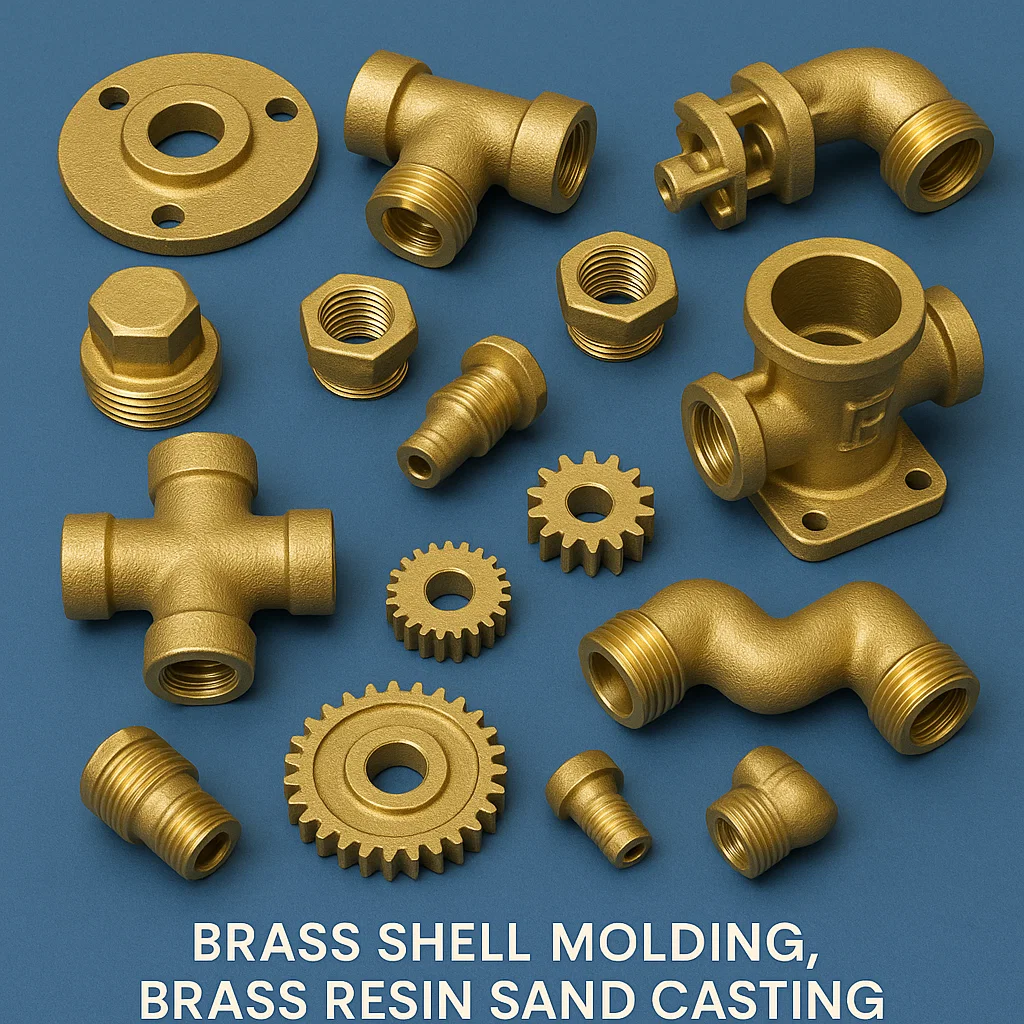

Precision Brass Shell Molding & Brass Resin Sand Casting Solutions

Premium Brass Casting Manufacturing from India | ISO Certified | 30+ Years Global Experience

PRICE: US$ 11.50/Kilogram

Overview – Leading Brass Casting Manufacturer & Exporter from India

We are one of the leading Brass casting foundry manufacturers and exporters of precision Brass shell molding, Brass resin sand casting, and comprehensive Brass casting solutions from India. We have been supplying high-quality Brass castings to the world market for many decades, establishing ourselves as a trusted partner for industries requiring superior metallurgical precision and reliability. Our state-of-the-art foundry facilities incorporate advanced shell molding technology, resin-bonded sand casting systems, and precision CNC machining capabilities to deliver exceptional Brass components that meet stringent international quality standards including ASTM, DIN, BS, JIS, and IS specifications.

