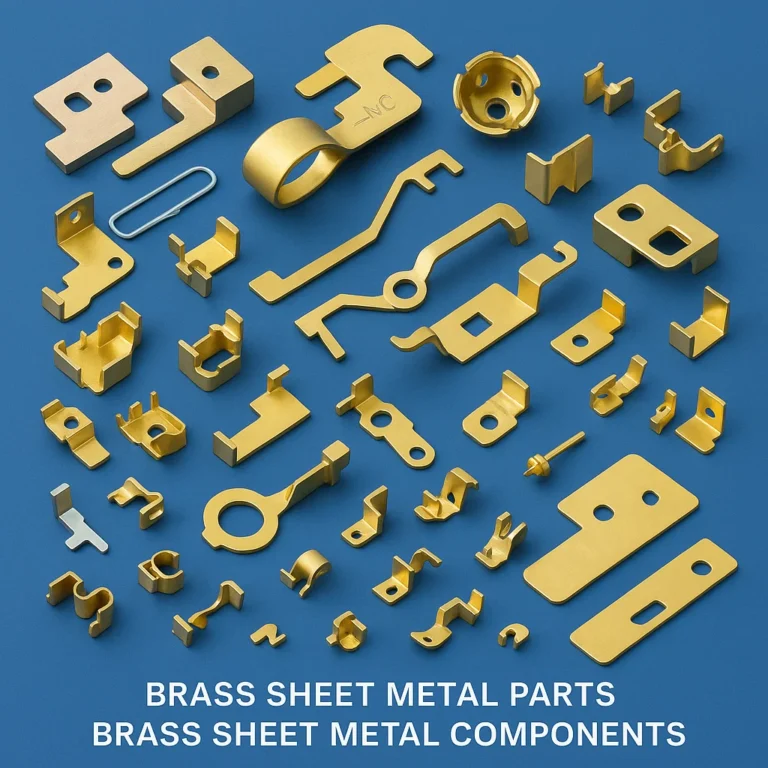

Complete Guide to Lead-Free Brass Parts, Lead Free Brass Machining & Lead Free Brass Components

Overview of Lead-Free Brass Fittings, Lead Free Brass Parts, Lead Free Brass Machined parts and Components

Lead-free brass represents a revolutionary advancement in copper alloy technology, developed to meet stringent environmental and health regulations while maintaining the excellent mechanical properties that make brass indispensable in modern manufacturing. Unlike traditional brass alloys that contain 2-4% lead for improved machinability, lead-free brass achieves similar performance through innovative alloy compositions and advanced metallurgical techniques.

Material Specifications & Compositions

Primary Lead-Free Brass Alloys

CuZn39Pb3 Alternative – ECO Brass™

- Copper (Cu): 60-63%

- Zinc (Zn): 35-39%

- Silicon (Si): 0.7-1.3%

- Iron (Fe): ≤0.35%

- Lead (Pb): ≤0.09%

- Aluminum (Al): ≤0.05%

- Tin (Sn): ≤0.3%

CDA 360 Lead-Free (C36000LF)

- Copper (Cu): 61-63%

- Zinc (Zn): Remainder

- Silicon (Si): 0.50-1.50%

- Bismuth (Bi): 0.10-0.50%

- Lead (Pb): ≤0.25%

Naval Brass Lead-Free (C46400LF)

- Copper (Cu): 59-62%

- Zinc (Zn): 37.0-39.25%

- Tin (Sn): 0.50-1.00%

- Silicon (Si): 0.10-0.50%

- Lead (Pb): ≤0.20%

Mechanical Properties

Tensile Strength: 380-520 MPa (55,000-75,000 psi) Yield Strength: 170-380 MPa (25,000-55,000 psi) Elongation: 25-45% in 50mm Hardness: 65-85 HRB (Rockwell B) Modulus of Elasticity: 100-110 GPa Density: 8.4-8.7 g/cm³ Thermal Conductivity: 115-125 W/m·K Electrical Conductivity: 25-30% IACS

Manufacturing Processes

Primary Production Methods

Continuous Casting (Gießen – German) The molten lead-free brass alloy is continuously cast into billets or rods using advanced cooling systems. Temperature control is critical, with pouring temperatures ranging from 1,050-1,100°C. The process utilizes electromagnetic stirring (Electromagnetische Rührung) to ensure homogeneous microstructure and eliminate segregation.

