Brass Screw Machine Parts & Brass Screw Machine Products – Precision Manufacturing Solutions

Overview of Brass Screw Machine Parts and Products

Price: US$ 10.20/kilogram

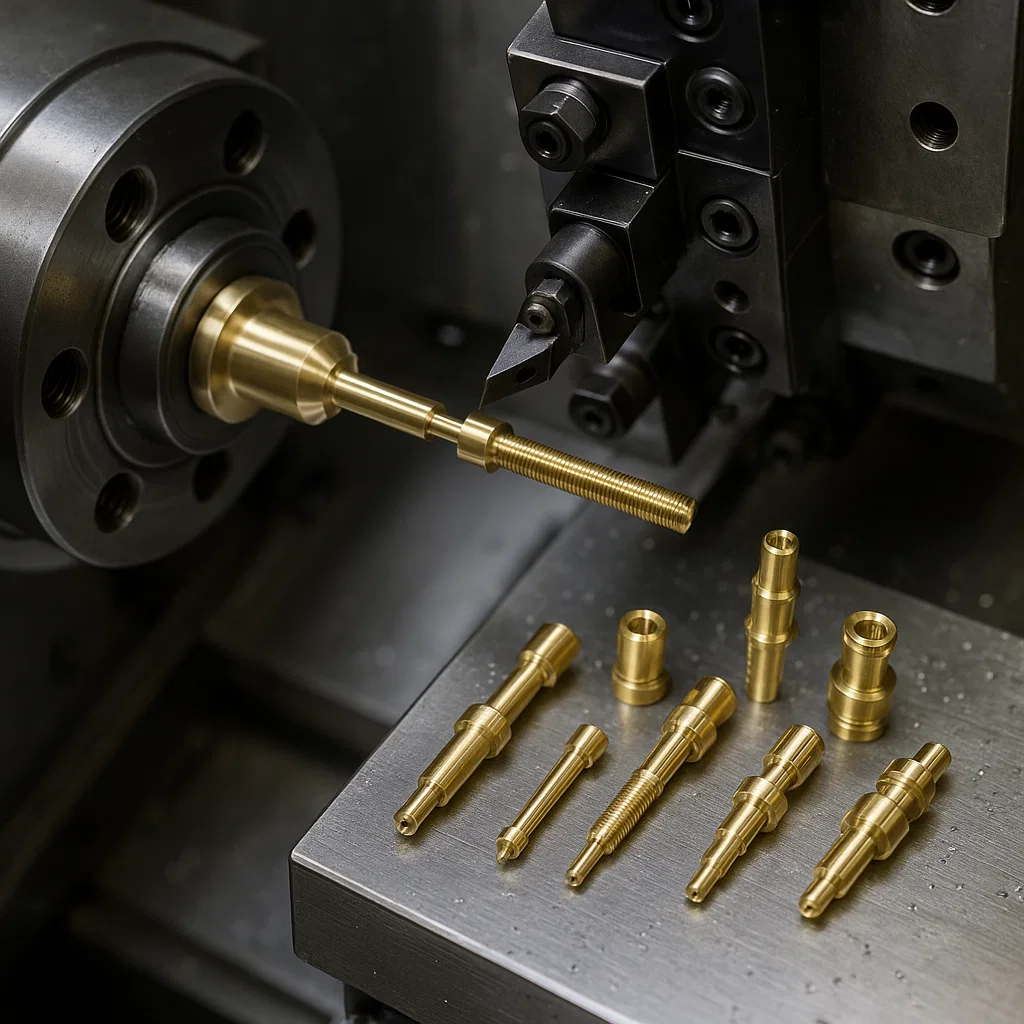

We are one of the leading manufacturers and exporters of Brass Screw Machine Parts and Products from India. We have been supplying precision-engineered Brass components to the world market for many decades. Our state-of-the-art manufacturing facility specializes in producing high-quality Brass Screw Machine Parts, Precision Brass Screw Machine Components, and CNC machined Brass components that meet the most stringent international standards. With over three decades of global exposure and experience, we have established ourselves as a trusted partner for industries requiring superior quality Brass machined parts. Our comprehensive range includes everything from simple turned components to complex multi-operation parts, all manufactured with exceptional precision and consistency. We utilize advanced Swiss screw machines, CNC turning centers, and precision machining equipment to deliver components that exceed customer expectations in terms of quality, dimensional accuracy, and surface finish.

Brass Screw Machine Parts represent a crucial category of precision-manufactured components that serve diverse industrial applications worldwide. These parts are produced using specialized screw machines that can achieve exceptional dimensional accuracy, superior surface finishes, and consistent quality across high-volume production runs. The inherent properties of Brass, including excellent machinability, corrosion resistance, and electrical conductivity, make it an ideal material choice for screw machine operations. Our manufacturing capabilities encompass both traditional cam-operated screw machines and modern CNC Swiss-type machines, allowing us to optimize production methods based on part complexity, volume requirements, and dimensional tolerances.

