Brass Pins , Brass Electrical Pins

Precision Machined Cold Forged Brass Pins – Manufacturer & Exporter India

We are one of the leading manufacturers and exporters of Brass Pins and Brass Electrical Pins from India. We have been supplying precision machined brass pins to the world market for many decades. Our comprehensive range includes Brass Connector Pins, Brass Contact Pins, Brass Terminal Pins, Brass Precision Pins, and specialized electrical contact components manufactured through advanced cold forging and automatic machining processes. With over three decades of global exposure and experience in brass pin manufacturing, we have established ourselves as a trusted supplier to industries requiring high-precision electrical and mechanical connection solutions. Our state-of-the-art manufacturing facility utilizes cutting-edge CNC machining technology and automated threading equipment to produce brass pins that meet international quality standards including ASTM, DIN, JIS, and IS specifications. We specialize in custom brass pin solutions with flexible production schedules, personalized packaging, and comprehensive technical support to meet diverse industrial applications worldwide.

Product Overview – Brass Pins & Brass Electrical Pins

Brass pins and brass electrical pins represent critical components in modern electrical, electronic, and mechanical assemblies. These precision-engineered components are manufactured from high-grade Brass alloys through sophisticated cold forging and automatic machining processes. Our brass pins offer exceptional electrical conductivity, corrosion resistance, and mechanical strength, making them ideal for applications requiring reliable electrical connections and mechanical fastening solutions.

