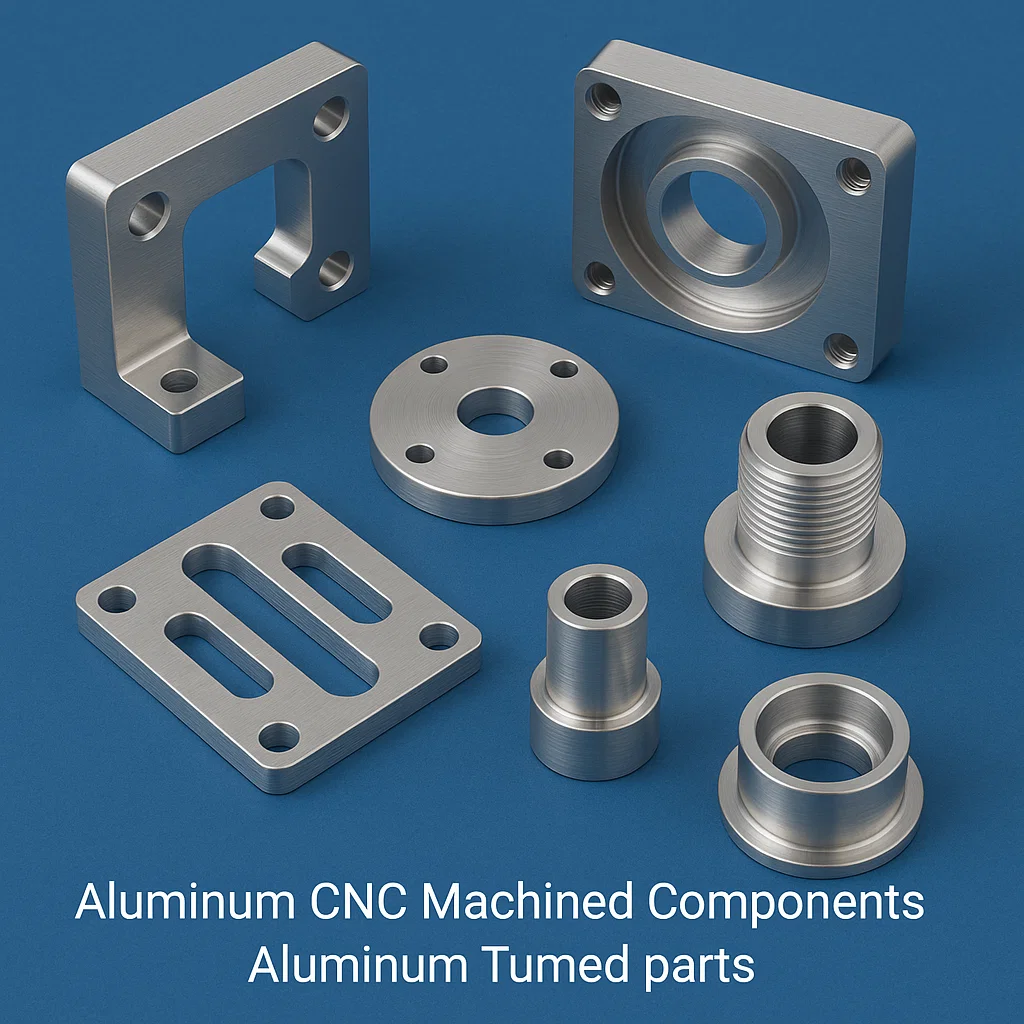

Precision Aluminum Parts: CNC Machined, Turned, and Milled Components

We are one of the leading manufacturers and exporters of high-precision Aluminum Parts from India. We have been supplying custom Aluminum Turned Parts, complex Aluminum CNC machined parts, and critical Aluminum Components to the world market for many decades. Our expertise spans across a multitude of industries, providing solutions that meet stringent international standards for quality, tolerance, and performance. Our state-of-the-art manufacturing facility is equipped with advanced machinery, allowing us to produce everything from simple Aluminum fasteners to intricate Aluminum precision parts for the aerospace and medical sectors. We utilize a wide range of material grades, including Aluminum 6061, 7075, 2024, and 5083, ensuring the right fit for every application, from prototyping to high-volume production runs. Our commitment to excellence is underscored by our robust quality assurance protocols and our ability to deliver within a competitive 4-6 week turnaround time.

In-Depth Look at Our Aluminum Components

Aluminum Turned Parts

Aluminum Turned Parts are manufactured using precision CNC lathes and Swiss-style turning centers, a process ideal for creating rotationally symmetric components. This subtractive manufacturing process is exceptionally efficient for producing high volumes of parts with excellent concentricity and surface finish. Typical Aluminum Turned Parts include Aluminum shafts, connectors, bushings, nozzles, and fasteners. We achieve tight tolerances, often holding diameters to within ±0.05 mm, utilizing bar stock from a variety of Aluminum grades like Aluminum 2011 (free-machining), Aluminum 6061, and Aluminum 7075. The process is governed by standards such as ASTM B211 for bar stock and DIN 912 for socket head cap screws. Industries that heavily rely on these components include automotive (for fuel systems and transmissions), hydraulic and pneumatic systems, and consumer electronics.