Precision Brass Screw Machine Components are engineered to meet the exacting requirements of industries such as automotive, electronics, plumbing, hardware, and instrumentation. These components undergo rigorous quality control processes to ensure conformance to specified tolerances, typically ranging from ±0.001″ to ±0.005″ depending on the application requirements. Our precision manufacturing approach incorporates advanced inspection equipment, statistical process control, and comprehensive documentation to guarantee consistent quality and traceability throughout the production process.

Swiss Screw Machine Parts in Brass leverage the unique capabilities of Swiss-type automatic lathes to produce complex, high-precision components with exceptional surface finishes. These machines excel at manufacturing long, slender parts with multiple features, including turned surfaces, cross-holes, flats, and threaded sections, all completed in a single setup. The Swiss machining process provides superior dimensional control and eliminates the need for secondary operations, resulting in cost-effective production of intricate Brass components.

CNC Machined Brass Screw Machine Parts combine the precision of computer numerical control technology with the excellent machining characteristics of Brass alloys. Our CNC machining capabilities include multi-axis turning, milling, drilling, and threading operations, enabling us to produce complex geometries and maintain tight tolerances. The programmable nature of CNC equipment allows for rapid setup changes and efficient production of both prototype quantities and high-volume orders.

CDA 360 Brass Screw Machining utilizes one of the most popular free-machining Brass alloys, known for its exceptional machinability and excellent surface finish characteristics. CDA 360 (C36000) contains approximately 61.5% Copper and 35.5% Zinc with small amounts of Lead, making it ideal for high-speed machining operations. This alloy produces short, easily manageable chips and requires minimal cutting forces, resulting in extended tool life and superior surface finishes.

Lead Free Brass Screw Machine Parts address the growing demand for environmentally compliant components in potable water applications and consumer products. These parts are manufactured using Lead-free Brass alloys such as C46400 (Naval Brass) or C89833 (Silicon Brass), which maintain excellent machinability while meeting strict environmental regulations. Our Lead-free Brass components are certified to comply with NSF/ANSI 61 and 372 standards for drinking water system components.

Precision Brass Machining encompasses our comprehensive manufacturing capabilities, including turning, milling, drilling, threading, and finishing operations performed to exacting specifications. Our precision machining processes are supported by advanced quality control systems, including coordinate measuring machines (CMM), optical comparators, and statistical process control software that ensures consistent quality and dimensional accuracy across all production runs.

Material Grades and International Standards

Our Brass Screw Machine Parts are manufactured using a comprehensive range of Brass alloys, each selected for specific application requirements and performance characteristics. The following table presents the primary material grades we utilize:

| Material Grade | International Standards | Composition | Key Properties | Applications |

|---|---|---|---|---|

| CDA 360 (C36000) | ASTM B16, BS 2874 CZ121, DIN 17660 Ms58, JIS H3250 C3604 | Cu 61.5%, Zn 35.5%, Pb 3.0% | Excellent machinability, good strength | General purpose screw machine products |

| CDA 361 (C36100) | ASTM B16, ISO CuZn39Pb3 | Cu 60.0%, Zn 37.0%, Pb 3.0% | High-speed machining, good surface finish | Precision components, fasteners |

| CDA 464 (C46400) | ASTM B21, BS 2874 CZ112, DIN 17660 Ms63 | Cu 60.0%, Zn 39.25%, Sn 0.75% | Corrosion resistant, Lead-free | Marine applications, plumbing |

| CDA 377 (C37700) | ASTM B16, JIS H3250 C3771 | Cu 58.5%, Zn 39.0%, Pb 2.5% | Good machinability, moderate strength | Hardware, electrical components |

| CDA 385 (C38500) | ASTM B124, BS 2874 CZ114, DIN 17660 Ms58 | Cu 57.0%, Zn 40.0%, Pb 3.0% | Architectural Bronze, good corrosion resistance | Decorative hardware, fittings |

| C89833 | ASTM B584, NSF/ANSI 61 & 372 | Cu 87.5%, Si 3.0%, Zn 9.5% | Lead-free, good machinability | Potable water applications |

| CDA 260 (C26000) | ASTM B36, BS 2874 CZ106, DIN 17660 Ms70 | Cu 70.0%, Zn 30.0% | High ductility, good cold working | Springs, electrical contacts |

| CDA 270 (C27000) | ASTM B36, JIS H3100 C2700 | Cu 65.0%, Zn 35.0% | Good strength, excellent forming | Complex stampings, deep drawn parts |

Indian Standards (IS) Specifications

Our products conform to relevant Indian Standards including:

- IS 6912: Specification for Brass Rods and Sections

- IS 1545: Specification for Brass Sheets and Strips

- IS 319: Specification for Brass Castings

- IS 6373: Free Cutting Brass Rods for General Engineering Purposes

European Standards Compliance

We maintain compliance with European standards including:

- EN 12163: Copper and Copper Alloy Rods for General Purposes

- EN 12164: Copper and Copper Alloy Rods for Free Machining Purposes

- EN 1982: Copper and Copper Alloy Ingots and Castings

Manufacturing Processes and Machinery

Our comprehensive manufacturing capabilities encompass multiple precision machining processes designed to produce high-quality Brass Screw Machine Parts with exceptional consistency and accuracy. The manufacturing process begins with careful material selection and inspection, followed by precision machining operations using state-of-the-art equipment.

