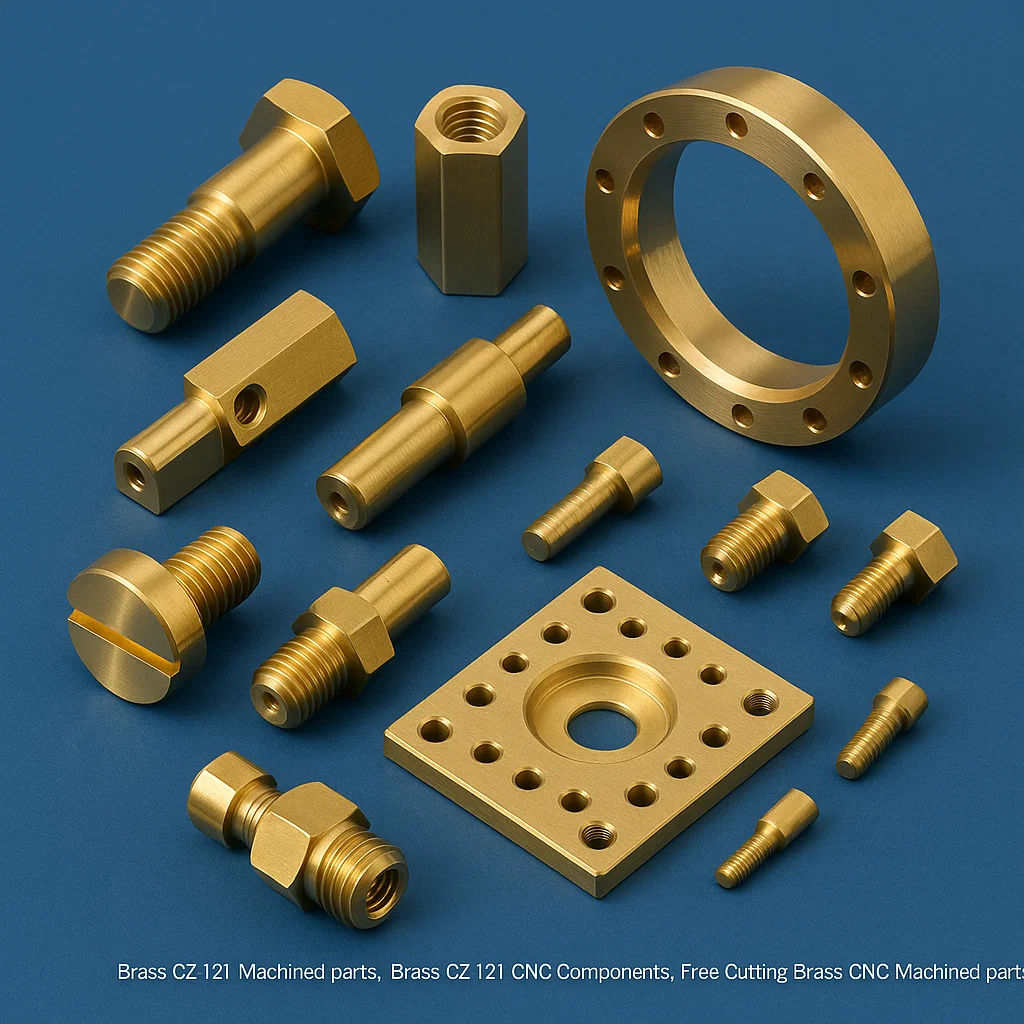

Brass CZ121 Machined parts, Brass CZ121 CNC Components, Free Cutting Brass CNC Machined parts

Premium Brass CZ121 Machined Parts | CNC Components | Free Cutting Brass Manufacturing

