Brass Turned Parts & Brass CNC Turned Parts – Precision Brass Machining

Price: US$ 9.25/kilogram

We are one of the leading manufacturers and exporters of precision Brass turned parts and Brass CNC machined components from India. We have been supplying high-quality Brass precision turned parts to the world market for many decades. Our state-of-the-art manufacturing facility specializes in producing custom Brass turned components, Brass automatic turned parts, and Brass Swiss turned parts with exceptional precision and reliability. With over three decades of expertise in CNC machining Brass parts, we serve diverse industries including automotive, aerospace, electronics, plumbing, and instrumentation. Our advanced manufacturing capabilities encompass Brass milled parts, Brass precision components, and complex multi-axis CNC turned parts that meet stringent international quality standards. We combine traditional craftsmanship with modern CNC technology to deliver superior Brass machined parts that exceed customer expectations in terms of dimensional accuracy, surface finish, and performance characteristics.

Overview of Brass Turned Parts Manufacturing

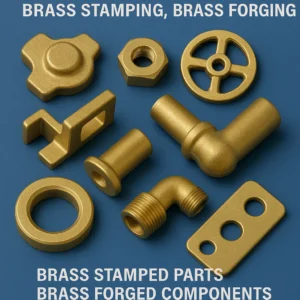

Brass turned parts represent a critical category of precision-engineered components manufactured through various turning processes including conventional lathe operations and advanced CNC machining techniques. These components are essential across multiple industries due to Brass’s excellent machinability, corrosion resistance, electrical conductivity, and aesthetic appeal. Our comprehensive manufacturing approach encompasses both high-volume production runs and specialized custom Brass turned components tailored to specific application requirements.

Brass Turned Parts

Traditional Brass turned parts are manufactured using conventional lathes and represent the foundation of precision component manufacturing. These parts are produced through controlled material removal processes where Brass rod or bar stock is rotated while cutting tools shape the component to exact specifications. Our Brass turned parts exhibit superior dimensional accuracy, excellent surface finish, and consistent mechanical properties. The turning process allows for the creation of cylindrical components, threaded parts, stepped shafts, bushings, and complex geometrical features. We specialize in producing Brass turned parts with tight tolerances ranging from ±0.01mm to ±0.05mm depending on the component complexity and application requirements. Our conventional turning capabilities include external turning, internal boring, facing, grooving, and knurling operations.

