Brass Pressed Parts & Brass Pressed Components – Precision Manufacturing Excellence

We are one of the leading manufacturers and exporters of precision Brass pressed parts, Brass pressed components, Brass sheet metal parts, and Brass deep drawn components from India. We have been supplying high-quality Brass pressed parts to the world market for many decades.

PRICE: US$ 11.20/Kilogram

Our state-of-the-art manufacturing facility, equipped with advanced pressing machinery and quality control systems, enables us to deliver superior Brass components that meet international standards and exceed customer expectations. With over three decades of experience in Brass forming, stamping, and deep drawing processes, we have established ourselves as a trusted partner for industries worldwide including automotive, electronics, plumbing, electrical, and precision engineering sectors.

Our expertise in working with various Brass grades and alloys, combined with our commitment to precision manufacturing and timely delivery, has made us a preferred choice for customers seeking reliable Brass pressed components. We maintain stringent quality standards throughout our manufacturing process, from raw material selection to final inspection, ensuring that every Brass pressed part meets the highest quality benchmarks.

Brass Pressed Components Overview

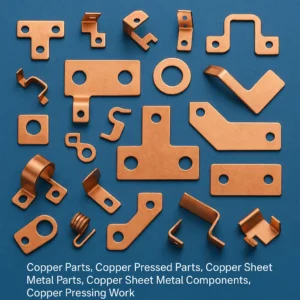

Brass pressed components represent a critical category of precision-engineered parts manufactured through advanced forming and stamping processes. These components are produced by applying controlled pressure to Brass sheet metal blanks using specialized dies and presses, resulting in complex geometries with exceptional dimensional accuracy and surface finish.

Our Brass pressed components are widely utilized in electrical connections, automotive assemblies, plumbing fixtures, and decorative applications where corrosion resistance, electrical conductivity, and aesthetic appeal are paramount. The manufacturing process involves multiple stages including:

• Material preparation

• Die design

• Pressing operations

• Secondary machining if required

• Comprehensive quality inspection

Our facility is equipped with hydraulic presses ranging from 50 tons to 500 tons capacity, enabling us to manufacture components from miniature electronic connectors to large architectural hardware pieces. Each Brass pressed component undergoes rigorous dimensional verification using coordinate measuring machines and optical inspection systems to ensure compliance with customer specifications and international quality standards.

Brass Pressed Parts Manufacturing Excellence

Brass pressed parts encompass a diverse range of components manufactured through precision stamping, forming, and pressing operations on Brass alloy materials. Our manufacturing capabilities include:

Progressive die stamping – Multi-stage operations with automatic part handling

Transfer die operations – Complex forming with precise positioning

Compound die forming – Multiple operations in single press stroke

Single-stage pressing – High-volume production and prototype development

The selection of appropriate Brass grades depends on the specific application requirements, with considerations for mechanical properties, corrosion resistance, machinability, and cost-effectiveness. Our engineering team works closely with customers to optimize part designs for manufacturability, ensuring efficient material utilization and minimizing production costs while maintaining quality standards.

The Brass pressed parts manufactured in our facility serve various industries including telecommunications equipment, marine hardware, musical instruments, and precision machinery components. Quality assurance protocols include incoming material inspection, in-process quality checks, statistical process control, and final dimensional verification using advanced metrology equipment.

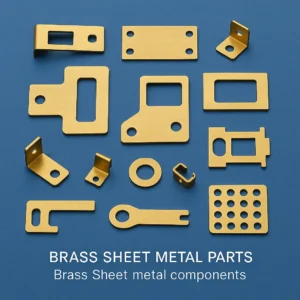

Brass Sheet Metal Parts – Precision Forming Solutions

Brass sheet metal parts are manufactured using cutting-edge sheet metal fabrication techniques combined with traditional Brass working expertise. Our capabilities include:

Laser cutting – Intricate geometries with minimal heat-affected zones

CNC punching – High-speed hole patterns and complex cutouts

Bending and forming – Consistent angles and dimensional accuracy

Welding and assembly – Complete fabricated assemblies

The manufacturing process begins with material selection from certified Brass sheet suppliers, followed by nesting optimization using CAD/CAM software to maximize material utilization and minimize waste. Advanced laser cutting systems enable us to achieve intricate geometries with minimal heat-affected zones, while CNC press brakes ensure consistent bend angles and dimensional accuracy across production batches.

