compliance

Quality bronze spade terminals meet or exceed:

- IEEE transformer connection standards

- IEC international electrical standards

- UL safety and performance requirements

- ANSI mechanical and electrical specifications

Installation Best Practices for Bronze Transformer Spade Terminals

Pre-Installation Preparation

Before installing transformer spade connectors:

- Verify compatibility with transformer terminal specifications

- Inspect terminals for any manufacturing defects or damage

- Clean connection surfaces to ensure optimal electrical contact

- Check torque specifications for your specific terminal type

Proper Installation Technique

When installing bronze transformer spade terminals:

- Align carefully to prevent cross-threading or misalignment

- Apply specified torque using calibrated torque wrenches

- Verify secure connection with gentle pull testing

- Apply appropriate sealant if required for environmental protection

Safety Considerations

Always follow safety protocols when working with transformer spade terminals:

- De-energize systems before installation

- Use appropriate personal protective equipment

- Follow lockout/tagout procedures

- Verify proper grounding before beginning work

Maintenance and Inspection of Bronze Spade Connectors

Regular Inspection Schedule

Bronze transformer spade terminals should be inspected:

- Annually for standard installations

- Semi-annually for harsh environment applications

- Quarterly for critical system components

- After any significant electrical events

What to Look For

During inspections of transformer spade connectors, check for:

- Corrosion or oxidation on connection surfaces

- Loose connections that may cause arcing or overheating

- Physical damage from vibration or environmental factors

- Discoloration indicating overheating or electrical problems

Maintenance Procedures

Proper maintenance of bronze spade terminals includes:

- Cleaning connections with appropriate solvents

- Re-torquing to manufacturer specifications

- Applying anti-oxidant compound if recommended

- Documenting all maintenance activities

Advantages Over Alternative Connection Methods

Compared to Aluminum Connectors

Bronze transformer spade terminals offer:

- Better corrosion resistance than aluminum alternatives

- Superior electrical conductivity

- Reduced galvanic corrosion when connected to copper conductors

- Longer service life in harsh environments

Versus Standard Crimp Connectors

Transformer spade connectors provide:

- Easier installation and removal for maintenance

- Better mechanical connection under vibration

- Visual verification of connection integrity

- Reusable design reducing replacement costs

Selecting the Right Bronze Transformer Spade Terminals

Key Selection Criteria

When choosing bronze spade connectors, consider:

- Current carrying capacity for your specific application

- Voltage rating appropriate for system requirements

- Environmental conditions including temperature and humidity

- Maintenance accessibility requirements

Quality Indicators

Look for these features in premium transformer spade terminals:

- High-grade bronze alloy construction

- Precision manufacturing tolerances

- Proper surface treatments for enhanced performance

- Comprehensive testing and certification documentation

Foreign terms:

German:

Bronze-Flachsteckhülsen für Transformatoren, NEMA-genormte Bronze-Flachsteckhülsen, Flachsteckanschlüsse für Transformatoren

Russian:

Бронзовые клеммы-лопатки для трансформаторов, Бронзовые клеммы-лопатки с расстоянием по стандарту NEMA, Клеммные наконечники типа “лопатка” для трансформаторов

French:

Connecteurs à languette en bronze pour transformateurs, Languettes de transformateur en bronze à espacement NEMA, Bornes à languette pour transformateurs

Spanish:

Conectores de pala de bronce para transformadores, Pletinas de bronce para transformadores con espaciado NEMA, Terminales de pala para transformadores

Future Trends in Transformer Spade Connector Technology

The evolution of bronze transformer spade terminals continues with:

- Enhanced bronze alloy formulations for improved performance

- Advanced surface treatments for extended service life

- Smart connector technologies for remote monitoring

- Environmentally friendly manufacturing processes

Conclusion

Bronze transformer spade terminals and transformer spade connectors represent a critical component in reliable electrical power systems. Their combination of excellent electrical properties, corrosion resistance, and mechanical durability makes them the preferred choice for demanding Bronze transformer applications.

Whether you’re installing new transformer systems or maintaining existing equipment, investing in high-quality bronze spade terminals ensures long-term reliability, reduced maintenance costs, and optimal system performance. By understanding the technical specifications, proper installation techniques, and maintenance requirements, electrical professionals can maximize the benefits of these essential electrical components.

For your next transformer project, consider the proven reliability and performance advantages of Bronze transformer spade terminals – your electrical system’s performance depends on making the right connection.