We are one of the leading manufacturers and exporters of precision Brass CZ121 machined parts, CNC components, and free cutting Brass parts from India. We have been supplying high-quality Brass CZ121 components to the world market for over three decades, serving industries across USA, Europe, Japan, China, and Southeast Asia. Our state-of-the-art manufacturing facility combines traditional craftsmanship with modern CNC technology to produce superior quality Brass CZ121 machined parts that meet international standards including ASTM, DIN, BS, JIS, and IS specifications. With ISO 9001:2015 certification and extensive experience in precision machining, we have established ourselves as a trusted partner for custom Brass CZ121 components across diverse industrial applications. Our commitment to excellence, competitive pricing, and reliable delivery schedules has made us a preferred supplier for OEMs, distributors, and end-users worldwide. We specialize in both standard and custom Brass CZ121 machined parts with tolerances as tight as ±0.005mm, ensuring consistent quality and performance in critical applications. Our comprehensive range includes turned parts, milled components, threaded fasteners, and complex geometrical shapes manufactured using advanced CNC machining centers and precision turning equipment.

Price: US$ 10.50/kilogram

Brass CZ121 Machined Parts Overview

Brass CZ121 Machined Parts represent the pinnacle of precision engineering in free cutting Brass applications. CZ121, also known as C36000 or 360 Brass in ASTM nomenclature, is a leaded Brass alloy containing approximately 61.5% Copper, 35.5% Zinc, and 3% Lead. This composition provides exceptional machinability, making it the preferred choice for high-volume production of intricate components. Our Brass CZ121 machined parts demonstrate superior dimensional accuracy, excellent surface finish, and consistent mechanical properties that meet stringent quality requirements across various industries. The lead content in CZ121 acts as a chip breaker, enabling faster machining speeds and longer tool life, which translates to cost-effective production and competitive pricing for our customers.

Brass CZ121 CNC Components manufactured in our facility utilize advanced computer numerical control technology to achieve complex geometries with exceptional precision. Our CNC machining capabilities include multi-axis turning, milling, drilling, tapping, and threading operations that produce components with tolerances ranging from ±0.01mm to ±0.005mm depending on the application requirements. The CNC process ensures repeatability and consistency across large production runs, making CZ121 CNC components ideal for automotive, electronics, plumbing, and instrumentation applications where precision and reliability are paramount.

Free Cutting Brass CNC Machined Parts leverage the superior machinability characteristics of CZ121 alloy to produce components with excellent surface finish and dimensional accuracy. The free cutting properties of this Brass alloy result from the lead content, which forms discrete particles that act as internal lubricants during machining operations. This characteristic enables high cutting speeds, reduced tool wear, and excellent chip formation, resulting in superior surface quality and faster production cycles.

Brass Free Machining Alloy CZ121 belongs to the family of free machining Brass alloys specifically designed for automatic screw machine operations and high-speed CNC machining. The alloy composition is optimized to provide the best balance between machinability, mechanical properties, and corrosion resistance. Our free machining Brass components exhibit excellent strength-to-weight ratio, natural antimicrobial properties, and attractive golden appearance that makes them suitable for both functional and decorative applications.

CZ121 Brass Alloy specifications conform to multiple international standards including BS EN 12164, ASTM B16, DIN 17672, and JIS H3250. The alloy designation CZ121 under European standards corresponds to UNS C36000 (USA), CuZn36Pb3 (Germany), and C3604 (Japan). This standardization ensures global compatibility and consistent quality across different markets and applications.

CZ 121 Brass Composition consists of Copper (60-63%), Zinc (35.5-37.5%), Lead (2.5-3.7%), and trace amounts of Iron, Aluminum, and other elements totaling less than 0.5%. This carefully controlled composition provides optimal machinability while maintaining adequate mechanical properties including tensile strength of 338-469 MPa, yield strength of 124-310 MPa, and elongation of 8-23% depending on the temper condition.

CZ121 Brass Turned Parts represent a significant portion of our production capacity, utilizing precision turning operations to create cylindrical components, shafts, bushings, and threaded fasteners. Our turning capabilities include both conventional and CNC turning with bar capacity up to 65mm diameter and length up to 300mm for single operations. Multi-spindle turning operations enable cost-effective production of high-volume components with consistent quality and dimensional accuracy.

