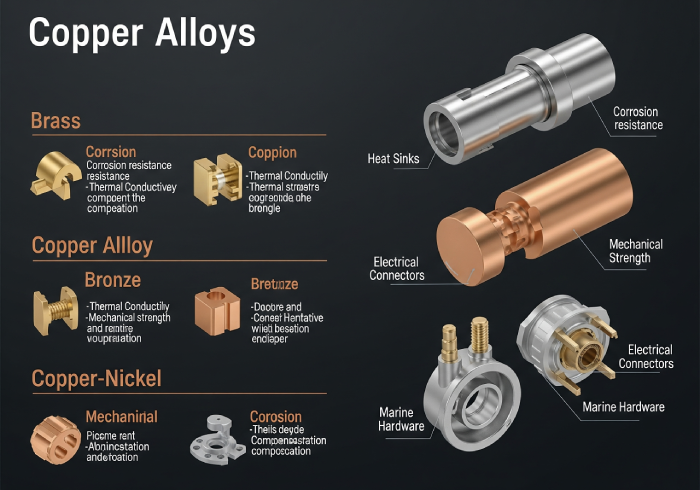

Copper’s versatility isn’t just about pure copper—in many industrial applications, specific copper alloys deliver tailored performance. Whether you need extra strength, superior corrosion resistance, or enhanced machinability, selecting the right alloy is crucial. In this blog, we explore five widely used copper alloys, their unique properties, and the applications that benefit most from each grade.

1. C10100 (Electrolytic Tough Pitch Copper)

Key Properties:

Electrical Conductivity: ≥ 100% IACS

Thermal Conductivity: 390 W/m·K

Machinability: Moderate

Ideal Uses:

Busbars and electrical conductors

Cable lugs and connectors

High‑current switchgear components

Why Choose C10100?

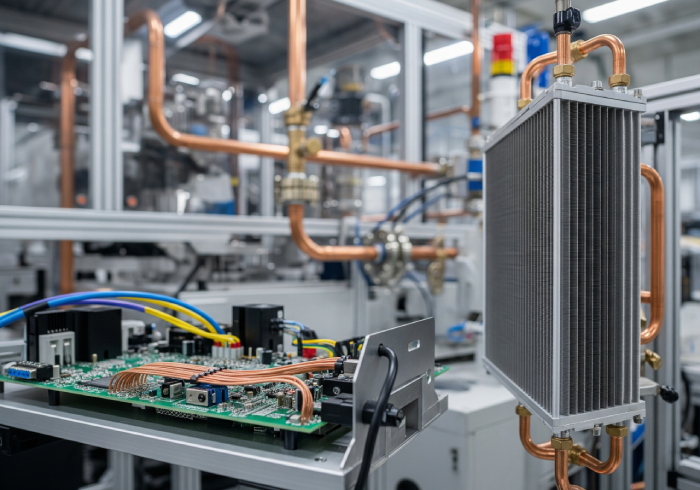

If maximum conductivity is your priority—such as in power distribution panels or grounding systems—C10100 ensures minimal power loss and excellent heat dissipation.

2. C11000 (Oxygen‑Free Electronic Copper)

Key Properties:

Conductivity: ≥ 101% IACS

Minimal Oxygen Content (< 0.02%)

Excellent Weldability

Ideal Uses:

Vacuum and cryogenic equipment

High‑reliability connectors in aerospace and medical devices

RF and microwave components

Why Choose C11000?

For critical electronic or vacuum applications, oxygen‑free copper prevents embrittlement and ensures long‑term reliability.

3. C83600 (Free‑Cutting Brass‑Bronze Blend)

Key Properties:

Lead Content: 2–3% for machinability

Tensile Strength: ~ 310 MPa

Machinability Rating: 80 (ASTM standard)

Ideal Uses:

Precision‑machined components like terminal blocks and fittings

Turned parts requiring tight tolerances

Rapid‑production CNC applications

Why Choose C83600?

Its exceptional machinability lets you achieve fine features and smooth threads, reducing cycle times and tooling wear.

4. C92700 (Tin Bronze)

Key Properties:

Tin Content: 5%

Wear Resistance: High

Corrosion Resistance: Excellent

Ideal Uses:

Pump impellers and valve stems

Marine hardware and seawater fittings

Bearing and bushing applications

Why Choose C92700?

In high‑wear or corrosive environments, tin bronze delivers durability while maintaining dimensional stability under load.

5. C95500 (Tellurium Copper)

Key Properties:

Tellurium Content: 0.5–1.0%

Machinability Rating: 85–90

Conductivity: ~ 70 % IACS

Ideal Uses:

Electrical switchgear components

Decorative architectural hardware

Heat exchanger tubes

Why Choose C95500?

Tellurium copper combines good conductivity with superior machinability, making it ideal for complex shapes and decorative finishes.

Selecting the Right Alloy: A Quick Checklist

| Alloy | Conductivity | Machinability | Corrosion Resistance | Typical Application |

|---|---|---|---|---|

| C10100 | ★★★★★ | ★★★☆☆ | ★★★☆☆ | Power distribution |

| C11000 | ★★★★★ | ★★☆☆☆ | ★★★★☆ | Vacuum/electronics |

| C83600 | ★★★☆☆ | ★★★★★ | ★★☆☆☆ | CNC machined fittings |

| C92700 | ★★☆☆☆ | ★★☆☆☆ | ★★★★★ | Marine & pump parts |

| C95500 | ★★★★☆ | ★★★★☆ | ★★★★☆ | Architectural & switchgear |

Use this checklist to map your project requirements—whether electrical performance, machining speed, or environmental durability—against the strengths of each alloy.

📞 Ready to Source Precision Copper Alloy Components?

Partner with Brass-Copper-Parts.com, Jamnagar’s ISO‑certified manufacturer, to get competitive quotes, rapid prototypes, and expert guidance on alloy selection.

📧 sales@brass-copper-parts.com

📞 +91‑22‑43449300 | WhatsApp Available