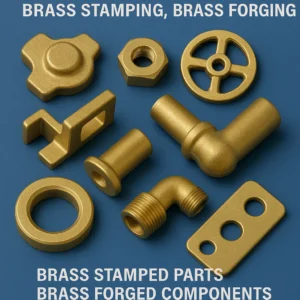

Brass DZR Components & DZR Brass Fittings – Dezincification Resistant Brass machining Solutions

We are one of the leading manufacturers and exporters of Brass DZR components, DZR Brass fittings, and Dezincification Resistant Brass products from India. We have been supplying high-quality DZR Brass solutions to the world market for many decades. Our comprehensive range includes precision-machined DZR Brass components, custom Brass DZR castings, and engineered fittings that meet the most stringent international standards for corrosion resistance and durability. With over three decades of expertise in Brass manufacturing and processing, we specialize in producing components that withstand dezincification in aggressive water conditions, making them ideal for plumbing, marine, and industrial applications. Our state-of-the-art manufacturing facilities utilize advanced CNC machining, precision casting, and quality control systems to ensure every Brass DZR component meets or exceeds customer specifications. From small-batch prototype development to large-scale production runs, we deliver consistent quality with competitive pricing and reliable global shipping. Our technical team works closely with customers to develop custom solutions for specific applications, ensuring optimal performance in challenging environments where standard Brass components may fail due to dezincification corrosion.

Overview of Brass DZR Components and DZR Brass Fittings

Brass DZR Components represent the pinnacle of corrosion-resistant Brass technology, specifically engineered to prevent dezincification in aggressive water environments. These components are manufactured using specially formulated Brass alloys that contain optimal levels of Copper, Zinc, and additional alloying elements such as Arsenic, Antimony, or Phosphorus. The dezincification resistance is achieved through controlled metallurgy and heat treatment processes that create a stable microstructure resistant to selective Zinc leaching. Our Brass DZR components find extensive applications in water distribution systems, heating and cooling systems, marine hardware, and industrial process equipment where long-term reliability is paramount.

DZR Brass Fittings are precision-engineered connection components designed for critical applications in potable water systems, hot water services, and marine environments. These fittings undergo rigorous testing according to international standards including ASTM B858, BS EN 12449, and AS/NZS 4020 to ensure compliance with drinking water safety requirements. Our DZR Brass fittings feature superior thread integrity, dimensional accuracy, and surface finish quality that ensures leak-free connections and extended service life. The manufacturing process incorporates advanced quality control measures including chemical composition analysis, mechanical property testing, and dezincification resistance verification.

Dezincification Resistant Brass materials form the foundation of our product range, utilizing carefully controlled alloy compositions that meet or exceed international specifications for dezincification resistance. These materials undergo comprehensive metallurgical analysis and heat treatment optimization to achieve the desired microstructure and properties. Our Dezincification Resistant Brass exhibits excellent machinability, corrosion resistance, and mechanical properties while maintaining cost-effectiveness for large-scale applications. The material selection process considers factors such as service temperature, water chemistry, mechanical loading, and environmental conditions to ensure optimal performance.

Dezincification Resistant Brass Machined Parts represent our core competency in precision manufacturing, combining advanced CNC machining capabilities with decades of experience in Brass component production. These parts are manufactured using multi-axis CNC machines, Swiss-type lathes, and specialized tooling designed specifically for Brass machining. Our machined parts achieve tight tolerances typically ranging from ±0.05mm to ±0.1mm depending on component geometry and customer requirements. Surface finishes from Ra 0.8 to Ra 3.2 micrometers are routinely achieved through optimized cutting parameters and post-machining processes.

Brass DZR Casting encompasses our foundry capabilities for producing complex-geometry components that would be difficult or uneconomical to machine from solid stock. Our casting processes include sand casting, investment casting, and centrifugal casting methods, each selected based on component requirements, production volume, and quality specifications. Cast DZR Brass components undergo heat treatment and machining operations to achieve final dimensions and properties. The casting process is optimized to minimize porosity, achieve uniform microstructure, and ensure consistent dezincification resistance throughout the component cross-section.