Primary Manufacturing Processes:

Automatic Screw Machine Operations utilize high-production cam-operated machines capable of producing simple to moderately complex parts at high speeds. These machines excel at producing cylindrical parts with various turned features, cross-holes, and cut-off operations. Our screw machines can handle bar stock diameters from 1/16″ to 2-5/8″, with typical production rates ranging from 100 to 2000 pieces per hour depending on part complexity.

Swiss-Type Automatic Lathe Manufacturing employs precision Swiss machines that provide superior dimensional control for complex, high-precision components. These machines feature guide bushings that support the workpiece near the cutting tool, enabling the production of long, slender parts with exceptional straightness and surface finish. Our Swiss machines can handle bar stock from 1/32″ to 1-1/4″ diameter with length-to-diameter ratios exceeding 20:1.

CNC Turning and Multi-Axis Machining operations utilize computer-controlled equipment to produce complex geometries and maintain tight tolerances. Our CNC capabilities include live tooling, sub-spindle operations, and Y-axis interpolation, enabling complete part production in a single setup. This approach minimizes handling, reduces cycle times, and ensures superior dimensional accuracy.

Machinery and Equipment

| Equipment Type | Specifications | Capabilities | Applications |

|---|---|---|---|

| Brown & Sharpe Screw Machines | #00 to #6 sizes | Bar stock 1/16″ to 2-5/8″ | High-volume simple parts |

| Citizen Swiss Machines | L12, L20, L32 models | 3mm to 32mm diameter | Precision complex components |

| Okuma CNC Lathes | Multi-axis with live tooling | Up to 12″ diameter | Large complex parts |

| Star Swiss Machines | SR-20, SR-32 models | Sub-spindle operations | Complete machining solutions |

| Hardinge Super Precision | DSM-59, HC series | Ultra-precision turning | Critical tolerance parts |

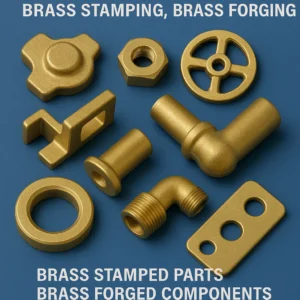

Typical Brass Screw Machine Parts and Industry Applications

The versatility of Brass Screw Machine Parts makes them essential components across numerous industries. Our manufacturing capabilities enable us to produce a comprehensive range of parts that serve diverse applications, from simple fasteners to complex precision instruments.

Automotive Industry Applications

The automotive sector represents one of the largest markets for Brass Screw Machine Parts, where these components serve critical functions in various systems. Brass Fuel System Components including fuel injector bodies, carburetor jets, and fuel line fittings benefit from Brass’s excellent machinability and corrosion resistance. Electrical System Parts such as terminal blocks, connector pins, and switch contacts utilize Brass’s superior electrical conductivity and ease of manufacturing. Cooling System Components including thermostat housings, radiator fittings, and temperature sensor bodies take advantage of Brass’s thermal conductivity and corrosion resistance properties.

Typical Automotive Parts:

- Fuel injector nozzles and bodies with precise internal passages

- Carburetor main jets with critical flow characteristics

- Electrical terminal strips with multiple contact points

- Brake system fittings requiring high pressure capabilities

- Air conditioning system components with refrigerant compatibility

- Engine sensor housings with threaded connections

- Transmission cooler fittings with hydraulic sealing requirements

Electronics and Electrical Industry

The electronics industry relies heavily on Precision Brass Screw Machine Components for applications requiring excellent electrical conductivity, EMI shielding, and precise dimensional control. Connector Components including pins, sockets, and housing parts must maintain consistent electrical properties while providing reliable mechanical connections. Switch Components such as contact blades, actuator mechanisms, and housing elements require precise manufacturing to ensure proper operation and longevity.

Electronics Applications Include:

- RF connector components with controlled impedance characteristics

- Printed circuit board standoffs and spacers with precise heights

- Potentiometer shafts and contact assemblies requiring smooth operation

- Relay components including contact springs and armature parts

- Transformer bushings and lead-in conductors for high-voltage applications

- Semiconductor package leads and heat sink mounting hardware

Plumbing and Hardware Industry

Brass Screw Machine Parts serve essential functions in plumbing and hardware applications where corrosion resistance, strength, and machinability are paramount. Plumbing Fittings including valve stems, packing nuts, and adapter fittings must withstand water pressure and provide leak-proof connections. Hardware Components such as lock cylinders, hinge pins, and decorative elements require precise manufacturing and attractive surface finishes.

