Brass DC Tape Clips, Bronze Tape Clips, DC Clips for Copper Grounding Tapes, DC Brass Earth Tape Clips

Brass DC Tape Clips, Bronze SC Tape Clips, Gun Metal DC tape Clips & Copper Earthing Tape Clips

We are one of the leading manufacturers and exporters of Brass DC tape clips, Bronze tape clips, and Copper earthing tape clips from India. We have been supplying premium quality electrical grounding and earthing accessories to the world market for many decades. Our extensive range of DC earthing clips, Bronze earthing clips, and Copper ground tape clips are engineered to meet the most demanding electrical grounding applications across industries. With state-of-the-art manufacturing facilities and rigorous quality control processes, we deliver products that comply with international standards including BS EN 62561-1, IEC 62561, ASTM, DIN, and IS/IEC 62305. Our commitment to excellence has made us a trusted partner for electrical contractors, OEMs, and system integrators worldwide. Each clip undergoes precision manufacturing using advanced CNC machining and casting techniques to ensure optimal conductivity, mechanical strength, and long-term durability in harsh environmental conditions.

Price: US$ 11.50/kilogram

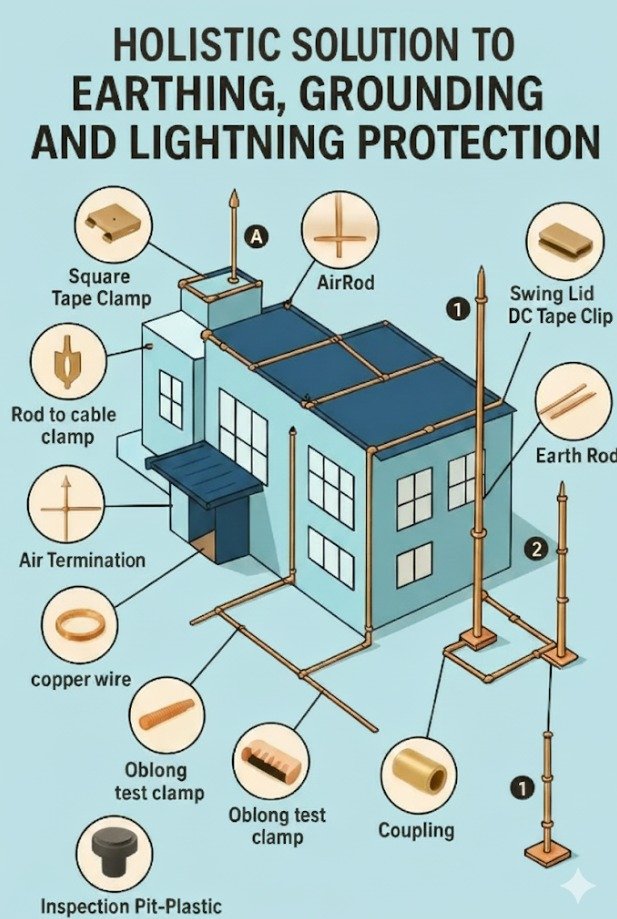

Product Overview & Applications

Our comprehensive range of tape clips represents the pinnacle of electrical grounding technology, designed for critical applications in power distribution, lightning protection, telecommunications, and industrial earthing systems. These precision-engineered components ensure secure, low-resistance connections between earthing tapes and structural elements, providing reliable fault current pathways and electromagnetic interference protection.

🔧 Advanced Manufacturing Excellence

CNC Precision Machining | Investment Casting | 30+ Years Experience

ISO 9001:2015 Certified | Global Export to 35+ Countries | Custom Solutions Available

Individual Product Specifications

Brass DC Tape Clips

Manufactured from high-conductivity Brass alloy CW614N (CuZn39Pb3) conforming to BS EN 12164 and ASTM B16 standards. These DC earthing clips feature exceptional electrical conductivity of 28% IACS minimum, making them ideal for direct current grounding applications in solar installations, telecommunications equipment, and DC power systems. The unique Brass composition provides excellent machinability and corrosion resistance in standard environmental conditions. Each clip undergoes precision CNC machining to achieve tight dimensional tolerances of ±0.1mm, ensuring consistent performance across batch productions.