Material Grades and International Specifications

| Standard | Grade/Designation | Composition (Cu-Zn-%) | Key Properties | Applications |

|---|---|---|---|---|

| ASTM B858 | C89833 (DZR-1) | Cu: 85-87, Zn: 11.5-13.5, As: 0.02-0.10 | Excellent DZR resistance, Good machinability | Plumbing fittings, Water meters |

| ASTM B858 | C89844 (DZR-2) | Cu: 59-62, Zn: 36-39, As: 0.02-0.15, Sb: 0.005-0.04 | Superior DZR resistance, High strength | High-pressure applications, Marine valves |

| ASTM B584 | C89320 (DZR Naval Brass) | Cu: 59-62, Zn: 37-39.25, Sn: 0.50-1.0, As: 0.02-0.10 | Excellent seawater resistance | Marine hardware, Propeller components |

| BS EN 12449 | CW602N | Cu: 57-59, Pb: 1.6-2.5, Zn: Balance | High strength, DZR compliant | Hot water systems, Valves |

| BS EN 12449 | CW617N | Cu: 57-59, Pb: 1.6-2.5, Zn: Balance, As: 0.02-0.15 | Enhanced DZR properties, Good machinability | Water fittings, Instrumentation |

| BS EN 12449 | CW511L (Lead-free DZR) | Cu: 57-60, Si: 0.05-0.25, Zn: Balance | Lead-free, Environmentally safe | Potable water, Food industry |

| DIN 17672 | CuZn40Pb2 (Ms58) | Cu: 57-60, Pb: 1.6-2.5, Zn: 37.5-40.5 | Good formability, Corrosion resistant | Pipe fittings, Hardware |

| DIN 17660 | CuZn39Pb3 (Ms60) | Cu: 58-61, Pb: 2.5-3.5, Zn: Balance, As: 0.02-0.15 | Excellent machinability, DZR resistant | Precision components, Valve bodies |

| DIN 17672 | CuZn36Pb2As (DZR Ms63) | Cu: 61-64, Pb: 1.6-2.5, Zn: 33-37, As: 0.02-0.15 | Superior corrosion resistance | Chemical processing, Marine |

| JIS H3250 | C3604 (Eco-Brass) | Cu: 57-61, Bi: 0.1-0.5, Zn: Balance | Lead-free, DZR resistant | Drinking water systems |

| JIS H3250 | C3602 (Naval DZR) | Cu: 59-62, Zn: 37-40, Sn: 0.5-1.0, As: 0.02-0.10 | Marine-grade corrosion resistance | Shipbuilding, Offshore platforms |

| JIS H3130 | C6782 (High-Copper DZR) | Cu: 64-67, Zn: 32-35, As: 0.02-0.15, P: 0.01-0.04 | Exceptional DZR resistance, High conductivity | Electrical components, Heat exchangers |

| IS 319 | Grade-1 (Leaded Brass) | Cu: 58-62, Pb: 2.5-3.7, Zn: Balance | Excellent machinability | General engineering, Fittings |

| IS 319 | Grade-2 (DZR Modified) | Cu: 60-63, Pb: 2.0-3.0, Zn: Balance, As: 0.02-0.12 | Enhanced DZR properties, Indian standard | Water supply systems, Municipal |

| GB/T 4423 | HPb59-1 | Cu: 57-60, Pb: 0.8-1.9, Zn: Balance | Good corrosion resistance | Marine applications, Valves |

| GB/T 4423 | HPb62-2 (Chinese DZR) | Cu: 60-63, Pb: 1.5-2.5, Zn: Balance, As: 0.02-0.15 | Chinese DZR standard, Cost-effective | Plumbing, Industrial fittings |

| GB/T 26303 | CuZn15 (High-Copper DZR) | Cu: 84-86, Zn: 14-16, P: 0.01-0.04 | Maximum DZR resistance, Premium grade | Critical applications, Aerospace |