Plumbing and Hardware Applications:

- Faucet cartridge components with precise sealing surfaces

- Valve stem assemblies requiring smooth operation under load

- Pipe fitting adapters with various thread configurations

- Lock mechanism components with critical tolerances

- Cabinet hardware elements requiring decorative finishes

- Sprinkler system components for fire protection applications

Instrumentation and Measurement Industry

The instrumentation sector demands Swiss Screw Machine Parts in Brass that provide exceptional dimensional accuracy and surface finish. Measurement Device Components including scale elements, pointer assemblies, and adjustment mechanisms require precise manufacturing to ensure accurate readings. Control System Parts such as valve components, regulator elements, and sensing device housings must maintain their dimensional stability under varying operating conditions.

Technical Specifications and Tolerances

Our Brass Screw Machine Parts are manufactured to meet stringent dimensional tolerances and surface finish requirements that exceed industry standards. The following specifications represent our standard capabilities, with tighter tolerances available for critical applications.

Dimensional Tolerance Capabilities

| Feature Type | Standard Tolerance | Precision Tolerance | Ultra-Precision |

|---|---|---|---|

| Turned Diameters | ±0.005″ (±0.127mm) | ±0.002″ (±0.051mm) | ±0.001″ (±0.025mm) |

| Length Dimensions | ±0.010″ (±0.254mm) | ±0.005″ (±0.127mm) | ±0.002″ (±0.051mm) |

| Threaded Features | Class 2A/2B | Class 3A/3B | Special precision threads |

| Cross Holes | ±0.003″ (±0.076mm) | ±0.001″ (±0.025mm) | ±0.0005″ (±0.013mm) |

| Surface Finish | 32-63 µin Ra | 16-32 µin Ra | 8-16 µin Ra |

| Concentricity | 0.005″ TIR | 0.002″ TIR | 0.001″ TIR |

| Perpendicularity | 0.005″ per inch | 0.002″ per inch | 0.001″ per inch |

Material Property Specifications

The mechanical and physical properties of our Brass materials ensure reliable performance across diverse applications:

| Property | CDA 360 | CDA 464 | C89833 | Test Method |

|---|---|---|---|---|

| Tensile Strength | 57,000 psi | 52,000 psi | 65,000 psi | ASTM E8 |

| Yield Strength | 20,000 psi | 25,000 psi | 35,000 psi | ASTM E8 |

| Elongation | 25% | 20% | 15% | ASTM E8 |

| Hardness | 70 HRB | 65 HRB | 80 HRB | ASTM E18 |

| Electrical Conductivity | 26% IACS | 26% IACS | 15% IACS | ASTM B193 |

| Density | 0.307 lb/in³ | 0.305 lb/in³ | 0.295 lb/in³ | ASTM B311 |

Size and Dimensional Capabilities

Our manufacturing equipment enables us to produce Brass Screw Machine Parts across a comprehensive range of sizes and configurations. The following dimensional capabilities represent our standard production ranges:

Bar Stock and Raw Material Sizes

| Machine Type | Minimum Diameter | Maximum Diameter | Maximum Length | Typical Applications |

|---|---|---|---|---|

| Swiss Screw Machines | 0.8mm (0.031″) | 32mm (1.260″) | 300mm (12.0″) | Precision small parts |

| Standard Screw Machines | 3mm (0.118″) | 65mm (2.560″) | 150mm (6.0″) | Medium volume production |

| CNC Turning Centers | 6mm (0.236″) | 300mm (12.0″) | 500mm (20.0″) | Large complex parts |

| Multi-Spindle Machines | 5mm (0.197″) | 50mm (1.968″) | 200mm (8.0″) | High volume simple parts |

Part Feature Capabilities

Threading Capabilities encompass metric threads from M1.0 to M30, unified threads from #0-80 to 1-1/4″-7, and specialized threads including NPT, BSPT, and Acme profiles. Our threading operations maintain Class 2A/2B standard tolerances with Class 3A/3B precision threading available for critical applications.

Cross Hole Operations can produce holes as small as 0.5mm (0.020″) diameter with positional accuracy of ±0.025mm (±0.001″). Multiple cross holes, angled holes, and intersecting passages are achievable using our Swiss-type machines and CNC equipment.

Surface Finish Capabilities range from standard machined finishes of 32-63 µin Ra to precision finishes of 8-16 µin Ra. Secondary finishing operations including polishing, buffing, and specialized coatings are available to meet specific application requirements.

Performance Metrics and Quality Standards

Our Precision Brass Screw Machine Components undergo comprehensive testing and inspection to ensure consistent quality and performance. We maintain detailed statistical process control data and implement continuous improvement methodologies to exceed customer expectations.

Quality Control Metrics

First-Pass Yield Rate: Our manufacturing processes consistently achieve first-pass yield rates exceeding 98%, indicating superior process control and minimal waste. This metric reflects our commitment to quality and efficient production methods.

Dimensional Accuracy Achievement: More than 95% of our parts meet or exceed specified tolerances on the first inspection, with continuous monitoring ensuring sustained performance throughout production runs.

On-Time Delivery Performance: We maintain a 96% on-time delivery rate for standard production orders, with expedited services available for urgent requirements.