Brass sheet metal parts find applications in HVAC systems, electrical enclosures, decorative panels, heat exchangers, and architectural elements where the natural antimicrobial properties of Brass provide additional functional benefits. Our quality management system ensures traceability of materials and processes, with comprehensive documentation supporting customer certification requirements and regulatory compliance.

Brass Sheet Metal Components – Advanced Manufacturing Techniques

Brass sheet metal components represent sophisticated engineered products requiring precise manufacturing techniques and extensive quality control measures. Our production capabilities encompass:

Hydroforming – Complex 3D shapes with uniform wall thickness

Spin forming – Seamless cylindrical and conical parts

Roll forming – Long continuous profiles and sections

Incremental sheet forming – Prototype and low-volume production

The component design phase involves finite element analysis to optimize material flow, predict forming forces, and minimize defects such as wrinkling, tearing, or springback. Our manufacturing facility utilizes servo-electric presses with programmable motion control systems, enabling precise force and position control throughout the forming cycle.

Brass sheet metal components manufactured in our facility include electronic housings, fluid control valves, heat sink assemblies, and precision brackets for aerospace and defense applications. Surface treatments such as passivation, plating, and coating are available to enhance corrosion resistance and aesthetic appearance according to customer specifications and industry standards.

Brass Deep Drawn Parts – Specialized Manufacturing Expertise

Brass deep drawn parts are produced through a specialized forming process that transforms flat Brass blanks into three-dimensional hollow components with height-to-diameter ratios exceeding traditional stamping limitations. Our deep drawing capabilities include:

Single-stage operations – Simple geometries with minimal complexity

Multi-stage operations – Complex shapes requiring multiple draws

Progressive deep drawing – High-volume automated production

Reverse drawing – Specialized geometries and wall thickness control

The deep drawing process requires careful consideration of material properties, lubrication systems, die design, and process parameters to prevent defects such as earing, thinning, or fracture. Our facility is equipped with double-action hydraulic presses specifically designed for deep drawing operations, with blank holder forces precisely controlled to manage material flow during the forming process.

Brass deep drawn parts find extensive applications in ammunition components, pressure vessels, decorative containers, electrical housings, and precision instrumentation where seamless construction and dimensional stability are critical requirements. Quality verification includes wall thickness measurements, dimensional inspection, and pressure testing where applicable.

## Material Grades and Specifications

| Standard | Grade/Alloy | Composition (%) | Tensile Strength (MPa) | Applications |

|---|---|---|---|---|

| ASTM B36 | C26000 (Cartridge Brass) | Cu 70, Zn 30 | 300-380 | Cartridge cases, lamp fixtures, fasteners |

| ASTM B36 | C36000 (Free Cutting Brass) | Cu 61.5, Zn 35.5, Pb 3 | 340-470 | Screw machine products, gears, pinions |

| BS 2870 | CZ108 (Alpha Brass) | Cu 70, Zn 30 | 280-350 | Deep drawn components, decorative items |

| DIN 17660 | CuZn37 (Ms63) | Cu 63, Zn 37 | 300-380 | Sheet metal work, pressing applications |

| JIS H3100 | C2600 (Yellow Brass) | Cu 70, Zn 30 | 310-390 | Hardware, decorative components |

| IS 319 | 70/30 Brass | Cu 70, Zn 30 | 285-370 | General engineering applications |

| GB/T 4423 | H70 (Chinese Standard) | Cu 68.5-71.5, Zn Balance | 295-385 | Electronic components, connectors |

## Manufacturing Processes and Machinery

Our comprehensive manufacturing capabilities utilize state-of-the-art equipment and proven processes to deliver superior Brass pressed components:

Primary Manufacturing Processes

Progressive Die Stamping Operations:

Servo-electric presses with programmable motion control systems ensure precise force application and repeatability across production batches. These advanced systems provide consistent quality and dimensional accuracy for high-volume production runs.

Transfer Die Forming:

Enables complex multi-stage operations with automatic part handling and positioning between stations. This process is ideal for components requiring multiple forming operations while maintaining tight tolerances throughout the production sequence.

Compound Die Operations:

Combine cutting, forming, and piercing operations in a single press stroke, maximizing production efficiency and dimensional consistency. This approach reduces handling time and minimizes tolerance stack-up for critical components.

Deep Drawing Processes:

Specialized hydraulic presses with independent blank holder control systems achieve optimal material flow and wall thickness distribution for hollow components with complex geometries.

Secondary Operations

CNC Machining Centers:

Provide precision secondary operations including drilling, tapping, milling, and turning to achieve tight tolerances and complex features not achievable through forming operations alone.