| ASTM B124 | C22000 (Commercial Bronze DZR) | Cu: 89-91, Zn: 9-11, P: 0.015-0.040 | Bronze-like properties, DZR enhanced | Decorative fittings, Architecture |

| EN 1982 | CC752S (Silicon DZR Brass) | Cu: 57-61, Zn: Balance, Si: 1.5-3.5, As: 0.02-0.15 | High strength, Cast grade | Pump housings, Valve bodies |

| ASTM B271 | C86300 (Manganese DZR Bronze) | Cu: 60-66, Zn: 22-28, Mn: 2.5-5.0, Fe: 2.0-4.0, Al: 5.5-7.5 | Ultra-high strength, Superior corrosion resistance | Heavy-duty marine, Industrial machinery |

| Australian AS 1567 | Grade 360 (Australian DZR) | Cu: 57-60, Pb: 1.5-2.5, Zn: Balance, As: 0.02-0.15 | Australian standard DZR compliance | Water utilities, Mining equipment |

Manufacturing Processes and Advanced Machinery

Our manufacturing processes incorporate cutting-edge technology and time-tested metallurgical practices to produce superior Brass DZR components. The process begins with incoming raw material analysis using X-ray fluorescence spectroscopy to verify chemical composition and ensure compliance with specified grades. Melting operations utilize electric induction furnaces with precise temperature control and atmosphere management to minimize oxidation and ensure uniform alloy distribution.

CNC Machining Centers

Multi-axis CNC machining centers from leading manufacturers including DMG Mori, Mazak, and Haas provide precision machining capabilities. These machines feature automated tool changers, high-pressure coolant systems, and advanced control systems that enable lights-out manufacturing for consistent quality and productivity.

Swiss-Type Lathes

Citizen and Star Swiss-type automatic lathes excel in producing small-diameter, high-precision components with exceptional surface finish quality. These machines utilize guide bushing technology to minimize deflection and achieve tolerances as tight as ±0.02mm on shaft components.

Heat Treatment Furnaces

Controlled atmosphere heat treatment furnaces with precise temperature profiling ensure optimal microstructure development for maximum dezincification resistance. Furnace atmospheres are carefully controlled to prevent oxidation and decarburization during processing.

Quality Control Equipment

Comprehensive quality control systems include coordinate measuring machines (CMM), optical comparators, surface roughness testers, and hardness testers to ensure every component meets specified requirements before shipment.

Typical Parts Produced and Applications

| Component Type | Typical Dimensions | Manufacturing Process | Key Applications | Industry Sectors |

|---|---|---|---|---|

| Compression Fittings | 6mm to 108mm OD | CNC Machining, Assembly | Plumbing connections, Gas systems | Construction, HVAC |

| Ball Valve Components | DN15 to DN300 | Precision Machining, Casting | Water control, Process systems | Water treatment, Chemical |

| Threaded Fittings | 1/8″ to 4″ NPT/BSP | CNC Turning, Threading | Pipe connections, Manifolds | Oil & Gas, Marine |

| Water Meter Bodies | 15mm to 300mm sizes | Sand Casting, Machining | Flow measurement, Utilities | Municipal, Industrial |

| Pump Components | Custom specifications | Investment Casting | Impellers, Housings, Shafts | Water supply, Agriculture |

| Marine Hardware | Various sizes | Forging, Machining | Seacocks, Through-hulls | Shipbuilding, Offshore |

DZR Brass Manufacturing Process Flow

Raw MaterialAnalysisMelting &AlloyingCasting/FormingHeatTreatmentCNCMachiningQualityControlFinishing &Packaging