Customer Satisfaction Metrics: Regular customer surveys indicate satisfaction ratings of 4.8/5.0 for product quality, 4.7/5.0 for delivery performance, and 4.9/5.0 for technical support and communication.

Turnaround Time and Production Scheduling

Standard Production Turnaround: 4-6 weeks for standard Brass Screw Machine Parts orders, including material procurement, machining operations, quality inspection, and packaging. This timeframe applies to quantities up to 50,000 pieces for most standard configurations.

Expedited Production Services: 2-3 week turnaround available for urgent orders with premium pricing. Rush orders receive priority scheduling and dedicated production resources to meet critical deadlines.

Prototype and Sample Production: 1-2 weeks for initial samples and prototypes, allowing rapid evaluation and approval before full production commitment.

Large Volume Production: 6-8 weeks for orders exceeding 100,000 pieces, with detailed production scheduling and milestone reporting to ensure transparency and communication throughout the manufacturing process.

Comprehensive Q&A Section

Q1: What makes Brass an ideal material for screw machine operations compared to other metals?

A1: Brass offers exceptional machinability characteristics that make it superior to many other materials for screw machine operations. The free-cutting properties of Brass alloys, particularly CDA 360, allow for high cutting speeds with minimal tool wear, resulting in excellent surface finishes and dimensional accuracy. The material’s relatively low cutting forces reduce machine stress and enable the production of thin-walled or delicate features without distortion. Additionally, Brass’s natural lubricity reduces the need for cutting fluids in many applications, and its tendency to form short, easily manageable chips prevents issues with chip evacuation that can occur with other materials.

Q2: How do Swiss screw machines differ from conventional screw machines in producing Brass parts?

A2: Swiss screw machines provide superior precision and capability for complex Brass Screw Machine Parts through their unique guide bushing design and operational characteristics. Unlike conventional screw machines where the bar stock is held only in the collet, Swiss machines support the workpiece with a guide bushing positioned very close to the cutting tools. This arrangement enables the production of parts with high length-to-diameter ratios while maintaining exceptional concentricity and surface finish. Swiss machines also offer sub-spindle capabilities for back-end operations, live tooling for milling and drilling, and the ability to perform multiple operations simultaneously, resulting in complete parts with minimal secondary processing.

Q3: What are the key advantages of Lead-free Brass alloys for drinking water applications?

A3: Lead Free Brass Screw Machine Parts manufactured from alloys such as C46400 or C89833 provide essential benefits for potable water system applications. These materials comply with stringent regulations including NSF/ANSI 61 and 372, California’s AB1953, and the Federal Safe Drinking Water Act amendments. Lead-free Brass maintains excellent corrosion resistance in water environments while eliminating health concerns associated with Lead leaching. The machinability of modern Lead-free alloys approaches that of traditional leaded Brass, enabling cost-effective production of complex components. Additionally, these alloys provide superior mechanical properties in many cases, with higher strength and better fatigue resistance than conventional leaded Brass.

Q4: How do you ensure dimensional accuracy across high-volume production runs?

A4: Our dimensional accuracy is maintained through comprehensive statistical process control (SPC) systems and advanced inspection procedures. We implement real-time monitoring using coordinate measuring machines (CMM), optical comparators, and automated inspection systems that track critical dimensions throughout production. Our operators perform first-piece inspections, in-process checks at predetermined intervals, and final inspections using calibrated measurement equipment traceable to NIST standards. Process parameters including cutting speeds, feeds, and tool wear are continuously monitored and adjusted to maintain optimal conditions. We also maintain detailed process documentation and capability studies that demonstrate our ability to hold specified tolerances consistently.

Q5: What secondary operations and finishes are available for Brass screw machine parts?

A5: We offer extensive secondary operations to enhance the functionality and appearance of Precision Brass Screw Machine Components. Surface finishing options include polishing, buffing, tumbling, and vibratory finishing to achieve specific surface textures and appearances. Coating services encompass electroplating (nickel, chrome, tin), anodizing for enhanced corrosion resistance, and specialty coatings for specific applications. Threading operations include standard metric and unified threads, as well as specialized profiles such as NPT, BSPT, and custom thread forms. Assembly services include press-fitting, welding, brazing, and multi-component assembly with full testing and quality verification.

Q6: How do material certifications and traceability work for your Brass parts?

A6: Complete material traceability begins with certified mill test reports (MTRs) for all raw materials, documenting chemical composition, mechanical properties, and compliance with applicable specifications. Each production lot receives a unique identifier that tracks the material from receipt through final shipment. We maintain detailed records of processing parameters, inspection results, and any secondary operations performed. Customers receive comprehensive documentation including material certifications, dimensional inspection reports, and compliance statements for relevant standards such as RoHS, REACH, or NSF requirements. Our quality management system is ISO 9001 certified, ensuring consistent documentation and traceability procedures.

Q7: What are your capabilities for producing complex geometries and multi-feature parts?