Deburring and Finishing:

Automated systems ensure smooth edges and consistent surface quality requirements across all production batches, meeting stringent customer specifications.

Heat Treatment Facilities:

Enable stress relief, annealing, and hardness modification to optimize mechanical properties for specific applications and performance requirements.

Quality Control Equipment

Coordinate Measuring Machines (CMM):

Touch probe and optical scanning capabilities provide comprehensive dimensional verification with measurement uncertainty traceable to international standards.

Surface Roughness Measurement:

Advanced systems ensure compliance with finish specifications and maintain consistent surface quality across production runs.

Statistical Process Control:

Real-time monitoring systems track critical parameters and maintain process capability indices, ensuring consistent quality delivery.

Sheet cutting, blanking, edge preparation

Precision die alignment, clearance verification

Controlled pressure application, material flow

Dimensional verification, surface quality check

Deburring, surface treatment, packaging

## Typical Parts Produced and Industries Served

Automotive Industry

Brass pressed components for fuel system connectors, brake line fittings, radiator components, electrical terminals, and decorative trim pieces. Our automotive-grade Brass parts meet stringent quality requirements including vibration resistance, corrosion protection, and thermal stability across operating temperature ranges.

Electronics and Telecommunications

Precision Brass pressed parts for RF connectors, cable terminals, shielding components, heat sinks, and electronic housings. These components provide excellent electromagnetic compatibility, thermal conductivity, and dimensional stability required for modern electronic applications.

Plumbing and Fluid Control

Brass pressed components for valve bodies, pipe fittings, compression fittings, water meter components, and flow control devices. The natural antimicrobial properties of Brass make these components ideal for potable water applications and medical device manufacturing.

Marine and Offshore

Corrosion-resistant Brass pressed parts for marine hardware, propeller components, navigation equipment housings, and deck fittings. These components withstand harsh saltwater environments while maintaining structural integrity and aesthetic appearance.

Musical Instruments

Precision Brass pressed components for wind instrument keys, valve assemblies, tuning slides, and decorative elements. The acoustic properties and workability of Brass make it ideal for musical instrument applications requiring precise dimensions and surface finish.

Typical Dimensional Specifications

L ± 0.1mmW ± 0.05mmØ ± 0.02mm

| Parameter | Standard Range | Precision Range | Tolerance Class |

|---|---|---|---|

| Overall Length (mm) | 5 – 500 | 0.5 – 200 | ±0.1 to ±0.5 |

| Width (mm) | 3 – 300 | 0.3 – 150 | ±0.05 to ±0.3 |

| Thickness (mm) | 0.3 – 5.0 | 0.1 – 3.0 | ±0.02 to ±0.1 |

| Hole Diameter (mm) | 1.0 – 50 | 0.5 – 25 | ±0.02 to ±0.1 |

| Surface Roughness (Ra μm) | 0.8 – 3.2 | 0.1 – 0.8 | N6 to N9 |

## International Standards and Certifications

Our manufacturing operations comply with internationally recognized standards ensuring consistent quality and performance across all Brass pressed components:

Quality Management Standards

ISO 9001:2015 Certification:

Ensures systematic quality management throughout all manufacturing processes with documented procedures, continuous improvement initiatives, and customer satisfaction monitoring.

AS9100D Compliance:

Aerospace quality management standard compliance for applications requiring enhanced quality controls, risk management, and complete traceability throughout the supply chain.

IATF 16949 Certification:

Automotive industry quality management system certification emphasizing defect prevention, supply chain management, and continuous improvement methodologies.

Material Standards Compliance

ASTM International Standards:

Complete compliance with ASTM specifications for Brass alloy compositions, mechanical testing methods, and acceptance criteria ensuring consistent material properties and performance characteristics.

British Standards (BS) Compliance:

Adherence to European market requirements and regulatory specifications including BS 2870 for wrought Copper and Copper alloy sheet, strip, and plate materials.

Deutsche Industrie Norm (DIN) Standards:

Compliance with German engineering standards and precision manufacturing requirements including DIN 17660 specifications for Brass alloy compositions and mechanical properties.

Japanese Industrial Standards (JIS) Compliance:

Adherence to Asian market applications and quality expectations including JIS H3100 specifications for Copper and Copper alloy plates, sheets, and strips.

Testing and Inspection Standards

Dimensional Inspection Standards:

Complete compliance with ASME Y14.5 geometric dimensioning and tolerancing principles ensuring accurate interpretation of engineering drawings and specifications.