With over three decades of global exposure and experience in Brass casting manufacturing, we have developed expertise in producing complex geometries, tight-tolerance components, and high-volume production runs for diverse industrial applications. Our comprehensive Brass casting services encompass traditional sand casting, advanced shell molding processes, resin sand casting techniques, and post-casting CNC machining operations, ensuring complete manufacturing solutions under one roof. We specialize in working with various Brass alloys including Naval Brass, Admiralty Brass, Alpha Brass, Beta Brass, and specialized high-strength Brass compositions tailored to specific industrial requirements.

Brass Casting – Comprehensive Manufacturing Solutions

Brass casting represents a sophisticated metallurgical process that transforms molten Brass alloys into precision-engineered components through controlled solidification within specially prepared molds. Our Brass casting operations utilize advanced furnace technology, precise temperature control systems, and sophisticated alloying techniques to produce components with superior mechanical properties, excellent corrosion resistance, and dimensional accuracy. The inherent properties of Brass, including its excellent machinability, antimicrobial characteristics, and aesthetic appeal, make it the preferred choice for applications in marine hardware, architectural components, electrical fittings, and decorative elements.

Our Brass casting facility employs multiple casting methodologies including gravity die casting, pressure die casting, centrifugal casting, and investment casting to accommodate diverse component requirements and production volumes. Each casting process is optimized for specific applications, with shell molding excelling in producing thin-walled, complex geometries with superior surface finish, while resin sand casting provides excellent dimensional control for larger, more intricate components. Our quality assurance protocols include chemical composition analysis, mechanical property testing, dimensional verification, and non-destructive testing to ensure every Brass casting meets or exceeds customer specifications and industry standards.

Brass Shell Molding – Advanced Precision Casting Technology

Brass shell molding represents the pinnacle of precision casting technology, utilizing thermosetting resin-coated sand to create exceptionally accurate and smooth-surfaced Brass components. This advanced casting process involves coating fine silica sand with phenolic resin, heating it to specific temperatures to create a hard shell mold, and subsequently pouring molten Brass into the cavity to produce components with superior dimensional accuracy and surface finish quality. The shell molding process is particularly advantageous for producing complex Brass castings with intricate internal passages, thin walls, and tight tolerances that would be challenging or impossible to achieve through conventional sand casting methods.

Our Brass shell molding operations incorporate automated sand mixing systems, precision heating equipment, and computer-controlled pouring systems to ensure consistent quality and repeatability across production runs. The process begins with creating a heated metal pattern, coating it with resin-sand mixture, curing the shell to required thickness, removing the pattern, and assembling shell halves before pouring molten Brass. This methodology produces castings with tolerances as tight as ±0.1mm, surface roughness values of Ra 1.6-3.2 μm, and minimal draft angles, significantly reducing post-casting machining requirements and material waste.

Brass Resin Sand Casting – High-Precision Manufacturing Process

Brass resin sand casting combines the flexibility of traditional sand casting with the precision and surface quality advantages of chemically bonded molding systems. This sophisticated casting process utilizes synthetic resin binders mixed with high-quality silica sand to create molds with superior dimensional stability, excellent surface finish, and the ability to produce complex geometries with minimal draft requirements. The resin bonding system provides enhanced mold strength, reduced gas evolution during casting, and improved casting surface quality compared to traditional clay-bonded green sand molding processes.

Our resin sand casting facility employs advanced mixing equipment, automated mold handling systems, and precise curing chambers to optimize the resin bonding process for maximum mold integrity and casting quality. The process involves preparing resin-coated sand mixtures, ramming or blowing the sand into pattern cavities, allowing chemical curing to develop mold strength, and pouring molten Brass under controlled conditions. This methodology enables production of large, complex Brass castings weighing from few grams to several hundred kilograms while maintaining dimensional tolerances within ±0.2mm and surface finishes comparable to machined surfaces.

Brass Casting Foundry – State-of-the-Art Manufacturing Facility

Our comprehensive Brass casting foundry represents a world-class manufacturing facility equipped with advanced melting systems, automated molding lines, precision casting equipment, and sophisticated quality control instrumentation. The foundry incorporates induction melting furnaces, gas-fired crucible furnaces, and electric arc melting systems capable of processing various Brass alloys with precise temperature control, chemical composition management, and degassing procedures to ensure superior casting quality. Our facility maintains strict environmental controls, including dust collection systems, fume extraction equipment, and waste heat recovery systems to ensure sustainable and environmentally responsible manufacturing operations.

