Aluminum Pressed Parts & Aluminum Sheet Metal Components

Premium Quality Custom Aluminum Pressing Solutions from India

Price: US$ 7/kilogram

We are one of the leading manufacturers and exporters of Aluminum Pressed Parts and Sheet Metal Components from India. We have been supplying high-precision aluminum components to the world market for many decades. With over three decades of experience in aluminum pressing work, we specialize in manufacturing custom aluminum pressed parts, deep drawn components, brackets, clamps, and saddles for industrial and electrical applications. Our state-of-the-art manufacturing facility utilizes advanced pressing machinery and quality control systems to deliver components that meet international standards including ASTM, DIN, JIS, and IS specifications. We maintain strict dimensional tolerances and surface finish requirements while ensuring cost-effective solutions for our global clientele. Our expertise extends beyond Aluminum to include pressing and sheet metal fabrication of Copper, Brass, and Stainless Steel materials, making us a comprehensive solution provider for diverse industrial requirements. From prototype development to high-volume production runs, our manufacturing capabilities are designed to meet the most demanding specifications while maintaining competitive pricing and reliable delivery schedules.

Overview of Aluminum Pressed Parts Manufacturing

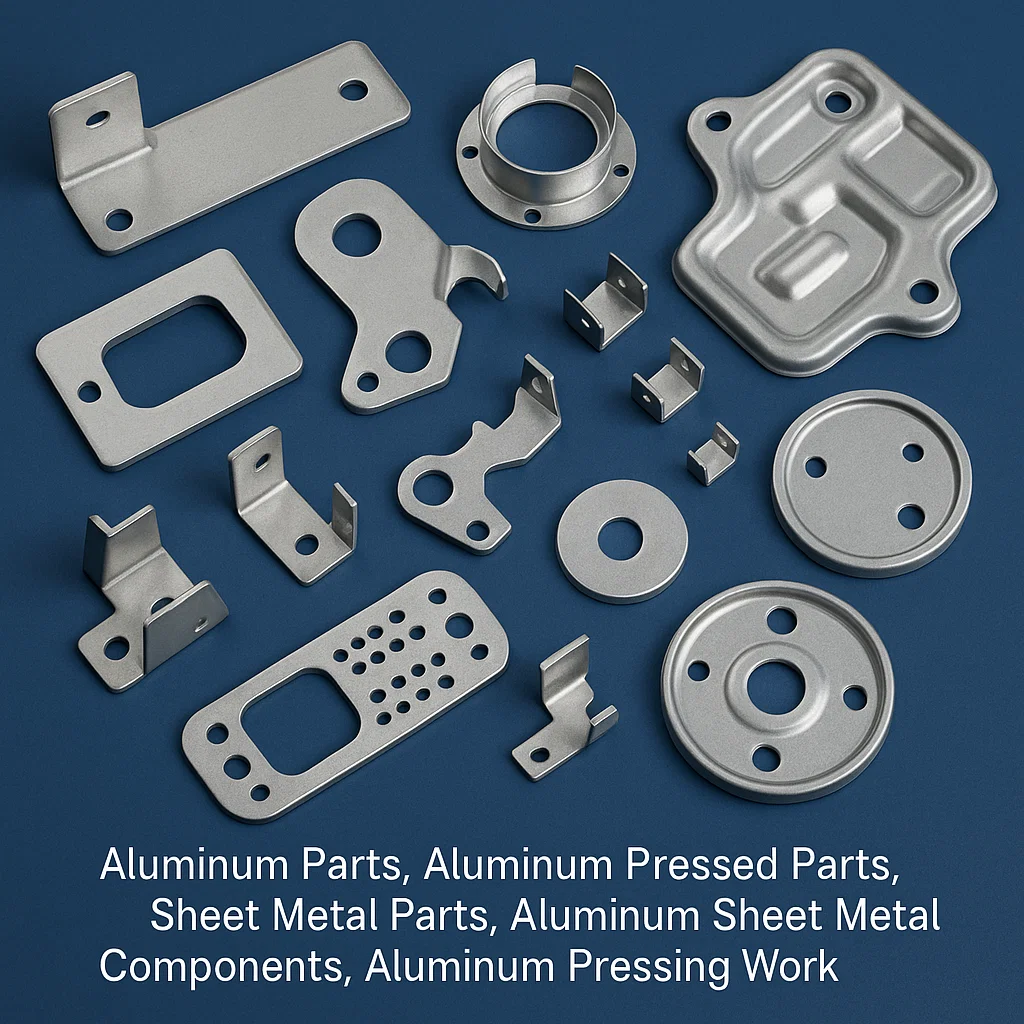

Aluminum pressed parts represent a critical component category in modern manufacturing, encompassing a wide range of formed and shaped aluminum components created through precision pressing operations. Our comprehensive aluminum pressing capabilities include progressive die stamping, deep drawing, bending, forming, and complex multi-stage operations. The versatility of aluminum as a material, combined with our advanced pressing technologies, allows us to manufacture components ranging from simple brackets and clamps to complex deep drawn housings and intricate electrical components.

Our aluminum pressing operations utilize high-tonnage hydraulic and mechanical presses ranging from 50 tons to 1000 tons capacity, enabling us to handle components from miniature electronic parts to large automotive and industrial assemblies. The pressing process involves controlled deformation of aluminum sheet and plate materials under precise force application, resulting in components with excellent dimensional accuracy, surface finish, and mechanical properties.

Manufacturing Process Flow

Aluminum Parts Categories & Applications