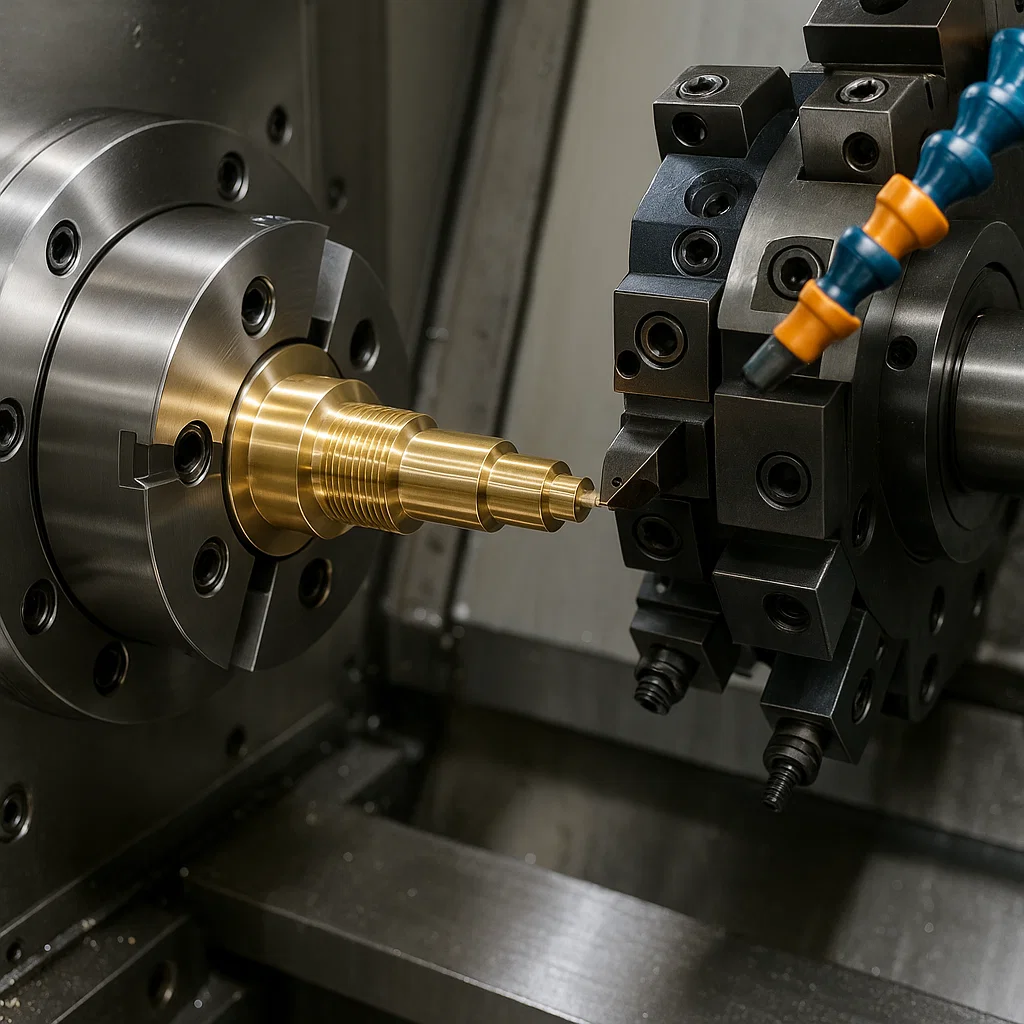

Brass CNC Turned Parts

Brass CNC turned parts represent the pinnacle of precision manufacturing, utilizing computer numerical control technology to achieve exceptional accuracy and repeatability. Our advanced CNC turning centers enable the production of complex Brass components with intricate geometries, multiple diameters, and precise threading operations in a single setup. CNC machining eliminates human error and ensures consistent quality across production runs, making it ideal for high-precision applications in aerospace, medical devices, and instrumentation. The automated nature of CNC turning allows for efficient production of both prototype quantities and large-scale manufacturing runs. Our CNC turned Brass parts feature superior dimensional stability, excellent concentricity, and precise surface finishes ranging from Ra 0.8 to Ra 3.2 micrometers.

Brass CNC Parts

Comprehensive Brass CNC parts encompass a broader range of components manufactured using various CNC machining processes beyond turning, including milling, drilling, and multi-axis operations. These parts are characterized by complex geometrical features, precise tolerances, and exceptional surface quality. Our CNC machining capabilities enable the production of Brass parts with intricate internal passages, custom profiles, and specialized features such as keyways, slots, and complex threading patterns. The versatility of CNC machining allows for the creation of both simple cylindrical components and highly complex assemblies requiring multiple manufacturing operations. We utilize advanced CAD/CAM software to optimize tool paths and ensure efficient material removal while maintaining dimensional accuracy.

Brass Precision Components

Brass precision components represent the highest tier of manufacturing excellence, characterized by extremely tight tolerances, superior surface finishes, and exceptional dimensional stability. These components are critical in applications where performance cannot be compromised, such as medical instruments, precision measuring equipment, and high-end electronic devices. Our precision manufacturing processes incorporate advanced quality control measures, statistical process control, and continuous monitoring to ensure consistent component quality. Brass precision components typically feature tolerances within ±0.005mm and surface finishes as fine as Ra 0.4 micrometers. The manufacturing process involves careful material selection, optimized cutting parameters, and specialized tooling to achieve the required precision levels.