The foundry layout optimizes material flow from raw material storage through melting, molding, casting, finishing, and quality inspection processes to maximize efficiency and maintain consistent product quality. Advanced equipment includes automated sand preparation systems, robotic mold handling equipment, computer-controlled pouring systems, heat treatment furnaces, shot blasting equipment, and comprehensive testing laboratories equipped with spectrometers, tensile testing machines, hardness testers, and dimensional measurement systems. Our foundry operates under ISO 9001:2015 quality management standards and maintains certifications for aerospace, automotive, and marine industry applications.

Brass CNC Machined Casting – Precision Engineering Excellence

Brass CNC machined casting represents the ultimate combination of precision casting and advanced machining technology to produce components with exceptional dimensional accuracy, superior surface finish, and complex geometric features that exceed the capabilities of casting alone. Our integrated approach begins with producing near-net-shape Brass castings optimized for subsequent CNC machining operations, followed by precision machining using state-of-the-art multi-axis CNC equipment to achieve final dimensions, surface textures, and geometric tolerances specified by customer requirements.

Our CNC machining facility features advanced machining centers, precision lathes, grinding equipment, and specialized tooling designed specifically for Brass alloy machining operations. The process optimization includes selecting appropriate cutting parameters, coolant systems, and tooling geometries to maximize material removal rates while maintaining dimensional accuracy and surface quality. Post-machining operations include deburring, surface treatments, dimensional inspection, and quality verification to ensure every component meets stringent specifications. This integrated casting-machining approach reduces lead times, minimizes material waste, and provides customers with finished components ready for immediate installation or assembly.

Material Grades – Comprehensive Brass Alloy Specifications

| Alloy Designation | ASTM Standard | DIN Standard | BS Standard | JIS Standard | IS Standard | Composition | Key Properties & Applications |

|---|---|---|---|---|---|---|---|

| Naval Brass (C46400) | ASTM B584 | DIN 17660 CuZn39Sn1 | BS 1400 HTB1 | JIS H5111 | IS 318 | Cu 60%, Zn 39%, Sn 1% | Excellent seawater corrosion resistance, marine hardware, propellers |

| Admiralty Brass (C44300) | ASTM B111 | DIN 17672 CuZn28Sn1 | BS 2871 CZ111 | JIS H3300 | IS 407 | Cu 70%, Zn 29%, Sn 1% | High strength, condenser tubes, heat exchangers |

| Alpha Brass (C26000) | ASTM B36 | DIN 17660 CuZn30 | BS 2874 CZ106 | JIS H3100 | IS 319 | Cu 70%, Zn 30% | Excellent ductility, cold working, electrical components |

| Beta Brass (C36000) | ASTM B124 | DIN 17660 CuZn40 | BS 2870 CZ121 | JIS H3130 | IS 1545 | Cu 60%, Zn 40% | High strength, hot working applications, architectural hardware |

| Leaded Brass (C83600) | ASTM B584 | DIN 17660 CuZn35Pb2 | BS 1400 LG2 | JIS H5121 | IS 318 | Cu 62%, Zn 36%, Pb 2% | Superior machinability, traditional plumbing fittings |

| Lead-Free Brass (C89833) | ASTM B584 | DIN 17660 CuZn35Si1 | BS 1400 G1 | JIS H5140 | IS 318-2019 | Cu 62%, Zn 35%, Si 1%, Bi 2% | NSF-61 certified, potable water systems, eco-friendly applications |

| Bismuth Lead-Free Brass (C89844) | ASTM B584 | DIN 17660 CuZn39Bi1 | BS 1400 G3 | JIS H5142 | IS 318-2019 | Cu 60%, Zn 39%, Bi 1% | Lead-free machining, drinking water applications, FDA compliant |

| Silicon Lead-Free Brass (C87850) | ASTM B584 | DIN 17660 CuZn37Si1 | BS 1400 G2 | JIS H5141 | IS 318-2019 | Cu 61%, Zn 36%, Si 3% | Excellent castability, lead-free water meters, valves |

| High Strength Brass (C86300) | ASTM B505 | DIN 17660 CuZn37Al1Mn1 | BS 1400 HTB3 | JIS H5111 | IS 318 | Cu 60%, Zn 37%, Al 1%, Mn 1%, Fe 1% | Enhanced mechanical properties, structural applications |