Aluminum CNC Machined Parts

Aluminum CNC Machined Parts represent the core of our manufacturing capability, involving computer-controlled milling, drilling, and turning operations to create highly complex, three-dimensional geometries from a solid block of material. This process is unmatched for producing Aluminum enclosures, brackets, manifolds, prototypes, and custom engine components. We employ advanced 3, 4, and 5-axis CNC machining centers to machine parts from all standard grades, including Aluminum 5083 (for marine applications) and Aluminum 6082 (a European standard with good machinability). We adhere to international standards like ISO 2768 for general tolerances and can machine to much tighter specifications as required by the drawing. The aerospace, defense, robotics, and telecommunications industries depend on our ability to produce lightweight, strong, and complex CNC machined Aluminum parts.

Aluminum Components

The term Aluminum Components is a broad category encompassing any part or assembly made from Aluminum that serves a specific function in a larger system. We specialize in manufacturing these critical components to exact customer specifications, whether they are Aluminum housings, chassis, levers, or custom-designed mechanisms. Our expertise allows us to select the optimal grade—be it the common Aluminum 6061-T6 or the high-strength Aluminum 7075-T651—and the best combination of processes (milling, turning, finishing) to ensure peak performance and cost-effectiveness. These components are vital in industries such as industrial automation, automotive manufacturing, and medical device manufacturing, where reliability is non-negotiable.

Aluminum Milled Parts

Aluminum Milled Parts are a specific subset of CNC machined parts where the primary material removal operation is performed by a rotating multi-point cutting tool. This process is ideal for creating flat surfaces, pockets, slots, and complex contours. Our multi-axis milling centers can produce parts with intricate details and exceptional accuracy. Typical Aluminum Milled Parts include mounting plates, heat sinks, instrument panels, and mold tools. We often use Aluminum 6061 for its excellent all-around properties and superb machinability. Finishes for milled parts can range from an as-machined finish to a hard anodized coating for increased wear resistance. These parts are fundamental in the consumer electronics, energy, and semiconductor equipment sectors.

Aluminum Precision Parts

Aluminum Precision Parts are components manufactured to exceptionally tight geometrical and dimensional tolerances, often in the microns. The production of these parts requires not only advanced CNC machining and turning equipment but also a climate-controlled environment and sophisticated metrology tools like CMMs (Coordinate Measuring Machines) for verification. We produce Aluminum Precision Parts such as optical mounts, sensor housings, medical implant trial components, and aerospace actuators. Materials like Aluminum 2024 for high strength-to-weight ratio or Aluminum 5052 for excellent formability are commonly selected. These parts are critical in aerospace, medical technology, optical engineering, and defense applications where there is zero margin for error.

Aluminum Electrical Components

Aluminum Electrical Components leverage the metal’s excellent electrical conductivity, light weight, and natural corrosion resistance. We manufacture a wide array of these components, including Aluminum heat sinks, busbars, connector housings, and waveguide components. The choice of material is crucial; Aluminum 6063 is often preferred for extruded heat sinks due to its thermal conductivity, while Aluminum 1100 offers high electrical conductivity for busbars. Processes include CNC machining, bending, and finishing with chemical films like chromate conversion coating (Alodine) to enhance surface conductivity and corrosion protection. These components are essential in power distribution, renewable energy systems (solar/wind), LED lighting, and telecommunications infrastructure.

Aluminum Parts

As a comprehensive Aluminum parts manufacturer, we offer a full spectrum of capabilities to produce any custom Aluminum part you require. From initial design consultation and material selection to CNC machining, finishing, and quality inspection, we manage the entire process in-house. Our global experience of three decades means we understand the nuanced requirements of different markets and can ensure our parts meet standards like ASTM, DIN, JIS, IS, and BS. Whether you need a single prototype or a million production parts, we have the flexibility, expertise, and capacity to be your trusted partner.

Technical Specifications & Data

Common Aluminum Grades and Properties

| Grade | Standard (ASTM) | Characteristics | Typical Applications |

|---|---|---|---|

| 1100 | B209 | Excellent corrosion resistance, high electrical/thermal conductivity, excellent workability | Electrical busbars, chemical equipment, heat exchangers |

| 2011 | B211 | Excellent free-machining grade, high mechanical strength | Screw machine products, fittings, fasteners |

| 2024 | B211 | Very high strength, good fatigue resistance | Aerospace structures, truck wheels, structural components |

| 5052 | B209 | Excellent corrosion resistance (especially to salt water), good weldability | Marine applications, automotive parts, fuel tanks |

| 6061 | B211 | Good strength, excellent corrosion resistance, great machinability & weldability | Automotive parts, bicycle frames, marine fittings, structural components |

| 6082 | (EN AW-6082) | European equivalent to 6061, good machinability | Automotive and bicycle components, structural applications |

| 6063 | B221 | Good extrudability, surface finish, and corrosion resistance | Architectural extrusions, window frames, heat sinks |

| 7075 | B211 | Very high strength, toughness, good fatigue strength | Aerospace frames, military applications, high-stress parts |