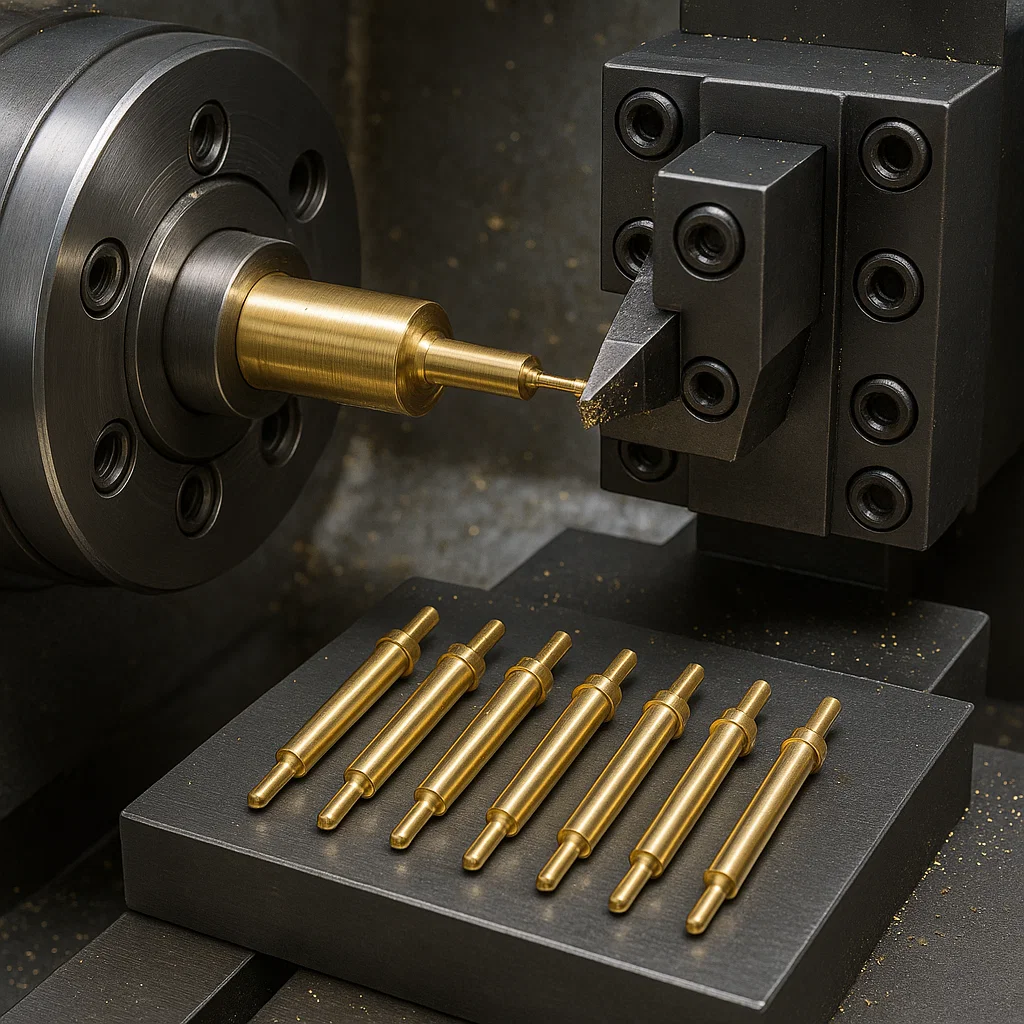

The manufacturing process involves precision cold forging of brass bars, followed by automatic machining and threading operations when required. This combination ensures dimensional accuracy, superior surface finish, and consistent mechanical properties across all produced components. Our brass electrical pins are designed to meet stringent industry requirements for electrical conductivity, contact resistance, and environmental durability.

Brass Pin Manufacturing Process Flow

Raw Material

Brass Bars

Cold Forging

Process

Precision

Machining

Threading

(If Required)

Quality

Control

Types of Brass Pins – Comprehensive Range

Brass Connector Pins

Brass connector pins are precision-engineered components designed for reliable electrical and mechanical connections in various industrial applications. These pins are manufactured from high-conductivity Brass alloys using cold forging techniques followed by precision machining. The connector pins feature optimized geometry for secure insertion and retention in mating connectors, ensuring consistent electrical performance and mechanical stability. Our brass connector pins are available in various diameters ranging from 0.5mm to 25mm with customizable lengths and specialized surface treatments including gold plating, tin plating, and nickel plating for enhanced corrosion resistance and electrical conductivity.

Brass Contact Pins

Brass contact pins represent specialized electrical components engineered for high-frequency signal transmission and power distribution applications. These precision-manufactured pins utilize high-conductivity Brass alloys with optimized grain structure achieved through controlled cold forging processes. The contact pins feature precise dimensional tolerances and superior surface finish to ensure minimal contact resistance and maximum electrical efficiency. Our brass contact pins are designed to withstand repeated insertion and extraction cycles while maintaining consistent electrical performance, making them ideal for automotive connectors, electronic equipment, and industrial control systems.

Brass Terminal Pins

Brass terminal pins are robust electrical connection components designed for permanent and semi-permanent electrical connections in various industrial and commercial applications. These pins are manufactured through precision cold forging of high-quality Brass bars, followed by automated machining to achieve exact dimensional specifications. The terminal pins feature specialized geometries including threaded ends, barbed configurations, and smooth cylindrical designs to accommodate different connection methods. Our brass terminal pins offer excellent electrical conductivity, corrosion resistance, and mechanical strength, making them suitable for electrical panels, junction boxes, and terminal blocks in harsh environmental conditions.

Brass Precision Pins

Brass precision pins represent the pinnacle of manufacturing accuracy and quality control in brass pin production. These components are manufactured using advanced CNC machining technology and precision cold forging techniques to achieve dimensional tolerances as tight as ±0.001mm. The precision pins undergo rigorous quality control processes including dimensional inspection, surface roughness measurement, and electrical conductivity testing. Our brass precision pins are specifically designed for applications requiring exact dimensional accuracy, such as electronic connectors, precision instruments, and high-reliability electrical systems where consistent performance is critical.

Brass Plug Pins

Brass plug pins are specialized electrical components designed for removable electrical connections in various plug and socket configurations. These pins are engineered with specific taper angles, insertion forces, and retention characteristics to ensure secure and reliable connections. The manufacturing process involves precision cold forging followed by automatic machining to achieve the required dimensional accuracy and surface finish. Our brass plug pins feature optimized contact areas and specialized surface treatments to minimize contact resistance and maximize electrical performance. These components are widely used in electrical plugs, socket assemblies, and portable electrical equipment requiring frequent connection and disconnection cycles.

Solid Brass Pins

Solid brass pins are monolithic components manufactured from single pieces of high-quality Brass alloy without any joints, welds, or assembly operations. These pins offer superior mechanical strength, electrical conductivity, and structural integrity compared to assembled or multi-piece alternatives. The manufacturing process involves precision cold forging of solid Brass bars followed by automated machining operations to achieve exact specifications. Our solid brass pins are available in various configurations including cylindrical, hexagonal, and custom profiles with diameters ranging from 1mm to 50mm. These components are ideal for applications requiring maximum reliability, such as high-current electrical connections, structural fasteners, and precision mechanical assemblies.