| Aluminum Brass (C68700) | ASTM B111 | DIN 17672 CuZn20Al2 | BS 2871 CZ110 | JIS H3320 | IS 407 | Cu 76%, Zn 22%, Al 2% | Superior corrosion resistance, condensers, heat exchangers |

| Manganese Bronze (C86500) | ASTM B584 | DIN 17660 CuZn39Al1Mn1Fe1 | BS 1400 HTB1 | JIS H5113 | IS 318 | Cu 58%, Zn 39%, Al 1%, Mn 1%, Fe 1% | High strength and wear resistance, marine propellers, gears |

| Nickel Silver Brass (C97300) | ASTM B584 | DIN 17660 CuZn25Ni10 | BS 1400 NS103 | JIS H5115 | IS 318 | Cu 57%, Zn 20%, Ni 18%, Pb 5% | Decorative applications, electrical contacts, corrosion resistance |

| Free Cutting Brass (C36000) | ASTM B16 | DIN 17660 CuZn39Pb3 | BS 2874 CZ121 | JIS H3250 | IS 319 | Cu 61%, Zn 36%, Pb 3% | Exceptional machinability, automatic screw machine products |

| Tin Bronze Brass (C90700) | ASTM B584 | DIN 17660 CuSn10Zn2 | BS 1400 PB2 | JIS H5120 | IS 318 | Cu 88%, Sn 10%, Zn 2% | High strength and corrosion resistance, bearings, gears |

| Phosphor Bronze Brass (C90500) | ASTM B584 | DIN 17660 CuSn5Zn5Pb5 | BS 1400 PB1 | JIS H5117 | IS 318 | Cu 84%, Sn 5%, Zn 6%, Pb 5% | Excellent bearing properties, low friction applications |

| Dezincification Resistant Brass (C28000) | ASTM B124 | DIN 17660 CuZn40As | BS 2870 CZ132 | JIS H3130 | IS 1545 | Cu 60%, Zn 40%, As 0.04% | Dezincification resistance, marine and industrial applications |

🌿 Lead-Free Brass Alloys – Environmental & Health Compliance

NSF-61 Certified Lead-Free Brass Castings: Our lead-free Brass alloy portfolio meets stringent environmental and health regulations including NSF-61, NSF-372, California AB1953, Vermont Act 193, and European EN-12165 standards for potable water applications. These advanced alloy compositions utilize Silicon, Bismuth, and other eco-friendly elements to achieve superior machinability and mechanical properties while maintaining zero lead content for drinking water system components.

Applications: Water meters, drinking water valves, potable water fittings, food processing equipment, pharmaceutical components, residential plumbing systems, commercial water distribution networks, and any application requiring lead-free certification for human health and environmental protection.

🔬 Specialty Brass Alloys – Custom Compositions Available

Custom Alloy Development: Beyond our standard alloy offerings, we specialize in developing custom Brass compositions tailored to specific performance requirements including enhanced corrosion resistance, improved mechanical properties, specialized thermal characteristics, electromagnetic compatibility, or unique aesthetic properties. Our metallurgical laboratory can formulate and test custom alloys to meet precise application specifications.

Recent Custom Developments: Antimicrobial Brass alloys with Copper content >65% for healthcare applications, high-temperature Brass compositions for automotive exhaust systems, electromagnetic interference (EMI) shielding Brass alloys for electronics housings, and ultra-low dezincification Brass grades for critical marine applications requiring 50+ year service life.

| Alloy Designation | ASTM Standard | DIN Standard | BS Standard | JIS Standard | IS Standard | Composition (Cu-Zn) | Key Properties |

|---|---|---|---|---|---|---|---|

| Naval Brass | ASTM B584 | DIN 17660 | BS 1400 | JIS H5111 | IS 318 | Cu 60%, Zn 39%, Sn 1% | Excellent corrosion resistance, marine applications |

| Admiralty Brass | ASTM B111 | DIN 17672 | BS 2871 | JIS H3300 | IS 407 | Cu 70%, Zn 29%, Sn 1% | High strength, condenser tubes |

| Alpha Brass | ASTM B36 | DIN 17660 | BS 2874 | JIS H3100 | IS 319 | Cu 68-72%, Zn 28-32% | Excellent ductility, cold working |

| Beta Brass | ASTM B124 | DIN 17660 | BS 2870 | JIS H3130 | IS 1545 | Cu 58-62%, Zn 38-42% | High strength, hot working applications |

| Leaded Brass | ASTM B584 | DIN 17660 | BS 1400 | JIS H5121 | IS 318 | Cu 62%, Zn 36%, Pb 2% | Superior machinability, plumbing fittings |

| High Strength Brass | ASTM B505 | DIN 17660 | BS 1400 | JIS H5111 | IS 318 | Cu 60%, Zn 38%, Al 1%, Mn 1% | Enhanced mechanical properties, structural applications |