Material Testing Protocols:

Testing performed according to ASTM E8 for tensile properties verification and ASTM E10 for hardness measurement ensuring consistent mechanical characteristics across production batches.

Corrosion Testing Standards:

Comprehensive testing per ASTM B117 salt spray corrosion resistance and ASTM G48 pitting corrosion standards providing validation of long-term durability performance.

Surface Finish Verification:

Surface finish measurement and verification according to ISO 4287 and ASME B46.1 standards ensuring compliance with customer specifications and industry requirements.

Manufacturing Tolerances and Quality Specifications

| Feature Type | Standard Tolerance | Precision Tolerance | Inspection Method |

|---|---|---|---|

| Linear Dimensions | ±0.1mm | ±0.05mm | CMM, Calipers |

| Hole Positions | ±0.08mm | ±0.03mm | CMM, Optical Comparator |

| Flatness | 0.1mm per 100mm | 0.05mm per 100mm | Surface Plate, Dial Indicator |

| Perpendicularity | 0.1mm per 25mm | 0.05mm per 25mm | CMM, Angle Blocks |

| Surface Roughness | Ra 1.6μm | Ra 0.8μm | Surface Roughness Tester |

| Concentricity | 0.08mm TIR | 0.03mm TIR | CMM, V-Blocks |

Surface Finishes and Treatments Available

Our comprehensive surface finishing capabilities enhance the performance, appearance, and durability of Brass pressed components:

Standard Surface Finishes

Mill Finish:

Provides the natural Brass appearance with standard surface roughness from the forming process. This finish maintains the inherent beauty and color of Brass while offering cost-effective production for general applications.

Polished Finish:

Achieves mirror-like surface quality through progressive abrasive operations using specialized polishing compounds and techniques. Ideal for decorative applications requiring high aesthetic appeal and reflective properties.

Brushed Finish:

Creates uniform directional texture for decorative applications and improved grip surfaces. This finish provides consistent appearance while offering enhanced tactile properties for functional components.

Tumbled Finish:

Removes sharp edges and provides uniform matte appearance through mass finishing processes. Excellent for components requiring smooth edges and consistent surface texture across complex geometries.

Protective Coatings

Clear Lacquer Coating:

Prevents tarnishing and oxidation while maintaining natural Brass appearance. This transparent protective layer extends component life while preserving the aesthetic characteristics of Brass materials.

Nickel Plating:

Provides enhanced corrosion resistance and wear protection for demanding applications. Available in bright nickel, satin nickel, and black nickel finishes to meet specific performance and aesthetic requirements.

Chrome Plating:

Delivers superior hardness and corrosion resistance for high-wear components. Hard chrome plating provides exceptional durability while decorative chrome offers brilliant reflective finish.

Zinc Plating with Chromate Conversion:

Offers cost-effective corrosion protection for industrial applications. Available in clear, yellow, and black chromate finishes providing varying levels of corrosion resistance and appearance options.

Specialized Treatments

Passivation Processes:

Enhance natural corrosion resistance through controlled surface oxidation. This chemical treatment creates a protective oxide layer that improves long-term durability in corrosive environments.

Anodizing Treatments:

Available for specific alloy compositions requiring enhanced surface properties. Provides improved wear resistance, corrosion protection, and decorative color options for specialized applications.

Chemical Etching:

Creates textured surfaces for improved adhesion of secondary coatings or decorative effects. This process enables custom surface patterns and textures not achievable through mechanical finishing methods.