Brass CNC Turned Parts (Detailed Analysis)

Advanced Brass CNC turned parts incorporate sophisticated programming techniques and multi-axis capabilities to create complex components with exceptional precision. Our CNC turning operations utilize live tooling capabilities enabling secondary operations such as cross-drilling, milling, and threading without part repositioning. This integrated approach reduces handling time, improves accuracy, and enhances production efficiency. The advanced CNC controls allow for adaptive machining strategies that automatically adjust cutting parameters based on material properties and cutting conditions. Our CNC turned parts feature complex internal geometries, precision threading with various pitch configurations, and specialized surface textures tailored to specific application requirements.

Brass Machined Parts

Brass machined parts encompass a comprehensive range of components produced through various machining processes including turning, milling, drilling, and grinding operations. These parts are characterized by precise dimensional control, excellent surface finish, and consistent mechanical properties. Our machining capabilities include conventional and CNC operations, enabling flexible production approaches based on component complexity and volume requirements. Brass machined parts often require multiple manufacturing steps and specialized fixturing to achieve the desired specifications. The machining process parameters are carefully optimized to prevent material work hardening and ensure dimensional stability throughout the manufacturing process.

Brass Custom Turned Components

Brass custom turned components are engineered solutions designed to meet specific customer requirements and application needs. These components often feature unique geometries, specialized threading patterns, and custom material specifications that cannot be accommodated through standard part offerings. Our engineering team collaborates closely with customers to develop optimized designs that balance functionality, manufacturability, and cost-effectiveness. The custom development process includes material selection, design optimization, prototype development, and validation testing. Custom turned components may incorporate special alloys, unique surface treatments, and precision assembly features to meet demanding application requirements.

Brass Precision Turned Parts

Brass precision turned parts are manufactured to exacting standards with minimal dimensional variation and superior surface quality. These components are essential in applications requiring consistent performance and reliability such as instrumentation, measurement devices, and precision assemblies. The manufacturing process involves careful material preparation, optimized cutting strategies, and comprehensive quality control measures. Precision turned parts feature tight tolerances typically within ±0.01mm and surface finishes ranging from Ra 0.8 to Ra 1.6 micrometers. The production process incorporates advanced measurement techniques and statistical process control to ensure consistent quality across production runs.

Brass Automatic Turned Parts

Brass automatic turned parts are produced using multi-spindle automatic lathes designed for high-volume production of relatively simple cylindrical components. These machines excel in producing consistent parts with minimal operator intervention, making them ideal for large-scale manufacturing operations. Automatic turning is particularly effective for components requiring basic turning operations such as external turning, facing, and simple threading. The automated nature of these machines ensures consistent cycle times and dimensional repeatability across extended production runs. Our automatic turning capabilities are optimized for components ranging from 3mm to 65mm in diameter with lengths up to 300mm.

CNC Machining Brass Parts

CNC machining of Brass parts represents a comprehensive manufacturing approach that combines turning, milling, and drilling operations in integrated machining centers. This approach enables the production of complex components with multiple features in a single setup, improving accuracy and reducing manufacturing time. CNC machining capabilities include live tooling for secondary operations, automated part handling systems, and integrated quality control measures. The programming flexibility of CNC systems allows for rapid adaptation to design changes and efficient production of both prototype and production quantities. Our CNC machining operations utilize advanced tooling systems and cutting strategies optimized for Brass materials.

Brass Swiss Turned Parts

Brass Swiss turned parts are manufactured using specialized Swiss-type lathes that excel in producing small, complex components with exceptional precision and surface finish. Swiss turning technology utilizes a sliding headstock design that provides superior support for long, slender parts and enables the production of components with extremely tight tolerances. The process is particularly effective for parts with diameter-to-length ratios exceeding 3:1 and components requiring multiple secondary operations. Swiss turned parts typically feature superior concentricity, minimal deflection, and excellent surface finish quality. Our Swiss turning capabilities accommodate parts ranging from 0.5mm to 32mm in diameter with lengths up to 300mm.