Bronze DC Tape Clips

Crafted from premium Bronze alloys including Gunmetal (BS 1400-LG2) and HTB1 Aluminum Bronze conforming to ASTM B150 and DIN 17672 specifications. These Bronze earthing clips offer superior mechanical strength with tensile strength exceeding 350 MPa and excellent resistance to stress corrosion cracking. The Bronze composition provides enhanced durability in marine environments and high-humidity conditions, making them perfect for coastal installations, offshore platforms, and industrial facilities with aggressive atmospheric conditions. Investment casting process ensures uniform grain structure and optimal mechanical properties.

Copper Tape Clips

Constructed from 99.9% pure electrolytic Copper grade C11000 (ETP Copper) meeting ASTM B152, BS EN 13599, and JIS H3100 standards. These Copper earthing clips provide maximum electrical conductivity at 100% IACS, ensuring minimal resistance in critical grounding paths. The high-purity Copper construction offers exceptional malleability and thermal conductivity, making them suitable for high-current fault conditions and applications requiring maximum electrical performance. Hot forging and precision machining processes maintain grain structure integrity for long-term reliability.

Copper Earth Tape Clips

Specialized Copper earth tape clips designed for comprehensive building earthing systems and lightning protection networks. Manufactured using high-strength Copper alloy C10200 (OF Copper) with oxygen-free composition ensuring zero hydrogen embrittlement and superior fatigue resistance. These clips feature reinforced mounting bases and enhanced grip mechanisms for securing wide earthing tapes in high-stress applications. Surface treatment options include tin plating per ASTM B545 for enhanced corrosion protection in harsh environments.

Copper Ground Tape Clips

Heavy-duty Copper ground tape clips engineered for industrial grounding applications requiring maximum current-carrying capacity. Manufactured from phosphor deoxidized Copper C12200 conforming to ASTM B75 and DIN 17670, these clips provide excellent spring characteristics and long-term dimensional stability. The phosphor content enhances mechanical properties while maintaining high electrical conductivity of 95% IACS minimum. Specialized heat treatment processes optimize stress relief and grain refinement for superior performance under thermal cycling conditions.

DC Earthing Clips

Multi-material DC earthing clips available in Brass, Bronze, and Copper variants, specifically designed for photovoltaic systems, telecommunications infrastructure, and DC power distribution networks. These clips incorporate advanced spring-loaded mechanisms ensuring consistent contact pressure throughout temperature variations. Manufacturing processes include precision die forging followed by CNC finishing to achieve optimal surface finish and dimensional accuracy. Special attention to contact geometry minimizes resistance and prevents hot spot formation under high current loads.

Bronze Earthing Clips

Premium Bronze earthing clips manufactured from high-strength Aluminum Bronze C95400 and Silicon Bronze C65500 alloys conforming to ASTM B150, BS 2871, and JIS H3250 standards. These clips offer exceptional strength-to-weight ratio with ultimate tensile strength exceeding 450 MPa and excellent fatigue resistance under cyclic loading conditions. The Bronze alloy composition provides natural antimicrobial properties and superior resistance to dezincification, making them ideal for underground and marine applications. Advanced casting and heat treatment processes ensure optimal microstructure and mechanical properties.