Electrical & Electronic Components

- Brass electrical terminals – ring, spade, pin, and bullet terminals

- Brass contact strips – for switches and relays

- Brass grounding clips – for electrical connections

- Brass fuse clips – spring-loaded electrical contacts

- Brass connector housings – for electrical assemblies

- Brass heat sinks – for electronic cooling applications

- Brass EMI/RFI shields – electromagnetic interference shielding

- Brass spring contacts – for battery compartments

- Brass lamp holders – electrical socket components

- Brass switch plates – decorative electrical covers

Automotive Parts

- Brass radiator fins – heat dissipation components

- Brass fuel system components – filters, strainers

- Brass brake line fittings – hydraulic connections

- Brass electrical connectors – automotive wiring harnesses

- Brass horn diaphragms – acoustic components

- Brass valve components – automotive engine parts

- Brass heat exchanger plates – cooling system parts

- Brass sensor housings – protective enclosures

- Brass mounting brackets – structural support components

- Brass gaskets and washers – sealing components

Plumbing & HVAC Components

- Brass pipe clips – pipe support systems

- Brass mounting brackets – for fixtures and equipment

- Brass valve discs – flow control components

- Brass strainer screens – filtration components

- Brass heat exchanger plates – thermal transfer components

- Brass manifold components – distribution systems

- Brass thermostat housings – temperature control devices

- Brass vent grilles – air circulation components

- Brass pipe flanges – connection components

- Brass expansion joints – thermal compensation parts

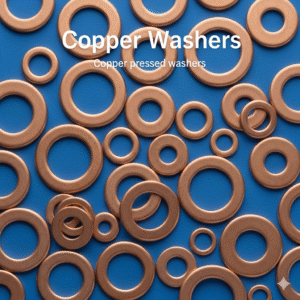

- Brass washers – flat, spring, and lock washers

- Brass clips – retaining and mounting clips

- Brass brackets – L-shaped and custom mounting brackets

- Brass stampings – decorative and functional shapes

- Brass grommets – protective edge components

- Brass eyelets – reinforcement rings

- Brass rivets – solid and hollow joining components

- Brass snap fasteners – quick-release mechanisms

- Brass spring clips – retention devices

- Brass shims – precision spacing components

- Brass instrument bells – trumpet, trombone bell sections

- Brass valve components – piston and rotary valve parts

- Brass mouthpiece blanks – partially formed mouthpieces

- Brass tubing bends – curved sections for wind instruments

- Brass key components – lever arms and springs

- Brass resonator plates – acoustic enhancement components

- Brass slide components – trombone slide parts

- Brass braces – structural support elements

- Brass water key components – moisture drainage parts

- Brass ligature components – reed instrument accessories

- Brass rosettes – decorative circular components

- Brass corner guards – protective edge strips

- Brass name plates – identification plaques

- Brass door hardware – hinges, handles, escutcheons

- Brass furniture hardware – drawer pulls, cabinet components

- Brass trim pieces – decorative edging components

- Brass medallions – ornamental circular pieces

- Brass bezels – decorative rings and frames

- Brass kick plates – door protection strips

- Brass corner brackets – architectural support elements

- Brass heat sinks – thermal management components

- Brass filter screens – industrial filtration

- Brass spring components – various spring configurations

- Brass bearing retainers – mechanical bearing components

- Brass diaphragms – pressure-sensitive membranes

- Brass valve seats – sealing surfaces

- Brass pump components – impeller parts and housings

- Brass instrument cases – protective enclosures

- Brass machinery guards – safety shielding

- Brass conveyor components – material handling parts

Precision Components

- Brass watch components – gears, springs, plates

- Brass optical components – lens mounts, frames

- Brass medical device parts – surgical instrument components

- Brass measuring instrument parts – gauge components

- Brass scientific instrument components – laboratory equipment parts

- Brass precision shims – ultra-thin spacing components

- Brass micro springs – miniature spring elements

- Brass contact points – precision electrical contacts

- Brass calibration weights – measurement standards

- Brass lens holders – optical assembly components

- Brass marine hardware – deck fittings, cleats

- Brass weather stripping – sealing components

- Brass anchor components – marine anchoring hardware

- Brass porthole frames – marine window components

- Brass compass housings – navigation instrument cases

- Brass outdoor lighting components – weatherproof fixtures

- Brass flagpole hardware – mounting and rigging components

- Brass marine electrical components – corrosion-resistant contacts

- Brass deck plates – marine flooring components

- Brass rigging hardware – sailing equipment components

These Brass pressed parts are manufactured using various techniques including:

- Deep drawing for complex shapes

- Progressive stamping for high-volume production

- Single-operation stamping for simple shapes

- Forming and bending for angular components

- Coining for precision dimensional control

- Blanking and piercing for cutout operations

Production Timeline: 4-6 Weeks Standard Delivery

Our streamlined manufacturing process ensures reliable delivery schedules while maintaining the highest quality standards:

Week 1-2: Design and Planning Phase

Customer Specification Review: Comprehensive analysis of technical requirements and application specifications

Design for Manufacturability Analysis: Engineering evaluation to optimize producibility and cost-effectiveness

Tooling Design and Fabrication: Precision die design and manufacturing using advanced CAD/CAM systems

Material Procurement: Sourcing of certified Brass materials with full traceability documentation

Production Planning: Scheduling optimization and resource allocation

Week 3-4: Manufacturing Phase

Setup and First Article Inspection: Complete tooling verification and initial part validation