Brass Milled Parts

Brass milled parts are produced using CNC milling machines that remove material using rotating cutting tools to create complex geometries and precise features. Milling operations enable the creation of components with flat surfaces, angular features, pockets, and complex three-dimensional shapes that cannot be achieved through turning operations alone. Our milling capabilities include three-axis, four-axis, and five-axis machining centers that provide exceptional flexibility in component geometry and feature orientation. Brass milled parts often incorporate precision holes, slots, keyways, and custom profiles that require specialized tooling and programming techniques. The milling process is optimized to minimize tool wear and ensure consistent surface finish quality.

Brass Material Grades & Specifications

Our comprehensive material selection includes various Brass alloys optimized for different applications and manufacturing requirements. Each alloy offers unique characteristics in terms of machinability, corrosion resistance, mechanical properties, and aesthetic appearance.

| Standard | Grade | Composition | Applications |

|---|---|---|---|

| ASTM B16 | C36000 (Free-Cutting Brass) | Cu 61.5%, Zn 35.5%, Pb 3% | High-speed machining, automatic screw machine products |

| ASTM B121 | C26000 (Cartridge Brass) | Cu 70%, Zn 30% | Deep drawing, stamping, general purposes |

| BS 2870 | CZ121 (58/3 Brass) | Cu 58%, Zn 39%, Pb 3% | Free-cutting applications, marine hardware |

| DIN 17660 | CuZn39Pb3 | Cu 58%, Zn 39%, Pb 3% | Precision turned parts, fittings |

| JIS H3250 | C3604 | Cu 61%, Zn 36%, Pb 3% | Automatic lathe products, electrical components |

| IS 6912 | Grade 1 | Cu 60-63%, Zn 35.5-37.5%, Pb 2.5-3.7% | General engineering applications |

| EN 12164 | CW614N | Cu 58-60%, Zn 37-40%, Pb 2.5-3.5% | Hot forging, machining applications |

| GB/T 4423 | HPb59-1 | Cu 57-60%, Zn 37.5-40%, Pb 0.8-1.9% | Precision instruments, watch components |

Manufacturing Processes & Machinery

Our manufacturing facility incorporates state-of-the-art machinery and proven manufacturing processes to ensure consistent quality and efficient production. The combination of traditional craftsmanship and modern technology enables us to meet diverse customer requirements across various industries.

Manufacturing Process Flow

Material Inspection → Bar Feeding → CNC Programming → Machining Operations → Quality Control → Secondary Operations → Final Inspection → Packaging

| Machine Type | Specifications | Capabilities | Typical Applications |

|---|---|---|---|

| CNC Turning Centers | 8-axis, 42mm bar capacity, ±0.005mm accuracy | Complex turning, live tooling, sub-spindle | Precision shafts, complex components |

| Swiss-Type CNC Lathes | 32mm bar capacity, 12-axis simultaneous | High precision, complex geometries | Small precision parts, medical components |

| Multi-Spindle Automatics | 6-spindle, 65mm bar capacity | High-volume production, consistent quality | Standard fasteners, bushings |

| CNC Milling Centers | 5-axis, 1000mm travel, 0.001mm resolution | Complex milling, drilling, threading | Custom brackets, complex housings |

| Centerless Grinders | 0.5-100mm diameter range, Ra 0.1 finish | Precision grinding, tight tolerances | Precision pins, rods, shafts |

Typical Parts Produced

Our extensive manufacturing capabilities enable the production of diverse Brass components serving multiple industries and applications. Each component category requires specialized manufacturing techniques and quality control measures to ensure optimal performance.

| Component Type | Size Range | Typical Tolerances | Applications |

|---|---|---|---|

| Precision Bushings | 5-100mm OD, 2-80mm ID | ±0.01mm | Automotive, machinery, hydraulics |

| Threaded Brass Fasteners | M3-M24, lengths up to 150mm | ±0.05mm | Electronics, marine, construction |

| Electrical Brass Connectors | 2-50mm diameter | ±0.02mm | Electrical, automotive, aerospace |

| Valve Components | 8-200mm diameter | ±0.03mm | Plumbing, HVAC, industrial |

| Instrument Parts | 1-75mm diameter | ±0.005mm | Medical, precision instruments |

| Automotive Components | 5-150mm diameter | ±0.02mm | Engine, transmission, brake systems |