Hot Rolling (Laminado en Caliente – Spanish) Billets are heated to 700-800°C and passed through a series of rolling mills to achieve desired dimensions. The reduction ratio typically ranges from 3:1 to 8:1, with intermediate annealing at 450-550°C to relieve work hardening and maintain ductility.

Cold Drawing (Tirage à Froid – French) Final dimensional precision is achieved through cold drawing processes, where rods are pulled through carbide dies at room temperature. This process increases tensile strength by 20-30% while maintaining surface finish quality of Ra 0.8-1.6 μm.

Extrusion (Estrusione – Italian) Complex profiles and hollow sections are produced through direct or indirect extrusion at temperatures of 650-750°C. Extrusion ratios of 10:1 to 40:1 are common, with exit speeds controlled at 15-25 m/min to prevent surface defects.

Heat Treatment Processes

Solution Annealing (Solubilización)

- Temperature: 450-550°C

- Hold Time: 1-4 hours depending on section thickness

- Cooling: Air cooling or controlled cooling rate

- Purpose: Stress relief and grain refinement

Stress Relief Annealing

- Temperature: 200-300°C

- Hold Time: 2-8 hours

- Atmosphere: Protective (nitrogen or argon)

- Cooling: Furnace cooling

Machining Characteristics & Parameters

Machinability Index

Lead-free brass achieves 85-95% of the machinability rating of traditional leaded brass through optimized chemistry and microstructure control.

Cutting Parameters

Turning Operations

- Cutting Speed: 200-400 m/min (SFM: 650-1,300)

- Feed Rate: 0.1-0.4 mm/rev

- Depth of Cut: 1-5 mm

- Tool Materials: Carbide (K10-K20), HSS, PCD

Milling Operations

- Cutting Speed: 150-300 m/min

- Feed per Tooth: 0.05-0.20 mm

- Axial Depth: 2-8 mm

- Radial Depth: 0.5-2.0 mm

Drilling Operations

- Surface Speed: 80-200 m/min

- Feed Rate: 0.08-0.25 mm/rev

- Point Angle: 118-135°

- Coolant: Soluble oil or synthetic coolant

Tool Selection & Geometry

Turning Tools

- Nose Radius: 0.4-1.2 mm

- Relief Angle: 6-8°

- Rake Angle: 0-15° positive

- Coating: TiN, TiAlN, or uncoated carbide

End Mills

- Helix Angle: 30-45°

- Number of Flutes: 2-4 for roughing, 4-6 for finishing

- Corner Radius: 0.1-0.5 mm

- Coating: AlCrN, TiAlN recommended

Quality Control & Testing

Chemical Analysis Methods

- X-Ray Fluorescence (XRF): Primary method for elemental composition

- Optical Emission Spectroscopy (OES): High precision for trace elements

- Inductively Coupled Plasma (ICP): Ultimate accuracy for lead content verification

Mechanical Testing Protocols

- Tensile Testing: ASTM E8, ISO 6892-1

- Hardness Testing: ASTM E18 (Rockwell), ISO 6506 (Brinell)

- Impact Testing: ASTM E23, ISO 148-1 (Charpy V-notch)

- Fatigue Testing: ASTM D7791, ISO 1143

Dimensional Inspection

- Coordinate Measuring Machine (CMM): Accuracy ±0.001 mm

- Optical Comparators: Profile verification

- Surface Roughness: Ra 0.1-3.2 μm typical range

- Geometric Tolerancing: Per ASME Y14.5M-2009

Applications & Industries

Plumbing & Water Systems (Sistemas de Fontanería)

- Fittings, valves, and connectors for potable water

- Compliance with NSF/ANSI 61, WRAS, and KTW standards

- Operating pressure: up to 16 bar (232 psi)