Production Run Execution: Full-scale manufacturing with continuous in-process quality controls

Secondary Operations: Precision machining, drilling, tapping, and specialized features

Surface Finishing: Application of protective coatings, plating, or specialized treatments

Week 5-6: Quality Assurance and Delivery

Final Dimensional Inspection: Comprehensive measurement and testing using CMM and optical systems

Custom Packaging: Protective packaging with customer-specific labeling and identification

Shipping Coordination: International logistics coordination with tracking and documentation

Delivery Confirmation: Customer notification and ongoing technical support

Expedited Production Options

Rush Orders: 2-3 week delivery schedules available for standard components with existing tooling

Express Tooling: Accelerated die manufacturing services for new component development

Inventory Management: Stock maintenance programs for high-volume repeat orders ensuring immediate availability

Performance Metrics Dashboard

Comprehensive Technical Q&A Session

Q1: What are the key advantages of Brass pressed components over other manufacturing methods?

A: Brass pressed components offer superior dimensional consistency, excellent surface finish quality, high production efficiency for volume manufacturing, minimal material waste, and the ability to create complex geometries in single operations. The pressing process also work-hardens the material, improving mechanical properties compared to machined components.

Q2: How do you ensure consistent quality across different production batches?

A: We implement statistical process control with real-time monitoring of critical parameters, maintain calibrated measuring equipment with traceability to international standards, conduct first article inspections for each production run, and utilize automated inspection systems to eliminate human error in dimensional verification.

Q3: What is the minimum order quantity for custom Brass pressed parts?

A: Minimum order quantities depend on component complexity and tooling requirements. For standard components with existing tooling, minimum orders start at 500 pieces. New component development typically requires minimum quantities of 1,000-5,000 pieces to justify tooling costs and setup expenses.

Q4: Can you provide material certifications and test reports with shipments?

A: Yes, we provide comprehensive material certifications including chemical composition analysis, mechanical property test reports, dimensional inspection certificates, and surface finish verification. All documentation is traceable to specific production batches and meets international certification requirements.

Q5: What secondary operations can be performed on Brass pressed components?

A: Our secondary operation capabilities include CNC machining for precision features, threading and tapping operations, assembly services with fasteners or other components, heat treatment for property modification, surface finishing including plating and coating, and quality testing per customer specifications.

Q6: How do you handle design modifications and engineering changes?

A: Our engineering team collaborates with customers throughout the design process using CAD modeling and simulation tools. Design changes are evaluated for manufacturability impact, cost implications, and timeline adjustments. We maintain revision control systems to track all design iterations and customer approvals.

Q7: What quality inspection equipment do you use for dimensional verification?

A: Our metrology laboratory includes coordinate measuring machines with 0.001mm resolution, optical comparators for profile verification, surface roughness measurement systems, hardness testers for material property validation, and automated inspection systems for high-volume production monitoring.

Q8: Can you accommodate special packaging and labeling requirements?

A: Absolutely. We offer customized packaging solutions including customer-branded labels, anti-tarnish packaging for long-term storage, ESD-protective packaging for electronic components, and specialized shipping containers for international logistics requirements.

Q9: What is your approach to continuous improvement and cost reduction?

A: We implement lean manufacturing principles, regularly review process efficiency metrics, invest in advanced manufacturing technology, provide ongoing employee training programs, and collaborate with customers on value engineering initiatives to optimize designs for cost-effective production.

Q10: How do you ensure supply chain reliability for critical components?

A: Our supply chain management includes qualified vendor networks with backup suppliers, inventory management systems maintaining strategic stock levels, long-term contracts with raw material suppliers, and contingency planning for supply disruptions to ensure uninterrupted customer deliveries.

Q11: What environmental and sustainability practices do you follow?

A: Our environmental management system includes recycling programs for Brass scrap and waste materials, energy-efficient manufacturing equipment, water treatment and recycling systems, waste minimization initiatives, and compliance with environmental regulations including RoHS and REACH requirements.

Q12: Can you provide prototyping services for new component development?

A: Yes, our prototyping capabilities include soft tooling for initial design verification, 3D printing for concept validation, prototype Brass pressing with temporary tooling, and rapid turnaround testing services to accelerate product development cycles.

Unique Selling Propositions – Why Choose Our Brass Pressed Components

Three Decades of Global Manufacturing Excellence

Our extensive experience spanning over thirty years in Brass component manufacturing has established us as industry leaders with deep technical expertise and proven track record serving customers worldwide. This experience translates into superior process knowledge, efficient problem-solving capabilities, and innovative solutions for complex manufacturing challenges.

