Brass Mold-In Inserts

Precision Threading Solutions for Injection Molding

High-quality Brass threaded inserts Brass Mold in inserts designed for permanent installation in plastic components through injection molding processes

Product Overview

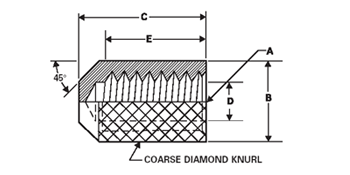

Brass mold-in inserts represent the pinnacle of threaded fastener technology for injection molded plastic components. These precision-engineered inserts feature a coarse diamond knurl exterior surface that creates an unbreakable mechanical bond with the surrounding plastic material during the molding process. Unlike post-molding installation methods such as heat insertion or ultrasonic welding, mold-in inserts are positioned directly in the injection mold cavity, allowing the molten plastic to flow around and permanently encapsulate the knurled exterior. This results in superior pull-out resistance, exceptional torque strength, and eliminates the risk of insert displacement or rotation. The internal threads are precision-machined to exact specifications, providing reliable engagement with standard fasteners while the brass construction offers excellent corrosion resistance, electrical conductivity, and thermal stability across a wide temperature range.

🔄 Through Hole Inserts

Complete thread engagement from both sides with coarse diamond knurl exterior for maximum retention in plastic materials. Ideal for applications requiring access from both ends.

🔒 Blind Hole Inserts

Closed bottom design with internal threads and diamond knurl exterior. Perfect for applications where one-sided access is sufficient and bottom sealing is required.

Available Thread Sizes

2-56 UNC

Fine precision threading

4-40 UNC

Small component applications

6-32 UNC

Standard electronics threading

8-32 UNC

Medium duty applications

10-24 UNC

Heavy duty small threads

1/4″-20 UNC

Standard quarter-inch threading

5/16″-18 UNC

Large diameter applications

Dimensional Specifications

Through Hole Insert Dimensions

| Thread Size | B – Thread Length (in) | C – Overall Length (in) | D – Insert Diameter (in) | E – Thread Diameter (in) | F – Flange Thickness (in) |

|---|---|---|---|---|---|

| 2-56 UNC | 0.156 | 0.218 | 0.125 | 0.086 | 0.031 |

| 4-40 UNC | 0.187 | 0.250 | 0.156 | 0.112 | 0.032 |

| 6-32 UNC | 0.218 | 0.281 | 0.187 | 0.138 | 0.032 |

| 8-32 UNC | 0.250 | 0.312 | 0.218 | 0.164 | 0.032 |

| 10-24 UNC | 0.281 | 0.343 | 0.250 | 0.190 | 0.032 |

| 1/4″-20 UNC | 0.343 | 0.406 | 0.312 | 0.250 | 0.032 |

| 5/16″-18 UNC | 0.406 | 0.468 | 0.375 | 0.312 | 0.032 |

Blind Hole Insert Dimensions

| Thread Size | B – Thread Depth (in) | C – Overall Length (in) | D – Insert Diameter (in) | E – Thread Diameter (in) | F – Flange Thickness (in) |

|---|---|---|---|---|---|

| 2-56 UNC | 0.125 | 0.187 | 0.125 | 0.086 | 0.031 |

| 4-40 UNC | 0.156 | 0.218 | 0.156 | 0.112 | 0.032 |

| 6-32 UNC | 0.187 | 0.250 | 0.187 | 0.138 | 0.032 |

| 8-32 UNC | 0.218 | 0.281 | 0.218 | 0.164 | 0.032 |

| 10-24 UNC | 0.250 | 0.312 | 0.250 | 0.190 | 0.032 |

| 1/4″-20 UNC | 0.312 | 0.375 | 0.312 | 0.250 | 0.032 |

| 5/16″-18 UNC | 0.375 | 0.437 | 0.375 | 0.312 | 0.032 |

Key Features & Benefits

Material Properties

- High-quality brass construction (360 brass alloy)

- Excellent corrosion resistance

- Superior thermal conductivity

- Non-magnetic properties

- Electrical conductivity for grounding applications

Design Features

- Coarse diamond knurl exterior for maximum retention

- Precision machined internal threads

- Uniform wall thickness for consistent performance

- Chamfered entry for easy installation

- Available in through-hole and blind configurations

Installation Benefits

- Molded directly into plastic components

- No secondary operations required

- Permanent installation prevents loosening

- Superior pull-out and torque resistance

- Cost-effective alternative to tapping plastic

Applications

🔌 Electronics

PCB mounting, enclosure assembly

🚗 Automotive

Interior components, trim assemblies

🏠 Appliances

Housing assemblies, control panels

🔧 Industrial

Equipment housings, control boxes

🎮 Consumer Goods

Device housings, toy assemblies

🏥 Medical

Device housings, instrument panels

Installation Guidelines

Mold Design Considerations

- Position insert in mold cavity before injection

- Ensure proper alignment with mold features

- Design adequate clearance for insert placement

- Consider gate location to minimize stress

- Use appropriate mold temperature (300-350°F typical)

Plastic Material Compatibility

- ABS – Excellent retention and performance

- Nylon – Superior strength and durability

- Polycarbonate – High temperature applications

- PBT/PET – Chemical resistance applications

- Polypropylene – With proper surface treatment

Quality Standards

📏 Precision

±0.002″ dimensional tolerance

🔍 Inspection

100% dimensional verification

✅ Standards

ANSI/ASME B18.8.2 compliant

🏆 Certification

ISO 9001:2015 manufacturing

Ready to Enhance Your Molding Process?

Contact us today for technical specifications, samples, or custom sizing options