Standard Tolerances

Linear Dimensions: ±0.1 mm (ISO 2768-m)

Hole Diameters: ±0.05 mm

True Position: 0.1 mm (can be held tighter based on application)

Surface Finish: 3.2 μm Ra (can be improved to 0.8 μm Ra or better with secondary finishing)

Dimensional Capacity

| Process | Typical Maximum Part Size |

|---|---|

| CNC Turning | Ø 100 mm x 300 mm |

| CNC Milling (3-Axis) | 600 x 500 x 500 mm |

| CNC Milling (5-Axis) | Ø 400 mm |

| Swiss-Type Turning | Ø 32 mm x 300 mm |

Why Choose Us As Your Aluminum Parts Supplier?

Three Decades of Global Expertise: Our 30 years of experience supplying to North America, Europe, and Asia mean we understand international quality standards and logistics.

Unmatched Customization: We don’t just make parts; we provide solutions. From material advice to custom packaging with your logo, we tailor our service to you.

Consistent Quality & Certification: Our ISO 9001:2015 certified processes ensure every batch of parts meets your specifications, every time.

Competitive Turnaround Time: We understand time-to-market is critical. Our efficient production planning enables us to reliably deliver in 4-6 weeks.

Superior Customer Support & Communication: You will have a dedicated project engineer for clear, timely communication, ensuring no surprises from order to delivery.

Packaging and Shipping: We use robust, export-worthy packaging to prevent damage in transit. Options include vacuum sealing, anti-corrosion VCI paper, and customized wooden crating for large parts. We have extensive experience shipping via air and sea freight worldwide.

Customer Testimonial

“We’ve been sourcing our precision Aluminum actuator housings from this team for over five years. The consistency in quality is remarkable, and their technical support during the design phase has saved us countless hours. They are a true partner, not just a vendor.” – Michael Roberts, Engineering Manager, USA

Frequently Asked Questions (Q&A)

Q1: What is the minimum order quantity (MOQ) for custom Aluminum parts?

A: We are highly flexible. While we cater to high-volume production, we also welcome prototype and low-volume orders to support your R&D efforts.

Q2: Can you help with material selection if I’m unsure what grade to use?

A: Absolutely. Our engineering team can advise on the best Aluminum grade based on your application’s requirements for strength, corrosion resistance, machinability, and cost.

Q3: Do you provide secondary finishing services?

A: Yes, we offer a full range of finishing services including anodizing (clear and color), powder coating, sandblasting, polishing, and plating.

Q4: How do you ensure quality control?

A: Every part undergoes rigorous inspection using tools like calipers, micrometres, and thread gauges. First Article Inspection (FAI) reports and full CMM inspection are available upon request.

Q5: What file formats do you need for a quotation?

A: We prefer 3D step files (.step, .stp) along with 2D PDF drawings (.pdf) that specify critical dimensions and tolerances.

Q6: Are your parts compliant with RoHS and REACH regulations?

A: Yes, we can provide compliance certificates for all relevant materials and processes upon request.

Q7: What is your lead time for prototypes?

A: For simple prototype parts, we can often deliver within 2-3 weeks.

Q8: Do you offer assembly services for machined components?

A: Yes, we can provide kitting or full assembly including press-fitting, threading, and loctiting.

Q9: How do you handle intellectual property (IP)?

A: We take IP very seriously. We are willing to sign strict NDAs, and your designs are kept completely confidential.

Q10: What are your payment terms?

A: Standard terms are 50% advance and 50% before shipment for new customers. We can discuss more flexible terms for established relationships.

Glossary of Terms

CNC Machining: A subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools to shape a block of material.

Tolerance: The permissible limit or limits of variation in a physical dimension.

Anodizing: An electrochemical process that converts the metal surface into a durable, corrosion-resistant, anodic oxide finish.

CMM (Coordinate Measuring Machine): A device that measures the geometry of physical objects by sensing discrete points on the surface with a probe.

ASTM International: An international standards organization that develops and publishes voluntary consensus technical standards for materials, products, systems, and services.

Related Search Terms

aluminum machining services, custom cnc aluminum parts, aluminum prototype parts, small aluminum parts manufacturer, aluminum cnc turning company, aluminum parts for automotive industry, aluminum components for aerospace, high precision machining services, aluminum enclosure manufacturer, anodized aluminum parts supplier.

Ready to Get Started?

Email us your drawings and specifications today for a competitive quotation. Let our three decades of expertise in precision Aluminum component manufacturing work for you.

📧 Email: sales@brass- copper-parts.com