CZ121 Brass Manufacturing Process Flow

Raw Material CZ121 Bar –> Stock CNC Turning –> Precision Machining –> Secondary Ops –> Threading/Milling –> Quality Control –> Inspection –> Surface FinishPolishing/Plating –> Packaging Custom Labeling –> Technical Specifications

Material Grades and International Standards

| Standard | Designation | Country/Region | Equivalent Grade | Composition Range |

|---|---|---|---|---|

| ASTM B16 | C36000 | USA | Free Cutting Brass | Cu 60.0-63.0%, Zn 35.0-37.0%, Pb 2.5-3.7% |

| BS EN 12164 | CZ121 | Europe/UK | Free Cutting Brass | Cu 57.0-60.0%, Zn 37.0-40.0%, Pb 2.0-3.5% |

| DIN 17672 | CuZn36Pb3 | Germany | Automatenmessing | Cu 60.0-63.0%, Zn 35.0-37.0%, Pb 2.5-3.5% |

| JIS H3250 | C3604 | Japan | Free Cutting Brass | Cu 60.0-63.0%, Zn 35.5-37.5%, Pb 2.5-3.7% |

| GB/T 4423 | HPb59-1 | China | Lead Brass | Cu 57.0-61.0%, Zn 35.0-39.0%, Pb 0.8-1.9% |

| IS 319 | BS-3 | India | Free Cutting Brass | Cu 60.0-63.0%, Zn 35.0-37.0%, Pb 2.5-3.7% |

Manufacturing Processes and Machinery

CNC Turning Operations

Our precision CNC turning operations utilize state-of-the-art equipment including DMG Mori, Haas, and Okuma turning centers with live tooling capabilities. The machines are equipped with bar feeders for continuous operation, sub-spindles for complete machining, and Y-axis capability for off-center operations. Maximum turning diameter reaches 65mm with length capacity up to 300mm for single-spindle operations.

Multi-Spindle Automatic Turning

High-volume production is achieved through our Citizen and Star multi-spindle automatic lathes capable of producing complex CZ121 Brass components in single operations. These machines excel in producing small to medium-sized precision components with cycle times as low as 15 seconds per piece, making them ideal for fasteners, fittings, and electronic components.

CNC Milling and Drilling

Secondary machining operations are performed on 3-axis and 4-axis CNC machining centers from Haas and DMG Mori. These operations include cross-drilling, milling flats, keyways, and complex geometrical features. The machines are equipped with high-pressure coolant systems and tool length measurement for consistent quality and extended tool life.

Thread Rolling and Forming

Thread production utilizes both cutting and rolling processes depending on application requirements. Thread rolling provides superior surface finish and strength characteristics for threaded fasteners, while thread cutting is employed for internal threads and special pitch requirements. Our capabilities include metric, imperial, and special threads up to M20 diameter.

Typical Parts Produced and Applications

| Component Type | Typical Dimensions | Industry Application | Key Features | Production Volume |

|---|---|---|---|---|

| Threaded Fasteners | M3 to M20 x 10-100mm | Automotive, Electronics | High strength threads, corrosion resistant | 10,000-100,000 pcs/month |

| Bushings and Sleeves | ID 5-50mm, Length 10-80mm | Mechanical Engineering | Wear resistance, self-lubricating | 5,000-50,000 pcs/month |

| Plumbing Fittings | 1/8″ to 2″ NPT/BSP | Plumbing, HVAC | Pressure tested, antimicrobial | 20,000-200,000 pcs/month |

| Electronic Connectors | Diameter 2-15mm | Electronics, Telecommunications | High conductivity, precision fit | 50,000-500,000 pcs/month |

| Valve Components | Custom specifications | Oil & Gas, Water Treatment | Pressure rating up to 16 bar | 1,000-10,000 pcs/month |

| Watch Components | Micro precision parts | Precision Instruments | Ultra-fine tolerances ±0.002mm | 100,000-1,000,000 pcs/month |