Technical Specifications and Tolerances

| Parameter | Standard Tolerance | Precision Tolerance | Measurement Method | Quality Standard |

|---|---|---|---|---|

| Linear Dimensions | ±0.1mm | ±0.05mm | CMM, Calipers | ISO 2768-m |

| Thread Pitch | 6H/6g | 4H/4g | Thread Gauges | ISO 965 |

| Surface Roughness | Ra 3.2 μm | Ra 0.8 μm | Profilometer | ISO 4287 |

| Roundness | 0.05mm | 0.02mm | CMM Analysis | ISO 1101 |

| Concentricity | 0.1mm | 0.05mm | CMM Analysis | ISO 1101 |

| Hardness | HB 85-120 | ±5 HB | Brinell Tester | ASTM E10 |

Material Properties and Performance Characteristics

| Property | CW602N (DZR) | C89833 (ASTM) | C89844 (DZR-2) | C89320 (Naval DZR) | CW617N (Enhanced DZR) | Test Method |

|---|---|---|---|---|---|---|

| Tensile Strength (MPa) | 380-520 | 345-415 | 420-580 | 400-550 | 390-530 | ASTM E8 |

| Yield Strength (MPa) | 160-310 | 140-275 | 180-340 | 170-320 | 165-315 | ASTM E8 |

| Elongation (%) | 15-25 | 18-30 | 12-22 | 16-28 | 14-24 | ASTM E8 |

| Hardness (HB) | 90-120 | 85-110 | 110-140 | 95-125 | 92-122 | ASTM E10 |

| Density (g/cm³) | 8.4-8.7 | 8.5-8.8 | 8.3-8.6 | 8.4-8.7 | 8.4-8.7 | Archimedes Method |

| Thermal Conductivity (W/mK) | 85-95 | 90-105 | 80-90 | 85-95 | 86-96 | ASTM E1461 |

| DZR Depth (μm) | <200 | <150 | <100 | <150 | <180 | ASTM B858 |

| Lead Content (%) | 1.6-2.5 | <0.25 | <0.25 | <0.25 | 1.6-2.5 | ICP-OES |

Specialized DZR Brass Alloy Families

Lead-Free DZR Brass Alloys

C89833 Series: Ultra-low lead content (<0.25%) DZR Brass specifically developed for drinking water applications. Contains controlled additions of Arsenic and Antimony for dezincification resistance while maintaining NSF/ANSI 61 compliance. Available in both wrought and cast forms with excellent machinability characteristics.

CW511L (Silicon Bronze DZR): Lead-free European standard alloy utilizing Silicon additions for strength enhancement and corrosion resistance. Particularly suitable for food industry and pharmaceutical applications where lead contamination is strictly prohibited.

Eco-Brass Variants (C3604, C36000): Japanese and North American lead-free DZR alloys using Bismuth as a machinability enhancer instead of Lead. These alloys provide comparable machining characteristics to traditional leaded Brass while meeting environmental regulations.

High-Strength DZR Naval Brass

C89320 Naval DZR: Enhanced with Tin additions (0.5-1.0%) for superior seawater corrosion resistance. This alloy demonstrates exceptional performance in marine environments with chloride concentrations up to 35,000 ppm. Commonly used in shipbuilding, offshore platforms, and desalination equipment.

C86300 Manganese Bronze DZR: Ultra-high strength DZR alloy containing Manganese, Iron, and Aluminum additions. Tensile strengths exceeding 600 MPa are achievable while maintaining excellent corrosion resistance in marine environments. Ideal for heavy-duty marine hardware and industrial machinery components.

Specialized Application DZR Alloys

High-Copper DZR (CuZn15): Premium grade alloy with 84-86% Copper content providing maximum dezincification resistance. Phosphorus additions enhance corrosion resistance in aggressive water chemistries. Used in critical applications where component failure is not acceptable.

Silicon DZR Brass (CC752S): Cast alloy with Silicon additions (1.5-3.5%) for enhanced strength and casting characteristics. Provides excellent fluidity during casting while maintaining DZR properties. Commonly used for complex-geometry pump housings and valve bodies.

Antimony-Enhanced DZR: Specialized alloys with controlled Antimony additions (0.05-0.15%) for applications requiring enhanced stress-corrosion cracking resistance. Particularly effective in hot water applications above 80°C where standard DZR alloys may be marginal.