Aluminum Parts manufactured through our pressing operations encompass a broad spectrum of components designed for industrial, automotive, electrical, and aerospace applications. These parts leverage aluminum’s excellent strength-to-weight ratio, corrosion resistance, and electrical conductivity properties. Our aluminum parts manufacturing includes structural components, decorative elements, functional hardware, and specialized assemblies that require precise dimensional control and superior surface finish.

Aluminum Pressed Parts specifically refer to components manufactured through controlled deformation processes using dies and punches. These parts typically feature complex geometries, tight tolerances, and uniform material distribution achieved through progressive or transfer pressing operations. Common aluminum pressed parts include automotive brackets, electrical enclosures, heat sinks, mounting hardware, and structural reinforcement components.

Aluminum Sheet Metal Parts are manufactured from flat aluminum sheets through cutting, bending, forming, and joining operations. Our sheet metal capabilities include laser cutting, plasma cutting, waterjet cutting, and precision forming using press brakes and specialized forming equipment. These parts often serve as enclosures, panels, covers, and structural elements in various industrial applications.

Aluminum Sheet Metal Components represent finished assemblies that may incorporate multiple sheet metal parts through welding, riveting, or mechanical fastening. These components often require secondary operations such as machining, threading, and surface treatment to achieve final specifications. Industries utilizing these components include HVAC, electrical equipment, telecommunications, and industrial machinery.

Aluminum Pressing Work encompasses all forming operations that involve controlled plastic deformation of aluminum materials. This includes deep drawing for cylindrical and rectangular housings, progressive stamping for complex parts with multiple features, and specialized forming operations for unique geometries. Our pressing work capabilities extend to prototype development, tooling design, and high-volume production runs.

Aluminum Deep Drawn Parts are specialized components manufactured through deep drawing processes where aluminum sheet is formed into three-dimensional shapes with significant depth-to-diameter ratios. These parts include cylindrical housings, rectangular enclosures, tapered containers, and complex shaped assemblies used in electrical, automotive, and industrial applications. Deep drawing operations require precise control of material flow, lubrication, and forming speeds to prevent defects and achieve optimal surface finish.