Technical Drawing and Dimensional Specifications

| Dimension | Nominal Value (mm) | Tolerance | Surface Finish Ra (μm) | Critical Feature |

|---|---|---|---|---|

| Overall Length | 150.0 | ±0.02 | 1.6 | Assembly fit |

| Overall Width | 100.0 | ±0.02 | 1.6 | Mounting dimension |

| Extension Length | 100.0 | ±0.02 | 0.8 | Functional surface |

| Central Hole Diameter | 40.0 | ±0.01 | 0.8 | Bearing surface |

| Wall Thickness | 10.0 | ±0.05 | 3.2 | Strength requirement |

Material Properties and Performance Characteristics

| Property | Value | Test Method | Condition | Application Relevance |

|---|---|---|---|---|

| Density | 8.50 g/cm³ | ASTM B311 | Room Temperature | Weight calculation |

| Tensile Strength | 338-469 MPa | ASTM B557 | As machined | Load bearing capacity |

| Yield Strength (0.2%) | 124-310 MPa | ASTM B557 | As machined | Design stress limits |

| Elongation | 8-23% | ASTM B557 | 50mm gauge length | Ductility assessment |

| Hardness | 65-85 HB | ASTM E10 | 10mm ball, 500kg | Wear resistance |

| Electrical Conductivity | 26% IACS | ASTM B193 | 20°C | Electrical applications |

| Thermal Conductivity | 115 W/m·K | ASTM E1461 | Room Temperature | Heat dissipation |

| Coefficient of Expansion | 20.5 × 10⁻⁶/°C | ASTM E228 | 20-100°C | Thermal design |

Quality Standards and Tolerances

Dimensional Tolerances

Standard dimensional tolerances range from ±0.02mm for general machining operations to ±0.005mm for critical dimensions. Tighter tolerances of ±0.002mm can be achieved for specific applications using precision grinding and finishing operations. All dimensional measurements are performed using calibrated CMM equipment traceable to national standards.

Surface Finish Standards

Surface finish specifications range from Ra 3.2 μm for general machined surfaces to Ra 0.4 μm for precision bearing surfaces. Surface roughness is measured using calibrated profilometers according to ISO 4287 standards. Special finishes including polishing, brushing, and coating can be applied as per customer requirements.

Geometric Tolerances

Geometric dimensioning and tolerancing (GD&T) specifications including straightness, roundness, cylindricity, and position tolerances are maintained according to ASME Y14.5 and ISO 1101 standards. Concentricity and runout tolerances can be held to 0.005mm TIR for critical rotating components.

Material Certification

All raw materials are supplied with mill test certificates confirming chemical composition and mechanical properties. Material traceability is maintained through heat number tracking, and additional testing including spectroscopic analysis and hardness testing is performed as required by customer specifications.

Industries and Applications

| Industry Sector | Typical Applications | Key Requirements | Volume Range | Special Features |

|---|---|---|---|---|

| Automotive | Fuel system components, electrical connectors, brake fittings | Corrosion resistance, precision fit | 10,000-1,000,000 pcs | TS16949 compliance |

| Electronics | PCB standoffs, connectors, shielding components | Electrical conductivity, EMI shielding | 50,000-5,000,000 pcs | RoHS compliance |

| Plumbing & HVAC | Pipe fittings, valves, pump components | Pressure rating, antimicrobial properties | 5,000-500,000 pcs | Lead-free options available |

| Marine | Propeller shafts, deck hardware, instruments | Saltwater corrosion resistance | 1,000-50,000 pcs | Marine grade certification |

| Instrumentation | Gauge components, measurement devices, sensors | Precision tolerances, stability | 1,000-100,000 pcs | Calibration traceability |

| Defense & Aerospace | Ammunition components, aircraft fittings | Reliability, consistent quality | 1,000-100,000 pcs | AS9100 certification available |

Turnaround Time and Production Scheduling

Our standard production turnaround time for Brass CZ121 machined parts is 4-6 weeks from order confirmation, depending on complexity and quantity requirements. This timeframe includes material procurement, machining operations, quality inspection, and packaging. For urgent requirements, we offer expedited production services with turnaround times as short as 2-3 weeks for standard components, subject to current production schedule and material availability.