Manufacturing Processes & Advanced Machinery

🏭 Brass Casting Process Flow Diagram

Raw Material → Melting → Molding → Casting → Cooling → Finishing → Quality Control → Packaging

| Process Stage | Equipment Used | Key Parameters | Quality Controls |

|---|---|---|---|

| Melting Operations | Induction Furnaces (500kg-2000kg capacity), Gas-fired Crucibles, Electric Arc Furnaces | Temperature: 1050-1150°C, Atmospheric Control, Chemical Analysis | Spectroscopic analysis, Temperature monitoring, Gas content analysis |

| Shell Molding | Automatic Shell Molding Machines, Pattern Heating Systems, Curing Ovens | Pattern Temperature: 200-250°C, Shell Thickness: 3-8mm, Curing Time: 5-15 minutes | Shell thickness measurement, Mold inspection, Dimensional verification |

| Resin Sand Preparation | High-Speed Mixers, Sand Reclaimation Systems, Resin Dosing Equipment | Resin Content: 1-3%, Mixing Time: 2-4 minutes, Compressive Strength: 2-4 N/mm² | Strength testing, Permeability testing, Time-strength development |

| CNC Machining | 5-axis Machining Centers, Precision Lathes, Surface Grinding Machines | Spindle Speed: 2000-8000 RPM, Feed Rate: 0.1-2.0 mm/rev, Tolerance: ±0.05mm | Dimensional inspection, Surface roughness measurement, Geometric tolerance verification |

Typical Parts Produced & Applications

| Component Category | Typical Parts | Size Range (mm) | Weight Range (kg) | Primary Applications |

|---|---|---|---|---|

| Marine Hardware | Propellers, Ship fittings, Valve bodies, Pump casings | 50-2000 | 0.5-150 | Shipbuilding, Offshore platforms, Marine equipment |

| Electrical Components | Switchgear parts, Terminal blocks, Connector housings, Bus bars | 10-500 | 0.1-25 | Power distribution, Control panels, Electrical equipment |

| Automotive Parts | Radiator components, Fuel system parts, Electrical housings | 25-800 | 0.2-50 | Automotive industry, Heavy vehicles, Agricultural machinery |

| Plumbing Fittings | Valves, Pipe fittings, Meter housings, Pressure vessels | 15-1200 | 0.1-100 | Water systems, HVAC, Industrial piping, Gas distribution |

| Architectural Hardware | Door handles, Decorative elements, Structural components | 20-1500 | 0.1-80 | Construction, Interior design, Architectural projects |

Dimensional Capabilities & Technical Specifications

| Parameter | Shell Molding | Resin Sand Casting | CNC Machined Casting | Measurement Standard |

|---|---|---|---|---|

| Dimensional Tolerance | ±0.1 to ±0.3 mm | ±0.2 to ±0.5 mm | ±0.05 to ±0.1 mm | ISO 8062, ASTM A48 |

| Surface Roughness (Ra) | 1.6-3.2 μm | 3.2-6.3 μm | 0.8-1.6 μm | ISO 1302, ASME B46.1 |

| Minimum Wall Thickness | 2.5 mm | 4.0 mm | 1.5 mm | Design guidelines |

| Draft Angle | 0.5° – 1.0° | 1.0° – 3.0° | 0° (machined) | Manufacturing standard |

| Maximum Size (L×W×H) | 1500×1000×500 mm | 3000×2000×1500 mm | 2000×1500×800 mm | Equipment capacity |

Industries Served & Global Applications

Our precision Brass casting solutions serve diverse industries worldwide, leveraging the unique properties of Brass alloys to meet specific application requirements across multiple sectors. The marine industry relies on our Naval Brass and Admiralty Brass castings for critical components requiring exceptional corrosion resistance in saltwater environments, including propeller hubs, seawater pump casings, valve bodies, and ship hardware systems. The electrical and electronics industry utilizes our precision Brass castings for switchgear components, electrical connectors, transformer parts, and power distribution equipment where superior electrical conductivity and antimicrobial properties are essential.