A7: Our CNC Machined Brass Screw Machine Parts capabilities extend to highly complex geometries through advanced multi-axis machining centers and Swiss-type equipment. We can produce parts with multiple diameters, complex profiles, cross holes, flats, keyways, and intricate internal features in single setups. Live tooling capabilities enable milling, drilling, and tapping operations perpendicular to the main axis. Sub-spindle operations allow back-end machining for complete part production without manual handling. Our programming capabilities include 3D modeling, CAM software optimization, and simulation to verify machining strategies before production begins.

Q8: How do you handle special alloy requirements or custom material specifications?

A8: We maintain relationships with specialty material suppliers to source non-standard Brass alloys or custom compositions when required. Our metallurgical expertise enables us to recommend alternative alloys that may provide cost advantages while meeting performance requirements. For custom alloys, we coordinate with certified foundries to produce material to specific compositions and provide complete chemical analysis and mechanical testing. We can also arrange for special heat treatments, stress relieving, or other material conditioning processes to achieve desired properties. Minimum quantities for custom alloys typically start at 1000-2000 pounds, depending on composition complexity.

Q9: What quality control measures ensure consistency in high-volume production?

A9: Our quality control system incorporates multiple checkpoints throughout the manufacturing process to ensure consistent quality in Brass Screw Machine Parts production. Statistical process control (SPC) charts track dimensional trends and alert operators to potential issues before defects occur. Automated inspection systems check critical dimensions on every part or statistical samples, depending on requirements. Tool wear monitoring systems track cutting tool condition and automatically adjust machining parameters or signal tool changes. First-piece inspections verify setup accuracy, and in-process inspections at predetermined intervals ensure continued conformance. Final inspections include dimensional verification, visual examination, and functional testing where applicable.

Q10: What are your packaging and shipping capabilities for international customers?

A10: Our packaging and shipping services are designed to ensure product protection during international transit while meeting customer-specific requirements. Standard packaging includes protective foam inserts, moisture barriers, and sturdy corrugated containers sized to optimize shipping costs. We can provide custom packaging with customer labels, logos, and part numbering systems. Export documentation services include commercial invoices, packing lists, certificates of origin, and material compliance statements. We work with established freight forwarders for ocean, air, and expedited shipping options. Special packaging for sensitive parts includes anti-tarnish treatments, individual wrapping, and custom foam inserts designed for specific part geometries.

Q11: How do you handle prototype development and design optimization services?

A11: Our prototype development process begins with design review and manufacturability analysis to optimize parts for efficient production. We utilize 3D modeling and finite element analysis to evaluate designs and suggest improvements for cost reduction or enhanced performance. Prototype quantities from single pieces to 100+ units can be produced using our CNC equipment with typical turnaround times of 1-2 weeks. We provide detailed inspection reports and can perform design modifications based on testing results. Our engineering team works closely with customers to transition prototypes to full production, including tooling optimization and process development to ensure seamless scaling.

Q12: What are your minimum order quantities and pricing structures?

A12: Minimum order quantities vary based on part complexity and manufacturing method, typically ranging from 1,000 pieces for simple screw machine parts to 500 pieces for complex Swiss machined components. Prototype and sample orders can be as small as 10-25 pieces. Our pricing structure offers volume discounts with breaks at 5,000, 10,000, 25,000, and 50,000+ piece quantities. Setup charges apply to first-time orders and include tooling, programming, and first-piece inspection costs. We provide detailed quotations including itemized pricing for base parts, secondary operations, packaging, and shipping to ensure complete transparency and enable accurate cost comparisons.

Why Choose Our Brass Screw Machine Parts

Three Decades of Global Manufacturing Excellence: Our extensive experience spanning over 30 years in Brass Screw Machine Parts manufacturing has established us as a trusted global supplier. This extensive experience translates into deep technical knowledge, proven manufacturing processes, and the ability to anticipate and solve potential issues before they impact production. Our team has worked with customers across diverse industries, providing insights and solutions that newer manufacturers cannot match.

Superior Communication and Technical Support: We pride ourselves on exceptional communication skills and technical support that sets us apart from competitors. Our English-speaking technical team provides detailed responses to inquiries, comprehensive technical documentation, and proactive updates throughout the production process. We understand that clear communication is essential for international business success, and we invest heavily in maintaining responsive, knowledgeable customer service that operates across multiple time zones.

Unmatched Flexibility in Production Scheduling: Unlike larger manufacturers with rigid production schedules, we offer remarkable flexibility in accommodating customer timing requirements. Our ability to adjust production schedules, expedite urgent orders, and accommodate design changes during production provides customers with responsive service that adapts to their business needs. This flexibility extends to order quantities, with the ability to handle everything from prototype quantities to large-scale production runs efficiently.

Customized Packaging and Branding Services: We understand that presentation and handling are crucial aspects of the supply chain. Our customized packaging services include customer logos, part numbering systems, color-coded containers, and specialized protective packaging designed for specific applications. We can accommodate unique packaging requirements such as individual wrapping, anti-tarnish treatments, and custom labeling systems that integrate seamlessly with customer inventory management systems.