Unmatched Customization Capabilities

We excel in adapting our manufacturing processes to meet unique customer requirements including:

• Custom alloy specifications tailored to specific performance requirements

• Specialized surface treatments for enhanced durability and appearance

• Unique geometric configurations for complex application demands

• Application-specific performance characteristics optimized for end-use requirements

Our flexible production systems enable efficient handling of both standard and highly customized component orders.

Advanced Communication and Customer Support

Our multilingual technical support team provides excellent communication throughout the entire project lifecycle, from initial inquiry to final delivery and beyond. We utilize modern communication technologies including:

• Video conferencing for design reviews and technical discussions

• Real-time production updates with progress tracking and milestone reporting

• Collaborative online platforms for seamless document sharing and project management

• 24/7 customer support ensuring immediate response to urgent requirements

Flexible Production Scheduling

Understanding the dynamic nature of global supply chains, we offer:

• Flexible production scheduling to accommodate changing customer requirements

• Expedited delivery options for urgent orders with 2-3 week turnaround capability

• Inventory management programs to maintain strategic stock levels for regular customers

• Just-in-time delivery services coordinated with customer production schedules

Comprehensive Global Logistics Network

Our established relationships with international partners enable efficient delivery worldwide:

• International freight forwarders with expertise in industrial component shipping

• Customs clearance specialists ensuring smooth border transitions and documentation

• Logistics partners providing door-to-door delivery services with complete tracking

• Full shipment tracking with real-time updates and delivery confirmation services

Value-Added Engineering Services

Beyond manufacturing, we provide comprehensive engineering support:

• Design optimization consulting to improve manufacturability and reduce costs

• Material selection guidance based on application requirements and performance criteria

• Cost reduction analysis identifying opportunities for process improvements

• Quality improvement recommendations enhancing product performance and reliability

• Technical training services supporting customer teams and long-term partnerships

## Material Properties and Technical Data

| Property | C26000 (70/30) | C36000 (Free Cutting) | CZ108 (Alpha Brass) | Test Method |

|---|---|---|---|---|

| Density (g/cm³) | 8.53 | 8.50 | 8.53 | ASTM B311 |

| Melting Point (°C) | 900-940 | 885-920 | 900-940 | ASTM E794 |

| Thermal Conductivity (W/m·K) | 120 | 115 | 120 | ASTM C177 |

| Electrical Conductivity (%IACS) | 27 | 26 | 27 | ASTM B193 |

| Modulus of Elasticity (GPa) | 103 | 97 | 103 | ASTM E111 |

| Coefficient of Expansion (×10⁻⁶/°C) | 20.3 | 20.8 | 20.3 | ASTM E228 |

| Corrosion Resistance | Excellent | Good | Excellent | ASTM B117 |

## Packaging and Shipping Excellence

Protective Packaging Solutions

Our packaging department utilizes anti-tarnish papers and films to prevent oxidation during storage and transportation. Components are carefully segregated using:

• Foam inserts for cushioning and shock absorption

• Plastic dividers preventing component-to-component contact

• Protective sleeves maintaining surface finish integrity

• Moisture control systems including desiccant packets for optimal storage conditions

Custom Labeling and Identification

Customer-specific labeling requirements are accommodated including:

• Company logos and branding integration per customer specifications

• Part numbers and revision levels for accurate inventory management

• Manufacturing dates and batch codes ensuring complete traceability

• Quality certifications and compliance marks meeting regulatory requirements

Barcode and QR code systems enable efficient inventory management and traceability throughout the customer’s supply chain. Multi-language labeling supports international distribution requirements.

International Shipping Expertise

Our logistics team coordinates worldwide shipping through established networks:

• Freight forwarders with expertise in industrial component transportation

• Customs clearance specialists ensuring regulatory compliance and documentation accuracy

• Documentation services including commercial invoices, packing lists, certificates of origin, and material certifications

Real-time shipment tracking and delivery confirmation ensure customer visibility throughout transportation with proactive communication regarding any delays or issues.

Sustainable Packaging Initiatives

Environmental responsibility drives our packaging material selection:

• Recyclable containers reducing environmental impact

• Biodegradable protective materials for eco-conscious customers

• Minimized packaging volumes reducing transportation carbon footprint

• Reusable packaging options available for regular customers seeking sustainable supply chain solutions

“We have been sourcing precision Brass pressed components from this manufacturer for over five years and consistently receive exceptional quality products with outstanding customer service. Their engineering team worked closely with us to optimize our component designs, resulting in 15% cost reduction while improving performance characteristics. The on-time delivery record and responsive communication have made them our preferred supplier for critical automotive applications. Their ability to accommodate our specialized packaging requirements and provide comprehensive quality documentation has streamlined our receiving processes significantly.”