Typical Component Dimensional Drawing

Standard Bushing Specification

←── L ──→

┌─────────┐ ↑

│ ○ │ │ OD

│ │ │ │

└─────────┘ ↓

← ID →

Dimensions:

L = 10-100mm (±0.02mm)

OD = 8-80mm (±0.01mm)

ID = 5-75mm (±0.01mm)

Surface Finish: Ra 1.6 μm

Surface Finishes & Treatments

Our comprehensive finishing capabilities enhance both the aesthetic appeal and functional performance of Brass turned parts. Surface treatments are selected based on application requirements, environmental conditions, and customer specifications.

| Finish Type | Specification | Benefits | Applications |

|---|---|---|---|

| As-Machined | Ra 0.8-3.2 μm | Natural Brass appearance, cost-effective | General engineering, prototypes |

| Polished | Ra 0.1-0.4 μm | Mirror finish, enhanced aesthetics | Decorative applications, optical |

| Nickel Plated | 5-25 μm thickness | Corrosion resistance, wear protection | Marine, automotive, electronics |

| Chrome Plated | 10-50 μm thickness | High hardness, decorative finish | Hydraulic components, decorative |

| Anodized | Type II/III per MIL-A-8625 | Enhanced corrosion resistance | Aerospace, marine applications |

| Passivated | Per ASTM A967 | Chemical cleaning, oxide removal | Food processing, medical |

Industries Served

Our Brass turned parts serve diverse industries where precision, reliability, and performance are paramount. Each industry presents unique challenges and requirements that our manufacturing capabilities are designed to address effectively.

Automotive Industry: Engine components, transmission parts, brake system elements, electrical connectors, and fuel system components requiring high precision and durability under demanding operating conditions.

Aerospace & Defense: Critical components for aircraft systems, navigation equipment, communication devices, and defense applications where failure is not an option and strict quality standards must be maintained.

Medical & Healthcare: Surgical instruments, diagnostic equipment components, implantable device parts, and laboratory equipment requiring biocompatibility and exceptional precision.

Electronics & Telecommunications: Connectors, terminals, shielding components, and precision housings for electronic devices and communication systems.

Marine & Offshore: Corrosion-resistant components for marine applications, offshore equipment, and subsea systems where material performance in harsh environments is critical.

Plumbing & HVAC: Valves, fittings, connectors, and system components for residential, commercial, and industrial plumbing and heating systems.

Tolerances & Quality Standards

Our commitment to quality excellence is demonstrated through rigorous tolerance control and adherence to international quality standards. Advanced measurement techniques and statistical process control ensure consistent component quality across all production runs.

| Feature Type | Standard Tolerance | Precision Tolerance | Measurement Method |

|---|---|---|---|

| External Diameter | ±0.02mm | ±0.005mm | Coordinate Measuring Machine (CMM) |

| Internal Diameter | ±0.025mm | ±0.008mm | Air gauging, CMM |

| Length/Height | ±0.05mm | ±0.01mm | Height gauge, CMM |

| Thread Pitch | ±0.02mm | ±0.005mm | Thread gauges, optical comparator |

| Concentricity | 0.05mm TIR | 0.01mm TIR | CMM, precision spindle |

| Surface Finish | Ra 1.6 μm | Ra 0.4 μm | Surface roughness tester |

Turnaround Time & Production Planning

Our efficient production planning and advanced manufacturing capabilities enable competitive lead times while maintaining exceptional quality standards. Standard production turnaround time ranges from 4-6 weeks depending on component complexity, quantity, and specification requirements. Rush orders can be accommodated with expedited processing for critical applications. Our production planning system optimizes manufacturing sequences to minimize setup times and maximize machine utilization efficiency.