Comprehensive Quality Documentation and Certification: Our quality management system provides complete documentation and certification services that exceed industry standards. Every shipment includes detailed inspection reports, material certifications, and compliance documentation for relevant standards. Our ISO 9001 certification ensures consistent quality management practices, while our supplier approval from major international companies demonstrates our ability to meet the most stringent requirements.

Advanced Manufacturing Technology Integration: Our investment in the latest manufacturing technology ensures superior product quality and competitive pricing. Swiss-type screw machines, advanced CNC equipment, and automated inspection systems provide capabilities that many competitors cannot match. This technology integration enables us to produce complex parts with exceptional accuracy while maintaining cost-effectiveness for high-volume orders.

Global Supply Chain Expertise: Our decades of experience in international markets provides customers with reliable supply chain management and logistics support. We understand the complexities of international shipping, customs documentation, and regulatory compliance. Our established relationships with freight forwarders and logistics providers ensure reliable delivery schedules and competitive shipping costs.

Customer Testimonials

“We have been sourcing precision Brass components from this manufacturer for over eight years, and their consistency and quality have been exceptional. The technical support team is incredibly knowledgeable and always provides detailed responses to our engineering questions. Their ability to meet our demanding delivery schedules while maintaining tight tolerances has made them an invaluable partner in our supply chain. The communication throughout the process is outstanding – we always know exactly where our orders stand and when to expect delivery.”

– Michael Richardson, Senior Procurement Engineer, Industrial Automation Systems Inc., Michigan, USA

International Standards Compliance

Our Brass Screw Machine Parts manufacturing processes and products comply with comprehensive international standards ensuring global acceptance and quality consistency:

ASTM International Standards: ASTM B16 (Free-Cutting Brass Rod), ASTM B21 (Naval Brass Rod), ASTM B124 (Copper and Copper-Alloy Forging Rod), ASTM B36 (Brass Plate, Sheet, Strip, and Rolled Bar), ASTM B584 (Copper Alloy Sand Castings for General Applications)

International Organization for Standardization (ISO): ISO 9001:2015 Quality Management Systems, ISO 14001:2015 Environmental Management, ISO 6362 Wrought Copper and Copper Alloys, ISO 1634 Copper and Copper Alloys Terminology

European Standards (EN): EN 12163 Copper and Copper Alloy Rods for General Purposes, EN 12164 Copper and Copper Alloy Rods for Free Machining Purposes, EN 1982 Copper and Copper Alloy Ingots and Castings

British Standards (BS): BS 2874 Copper and Copper Alloys – Rods and Sections, BS EN 1652 Copper and Copper Alloys – Plate, Sheet and Strip for General Purposes

German Standards (DIN): DIN 17660 Copper-Zinc Alloys (Brass), DIN 17672 Brazing Filler Metals, DIN 50930 Corrosion of Metals in Water

Japanese Industrial Standards (JIS): JIS H3250 Copper and Copper Alloy Rods and Bars, JIS H3100 Copper and Copper Alloy Sheets and Strips

Material Properties and Performance Data

Corrosion Resistance Performance

Brass Screw Machine Parts manufactured from our standard alloys demonstrate excellent corrosion resistance across diverse environmental conditions. CDA 360 exhibits superior performance in atmospheric conditions with dezincification resistance ratings exceeding industry standards. Naval Brass (CDA 464) provides outstanding resistance to saltwater environments and marine applications. Lead-free alloys maintain corrosion resistance equivalent to traditional Brass while meeting environmental compliance requirements.

Mechanical Property Stability

Temperature stability testing demonstrates that our Brass materials maintain mechanical properties across operating temperature ranges from -40°C to +150°C. Fatigue testing according to ASTM standards shows superior performance compared to alternative materials, with endurance limits exceeding 25,000 psi for CDA 360 under standard test conditions.

Electrical Conductivity Characteristics

Electrical conductivity measurements performed according to ASTM B193 demonstrate consistent performance across production lots. CDA 360 maintains 26% IACS conductivity with minimal variation, while specialty electrical grades can achieve up to 45% IACS where required for specific applications.

Unique Service Propositions (USPs)

Complete Customization Capabilities: Our manufacturing flexibility extends beyond standard parts to complete custom solutions. We work with customers to develop proprietary designs, optimize existing parts for improved performance or cost reduction, and create unique solutions that provide competitive advantages. This includes reverse engineering services, design optimization consulting, and prototype development support.

Integrated Supply Chain Management: We offer comprehensive supply chain services including inventory management, scheduled deliveries, vendor-managed inventory programs, and integrated logistics solutions. Our ERP system can interface with customer systems to provide real-time inventory updates and automated ordering capabilities.

Technical Consultation and Design Support: Our engineering team provides valuable consultation services including material selection guidance, manufacturability analysis, cost optimization studies, and alternative design recommendations. This technical support extends throughout the customer relationship, ensuring optimal part performance and cost-effectiveness.