Material Grades & International Standards

| Material | International Standards | USA Standards | European Standards | Japanese Standards | Chinese Standards |

|---|---|---|---|---|---|

| Brass CW614N | IS 6912, BS EN 12164 | ASTM B16, SAE CA360 | EN 12163, DIN 17660 | JIS H3250 C3601 | GB/T 4423 HPb59-1 |

| Bronze Gunmetal | IS 318, BS 1400-LG2, CDA 836 | ASTM B62, SAE 40 | EN 1982 CC483K | JIS H5111 BC6 | GB/T 1176 ZCuSn10P1 |

| Copper ETP | IS 1897, BS EN 13599 | ASTM B152 C11000 | EN 13599 CW004A | JIS H3100 C1100 | GB/T 2040 T2 |

| Aluminum Bronze | IS 6911, BS 2872-CZ110 | ASTM B150 C95400 | EN 12163 CW307G | JIS H3250 C6191 | GB/T 4423 QAl10-4-4 |

| Phosphor Bronze | IS 6322, BS 2870-PB102 | ASTM B103 C51000 | EN 12163 CW451K | JIS H3110 C5191 | GB/T 4423 QSn6.5-0.1 |

Manufacturing Processes & Machinery

Our state-of-the-art manufacturing facility employs multiple precision processes to ensure consistent quality and performance. Investment casting using ceramic shell molds provides excellent surface finish and dimensional accuracy for complex geometries. CNC machining centers including 5-axis Haas and DMG Mori machines achieve tight tolerances and superior surface finish. Hot forging processes using hydraulic presses up to 500 tons capacity ensure optimal grain flow and mechanical properties. Heat treatment in controlled atmosphere furnaces provides stress relief and metallurgical optimization.

Comprehensive Dimensional Chart

| Part Code | Tape Size (mm) | Material | Base Width (mm) | Base Length (mm) | Hole Diameter (mm) | Thickness (mm) | Weight (grams) |

|---|---|---|---|---|---|---|---|

| BCP-DC-253-BR | 25 × 3 | Brass | 28.0 ± 0.1 | 40.0 ± 0.1 | 6.5 ± 0.1 | 3.5 | 45 |

| BCP-DC-406-BR | 40 × 6 | Brass | 42.0 ± 0.1 | 55.0 ± 0.1 | 8.0 ± 0.1 | 4.0 | 78 |

| BCP-DC-506-BR | 50 × 6 | Brass | 52.0 ± 0.1 | 60.0 ± 0.1 | 8.0 ± 0.1 | 4.5 | 95 |

| BCP-DC-253-BZ | 25 × 3 | Bronze | 28.0 ± 0.1 | 40.0 ± 0.1 | 6.5 ± 0.1 | 3.5 | 48 |

| BCP-DC-406-BZ | 40 × 6 | Bronze | 42.0 ± 0.1 | 55.0 ± 0.1 | 8.0 ± 0.1 | 4.0 | 82 |

| BCP-DC-506-BZ | 50 × 6 | Bronze | 52.0 ± 0.1 | 60.0 ± 0.1 | 8.0 ± 0.1 | 4.5 | 98 |

| BCP-DC-253-CU | 25 × 3 | Copper | 28.0 ± 0.1 | 40.0 ± 0.1 | 6.5 ± 0.1 | 3.5 | 52 |

| BCP-DC-406-CU | 40 × 6 | Copper | 42.0 ± 0.1 | 55.0 ± 0.1 | 8.0 ± 0.1 | 4.0 | 86 |

Material Property Comparison

| Property | Brass CW614N | Bronze Gunmetal | Copper ETP | Test Standard |

|---|---|---|---|---|

| Electrical Conductivity (% IACS) | 28 min | 15 min | 100 min | ASTM B193 |

| Tensile Strength (MPa) | 360-450 | 350-420 | 220-250 | ASTM E8 |

| Yield Strength (MPa) | 180-220 | 160-200 | 70-100 | ASTM E8 |

| Elongation (%) | 15-25 | 8-15 | 35-45 | ASTM E8 |

| Hardness (HB) | 120-140 | 90-120 | 45-65 | ASTM E10 |

| Corrosion Rate (mpy) | 0.1-0.3 | 0.05-0.15 | 0.2-0.5 | ASTM G31 |

Fastener Options & Compatibility

Our tape clips are designed to work seamlessly with various fastener systems. Stainless Steel screws in grades 316L and 304L provide maximum corrosion resistance for marine and industrial applications. Brass screws offer galvanic compatibility with Brass clips, preventing electrochemical corrosion in critical applications. Standard thread patterns include M6, M8, and M10 metric threads, with UNC and BSW threads available upon request.