Regional Standard DZR Alloys

Australian AS 1567: Grade 360 DZR Brass specifically developed for Australian water conditions with unique mineral content. Features optimized Arsenic levels for local water chemistry compatibility and compliance with Australian plumbing standards.

Chinese GB/T Standards: HPb62-2 and similar grades developed for Chinese market requirements with cost-optimization while maintaining DZR performance. These alloys balance material cost with performance requirements for large-scale infrastructure projects.

Indian IS 319 Modified: Grade-2 DZR represents Indian standard development with Arsenic enhancement for local water conditions. Optimized for Indian municipal water systems with varying pH and mineral content across different regions.

Industries and Applications

Our Brass DZR components and DZR Brass fittings serve a diverse range of industries where corrosion resistance, reliability, and performance are critical factors. The plumbing and water supply industry represents our largest market segment, with components used in residential, commercial, and industrial water distribution systems. These applications demand strict compliance with drinking water safety standards and long-term durability in varying water chemistry conditions.

The marine and offshore industry relies extensively on our DZR Brass components for seawater applications where standard Brass materials would quickly fail due to dezincification and corrosion. Our components are used in seacocks, through-hull fittings, propeller shafts, and marine hardware where exposure to saltwater demands superior corrosion resistance and mechanical integrity.

HVAC and refrigeration systems utilize our DZR Brass fittings for refrigerant lines, water loops, and control systems where thermal cycling and chemical compatibility are important considerations. The automotive industry incorporates our components in cooling systems, fuel systems, and hydraulic applications where reliability and precision are paramount.

The oil and gas industry employs our Brass DZR components in instrumentation, control systems, and process equipment where exposure to aggressive environments requires materials with proven performance records. Water treatment and chemical processing industries use our components in pumps, valves, and piping systems where chemical compatibility and corrosion resistance are essential.

Performance Metrics and Quality Standards

Dezincification Resistance Testing: All DZR Brass materials undergo standardized dezincification resistance testing according to ASTM B858, BS EN 12449, and ISO 6509. Test specimens are exposed to copper sulfate solution at elevated temperature for specified durations to verify resistance to selective zinc leaching. Components must demonstrate depth of dezincification less than 200 micrometers to meet DZR classification requirements.

| Performance Metric | Target Value | Measurement Frequency | Compliance Standard |

|---|---|---|---|

| Dimensional Accuracy | 99.5% within tolerance | Every batch | ISO 2768 |

| Surface Finish Quality | Ra ≤ specified value | Sample testing | ISO 4287 |

| Chemical Composition | Within spec limits | Each heat/batch | ASTM E1019 |

| DZR Resistance | <200 μm depth | Material qualification | ASTM B858 |

| Pressure Testing | 1.5× working pressure | Fitting validation | ASME B31.3 |

| Lead Content | <0.25% (NSF certified) | Each production lot | NSF/ANSI 61 |

Turnaround Time and Production Capabilities

Our standard production turnaround time for Brass DZR components and DZR Brass fittings is 4-6 weeks from order confirmation, depending on component complexity, quantity requirements, and current production schedule. This timeframe includes material procurement, manufacturing operations, quality control testing, and preparation for shipment. For urgent requirements, expedited production schedules can be arranged with 2-3 week delivery for standard components, subject to capacity availability and additional expedite charges.

Our production capabilities encompass batch sizes ranging from prototype quantities of 10-50 pieces to large production runs exceeding 100,000 pieces per order. Small batch production utilizes flexible manufacturing cells and quick-changeover tooling to minimize setup times and maintain cost-effectiveness. Large volume production leverages dedicated production lines and automated handling systems to achieve optimal efficiency and consistent quality. Our planning systems integrate with supply chain management to ensure material availability and optimal production scheduling.