– Robert M. Anderson, Senior Procurement Manager, Detroit

## Glossary of Technical Terms

Manufacturing and Process Terms

Blank Holder Force:

The controlled pressure applied to the sheet metal blank during deep drawing operations to manage material flow and prevent wrinkling or tearing defects. This critical parameter ensures optimal forming conditions and dimensional accuracy.

Deep Drawing Ratio:

The relationship between the initial blank diameter and the final drawn part diameter, indicating the severity of the forming operation and material flow requirements. Higher ratios require more sophisticated tooling and process control.

Die Clearance:

The dimensional gap between punch and die components in stamping operations, critical for achieving proper cutting action and edge quality in formed parts. Optimal clearance depends on material thickness and properties.

Forming Limit Diagram:

Graphical representation of material forming capabilities showing safe forming zones and failure boundaries for sheet metal operations. Essential for preventing defects during complex forming processes.

Press Tonnage Calculation:

Engineering determination of required forming force based on material properties, part geometry, and tooling design parameters. Critical for selecting appropriate manufacturing equipment.

Material and Quality Terms

Brass Alloy Classification:

Systematic designation of Brass compositions based on Copper and Zinc content ratios, with additional alloying elements for specific property enhancement. Classifications follow international standards for consistency.

Material Flow Analysis:

Engineering study of metal movement during forming operations to optimize die design and prevent defects such as thinning, tearing, or dimensional distortion. Uses advanced simulation software for accuracy.

Work Hardening Effect:

Increase in material strength and hardness resulting from plastic deformation during forming operations, improving mechanical properties of formed components compared to annealed materials.

Measurement and Quality Control Terms

Dimensional Tolerance Stack-up:

The cumulative effect of individual feature tolerances on assembly fit and function, requiring careful analysis for multi-component assemblies. Critical for ensuring proper functionality.

Geometric Dimensioning and Tolerancing (GD&T):

International standard system for defining and communicating engineering tolerances and geometric relationships on technical drawings. Ensures consistent interpretation across global supply chains.

Statistical Process Control (SPC):

Quality management methodology using statistical analysis of process data to monitor manufacturing stability and predict quality trends. Enables proactive quality management and continuous improvement.

Surface Roughness Measurement:

Quantitative assessment of surface texture using standardized parameters including Ra (average roughness), Rz (maximum height), and Rq (root mean square roughness). Critical for functional and aesthetic requirements.

Related parts -Brass pressed parts manufacturer India, Brass pressed components exporter, precision Brass stamping, Brass sheet metal fabrication, Brass deep drawn parts, custom Brass pressing, Brass component manufacturing

High precision Brass pressed electronic components, automotive Brass pressed parts supplier, marine grade Brass pressed hardware, medical device Brass pressed components, aerospace Brass pressed parts manufacturer

**Industry-specific Terms:** Brass electrical connectors, Brass plumbing fittings, Brass automotive components, Brass marine hardware, Brass musical instrument parts, Brass decorative elements

**Technical parts** Brass progressive die stamping, Brass transfer die forming, Brass hydroforming services, Brass CNC machining, Brass surface finishing, Brass quality testing ,Brass parts manufacturer India, Brass components exporter Gujarat, Indian Brass pressing company, Asia Brass manufacturing, global Brass supplier \ Brass forming processes, Brass stamping operations, Brass sheet metal working, Brass precision machining, Brass assembly services, Brass prototype development

Get Your Custom Brass Pressed Components Quote Today

Ready to experience world-class Brass pressed parts manufacturing with three decades of proven expertise? Our technical team is standing by to discuss your specific requirements and provide comprehensive solutions for your precision component needs.

📧 Email us your technical drawings and specifications for a detailed quotation

📞 Call us at +91-22 43449300 for immediate technical consultation

💬 WhatsApp us for quick communication and updates

📋 Request our comprehensive product catalog and capability brochure

Experience the difference that precision manufacturing, superior quality control, and exceptional customer service can make for your Brass component requirements. Contact us today and discover why leading companies worldwide trust us for their critical Brass pressed parts and components.

Professional engineering support • Global shipping capabilities • ISO certified quality systems • Three decades of manufacturing excellence