Industries & Applications

Power Generation & Distribution: Substation earthing, transformer grounding, switchgear earthing, generator earthing systems, overhead line grounding. Renewable Energy: Solar panel grounding, wind turbine earthing, battery energy storage systems, inverter grounding, DC combiner box earthing. Telecommunications: Cell tower grounding, data center earthing, fiber optic cable grounding, satellite earth stations, microwave tower earthing. Industrial Applications: Chemical plant grounding, oil refinery earthing, mining equipment grounding, manufacturing facility earthing, explosive atmosphere grounding. Building & Construction: Lightning protection systems, building earthing, elevator shaft grounding, fire alarm system earthing, emergency power system grounding.

Technical Specifications & Tolerances

| Parameter | Standard Tolerance | Precision Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ± 0.2 mm | ± 0.1 mm | CMM/Calipers |

| Hole Diameter | ± 0.1 mm | ± 0.05 mm | Go/No-Go Gauge |

| Surface Roughness | Ra 3.2 μm | Ra 1.6 μm | Surface Profilometer |

| Flatness | 0.1 mm | 0.05 mm | Dial Indicator |

| Parallelism | 0.1 mm | 0.05 mm | CMM |

Performance Metrics & Testing

Electrical Performance: Contact resistance < 0.1 milliohm per ASTM B539, Current carrying capacity up to 500A continuous per IEC 60865, Withstand fault current up to 25kA for 1 second. Mechanical Performance: Tensile load capacity 2000N minimum per BS EN 50164-1, Torque retention > 80% after 1000 thermal cycles, Vibration resistance per IEC 60068-2-6. Environmental Performance: Salt spray resistance 720 hours per ASTM B117, UV resistance per ASTM G154, Temperature cycling -40°C to +85°C per IEC 60068-2-14.

Turnaround Time & Manufacturing Capacity

Standard Production Lead Time: 4-6 weeks from order confirmation for quantities up to 10,000 pieces. Express Production: 2-3 weeks available for urgent requirements with 25% expedite charges. Manufacturing Capacity: 50,000 pieces per month with ability to scale up to 100,000 pieces for large projects. Custom Tooling: 6-8 weeks for new designs with prototype samples available in 2 weeks.

Technical Q&A Session

A: Our minimum order quantity for custom sizes is 1000 pieces per specification. We can accommodate tape widths from 20mm to 100mm and thickness from 2mm to 10mm with appropriate tooling modifications.

A: Each batch undergoes electrical conductivity testing using calibrated micro-ohmmeters. We maintain statistical process control with Cpk values > 1.33 for all electrical parameters, ensuring batch-to-batch consistency.

A: We offer tin plating per ASTM B545, nickel plating per ASTM B689, and passivation treatments. For marine applications, we recommend tin plating with minimum thickness of 5 microns.

A: Yes, we can supply clips with pre-installed Stainless Steel or Brass fasteners. This reduces installation time and ensures proper torque specifications are maintained during assembly.

A: Standard shipments include material test certificates (MTC) with chemical analysis and mechanical properties. Additional testing reports for electrical conductivity, dimensional inspection, and environmental testing available upon request.

A: Our clips are tested per IEC 60068-2-6 for vibration resistance. The spring-loaded design maintains consistent contact pressure even under continuous vibration up to 2G acceleration.

A: With proper installation and appropriate material selection, service life exceeds 25 years in standard atmospheric conditions. Marine environments may require more frequent inspection cycles.

A: Yes, we regularly manufacture clips for T-profile tapes, angled tapes, and multi-conductor configurations. Custom profiling available with appropriate tooling and minimum quantities.