Standard Production

Timeline: 4-6 weeks

Batch Size: 100-10,000 pieces

Applications: Regular inventory replenishment

Quality Level: Standard inspection protocols

Expedited Production

Timeline: 2-3 weeks

Batch Size: 50-5,000 pieces

Applications: Emergency replacement, Project deadlines

Quality Level: Enhanced inspection and testing

Prototype Development

Timeline: 1-2 weeks

Batch Size: 5-50 pieces

Applications: New product development, Testing

Quality Level: 100% inspection and documentation

Volume Production

Timeline: 6-8 weeks

Batch Size: 10,000+ pieces

Applications: OEM supply agreements

Quality Level: Statistical process control

Frequently Asked Questions (Q&A)

Q1: What makes DZR Brass different from regular Brass?

A: DZR (Dezincification Resistant) Brass contains specific alloying elements like Arsenic, Antimony, or Phosphorus that prevent selective Zinc leaching in corrosive environments. Regular Brass can suffer from dezincification, leading to component failure, while DZR Brass maintains structural integrity and performance in aggressive water conditions.

Q2: Are your DZR Brass components suitable for drinking water applications?

A: Yes, our DZR Brass components comply with major drinking water safety standards including NSF/ANSI 61, BS 6920, and AS/NZS 4020. Lead content is maintained below 0.25% for NSF certified grades, ensuring safety for potable water contact applications.

Q3: What testing do you perform to verify dezincification resistance?

A: We conduct standardized dezincification testing according to ASTM B858, BS EN 12449, and ISO 6509. Test specimens are exposed to copper sulfate solution at 75°C for specified durations. Components must show dezincification depth less than 200 micrometers to meet DZR classification.

Q4: Can you manufacture custom DZR Brass components to our specifications?

A: Absolutely. We specialize in custom manufacturing based on customer drawings, specifications, and performance requirements. Our engineering team works closely with customers to optimize designs for manufacturability while meeting all technical and quality requirements.

Q5: What is the maximum operating temperature for DZR Brass components?

A: DZR Brass components can operate continuously at temperatures up to 120°C (248°F) for water service applications. For specialized high-temperature applications, we can recommend specific alloy grades and heat treatment conditions to optimize performance.

Q6: Do you provide material certificates and test reports?

A: Yes, we provide comprehensive Mill Test Certificates (MTC) including chemical composition analysis, mechanical properties, dezincification test results, and dimensional inspection reports. Additional testing such as pressure testing or specialized analysis can be provided upon request.

Q7: What surface finishes are available for DZR Brass components?

A: Standard finishes include machined (as-machined), polished, nickel plated, chrome plated, and powder coated. Surface roughness typically ranges from Ra 0.8 to Ra 3.2 micrometers depending on application requirements and finishing processes selected.

Q8: How do you ensure consistent quality across large production runs?

A: We implement Statistical Process Control (SPC) with real-time monitoring of critical parameters. Our quality management system includes incoming material inspection, in-process monitoring, final inspection, and batch tracking throughout the production process.

Q9: Can DZR Brass be welded or brazed for assembly operations?

A: Yes, DZR Brass can be successfully welded using TIG or MIG processes with appropriate Brass filler materials. Brazing is commonly used for joining operations using Copper-Phosphorus or Silver-based brazing alloys. Proper joint design and heat input control are essential for maintaining DZR properties.

Q10: What is your minimum order quantity for custom components?

A: Minimum order quantities depend on component complexity and manufacturing process. For machined parts, typical minimums range from 50-100 pieces. For cast components, minimums may be 100-500 pieces depending on casting method and tooling requirements.

Q11: Do you offer inventory management and consignment programs?

A: Yes, we provide vendor-managed inventory (VMI) and consignment stocking programs for qualified customers with predictable usage patterns. These programs help optimize inventory levels while ensuring component availability for production schedules.

Q12: How do you handle packaging and shipping for international orders?

A: We offer customized packaging solutions including anti-corrosion treatments, moisture barriers, and customer-specific labeling. Shipping methods include air freight, sea freight, and express courier services with full documentation for customs clearance and traceability.