Performance Metrics & Quality Indicators

| Metric | Target Value | Measurement Frequency | Control Method |

|---|---|---|---|

| Dimensional Accuracy | 99.7% within tolerance | Every part | Statistical Process Control |

| Surface Finish Consistency | ±10% variation | Sample basis | Regular calibration |

| On-Time Delivery | 98% or higher | Monthly | Production planning system |

| Customer Satisfaction | 95% or higher | Quarterly | Customer feedback surveys |

| First Pass Yield | 97% or higher | Daily | Quality control monitoring |

Material Properties & Specifications

| Property | C36000 (Free-Cutting) | C26000 (Cartridge) | CZ121 (BS Standard) | Test Method |

|---|---|---|---|---|

| Tensile Strength | 340-470 MPa | 300-540 MPa | 370-540 MPa | ASTM E8 |

| Yield Strength | 125-310 MPa | 75-450 MPa | 140-430 MPa | ASTM E8 |

| Elongation | 53-23% | 68-8% | 45-15% | ASTM E8 |

| Hardness | 56-85 HRB | 40-95 HRB | 65-95 HRB | ASTM E18 |

| Electrical Conductivity | 26% IACS | 28% IACS | 26% IACS | ASTM B193 |

| Thermal Conductivity | 115 W/m·K | 120 W/m·K | 115 W/m·K | ASTM E1461 |

Frequently Asked Questions (FAQ)

Q1: What is the minimum order quantity for Brass turned parts?

A: Our minimum order quantity varies based on component complexity and specifications. For standard parts, the MOQ is typically 100 pieces, while custom components may require 500-1000 pieces to optimize production efficiency and cost-effectiveness.

Q2: Can you provide material certifications for Brass components?

A: Yes, we provide comprehensive material certifications including chemical composition analysis, mechanical property testing, and traceability documentation conforming to international standards such as ASTM, EN, JIS, and IS specifications.

Q3: What tolerances can you achieve on CNC turned Brass parts?

A: Our CNC turning capabilities can achieve tolerances as tight as ±0.005mm for critical dimensions, with standard tolerances typically maintained at ±0.01-0.02mm depending on component geometry and size.

Q4: Do you offer rapid prototyping services for Brass components?

A: Yes, we provide rapid prototyping services with typical turnaround times of 3-5 days for simple components and 7-10 days for complex parts, enabling quick design validation and testing.

Q5: What surface finishes are available for Brass turned parts?

A: We offer various surface finishes including as-machined, polished, plated (nickel, chrome), anodized, and passivated finishes. Custom finishing requirements can be accommodated based on application needs.

Q6: Can you machine Brass parts from customer-supplied materials?

A: Yes, we can machine components from customer-supplied Brass materials provided they meet our quality standards and are accompanied by appropriate material certifications and specifications.

Q7: What quality control measures are implemented during production?

A: Our quality control process includes incoming material inspection, in-process monitoring, statistical process control, final dimensional verification using CMM equipment, and comprehensive documentation for full traceability.

Q8: Are your Brass turned parts suitable for high-temperature applications?

A: Brass components can typically operate in temperatures up to 200-300°C depending on the specific alloy and application requirements. We can recommend appropriate materials based on your temperature specifications.

Q9: Do you provide secondary operations such as drilling and threading?

A: Yes, our manufacturing capabilities include comprehensive secondary operations including drilling, tapping, milling, grinding, and assembly services to provide complete finished components.

Q10: What packaging options are available for international shipping?

A: We offer various packaging solutions including individual part protection, bulk packaging, custom labeling, and specialized packaging for fragile or precision components to ensure safe international shipping.

Q11: Can you provide design assistance for optimizing Brass components?

A: Our experienced engineering team provides design for manufacturability (DFM) analysis, material selection guidance, and optimization recommendations to improve component performance and reduce manufacturing costs.

Q12: What is your typical production capacity for Brass turned parts?

A: Our production capacity varies based on component complexity, but we typically maintain capacity for 100,000-500,000 pieces per month across our various manufacturing cells and can scale production based on customer requirements.