Brass PCB Pins

Brass PCB pins are specialized components designed specifically for printed circuit board applications, including through-hole mounting, surface mount technology, and flexible circuit connections. These pins are manufactured with precise dimensional control to ensure perfect fit with standard PCB hole sizes and spacing requirements. The manufacturing process utilizes advanced cold forging techniques followed by precision machining to achieve the required geometry and surface finish. Our brass PCB pins feature optimized insertion characteristics, excellent solderability, and superior electrical performance for both analog and digital circuit applications. These components are available with various surface finishes including gold plating, tin plating, and organic solderability preservatives (OSP) to meet specific PCB assembly requirements.

Material Specifications & International Standards

| Standard | Designation | Copper Content (%) | Zinc Content (%) | Other Elements | Applications |

|---|---|---|---|---|---|

| ASTM B36 | C36000 (Free Cutting Brass) | 60-63 | 35.5-38.5 | Pb: 2.5-3.7 | High-speed machining applications |

| DIN 17660 | CuZn37 (Ms63) | 62-65 | Remainder | Pb: <0.2 | Electrical connector pins |

| JIS H3250 | C3604 (Brass Rod) | 57-61 | 35.5-42 | Pb: 1.8-3.7 | Precision machined components |

| BS 2874 | CZ121 (High Tensile Brass) | 57-60 | 38-42 | As: 0.02-0.15 | High strength applications |

| IS 319 | Grade 1 Brass | 58-62 | Remainder | Pb: 2.0-3.0 | General purpose brass pins |

| GB/T 4423 | H62 (Chinese Standard) | 60.5-63.5 | Remainder | Pb: <0.08 | Electronic components |

Manufacturing Processes & Technology

Our brass pin manufacturing utilizes advanced cold forging technology combined with precision automatic machining to achieve superior quality and dimensional accuracy. The cold forging process involves deforming Brass billets at room temperature using high-pressure hydraulic presses, resulting in improved grain structure, increased mechanical strength, and enhanced surface finish. This process eliminates material waste while achieving near-net-shape components with minimal subsequent machining requirements.

The automatic machining operations utilize state-of-the-art CNC multi-spindle automatic lathes equipped with precision tooling systems. These machines are capable of performing multiple operations including turning, drilling, threading, and surface finishing in a single setup, ensuring consistent dimensional accuracy and superior surface quality. Threading operations, when required, are performed using precision thread rolling or cutting techniques depending on specific application requirements.

Machinery & Equipment Used

| Equipment Type | Specification | Capacity | Applications |

|---|---|---|---|

| Cold Forging Press | Hydraulic Multi-Stage | 50-500 Tons | Primary shaping of brass pins |

| CNC Multi-Spindle Lathe | 8-Spindle Automatic | Ø0.5-25mm | Precision machining operations |

| Thread Rolling Machine | Planetary Thread Roller | M1-M20 | High-quality thread formation |

| Surface Treatment Line | Automated Plating System | 1000 pcs/hour | Electroplating & surface finishing |

Technical Specifications & Dimensional Charts

| Pin Type | Diameter Range (mm) | Length Range (mm) | Standard Tolerances | Surface Finish (Ra) |

|---|---|---|---|---|

| Brass Connector Pins | 0.5 – 25 | 5 – 200 | ±0.05 to ±0.001 | 0.8 – 0.2 μm |

| Brass Contact Pins | 0.8 – 15 | 8 – 150 | ±0.03 to ±0.001 | 0.6 – 0.1 μm |

| Brass Terminal Pins | 2 – 30 | 10 – 300 | ±0.1 to ±0.02 | 1.6 – 0.4 μm |

| Brass Precision Pins | 1 – 20 | 5 – 250 | ±0.005 to ±0.001 | 0.4 – 0.05 μm |

| Brass PCB Pins | 0.3 – 5 | 3 – 50 | ±0.02 to ±0.005 | 0.8 – 0.2 μm |

Material Properties & Performance Metrics

| Property | Units | Typical Value | Test Method |

|---|---|---|---|

| Electrical Conductivity | % IACS | 25-30 | ASTM B193 |

| Tensile Strength | MPa | 300-500 | ASTM E8 |

| Contact Resistance | mΩ | 0.5-2.0 | ASTM B539 |

| Hardness | HV | 120-180 | ASTM E384 |

| Insertion Force | N | 2-15 | IEC 60512 |

| Operating Temperature | °C | -40 to +200 | Customer Specification |

Industries & Applications

Our brass pins and brass electrical pins serve diverse industries requiring reliable electrical connections and precision mechanical components. The automotive industry extensively utilizes our brass connector pins and contact pins in engine management systems, lighting assemblies, and electronic control units. The electronics industry depends on our precision brass PCB pins for circuit board assemblies, electronic connectors, and communication equipment.