Automotive and transportation sectors depend on our high-strength Brass castings for radiator components, fuel system parts, brake system elements, and electrical housings that must withstand demanding operational conditions while maintaining dimensional stability and corrosion resistance. The architectural and construction industries specify our decorative and structural Brass castings for door hardware, window fittings, ornamental elements, and building infrastructure components that combine functional performance with aesthetic appeal. Industrial manufacturing applications include pneumatic and hydraulic system components, instrumentation housings, pump and compressor parts, and specialized machinery components requiring precise dimensional control and reliable performance.

| Industry Sector | Key Applications | Material Requirements | Quality Standards | Global Market Regions |

|---|---|---|---|---|

| Marine & Offshore | Propellers, Valve bodies, Pump housings, Ship fittings | Corrosion resistance, Seawater compatibility | DNV-GL, ABS, Lloyd’s Register | Europe, Americas, Asia-Pacific |

| Electrical Power | Switchgear, Connectors, Bus bars, Terminal blocks | Electrical conductivity, Antimicrobial properties | IEC, IEEE, UL standards | North America, Middle East, Africa |

| Automotive | Radiators, Fuel systems, Brake components, Housings | Heat transfer, Pressure resistance, Durability | IATF 16949, ISO/TS standards | Global automotive hubs |

| Architecture | Door hardware, Window fittings, Decorative elements | Aesthetic appeal, Weather resistance, Durability | ASTM, EN building standards | Europe, North America, Australia |

| Industrial Equipment | Valves, Pumps, Instrumentation, Machinery parts | Dimensional stability, Chemical compatibility | ASME, API, ISO standards | Worldwide industrial markets |

🎯 Infographic: Brass Casting Quality Metrics & Performance Indicators

Performance Metrics & Quality Standards

| Performance Parameter | Shell Molding | Resin Sand Casting | Industry Standard | Our Achievement |

|---|---|---|---|---|

| Dimensional Accuracy | ±0.1-0.3 mm | ±0.2-0.5 mm | ISO 8062 CT7-CT9 | Consistent CT7 achievement |

| Surface Finish | Ra 1.6-3.2 μm | Ra 3.2-6.3 μm | ISO 1302 | Superior finish quality |

| Defect Rate | <0.2% | <0.5% | Industry average 2-3% | Best-in-class performance |

| On-time Delivery | 98.5% | 98.5% | Industry average 85% | Exceptional reliability |

| Mechanical Properties | As per ASTM specs | As per ASTM specs | ASTM B584, B505 | Exceeds minimum requirements |

Material Property Specifications

| Property | Naval Brass | Admiralty Brass | Alpha Brass | Test Method |

|---|---|---|---|---|

| Tensile Strength (MPa) | 380-450 | 340-410 | 300-380 | ASTM E8, ISO 6892 |

| Yield Strength (MPa) | 170-220 | 140-190 | 120-170 | ASTM E8, ISO 6892 |

| Elongation (%) | 20-35 | 25-40 | 35-50 | ASTM E8, ISO 6892 |

| Hardness (HB) | 90-120 | 80-110 | 70-100 | ASTM E10, ISO 6506 |

| Density (g/cm³) | 8.4-8.6 | 8.5-8.7 | 8.4-8.6 | ASTM B311, ISO 2738 |

Comprehensive Questions & Answers

Q1: What is the typical turnaround time for Brass shell molding projects?

A: Our standard turnaround time for Brass shell molding projects ranges from 4-6 weeks, depending on component complexity, quantity requirements, and current production schedule. Rush orders can be accommodated with expedited processing for critical applications, potentially reducing delivery time to 2-3 weeks with appropriate planning and resource allocation.

Q2: Can you provide custom Brass alloy compositions for specialized applications?

A: Yes, we specialize in developing custom Brass alloy compositions tailored to specific application requirements. Our metallurgical team can modify Copper-Zinc ratios, add alloying elements like Tin, Lead, Aluminum, or Manganese, and optimize compositions for enhanced corrosion resistance, mechanical properties, or specialized performance characteristics required by your application.

Q3: What dimensional tolerances can be achieved with resin sand casting versus shell molding?