Material Grades & International Standards

| Aluminum Grade | International Standards | Chemical Composition | Typical Applications | Mechanical Properties |

|---|---|---|---|---|

| 1100 | ASTM B209, EN AW-1050A, JIS A1050, IS 737 | 99.00% Al min | Electrical conductors, chemical equipment | Tensile: 90-110 MPa |

| 3003 | ASTM B209, EN AW-3003, JIS A3003, DIN 1.4345 | Al-1.2%Mn | General sheet metal work, heat exchangers | Tensile: 110-130 MPa |

| 5052 | ASTM B209, EN AW-5052, JIS A5052, IS 65348 | Al-2.5%Mg | Marine applications, automotive body panels | Tensile: 190-230 MPa |

| 6061 | ASTM B221, EN AW-6061, JIS A6061, DIN 3.3211 | Al-1%Mg-0.6%Si | Structural components, aerospace parts | Tensile: 260-310 MPa |

| 6063 | ASTM B221, EN AW-6063, JIS A6063, BS 1474 | Al-0.7%Mg-0.4%Si | Architectural extrusions, decorative trim | Tensile: 185-240 MPa |

| 7075 | ASTM B209, EN AW-7075, JIS A7075, DIN 3.4365 | Al-5.6%Zn-2.5%Mg | Aerospace, high-strength applications | Tensile: 510-580 MPa |

Manufacturing Processes & Machinery

Our aluminum pressing operations utilize state-of-the-art manufacturing equipment designed for precision, efficiency, and consistency. The manufacturing process begins with material preparation, including cutting, deburring, and cleaning operations to ensure optimal pressing conditions. Progressive die stamping operations are performed using high-speed mechanical presses with servo-controlled feed systems for precise material advancement and positioning.

Hydraulic Presses

Capacity Range: 100-1000 tons

Bed Size: Up to 2000mm x 1500mm

Stroke Length: 200-800mm

Applications: Deep drawing, forming, blanking

Mechanical Presses

Capacity Range: 50-500 tons

SPM: 30-120 strokes per minute

Precision: ±0.05mm repeatability

Applications: Progressive stamping, piercing

Servo Presses

Capacity Range: 80-800 tons

Speed Control: Variable 0.1-100mm/s

Position Accuracy: ±0.01mm

Applications: Complex forming, multi-stage operations

Typical Aluminum Pressed Components

Our comprehensive range of aluminum pressed components includes Aluminum Clamps for securing pipes, cables, and structural elements in industrial and electrical installations. These clamps feature precise formed profiles with integrated mounting holes, smooth edges, and corrosion-resistant finishes suitable for outdoor and marine environments. Aluminum Brackets manufactured through our pressing operations include L-brackets, U-brackets, mounting brackets, and custom-designed structural support elements used in construction, automotive, and machinery applications.

Aluminum Saddles represent specialized pressed components designed for cable support, pipe mounting, and equipment installation applications. These saddles feature contoured profiles, integrated fastening systems, and dimensional precision required for reliable installation and long-term performance. Our aluminum saddle manufacturing includes standard catalog items as well as custom-engineered solutions for specific application requirements.

| Component Type | Typical Dimensions (mm) | Material Thickness (mm) | Tolerance Grade | Surface Finish | Primary Applications |

|---|---|---|---|---|---|

| Aluminum Clamps | 25-200 diameter | 1.5-6.0 | IT7-IT9 | Mill finish, Anodized | Pipe mounting, cable management |

| Aluminum Brackets | 50×50 to 300×300 | 2.0-8.0 | IT8-IT10 | Powder coated, Anodized | Structural support, equipment mounting |

| Aluminum Saddles | 40-150 width | 2.5-5.0 | IT7-IT9 | Mill finish, Painted | Cable tray support, conduit mounting |

| Deep Drawn Housings | 30-400 diameter | 0.8-4.0 | IT6-IT8 | Anodized, Chromated | Electronic enclosures, automotive |

| Heat Sinks | 25-200 length | 3.0-10.0 | IT8-IT10 | Natural, Black anodized | LED lighting, power electronics |