The aerospace and defense sectors require our high-precision brass pins for avionic systems, navigation equipment, and military electronics where reliability and performance are critical. Industrial automation and control systems utilize our brass terminal pins for panel-mount connections, sensor assemblies, and control circuitry. The telecommunications industry relies on our brass contact pins for networking equipment, fiber optic connections, and high-frequency signal transmission applications.

Quality Control & Testing Standards

Our quality assurance program encompasses comprehensive testing protocols aligned with international standards including ISO 9001:2015, IATF 16949, and AS9100D certifications. All brass pins undergo rigorous dimensional inspection using coordinate measuring machines (CMM) with accuracy of ±0.001mm. Electrical testing includes conductivity measurement, contact resistance verification, and insulation resistance testing according to applicable IEC and ASTM standards.

Material verification involves chemical composition analysis using X-ray fluorescence spectroscopy and optical emission spectroscopy to ensure compliance with specified alloy requirements. Mechanical testing includes tensile strength, hardness measurement, and fatigue testing for applications requiring repeated cycling. Environmental testing encompasses salt spray corrosion resistance, thermal cycling, and humidity exposure testing to validate performance in harsh operating conditions.

Customer Testimonial

“We have been sourcing precision brass connector pins from this manufacturer for over 8 years for our automotive electronic systems. Their consistent quality, on-time delivery, and excellent technical support have made them our preferred supplier. The dimensional accuracy and electrical performance of their brass pins consistently exceed our stringent specifications. Their ability to customize products according to our specific requirements while maintaining competitive pricing has been exceptional.”

– Robert Johnson, Senior Procurement Manager, D**** Automotive Systems,

Frequently Asked Questions (Q&A)

Q1: What is the minimum order quantity for custom brass pins?

A: Our minimum order quantity varies based on complexity and specifications, typically ranging from 1,000 to 10,000 pieces for custom brass pins. For standard configurations, we can accommodate smaller quantities of 500 pieces.

Q2: Can you provide brass pins with special surface treatments?

A: Yes, we offer comprehensive surface treatment options including gold plating, silver plating, tin plating, nickel plating, and organic coatings. We can also provide specialized treatments like passivation and chromate conversion coatings based on specific application requirements.

Q3: What tolerances can you achieve for precision brass pins?

A: We can achieve dimensional tolerances as tight as ±0.001mm for critical dimensions using our precision CNC machining capabilities. Standard tolerances range from ±0.05mm to ±0.01mm depending on the component geometry and size.

Q4: Do you provide material certificates and test reports?

A: Yes, we provide comprehensive material certificates including chemical composition analysis, mechanical property test reports, dimensional inspection reports, and electrical performance verification data with every shipment.

Q5: What is the typical lead time for brass pin orders?

A: Our standard turnaround time is 4-6 weeks from order confirmation for most brass pin configurations. Rush orders can be accommodated with expedited processing in 2-3 weeks depending on quantity and complexity.

Q6: Can you manufacture brass pins according to customer drawings?

A: Absolutely. We specialize in custom manufacturing according to customer specifications, drawings, and samples. Our engineering team can also provide design optimization suggestions to improve manufacturability and performance.

Q7: What quality certifications do you maintain?

A: We maintain ISO 9001:2015, IATF 16949 (automotive), and AS9100D (aerospace) certifications. Our products comply with RoHS, REACH, and other international environmental and safety standards.

Q8: Do you offer packaging customization services?

A: Yes, we provide customized packaging solutions including anti-static packaging, moisture barrier bags, custom labeling with customer logos, and specialized shipping containers based on specific requirements.

Q9: Can you supply brass pins for high-temperature applications?

A: Our standard brass pins are suitable for operating temperatures up to 200°C. For higher temperature applications, we can provide specialized brass alloys or alternative materials like Bronze or Copper alloys.