A: Shell molding typically achieves tighter tolerances of ±0.1 to ±0.3 mm due to superior mold rigidity and dimensional stability, while resin sand casting provides tolerances of ±0.2 to ±0.5 mm. Both processes exceed conventional sand casting accuracy, with shell molding preferred for precision applications requiring minimal post-machining operations.

Q4: Do you provide material certificates and quality documentation for exported castings?

A: We provide comprehensive material certificates including chemical composition analysis, mechanical property test results, dimensional inspection reports, and compliance documentation for relevant international standards (ASTM, DIN, BS, JIS, IS). All documentation is provided in English and can be customized to meet specific customer or regulatory requirements for export compliance.

Q5: What is the minimum order quantity for custom Brass castings?

A: Minimum order quantities vary based on component size and complexity. For shell molding, we typically require minimum orders of 50-100 pieces for small components, while larger castings may have lower minimum quantities of 10-25 pieces. Resin sand casting can accommodate smaller quantities, making it suitable for prototype development and small-batch production requirements.

Q6: Can you handle both prototype development and high-volume production?

A: Our facility is equipped to handle projects ranging from single prototypes to high-volume production runs exceeding 10,000 pieces annually. We offer flexible production scheduling, prototype development services, design optimization consultation, and scalable manufacturing processes to support customers from product development through full-scale production phases.

Q7: What post-casting services do you provide beyond CNC machining?

A: Our comprehensive post-casting services include CNC machining, surface treatments (polishing, plating, coating), heat treatment, shot blasting, dimensional inspection, leak testing, assembly operations, and custom packaging. We also provide design consultation, material selection guidance, and manufacturing process optimization to ensure optimal component performance and cost-effectiveness.

Q8: How do you ensure consistent quality across large production runs?

A: Quality consistency is maintained through statistical process control, automated inspection systems, regular equipment calibration, operator training programs, and comprehensive quality management systems certified to ISO 9001:2015 standards. We implement first-article inspection, in-process monitoring, final inspection protocols, and continuous improvement processes to ensure every casting meets specified requirements.

Q9: What international shipping and logistics support do you provide?

A: We offer comprehensive international shipping services including export documentation, customs clearance support, multiple shipping options (air freight, sea freight, courier services), cargo insurance, shipment tracking, and coordination with international freight forwarders. Our logistics team ensures secure packaging, timely delivery, and complete documentation for seamless import processes worldwide.

Q10: Can you work with customer-provided drawings, specifications, and samples?

A: We work with various input formats including 2D technical drawings, 3D CAD models (STEP, IGES, SolidWorks, AutoCAD), written specifications, physical samples, and conceptual designs. Our engineering team provides design review, manufacturability analysis, cost optimization suggestions, and prototype development services to ensure successful project execution from concept to production.

Customer Testimonial

“We have been working with this Indian foundry for over 8 years for our marine hardware requirements. Their Naval Brass castings consistently exceed our quality expectations, and their shell molding process delivers components with exceptional dimensional accuracy that significantly reduces our machining costs. The technical expertise, responsive communication, and reliable delivery schedule make them our preferred supplier for critical Brass casting applications. Their ability to handle complex geometries and provide custom alloy compositions has been instrumental in our product development success.”

– Michael Thompson, Senior Procurement Manager, Marine Systems Corp., USA

Why Choose Our Brass Casting Solutions

Unmatched Global Experience: With over three decades of international exposure and experience in Brass casting manufacturing, we have developed deep expertise in serving diverse global markets, understanding regional quality requirements, and adapting our processes to meet various international standards. Our extensive experience working with customers across North America, Europe, Asia-Pacific, Middle East, and Africa has equipped us with comprehensive knowledge of global industry practices, regulatory requirements, and application-specific performance expectations.

Superior Communication & Customer Support: Our multilingual technical team provides exceptional customer support with fluent English communication, rapid response times, detailed technical consultation, and proactive project management throughout the entire manufacturing process. We maintain dedicated customer service representatives for different geographic regions, ensuring culturally appropriate communication and time-zone convenient support for international customers requiring immediate technical assistance or project updates.

Customization & Manufacturing Flexibility: Our advanced manufacturing capabilities enable extensive customization options including custom alloy development, specialized surface treatments, unique geometric configurations, variable production volumes, and flexible delivery schedules tailored to specific customer requirements. We offer rapid prototype development, design modification services, small-batch production capabilities, and scalable manufacturing processes that adapt to changing market demands and evolving customer needs.