Size & Dimensional Chart

| Component Category | Minimum Diameter | Maximum Diameter | Maximum Length | Typical Wall Thickness |

|---|---|---|---|---|

| Precision Pins | 0.5mm | 25mm | 200mm | Solid |

| Bushings & Sleeves | 5mm | 200mm | 300mm | 2-20mm |

| Threaded Fasteners | 2mm (M2) | 50mm (M50) | 500mm | Solid |

| Flanged Components | 8mm | 300mm | 150mm | 3-25mm |

| Valve Bodies | 10mm | 250mm | 400mm | 5-30mm |

| Custom Profiles | 3mm | 400mm | 600mm | Variable |

Why Choose Our Brass Turned Parts

Unmatched Experience & Expertise: With over three decades of specialized experience in Brass machining and turning operations, our team brings deep technical knowledge and proven expertise to every project. Our engineers understand the unique characteristics of various Brass alloys and optimize manufacturing processes to achieve superior results.

Advanced Manufacturing Technology: Our state-of-the-art facility features the latest CNC turning centers, Swiss-type lathes, and multi-axis machining equipment, enabling us to produce complex components with exceptional precision and efficiency. Continuous investment in technology ensures we remain at the forefront of manufacturing capabilities.

Faster Turnaround Times: Our efficient production planning system and optimized manufacturing processes enable industry-leading turnaround times of 4-6 weeks for standard orders, with expedited processing available for urgent requirements. Strategic inventory management and flexible scheduling accommodate changing customer needs.

Superior Customer Support: Our dedicated customer service team provides comprehensive support throughout the entire project lifecycle, from initial design consultation to final delivery and beyond. Regular communication updates and proactive problem-solving ensure smooth project execution.

Global Market Experience: Having supplied Brass turned parts to customers across North America, Europe, Asia, and other international markets for many decades, we understand diverse quality standards, regulatory requirements, and business practices, enabling seamless international partnerships.

Comprehensive Quality Assurance: Our quality management system encompasses rigorous incoming material inspection, in-process monitoring, statistical process control, and final verification using advanced measurement equipment to ensure consistent component quality and customer satisfaction.

Flexible Production Capabilities: Our diverse manufacturing capabilities enable flexible production approaches ranging from prototype quantities to high-volume production runs, accommodating various customer requirements and project scales efficiently.

Customized Packaging Solutions: We offer specialized packaging services including custom labeling with customer logos, protective packaging for delicate components, and documentation packages tailored to specific customer requirements and international shipping needs.

Customer Testimonial

“We have been sourcing precision Brass turned parts from this Indian manufacturer for over eight years, and their consistent quality and reliability have been exceptional. Their CNC machining capabilities and attention to detail have enabled us to meet our stringent aerospace quality requirements while maintaining competitive costs. The communication is excellent, and they always deliver on time. Highly recommended for anyone seeking reliable Brass component manufacturing.” – Harvey Davidson, Senior Procurement Manager, USA

Unique Selling Propositions (USPs)

Design Optimization Services: Our engineering team provides comprehensive design for manufacturability analysis, helping customers optimize component designs for improved functionality, reduced manufacturing costs, and enhanced performance characteristics.

Flexible Production Scheduling: We accommodate varying production schedules and urgent requirements through flexible manufacturing planning, enabling customers to respond quickly to market demands and changing business conditions.

Custom Alloy Development: Working closely with material suppliers, we can develop custom Brass alloy compositions tailored to specific application requirements, providing unique material solutions for specialized applications.

Integrated Supply Chain Management: Our comprehensive supply chain capabilities include material sourcing, inventory management, and logistics coordination, providing customers with a single-source solution for their Brass component requirements.

Value Engineering Services: Our experienced team conducts thorough value engineering analysis to identify cost reduction opportunities while maintaining or improving component quality and performance.

Packaging & Shipping

Our comprehensive packaging and shipping services ensure safe delivery of Brass turned parts to customers worldwide. We utilize specialized packaging materials and techniques designed to protect components during international transportation while minimizing shipping costs and environmental impact.

Standard Packaging: Components are individually wrapped in protective film and packed in moisture-resistant containers with desiccant packets to prevent corrosion during shipping. Bulk packaging options are available for high-volume orders.