Q10: What inspection and testing capabilities do you have?

A: We have comprehensive in-house testing facilities including CMM dimensional inspection, XRF material analysis, electrical conductivity testing, salt spray corrosion testing, and mechanical property testing capabilities.

Q11: Do you provide technical support for product selection?

A: Yes, our experienced technical team provides comprehensive application support, material selection guidance, design optimization recommendations, and performance validation assistance throughout the product development process.

Q12: Can you handle large volume production requirements?

A: Our manufacturing facility is equipped to handle large volume production requirements up to 10 million pieces annually while maintaining consistent quality and on-time delivery performance.

Our Unique Selling Propositions (USPs)

Customization Capability: Our engineering team specializes in developing custom brass pin solutions tailored to specific application requirements. We provide comprehensive design support, prototype development, and production optimization to ensure optimal performance and cost-effectiveness.

Flexible Production Scheduling: We understand the dynamic nature of modern manufacturing and offer flexible production scheduling to accommodate urgent requirements, seasonal demand variations, and just-in-time delivery preferences without compromising quality standards.

Personalized Packaging Solutions: Our packaging department provides customized packaging options including customer-branded labels, specialized protective packaging, and automated packaging systems to meet specific shipping and handling requirements.

Global Experience & Expertise: With over three decades of international experience, we understand diverse market requirements, regulatory standards, and quality expectations across different industries and geographic regions.

Superior Communication & Support: Our multilingual technical support team ensures clear communication throughout the project lifecycle, providing regular updates, technical guidance, and responsive customer service.

Packaging & Shipping

Our packaging solutions are designed to protect brass pins during transportation while meeting specific customer requirements. Standard packaging includes anti-static polyethylene bags, moisture barrier protection, and robust corrugated shipping containers with appropriate cushioning materials. For export shipments, we provide fumigation-free wooden packaging or metal containers compliant with international shipping regulations.

Specialized packaging options include vacuum-sealed packages for long-term storage, tray packaging for automated assembly processes, and tape-and-reel packaging for electronic component applications. All packages include comprehensive labeling with product identification, quantity information, lot traceability, and handling instructions. We maintain partnerships with reliable international freight forwarders to ensure timely and secure delivery worldwide.

Glossary of Technical Terms

Cold Forging: A metalworking process where brass billets are shaped at room temperature using high pressure, resulting in improved mechanical properties and dimensional accuracy.

Contact Resistance: The electrical resistance measured across the contact interface between mating brass pins and corresponding connectors, typically measured in milliohms.

Electrical Conductivity: A material’s ability to conduct electric current, typically expressed as a percentage of International Annealed Copper Standard (%IACS) for brass alloys.

Insertion Force: The mechanical force required to insert a brass pin into its mating connector, measured in Newtons and critical for connector design and user experience.

PCB Pins: Specialized brass pins designed for printed circuit board applications, including through-hole mounting and surface mount technology connections.

Surface Roughness (Ra): A quantitative measure of surface texture, expressed in micrometers, critical for electrical contact performance and component mating characteristics.

Threading: The process of creating helical grooves on brass pin surfaces to enable threaded connections, performed through cutting or rolling operations.

Tolerance: The allowable dimensional variation in manufactured brass pins, expressed as plus/minus values from nominal dimensions to ensure proper fit and function.

Get Your Custom Brass Pin Solution Today!

Experience the difference of working with India’s leading brass pin manufacturer with over 30 years of global expertise.

📧 Email Us: sales@brass-copper-parts. com Send your detailed specifications, drawings, and quantity requirements to receive a comprehensive quotation within 24 hours. Our technical team reviews every inquiry personally to ensure accurate pricing and delivery schedules.

📱 WhatsApp/Phone Consultation: Connect directly with our technical specialists for immediate assistance with part design, material selection, and manufacturing recommendations. Our multilingual team provides support across global time zones.

📋 Request Technical Brochure: Download our comprehensive technical catalog featuring complete specifications, material properties, dimensional capabilities, and case studies from successful projects across diverse industries.

🎯 Get Instant Quote: Upload your drawings and specifications through our secure online portal for rapid quotation turnaround. Our automated systems provide preliminary pricing immediately with detailed quotes following within hours.

Special Offer: Mention this webpage for a 5% discount on your first order of brass pins above 10,000 pieces!