- Temperature range: -20°C to +200°C

Automotive Components (Componenti Automobilistici)

- Fuel injection systems

- Brake line fittings

- Radiator components

- Electrical connectors and terminals

Marine Hardware (Quincaillerie Marine – French)

- Propeller shafts and fittings

- Seawater-resistant components

- Navigation equipment housings

- Corrosion resistance in saltwater environments

Electrical & Electronics

- Connector pins and sockets

- Switch components

- Transformer bushings

- EMI/RFI shielding applications

International Standards & Compliance

North American Standards

- ASTM B16: Standard Specification for Free-Cutting Brass Rod, Bar and Shapes

- ASTM B124: Standard Specification for Copper and Copper Alloy Forging Rod, Bar and Shapes

- NSF/ANSI 61: Drinking water system components – Health effects

- NSF/ANSI 372: Drinking water system components – Lead content

European Standards

- EN 12164: Copper and copper alloys – Rod for general purposes

- EN 12165: Copper and copper alloys – Wrought and unwrought forging stock

- DIN 17660: Copper-zinc alloys; Chemical composition and mechanical properties

- WRAS: Water Regulations Advisory Scheme (UK)

Asian Standards

- JIS H3250: Copper and copper alloy rods and bars

- GB/T 4423: Copper and copper alloy bars (China)

- KS D 5101: Copper and copper alloy bars (South Korea)

Foreign Technical Terms & Translations

German (Deutsch)

- Bleifreies Messing: Lead-free brass

- Spanbarkeit: Machinability

- Gefügestruktur: Microstructure

- Warmumformung: Hot forming

- Korngröße: Grain size

French (Français)

- Laiton sans plomb: Lead-free brass

- Usinabilité: Machinability

- Recuit de détente: Stress relief annealing

- Tréfilage: Wire drawing

- Résistance à la corrosion: Corrosion resistance

Spanish (Español)

- Latón sin plomo: Lead-free brass

- Mecanización: Machining

- Tratamiento térmico: Heat treatment

- Propiedades mecánicas: Mechanical properties

- Control de calidad: Quality control

Italian (Italiano)

- Ottone senza piombo: Lead-free brass

- Lavorabilità: Machinability

- Microstruttura: Microstructure

- Formatura a caldo: Hot forming

- Resistenza alla trazione: Tensile strength

Japanese (日本語)

- 無鉛黄銅 (Muen-ōdō): Lead-free brass

- 切削性 (Sessakusei): Machinability

- 熱処理 (Netsu-shori): Heat treatment

- 機械的性質 (Kikai-teki seishitsu): Mechanical properties

- 品質管理 (Hinshitsu-kanri): Quality control

Environmental & Health Benefits

Regulatory Compliance

Lead-free brass eliminates health risks associated with lead leaching in potable water systems, meeting strictest international standards including the US Reduction of Lead in Drinking Water Act and EU Drinking Water Directive.

Sustainability Advantages

- 100% recyclable without quality degradation

- Reduced environmental impact in production

- Lower energy requirements for machining

- Compliance with RoHS and REACH regulations

Economic Benefits

- Eliminates need for special handling procedures

- Reduces disposal costs and environmental liability

- Qualifies for green building certifications (LEED, BREEAM)

- Future-proof against evolving environmental regulations

Future Developments & Innovations

Advanced Alloy Development

Research continues into nano-structured lead-free brasses with enhanced properties, including bismuth and silicon additions for improved machinability and corrosion resistance.

Smart Manufacturing Integration

Implementation of Industry 4.0 technologies including AI-driven quality control, predictive maintenance systems, and real-time alloy composition monitoring.

Additive Manufacturing Applications

Development of lead-free brass powders for 3D printing applications, opening new possibilities for complex geometries and rapid prototyping in brass components.

Lead-free brass represents not just regulatory compliance, but a technological advancement that maintains the outstanding properties of traditional brass while eliminating environmental and health concerns. As manufacturing processes continue to evolve and regulations become more stringent, lead-free brass positions manufacturers at the forefront of sustainable, high-performance metalworking solutions.