A: Our manufacturing facility is ISO 9001:2015 certified with additional certifications including AS9100 for aerospace applications and IATF 16949 for automotive components.

A: For projects exceeding 100,000 pieces, we develop dedicated production schedules with milestone deliveries. Project management team coordinates with customers to ensure on-time delivery requirements are met.

Why Choose Our Products Over Competitors

Unmatched Manufacturing Excellence: Three decades of specialized experience in electrical grounding components with continuous investment in advanced manufacturing technology. Superior Customer Support: Technical support team with electrical engineering backgrounds provides application guidance and custom design assistance. Global Experience: Products successfully deployed in over 35 countries across diverse climatic and industrial conditions. Customization Capabilities: Complete in-house design and manufacturing capabilities enabling rapid prototyping and custom solutions. Quality Assurance: ISO 9001:2015 certified facility with stringent quality control processes and comprehensive testing protocols.

Customer Testimonial

“We have been using tape clips from this manufacturer for our solar farm projects across the Southwest United States for over 8 years. The quality consistency is exceptional, and their ability to deliver custom sizes on tight schedules has been crucial for our project success. The technical support team understands our requirements and always provides valuable engineering input. Highly recommended for any serious grounding application.”

– Sunny Wales, Senior Project Manager, Middle East

Packaging & Shipping

Standard Packaging: Clips packed in moisture-resistant polyethylene bags with desiccant sachets, then placed in corrugated cardboard boxes with foam inserts. Export Packaging: Wooden crates or steel drums for larger quantities with proper cushioning and moisture barriers. Custom Packaging: Customer-branded packaging with logos and part number labeling available. Shipping Options: Sea freight for large volumes, air freight for urgent requirements, express courier for samples and small quantities. Documentation: Commercial invoice, packing list, material certificates, and relevant export documents provided with all shipments.

International Standards Compliance

| Standard | Description | Applicable Products |

|---|---|---|

| BS EN 62561-1 | Lightning protection components – Requirements for connection components | All earthing clips |

| IEC 62561-1 | Lightning protection system components | Lightning protection applications |

| IS/IEC 62305 | Protection against lightning | Building lightning protection |

| ASTM B539 | Standard Test Methods for Measuring Contact Resistance | Electrical testing |

| DIN VDE 0185-305 | Lightning protection installations | German market compliance |

Glossary of Technical Terms

Earthing Clips: Mechanical connectors used to secure earthing conductors to structures or equipment. DC Earthing: Grounding systems specifically designed for direct current electrical installations. Contact Resistance: Electrical resistance at the interface between conductor and clip. IACS: International Annealed Copper Standard used for conductivity measurement. Galvanic Corrosion: Electrochemical corrosion between dissimilar metals. Fault Current: Excessive current flowing during electrical faults. Tensile Strength: Maximum stress a material can withstand while being stretched. Thermal Cycling: Repeated heating and cooling testing to evaluate material performance. Investment Casting: Precision casting process using ceramic molds. CNC Machining: Computer-controlled precision machining process.

Related Parts:

Brass earthing accessories, Bronze grounding clamps, Copper tape connectors, DC grounding hardware, Lightning protection clips, Electrical earthing components, Substation grounding clips, Solar grounding accessories, Telecom earthing hardware, Industrial grounding clamps, Marine earthing clips, Building lightning protection, Earthing tape clamps, Ground tape clips, Electrical bonding clips, Grounding system accessories, Earthing installation hardware, Lightning conductor clips, Fault current path clips, EMI grounding clips

Get Your Custom Quote Today!

Ready to enhance your earthing system with premium quality tape clips?

📧 Email: Send your requirements to sales@brass-copper-parts. com for detailed quotation

📞 Phone: Call us at +91-22 -43449300 for immediate technical assistance

💬 WhatsApp: +91-22 -43449300 for instant communication

📑 Download Brochure: Request our comprehensive product catalog and technical specifications

Contact our technical team today to discuss your specific requirements and receive a competitive quotation within 24 hours!