Global Market Expertise: Our experience serving markets in North America, Europe, Asia, and Australia provides unique insights into regional preferences, regulatory requirements, and market trends. This global perspective enables us to provide solutions that work effectively across multiple markets and applications. Apart from Brass Screw Machine Parts, We also offer Stainless Steel Screw Machine Parts, Copper Screw Machine Parts, Bronze Screw Machine parts, Aluminum Screw Machine Parts and Stainless Steel Screw Machine Products, Bronze Screw Machine Products, Copper Screw MAchine products from bars and castings.

Packaging and Shipping Solutions

Protective Packaging Systems: Our standard packaging utilizes multi-layer protection including anti-tarnish treatments, moisture barrier films, and impact-resistant containers. Parts are carefully arranged to prevent contact damage and can be individually wrapped when required. Custom foam inserts are designed using CAD systems to provide optimal protection for specific part geometries.

International Shipping Expertise: We maintain partnerships with major international freight forwarders and shipping companies to provide reliable, cost-effective transportation solutions. Ocean freight, air freight, and expedited courier services are available with full tracking and insurance coverage. We handle all export documentation including commercial invoices, packing lists, certificates of origin, and any required compliance certifications.

Custom Labeling and Identification: Our labeling capabilities include customer part numbers, lot codes, date codes, and barcode systems compatible with customer inventory management systems. Labels can include company logos, safety warnings, and handling instructions in multiple languages as required.

Sustainable Packaging Options: Environmental considerations are incorporated into our packaging design with recyclable materials, minimal packaging waste, and reusable container options for regular shipments. We work with customers to develop packaging solutions that meet both protection requirements and environmental objectives.

Glossary of Terms

Automatic Screw Machine: Precision manufacturing equipment designed for high-volume production of turned parts from bar stock material, utilizing cam-operated or CNC control systems to perform multiple machining operations automatically.

Swiss Screw Machine: Specialized automatic lathe featuring a guide bushing that supports the workpiece near the cutting tools, enabling production of long, slender parts with exceptional accuracy and surface finish.

Free-Cutting Brass: Brass alloys containing Lead additions that improve machinability by promoting chip formation and reducing cutting forces, resulting in superior surface finishes and extended tool life.

CDA (Copper Development Association): Standardized numbering system for Copper and Copper alloy designations used throughout North America, providing consistent material identification and specification references.

Dezincification: Corrosion phenomenon in Brass alloys where Zinc is selectively removed, leaving a porous Copper-rich structure with reduced mechanical properties and increased permeability.

IACS (International Annealed Copper Standard): Standard measurement system for electrical conductivity, with pure annealed Copper defined as 100% IACS conductivity for comparison purposes.

Ra Surface Roughness: Arithmetic average surface roughness measurement expressing the average height deviations from the mean surface level, typically measured in microinches (µin) or micrometers (µm).

TIR (Total Indicator Reading): Measurement of runout or eccentricity representing the total variation in a feature as measured with a dial indicator during one complete revolution.

Lead-Free Brass: Brass alloys formulated without Lead additions to comply with environmental regulations for potable water applications, utilizing alternative elements to maintain machinability.

CMM (Coordinate Measuring Machine): Precision measurement equipment utilizing computer control to accurately determine dimensional characteristics and geometric relationships of manufactured parts.

Related Search Terms

Brass screw machine products, precision Brass machining services, CNC Brass turning, Swiss machined Brass parts, automotive Brass components, electrical Brass fittings, plumbing Brass hardware, free-cutting Brass machining, Lead-free Brass parts, Naval Brass machining, CDA 360 Brass components, Brass instrument parts, hardware Brass fittings, decorative Brass elements, Brass valve components, threaded Brass fittings, Brass terminal blocks, connector Brass parts, Brass spacers and standoffs, custom Brass machining, small Brass parts manufacturing, precision Brass turning, Brass prototype development, high-volume Brass production, specialty Brass alloys, corrosion-resistant Brass, marine Brass components, architectural Brass hardware, Brass electrical contacts, instrument Brass parts

Contact Us for Your Brass Screw Machine Parts Requirements

Ready to experience the superior quality and service that sets us apart in Brass Screw Machine Parts manufacturing? Our team of technical experts is standing by to discuss your specific requirements and provide detailed quotations for your projects.

📧 Email Us: Send your detailed specifications, drawings, and quantity requirements to receive a comprehensive quotation within 24 hours. Our technical team reviews every inquiry personally to ensure accurate pricing and delivery schedules.

📱 WhatsApp/Phone Consultation: Connect directly with our technical specialists for immediate assistance with part design, material selection, and manufacturing recommendations. Our multilingual team provides support across global time zones.

📋 Request Technical Brochure: Download our comprehensive technical catalog featuring complete specifications, material properties, dimensional capabilities, and case studies from successful projects across diverse industries.

🎯 Get Instant Quote: Upload your drawings and specifications through our secure online portal for rapid quotation turnaround. Our automated systems provide preliminary pricing immediately with detailed quotes following within hours.

Your Success is Our Priority – With three decades of manufacturing excellence, we’re committed to providing Brass Screw Machine Parts that exceed your expectations for quality, precision, and value. Contact us today to discover why customers worldwide trust us for their most critical component requirements.