Custom Packaging Solutions: We provide customized packaging services including branded packaging with customer logos, specialized protective packaging for delicate components, and documentation packages tailored to specific customer requirements.

International Shipping: Our logistics team manages comprehensive international shipping services including documentation preparation, customs clearance, and tracking services. We work with established freight forwarders to ensure reliable and cost-effective delivery worldwide.

Quality Documentation: Each shipment includes comprehensive quality documentation including material certifications, dimensional inspection reports, and traceability information conforming to international standards and customer requirements.

International Standards Compliance

Our manufacturing processes and quality systems comply with comprehensive international standards ensuring global acceptability and customer confidence in our Brass turned parts.

ISO Standards: ISO 9001:2015 (Quality Management), ISO 14001:2015 (Environmental Management), ISO 45001:2018 (Occupational Health & Safety)

Industry-Specific Standards: AS9100D (Aerospace Quality Management), ISO 13485:2016 (Medical Devices), IATF 16949:2016 (Automotive Quality Management)

Material Standards: ASTM (American Society for Testing and Materials), EN (European Norms), JIS (Japanese Industrial Standards), IS (Indian Standards), BS (British Standards), DIN (Deutsches Institut für Normung)

Testing Standards: ASTM E8 (Tensile Testing), ASTM E18 (Hardness Testing), ASTM B193 (Electrical Conductivity), ASTM E1461 (Thermal Conductivity)

Glossary of Terms

CNC Turning: Computer Numerical Control turning process that uses programmed instructions to control machine operations for precise component manufacturing.

Swiss Turning: Specialized turning process using sliding headstock lathes designed for high-precision, small-diameter components with excellent surface finish.

Live Tooling: Powered cutting tools mounted on CNC lathes enabling secondary operations such as drilling, milling, and threading without part repositioning.

Concentricity: Geometric tolerance specification indicating how closely cylindrical features share a common axis, measured as Total Indicator Reading (TIR).

Surface Roughness (Ra): Arithmetic average deviation of surface profile from the mean line, measured in micrometers (μm) or microinches (μin).

Machinability: Material characteristic indicating how easily it can be machined, affected by composition, hardness, and thermal properties.

Free-Cutting Brass: Brass alloy containing lead additives that improve machinability by acting as a lubricant and chip breaker during cutting operations.

Statistical Process Control (SPC): Quality control methodology using statistical techniques to monitor and control manufacturing processes for consistent output quality.

Related Parts:

Brass turning services, precision Brass machining, custom Brass components, CNC Brass parts manufacturing, Brass automatic screw machine products, Swiss turned Brass parts, Brass precision turned components, CNC machined Brass parts, Brass component manufacturer India, export quality Brass parts, precision engineering Brass components,

OEM Brass turned parts, small diameter Brass parts, complex Brass machining, high precision Brass turning, Brass parts supplier India, custom Brass manufacturing, Brass CNC services, precision Brass fabrication, Brass component exporter India, DZR Brass turned parts, dezincification resistant Brass components, lead-free Brass machining, NSF 61 compliant Brass parts, potable water Brass components, marine grade Brass turning, WRAS approved Brass parts, RoHS compliant Brass components, drinking water safe Brass parts, environmentally friendly Brass machining

Manufacturing Process:

Raw Material → Inspection → CNC Programming → Turning Operations → Quality Control → Finishing → Packaging → Shipping]

Get Your Custom Brass Turned Parts Quote Today

Ready to experience the precision and quality of our Brass turned parts? Our engineering team is standing by to discuss your specific requirements and provide comprehensive solutions tailored to your application needs.

📧 Email: sales@brass -copper-parts. com for detailed technical discussions and project specifications

📱 WhatsApp: +91-22 43449300 for immediate assistance and quick responses

📞 Phone: +91-22 43449300 to speak directly with our technical experts

📋 Request Quote: With your specifications

📖 Download Brochure: Email us with detailed specifications and capabilities

Contact us today to discuss how our three decades of Brass machining expertise can benefit your next project!