Size and Dimensional Chart

| Component Type | Size Range | Thread Specifications | Maximum Pressure Rating | Temperature Range |

|---|---|---|---|---|

| Compression Fittings – Straight | 6mm – 108mm OD | M6 – M110 x 1.5 | 16 bar (232 psi) | -20°C to +120°C |

| Compression Fittings – Elbow | 8mm – 54mm OD | M8 – M60 x 1.5 | 16 bar (232 psi) | -20°C to +120°C |

| Threaded Fittings – NPT | 1/8″ – 4″ NPT | NPT per ASME B1.20.1 | 20 bar (290 psi) | -30°C to +150°C |

| Threaded Fittings – BSP | 1/8″ – 4″ BSP | BSP per ISO 228-1 | 25 bar (362 psi) | -30°C to +150°C |

| Ball Valve Bodies | DN15 – DN300 | Flanged ANSI/DIN | 40 bar (580 psi) | -40°C to +180°C |

| Water Meter Bodies | 15mm – 300mm | ISO 4064 compliant | 10 bar (145 psi) | 0°C to +90°C |

| Marine Through-hulls | 1/2″ – 6″ diameter | NPT/BSP threads | 5 bar (72 psi) | -10°C to +60°C |

| Custom Machined Parts | Per customer specification | Any standard thread | Application dependent | Application dependent |

Why Choose Our DZR Brass Components

Three Decades of Global Experience: With over 30 years of experience in Brass manufacturing and international trade, we have developed deep expertise in DZR Brass technology, global quality standards, and customer service excellence. Our long-standing relationships with customers worldwide demonstrate our commitment to quality, reliability, and continuous improvement.

Superior Quality Control

Our quality management system exceeds ISO 9001 requirements with additional controls specific to DZR Brass manufacturing. Every batch undergoes comprehensive testing including chemical analysis, mechanical testing, and dezincification resistance verification to ensure consistent performance.

Customization Capabilities

We excel in developing custom solutions tailored to specific application requirements. Our engineering team collaborates closely with customers from initial concept through production to optimize designs for performance, manufacturability, and cost-effectiveness.

Flexible Production Scheduling

Our manufacturing systems are designed for flexibility, allowing us to accommodate varying batch sizes, expedited deliveries, and changing requirements. We maintain strategic inventory levels of raw materials to support responsive production scheduling.

Global Shipping Network

Established relationships with international freight forwarders and shipping companies ensure reliable, cost-effective delivery to customers worldwide. We handle all documentation requirements for customs clearance and regulatory compliance.

Advanced Communication Systems: Our customer service team utilizes modern communication tools including email, WhatsApp, video conferencing, and project management platforms to maintain clear, timely communication throughout the order process. Regular updates on production status, quality testing results, and shipping schedules keep customers informed and confident in our service.

Customized Packaging Solutions: We understand that different applications and shipping destinations require specific packaging approaches. Our packaging capabilities include anti-corrosion treatments, moisture barrier packaging, custom labeling with customer logos and part numbers, and specialized containers for delicate components. This attention to packaging details ensures components arrive in perfect condition and are ready for immediate use or assembly.

International Standards Compliance

| Standard Organization | Applicable Standards | Scope | Compliance Level |

|---|---|---|---|

| ASTM International | B858, B584, B62, E8, E10 | Material specifications, Testing methods | Full compliance |

| British Standards (BSI) | BS EN 12449, BS 6920, BS EN 1982 | DZR requirements, Water contact safety | Certified compliance |

| Deutsches Institut (DIN) | DIN 17672, DIN 50930-6 | Brass specifications, Corrosion testing | Full compliance |

| Japanese Industrial Standards | JIS H3250, JIS H3270 | Brass alloys, Eco-friendly materials | Certified grades available |

| Indian Standards (BIS) | IS 319, IS 1545, IS 6392 | Brass specifications, Fittings standards | Full compliance |

| Chinese National Standards | GB/T 4423, GB/T 1176 | Brass alloys, Manufacturing standards | Qualified supplier status |

| NSF International | NSF/ANSI 61, NSF/ANSI 372 | Drinking water safety, Lead content | Certified products |

| Australian Standards | AS/NZS 4020, AS 1345 | Water contact materials, Fittings | Compliant materials |

Packaging and Shipping Services

Our comprehensive packaging and shipping services are designed to ensure your DZR Brass components arrive in perfect condition regardless of destination or shipping method. Standard packaging includes protective wrapping with VCI (Vapor Corrosion Inhibitor) materials to prevent oxidation during storage and transit. Components are carefully arranged in moisture-resistant containers with appropriate cushioning materials to prevent damage during handling and transportation.