Multi-Material Capabilities

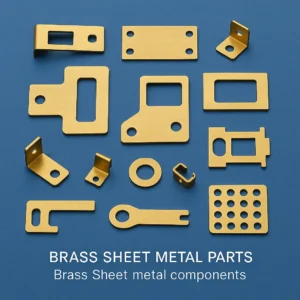

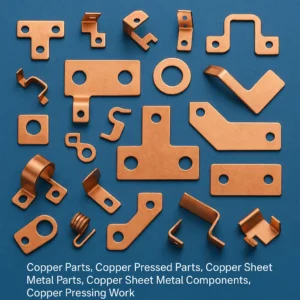

We also press Copper, Brass, and Stainless Steel and make sheet metal components from these materials. Our multi-material pressing capabilities enable comprehensive solutions for diverse industrial requirements. Copper pressing operations focus on electrical and thermal applications, including bus bars, heat exchangers, and electrical contacts with excellent conductivity properties. Brass pressing encompasses decorative hardware, plumbing fittings, and precision components requiring superior machinability and corrosion resistance.

Stainless Steel pressing operations handle grades including 304, 316, 430, and specialized alloys for food processing, medical, and chemical industry applications. Our stainless steel sheet metal components feature superior corrosion resistance, hygienic properties, and excellent mechanical strength for demanding service conditions. Multi-material pressing capabilities allow us to offer complete assembly solutions incorporating different materials optimized for specific functional requirements.

| Material | Common Grades | Pressing Characteristics | Typical Applications | Surface Treatments |

|---|---|---|---|---|

| Copper | C101, C102, C110 | Excellent formability, high conductivity | Electrical contacts, heat exchangers | Tin plating, nickel plating |

| Brass | C260, C360, C464 | Good formability, decorative finish | Plumbing fittings, architectural hardware | Polished, lacquered, antiqued |

| Stainless Steel | 304, 316, 430, 17-4PH | High strength, work hardening | Food equipment, medical devices | Passivated, electropolished, PVD |

Industries Served & Applications

Our aluminum pressed parts and sheet metal components serve diverse industries including automotive manufacturing, electrical equipment, construction, aerospace, telecommunications, and industrial machinery. Automotive applications include structural brackets, mounting hardware, heat shields, and decorative trim components requiring lightweight design and corrosion resistance. Electrical industry applications encompass enclosures, heat sinks, bus bars, and mounting hardware for power distribution, control panels, and electronic equipment.

Construction industry utilizes our aluminum components for architectural hardware, structural connections, cladding systems, and specialized fastening solutions. Aerospace applications require high-strength aluminum alloys formed into precision components with strict dimensional and material property requirements. Telecommunications applications include antenna brackets, equipment enclosures, and specialized mounting hardware designed for outdoor installation and RF shielding requirements.

Quality Standards & Tolerances

Dimensional Tolerances

Linear Dimensions: ±0.1mm standard, ±0.05mm precision

Hole Positions: ±0.08mm

Angular Tolerances: ±1° standard, ±0.5° precision

Flatness: 0.2mm per 100mm length

Surface Finish

As-Pressed: Ra 1.6-3.2 μm

Machined Surfaces: Ra 0.8-1.6 μm

Anodized: Class I, II, III available

Powder Coated: 50-100 μm thickness

Material Properties

Hardness Testing: Brinell, Rockwell

Tensile Testing: Per ASTM E8/E8M

Corrosion Testing: Salt spray per ASTM B117

Conductivity: Eddy current testing

Turnaround Time & Production Capabilities

Our standard turnaround time for aluminum pressed parts and sheet metal components is 4-6 weeks from order confirmation to delivery, depending on complexity, quantity, and material requirements. Rush orders can be accommodated with expedited tooling and production scheduling for critical applications. Prototype development and sampling typically require 2-3 weeks for simple components and up to 4 weeks for complex multi-stage pressing operations.

Production capabilities include batch quantities from 100 pieces to high-volume runs exceeding 1 million pieces annually. Our flexible manufacturing approach accommodates both just-in-time delivery requirements and scheduled production runs with inventory management services. Quality documentation including material certificates, dimensional reports, and surface finish verification are provided with all shipments to ensure traceability and compliance with customer specifications.