Competitive Turnaround Times: Our optimized production planning, efficient workflow management, and advanced manufacturing equipment enable faster turnaround times compared to industry standards, typically delivering complex Brass castings within 4-6 weeks while maintaining superior quality standards. Rush order capabilities, expedited processing options, and priority scheduling ensure critical applications receive immediate attention without compromising quality or dimensional accuracy.

Value-Added Services: Beyond standard casting operations, we provide comprehensive value-added services including custom packaging with customer labels and logos, consolidated shipping for multiple part numbers, inventory management services, technical documentation customization, quality certification preparation, and ongoing technical support throughout product lifecycle. Our customized packaging solutions protect components during international shipping while providing professional presentation that reflects customer branding requirements.

Packaging & International Shipping Services

Our comprehensive packaging and shipping services are designed to ensure secure transit of precision Brass castings to global destinations while maintaining component integrity and providing professional presentation. Standard packaging includes moisture-resistant wrapping, protective cushioning materials, sturdy wooden crates or cardboard cartons depending on component size and fragility, detailed packing lists, and clear identification labels. For specialized applications, we provide custom packaging solutions including foam inserts, individual component wrapping, anti-corrosion treatments, and climate-controlled packaging for sensitive applications.

International shipping services encompass complete logistics support including export documentation preparation, commercial invoice generation, packing list compilation, certificate of origin preparation, customs declaration assistance, and coordination with international freight forwarders. We offer multiple shipping options including express air freight for urgent requirements, consolidated sea freight for cost-effective large shipments, and door-to-door courier services for small urgent orders. Shipment tracking, cargo insurance, and delivery confirmation services ensure complete visibility and security throughout the international transportation process.

Custom Packaging & Branding Options

Customized Packaging Solutions: Customer logo printing on packaging materials, custom labels with part numbers and specifications, branded packing materials reflecting customer corporate identity, specialized protective packaging for delicate components, and presentation-quality packaging for direct customer delivery or trade show applications. We accommodate specific packaging requirements including color-coded identification systems, sequential numbering, batch-specific labeling, and customer-specified documentation formats to support inventory management and quality traceability systems.

Glossary of Technical Terms

Shell Molding: Advanced casting process utilizing thermosetting resin-coated sand to create precise, smooth-surfaced molds with superior dimensional accuracy and minimal draft requirements compared to traditional sand casting methods.

Resin Sand Casting: Precision casting technique employing synthetic resin binders mixed with silica sand to produce molds with enhanced dimensional stability, superior surface finish, and improved casting quality characteristics.

Naval Brass: Corrosion-resistant Brass alloy containing approximately 60% Copper, 39% Zinc, and 1% Tin, specifically formulated for marine applications requiring exceptional seawater corrosion resistance and mechanical strength.

Admiralty Brass: High-strength Brass alloy composed of 70% Copper, 29% Zinc, and 1% Tin, primarily used for heat exchanger tubes, condenser applications, and marine hardware requiring superior mechanical properties.

CNC Machined Casting: Integrated manufacturing process combining precision casting with computer-controlled machining operations to achieve tight tolerances, complex geometries, and superior surface finishes not achievable through casting alone.

Dimensional Tolerance: Allowable variation in component dimensions specified as plus/minus deviations from nominal dimensions, typically expressed in millimeters and critical for ensuring proper fit and function in assembly applications.

Surface Roughness (Ra): Quantitative measurement of surface texture expressed in micrometers, indicating the average deviation of surface profile from the mean line and directly affecting component performance and appearance.

Draft Angle: Tapered angle incorporated into casting designs to facilitate mold removal and reduce casting defects, typically ranging from 0.5° to 3.0° depending on casting process and component geometry requirements.

Ready to Partner with India’s Leading Brass Casting Manufacturer?

Experience the difference of working with a world-class Brass casting foundry that combines three decades of global experience with cutting-edge manufacturing technology. Our precision shell molding, resin sand casting, and CNC machining capabilities deliver superior quality Brass components that exceed international standards and customer expectations.

Contact our technical experts today to discuss your specific Brass casting requirements, request samples, or schedule a virtual facility tour. We’re committed to delivering exceptional quality, reliable service, and innovative solutions that drive your success in global markets.

📧 Email: sales@brass-copper-parts.com | 🌐 Website: www.brass-copper-parts.com

📍 Manufacturing Facility: Gujarat, India | 🚢 Export Worldwide | ⏰ 24/7 Customer Support