Production planning is managed through advanced ERP systems that optimize machine utilization and minimize setup times. Large volume orders are scheduled for continuous production runs to maximize efficiency and maintain competitive pricing. Customers receive regular production updates and can track order status through our online portal system.

Express Production Services: For critical applications requiring faster delivery, we maintain safety stock of common CZ121 bar materials and can prioritize urgent orders through our dedicated express production line. Express services carry a premium of 25-50% depending on urgency level and may require minimum order quantities.

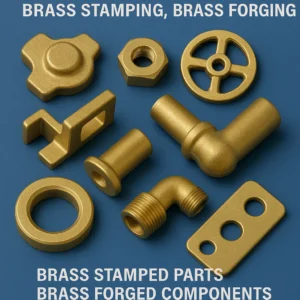

Typical CZ 121 Brass Turned Parts and Free cutting brass Components we make-

Electrical & Electronics:

Brass terminal pins, Brass connector bodies, fuse caps, Brass socket contacts, Brass plug pins, circuit board standoffs, switch components, lead frames, electrical Brass bushings, RF connector bodies

Plumbing & Fluid Handling:

Brass compression fittings, Brass valve stems, faucet cartridges, Brass water meter components and Water Meter conenctors, Brass coupling nuts, irrigation connectors, ball valve seats, hose barb fittings,Brass showerhead inserts, pressure regulator pins , Brass Radiator airvents, Brass Radiator Keys (Tommy bar type and Clock type keys)

Automotive:

fuel injection components, carburetor jets, sensor housings, brake bleeder screws, valve guide inserts, transmission bushings, pneumatic fittings, light bulb sockets, quick-connect fittings

Industrial Machinery:

Brass pneumatic fittings, Brass hydraulic adapters, guide pins, bushings and bearings, spray nozzle orifices, grease fittings, adjustment screws, sensor probes, knurled knobs, shaft collars

Marine:

through-hull fittings, seacock components, marine hardware fasteners, cleat pins, instrument housing components, deck fitting inserts, pump impellers

Consumer Goods & Hardware:

door lock cylinders, hinge pins, decorative furniture components, zipper sliders, pen barrels and tips, watch cases, lamp fittings, musical instrument valves and mouthpieces, razor components

Why Choose Our Brass CZ121 Machined Parts?

Three Decades of Global Experience

Our 30+ years of manufacturing experience in precision Brass machining has established us as a trusted partner for customers across USA, Europe, Asia-Pacific, and Middle East markets. This extensive experience translates to superior understanding of international quality standards, customer requirements, and efficient production methodologies that benefit our clients through consistent quality and competitive pricing.

Superior Customer Communication

Our multilingual technical team provides excellent communication support in English, German, Japanese, and Chinese languages, ensuring clear understanding of technical requirements and project specifications. Regular project updates, technical consultations, and responsive customer service have made us the preferred supplier for long-term partnerships with global OEMs and distributors.

Flexible Production Capabilities

Our manufacturing flexibility allows us to handle orders ranging from prototype quantities of 50 pieces to high-volume production runs exceeding 1 million pieces annually. This scalability is supported by diverse machining equipment including both CNC and conventional machinery, enabling cost-effective production regardless of order size or complexity.

Custom Packaging Solutions

We offer customized packaging solutions including customer-branded labels, special protective packaging for delicate components, and bulk packaging options for high-volume shipments. Our packaging engineers work with customers to develop optimal packaging that reduces shipping costs while ensuring product protection during international transit.

Surface Finishes and Secondary Operations

| Finish Type | Process Description | Typical Ra (μm) | Applications | Additional Benefits |

|---|---|---|---|---|

| As Machined | Standard CNC machining finish | 0.8 – 3.2 | General purpose components | Cost effective, good appearance |

| Polished | Mechanical polishing to mirror finish | 0.1 – 0.4 | Decorative applications, food industry | Enhanced corrosion resistance |

| Brushed | Directional brushing for satin finish | 0.4 – 1.6 | Architectural, automotive trim | Hides minor scratches, uniform appearance |

| Passivated | Chemical passivation treatment | As base | Marine, chemical processing | Improved corrosion resistance |

| Nickel Plated | Electroplated nickel coating 5-25μm | 0.2 – 0.8 | Electronics, wear applications | Hardness improvement, conductivity |

| Chrome Plated | Hard chrome plating 10-50μm | 0.1 – 0.4 | Hydraulic components, tooling | Extreme wear resistance |

Frequently Asked Questions

Q1: What is the minimum order quantity for CZ121 Brass machined parts?