Why Choose Our Aluminum Pressed Parts

Global Experience

Three decades of international manufacturing experience with customers across North America, Europe, Asia, and Australia. Deep understanding of diverse industry requirements and regulatory compliance standards.

Superior Communication

English-speaking technical team with excellent communication skills for project coordination, technical discussions, and customer support throughout the manufacturing process.

Customization Capability

Complete ability to customize components, tooling, processes, and finishing to meet specific application requirements without compromising quality or delivery schedules.

Production Flexibility

Flexibility in production time with rush order capabilities, scheduled deliveries, and inventory management services to support diverse customer requirements.

Custom Packaging

Customized packaging with customer labels and logos including anti-corrosion treatments, export documentation, and specialized shipping arrangements for global delivery.

Technical Support

Comprehensive technical support including design assistance, material selection, process optimization, and value engineering to achieve optimal cost-performance balance.

Typical Aluminum Pressed parts-

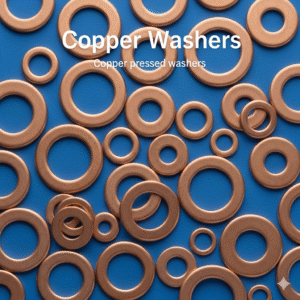

- Washers: Flat washers, spring washers, and fender washers are commonly punched or stamped from Aluminum sheet for use in applications where a lightweight, corrosion-resistant, or non-magnetic component is required.

- Pipe Clamps: Stamped and formed Aluminum pipe clamps are used to secure pipes and conduits in place. Their lightweight and superior corrosion resistance make them ideal for outdoor, marine, and industrial environments.

- Brackets and Plates: L-brackets, U-brackets, and various mounting plates are stamped from Aluminum for general-purpose structural support where weight reduction is a key factor.

- Shims: Precision-stamped shims for alignment and spacing in machinery and assemblies.

- Enclosures and Covers: Protective housings and covers for instruments, junction boxes, and control panels.

- Automotive Body Panels: Fenders, hoods, doors, and trunks are often stamped from Aluminum sheet for weight reduction, which improves fuel efficiency.

- Structural Supports: Lightweight mounting brackets, seat frames, and small structural components for cars and aircraft.

- Heat Shields: Stamped Aluminum heat shields are used to protect sensitive components from engine heat.

- Aircraft Components: Stamped fuselage panels, ribs, and other structural parts are common due to the material’s low density.

- Heat Sinks: Stamped and formed heat sinks for computers, LED lighting, and other electronic devices, leveraging Aluminum’s high thermal conductivity.

- Enclosures and Housings: Lightweight housings for computers, laptops, routers, and various electronic equipment.

- Electrical Busbars and Terminals: Stamped connectors and busbars for high-current applications.

- Battery Casings: Lightweight, impact-resistant battery enclosures for consumer electronics and electric vehicles.

- Beverage Cans: One of the most common deep-drawn Aluminum products globally.

- Food Containers: Stamped foil trays and containers for frozen foods and takeout.

- Appliance Components: Stamped panels, covers, and decorative trims for refrigerators, microwaves, and washing machines.

- Cookware: Pans and pots stamped from Aluminum for even heat distribution.

- Roofing and Siding: Stamped or roll-formed Aluminum panels used for roofing, siding, and gutters.

- Window and Door Frames: While often extruded, some components are stamped for specific profiles and fittings.

- Flashing: Stamped Aluminum flashing for roofing and construction to prevent water leaks.

Frequently Asked Questions

Q1: What aluminum alloys do you work with for pressed parts?

A: We work with all major aluminum alloys including 1100, 3003, 5052, 6061, 6063, and 7075. We can also source specialty alloys based on customer requirements and provide material certificates for all grades.

Q2: What are your minimum order quantities for aluminum pressed parts?