Custom packaging solutions can incorporate customer-specific labeling, logos, and part number identification systems to support direct integration into customer inventory management systems. For high-value or precision components, we offer specialized packaging including foam inserts, individual component protection, and anti-static materials for sensitive applications.

Standard Packaging Options

VCI protective wrapping, corrugated cartons with cushioning, moisture barrier bags, component identification labels, packing lists with quality certificates, and standard shipping documentation for efficient handling.

Export Packaging Services

Wooden crates for heavy components, sea-worthy packaging with additional corrosion protection, fumigation certificates where required, export documentation including commercial invoices, packing lists, and certificates of origin.

Express Shipping Solutions

Air freight packaging optimized for weight and volume, express courier services with tracking, emergency replacement parts with 24-48 hour delivery, and specialized handling for time-critical shipments.

Custom Labeling Services

Customer logo incorporation, part number and specification labels, barcode systems for inventory tracking, multilingual labeling for international markets, and specialized marking for traceability requirements.

Customer Testimonial

“We have been sourcing DZR Brass fittings from this manufacturer for over 8 years, and their consistency in quality and delivery performance has been exceptional. Their technical support team helped us optimize our valve designs for better performance and cost-effectiveness. The dezincification resistance of their components has exceeded our expectations in challenging water chemistry conditions. We particularly appreciate their flexible approach to custom specifications and their ability to scale production according to our project timelines. Their communication throughout the entire process, from initial quotation to final delivery, has been professional and responsive. I would highly recommend them to any company seeking reliable DZR Brass components with superior quality and service.”

– Michael Rodriguez, Senior Procurement Manager, Houston, Texas, USA

Glossary of Technical Terms

A corrosion process where Zinc is selectively leached from Brass alloys in certain water conditions, leaving behind a porous Copper-rich structure that lacks mechanical integrity and can lead to component failure.

Brass components manufactured from alloys specifically formulated with additives like Arsenic, Antimony, or Phosphorus to resist dezincification corrosion in aggressive water environments.

A European standard (BS EN 12449) dezincification-resistant Brass alloy containing approximately 58-60% Copper, with controlled levels of Lead and Zinc, designed for hot water applications.

A certification standard for materials and components that contact drinking water, ensuring they do not contribute harmful levels of contaminants to potable water supplies.

A precision machining process using sliding-headstock lathes with guide bushings to support workpieces during machining, enabling production of small-diameter, high-precision components with excellent surface finishes.

A document provided by the manufacturer certifying the chemical composition, mechanical properties, and compliance with specified standards for a particular batch or heat of material.

A quality control methodology that uses statistical methods to monitor and control manufacturing processes, ensuring consistent product quality and early detection of process variations.

Vapor Corrosion Inhibitor packaging materials that release protective molecules to prevent oxidation and corrosion of metal components during storage and transportation.

A manufacturing process where Brass is heated above its recrystallization temperature and shaped using compressive forces, resulting in improved grain structure and mechanical properties.

A precision casting process that produces components with excellent surface finish and dimensional accuracy by creating ceramic molds around wax patterns that are subsequently melted out.

Get Your Custom DZR Brass Components Quote Today

Ready to experience the quality and reliability of our DZR Brass components and fittings? Our technical experts are standing by to assist with your specific requirements, from material selection to custom manufacturing solutions.

Contact Information:

📧 Email: sales@brass-copper-parts. com

📞 Phone: +91-22 -43449300

Quality Assured | Global Shipping | 30+ Years Experience | ISO Certified Manufacturing

Your trusted partner for precision DZR Brass components and superior customer s