A: Our minimum order quantity varies depending on part complexity and machining requirements. For standard turned parts, the minimum is typically 500 pieces, while complex milled components may require 100-250 pieces minimum. Prototype quantities starting from 10-50 pieces can be accommodated with setup charges.

Q2: Can you provide material certificates and test reports?

A: Yes, we provide comprehensive material certificates including mill test certificates for raw materials, chemical composition analysis reports, mechanical property test results, and dimensional inspection reports. All certificates are traceable to batch/heat numbers and include calibration certificates for measuring equipment.

Q3: What tolerances can you achieve on CZ121 Brass components?

A: Standard machining tolerances range from ±0.02mm to ±0.05mm depending on feature size and complexity. Precision tolerances of ±0.005mm to ±0.01mm can be achieved for critical dimensions using specialized equipment and inspection procedures. Ultra-precision tolerances of ±0.002mm are possible for specific applications.

Q4: Do you offer lead-free alternatives to CZ121?

A: Yes, we offer lead-free Brass alternatives including CZ132 (C37700), CZ131 (C35300), and eco-friendly Brass alloys that comply with RoHS and REACH regulations. These alternatives provide similar machinability characteristics while meeting environmental and health safety requirements for specific applications.

Q5: What secondary operations can be performed on machined parts?

A: We offer comprehensive secondary operations including threading, cross-drilling, milling, grinding, polishing, plating, heat treatment, and assembly operations. Special processes such as knurling, broaching, and engraving can also be performed as required. All secondary operations are performed in-house to maintain quality control and delivery schedules.

Q6: How do you ensure consistent quality across large production runs?

A: Quality consistency is maintained through statistical process control (SPC), regular machine calibration, first article inspection, in-process monitoring, and final inspection using CMM equipment. Our ISO 9001:2015 certified quality management system ensures documented procedures, traceability, and continuous improvement processes.

Q7: Can you handle special packaging and labeling requirements?

A: Absolutely. We offer custom packaging solutions including customer-branded labels, barcoding, serialization, protective packaging for delicate parts, and special shipping containers. Our packaging team works with customers to develop optimal solutions that meet specific handling, storage, and shipping requirements while minimizing costs.

Q8: What is your capacity for high-volume production?

A: Our production capacity exceeds 2 million pieces per month across all product lines, with individual part capacity ranging from 1,000 to 500,000 pieces monthly depending on complexity. High-volume orders are scheduled on dedicated production lines with optimized tooling and automation to ensure consistent quality and competitive pricing.

Q9: Do you provide design assistance for new components?

A: Yes, our experienced engineering team provides design for manufacturability (DFM) analysis, material selection guidance, tolerance optimization, and cost reduction suggestions. We work collaboratively with customers during the design phase to optimize components for efficient production while meeting functional requirements.

Q10: How do you handle international shipping and documentation?

A: We have extensive experience in international logistics and documentation requirements. Our export team handles all necessary documentation including commercial invoices, packing lists, certificates of origin, and customs declarations. We work with reliable freight forwarders to ensure timely and secure delivery to destinations worldwide.

Customer Testimonial

“We have been sourcing precision Brass CZ121 components from this manufacturer for over 8 years, and their consistency in quality and delivery has been exceptional. The technical expertise of their team and ability to handle complex geometries with tight tolerances has made them our preferred supplier for critical automotive applications. Their communication throughout the project lifecycle and proactive approach to problem-solving sets them apart from other suppliers we have worked with.” – Robert Mitchell, Senior Procurement Manager, Detroit, USA

Packaging and Shipping

Our comprehensive packaging solutions are designed to protect precision Brass CZ121 components during international transit while optimizing shipping costs and handling efficiency. Standard packaging includes anti-static bags for electronic components, foam inserts for delicate parts, and moisture barrier protection for long-term storage. Bulk packaging options utilize custom-designed bins and containers that maximize shipping efficiency for high-volume orders.