A: Our minimum order quantity is typically 100 pieces for standard components. For custom tooling projects, minimum quantities of 500-1000 pieces are generally required to justify tooling costs.

Q3: Can you provide secondary operations like machining and finishing?

A: Yes, we offer complete secondary operations including CNC machining, drilling, tapping, deburring, anodizing, powder coating, and assembly services for finished components.

Q4: What quality certifications do you maintain?

A: We maintain ISO 9001:2015 certification with full traceability, material certificates, dimensional inspection reports, and compliance with international standards including ASTM, DIN, JIS, and IS specifications.

Q5: Do you provide design assistance for new aluminum pressing projects?

A: Yes, our engineering team provides comprehensive design assistance including DFM analysis, tooling design, material selection, and process optimization to ensure manufacturable and cost-effective solutions.

Q6: What surface finishes are available for aluminum pressed parts?

A: We offer mill finish, anodizing (clear, color, hard coat), powder coating, painting, chromating, and specialized coatings for corrosion protection and aesthetic requirements.

Q7: Can you handle complex geometries and deep drawn aluminum parts?

A: Yes, our deep drawing capabilities handle draw ratios up to 3:1 with complex geometries including stepped, tapered, and flanged components using progressive and transfer press operations.

Q8: What inspection and testing capabilities do you have?

A: We maintain coordinate measuring machines (CMM), optical comparators, hardness testers, tensile testing equipment, and surface roughness measurement for complete quality verification.

Q9: Do you export aluminum pressed parts globally?

A: Yes, we export to over 25 countries with complete export documentation, packaging services, and logistics coordination for door-to-door delivery worldwide.

Q10: Can you work with customer-supplied materials for pressing operations?

A: Yes, we can process customer-supplied aluminum materials with proper material verification, handling procedures, and documentation to maintain traceability and quality control.

Q11: What tooling services do you provide for aluminum pressing projects?

A: We provide complete tooling services including design, manufacturing, tryout, and maintenance of progressive dies, transfer dies, and deep draw tooling with full documentation and backup capabilities.

Q12: How do you ensure consistent quality in high-volume production?

A: We utilize statistical process control (SPC), automated inspection systems, regular tool maintenance schedules, and trained operators with documented procedures to ensure consistent quality in high-volume production runs.

“We have been sourcing aluminum brackets and electrical clamps from this manufacturer for over 8 years. Their consistent quality, competitive pricing, and exceptional communication have made them our preferred supplier. The technical support team understands our requirements perfectly, and deliveries are always on schedule. Highly recommended for anyone looking for reliable aluminum pressing capabilities from India.”

– Michael Patterson, Procurement Manager, UK

Packaging & Shipping

Our comprehensive packaging solutions ensure safe delivery of aluminum pressed parts and sheet metal components worldwide. Standard packaging includes anti-corrosion treatments, moisture barriers, and protective cushioning materials selected based on component geometry and destination requirements. Customized packaging with customer labels and logos is available for retail-ready products and branded component supplies.

Export packaging complies with international shipping standards including ISPM-15 wooden packaging requirements, dangerous goods classifications when applicable, and country-specific documentation requirements. We coordinate with freight forwarders, shipping lines, and logistics providers to ensure cost-effective and timely delivery to destinations worldwide. Shipment tracking, insurance options, and delivery confirmation services are provided for all international orders.

Glossary of Technical Terms

Related Parts:

Request Your Custom Quote Today

Ready to discuss your aluminum pressed parts requirements? Our technical team is standing by to provide expert guidance and competitive pricing for your project.

📧 Email Quote Request

Send detailed specifications to:

sales@brass-copper-parts. com

📱 WhatsApp Consultation

Quick discussions and file sharing:

+91-22-43449300

📞 Technical Support

Speak with our engineers:

+91-22-43449300

📁 Request Brochure

Comprehensive capability guide:

sales@brass-copper-parts. com

Contact us today for competitive pricing, technical expertise, and reliable delivery of your aluminum pressed parts requirements!