International shipping is handled through established partnerships with leading freight forwarders including DHL, FedEx, UPS, and ocean freight carriers. All shipments include comprehensive documentation, insurance coverage, and tracking capabilities. Special handling requirements such as temperature-controlled transport, hazardous material classification, and expedited delivery options are available upon request.

Standard Packaging Options

Individual part protection using anti-static bags, foam inserts, or custom-formed trays. Bulk packaging in corrugated boxes with foam dividers or plastic bins with snap-on lids. All packaging materials are recyclable and comply with international shipping regulations.

Custom Labeling Services

Customer-branded labels with company logos, part numbers, barcodes, and QR codes. Serialization and traceability labels for critical applications. Multi-language labeling for international markets and compliance with local regulations.

Glossary of Technical Terms

| Term | Definition | Application Context |

|---|---|---|

| Free Cutting Brass | Brass alloys with lead addition (typically 2-4%) that improves machinability by acting as a chip breaker and internal lubricant | High-speed machining operations, automatic screw machines |

| CZ121 | European standard designation for free cutting Brass with approximately 60% Copper, 37% Zinc, and 3% Lead | International specification compliance, material ordering |

| Machinability Index | Relative measure of how easily a material can be machined, with free cutting Brass rating 100% compared to other alloys | Production planning, tool life estimation, cost calculation |

| Dezincification | Selective corrosion process where zinc is leached from Brass alloys, leaving porous Copper structure | Material selection for corrosive environments, water applications |

| Season Cracking | Stress corrosion cracking in Brass alloys exposed to ammonia or ammoniacal compounds under tensile stress | Component design, stress relief heat treatment |

| Cold Working | Plastic deformation of Brass below its recrystallization temperature, increasing strength but reducing ductility | Forming operations, work hardening considerations |

Related Parts:

Primary : Brass CZ121 machined parts, CNC Brass components, free cutting Brass CZ121, precision Brass machining, CZ121 turned parts, Brass CNC manufacturing, custom Brass components India,

High precision CZ121 Brass machined components, free cutting Brass CNC turned parts manufacturer, custom CZ121 Brass threaded fasteners, precision Brass CZ121 electronic connectors, automotive grade CZ121 Brass components, ISO certified Brass CZ121 machining services

Industry-specific Terms: Brass plumbing fittings CZ121, electronic Brass connectors machined, automotive Brass CZ121 fasteners, marine grade Brass components, instrumentation Brass CZ121 parts, HVAC Brass CZ121 fittings

Technical Specifications: CZ121 chemical composition, C36000 equivalent Brass alloy, Brass CZ121 material properties, free cutting Brass machinability, CZ121 tolerance capabilities, Brass surface finish options

Get Your Custom Brass CZ121 Components Quote Today!

Ready to experience the precision and quality of our Brass CZ121 machined parts, CZ121 Brass Turned parts? Our technical team is standing by to assist with your specific requirements and provide competitive quotations for your projects.

Download our comprehensive Brass CZ121 technical brochure with detailed specifications, case studies, and application examples. Contact us today to discuss your specific requirements and receive a customized quotation within 24 hours.

📧 Request Detailed Quote: Email us at sales@brass-copper-parts. com with your specifications for personalized pricing and technical recommendations.

📱 Immediate Assistance: Contact us via WhatsApp at +91-22-43449300 for instant technical support and order processing.

📞 Speak with Experts: Call our technical team at +91-22-43449300 for application consultation and custom solutions.

📋 Download Brochure: Email sales@brass-copper-parts. com to receive comprehensive product catalogs, technical drawings, and specification sheets.

🌐 Global Shipping: Worldwide delivery available with express shipping options for urgent project requirements.