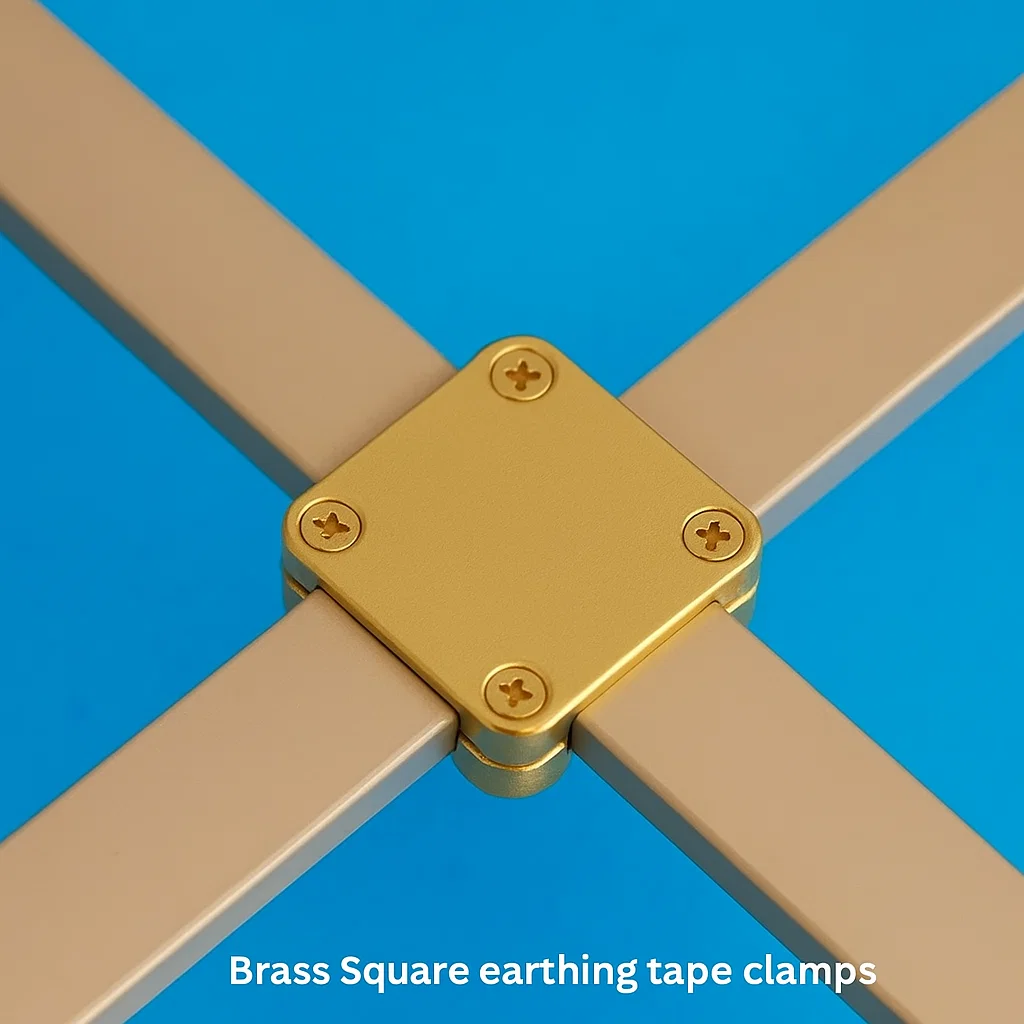

Brass Square Tape Clamps | Bronze Tape Clamps | Square Grounding Clamps for Copper Tape – Premium Quality Earthing Solutions

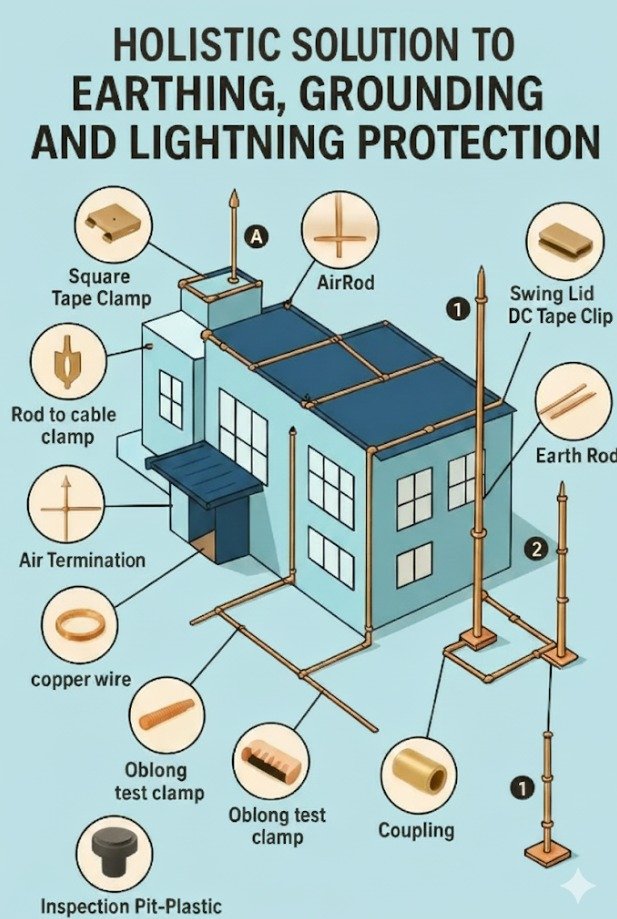

We are one of the leading manufacturers and exporters of Brass Square Tape Clamps, Bronze Tape Clamps, and Grounding Clamps from India. We have been supplying high-quality earthing and lightning protection components to the world market for many decades. Our comprehensive range of Square Tape Clamps encompasses Brass, Bronze, and Copper variants designed for superior electrical conductivity and corrosion resistance. With over three decades of manufacturing expertise, we specialize in precision-engineered grounding solutions that meet international standards including BS EN 62561-1, IEC 62561, ASTM B124, UL 467, and IS/IEC 62305. Our state-of-the-art manufacturing facility in India combines traditional metallurgical expertise with modern CNC machining technology to deliver consistently high-quality products. We serve diverse industries including power generation, telecommunications, renewable energy, marine installations, and industrial plants across North America, Europe, Asia-Pacific, and Middle East regions. Our commitment to quality, customization capabilities, and competitive pricing has established us as a trusted partner for electrical contractors, OEM manufacturers, and engineering consultants worldwide.

Price: US$ 10.90/kilogram

Product Overview and Applications

Brass Square Tape Clamps, Bronze Square Tape Clamps, and Grounding Tape Clamps are critical components in electrical earthing and lightning protection systems. These precision-engineered clamps provide secure, low-resistance connections between flat Copper earth tapes and structural elements such as steel beams, rebar, or grounding electrodes. The square profile design ensures optimal contact pressure distribution, minimizing contact resistance and ensuring reliable fault current dissipation.

Brass Earth Tape Clamps are manufactured from high-conductivity Brass alloys (CuZn39Pb3/CW614N) offering excellent electrical properties combined with good corrosion resistance for above-ground and moderate environmental conditions. These clamps feature precision-machined threads, self-locking mechanisms, and are ideal for telecommunications, commercial buildings, and residential earthing systems.

Bronze Square Tape Clamps utilize high-tensile Bronze alloys including Phosphor Bronze (CuSn8P) and Gunmetal (CuSn10Zn2) providing superior mechanical strength, exceptional corrosion resistance, and excellent performance in harsh marine, chemical, and underground environments. These heavy-duty clamps are specifically designed for power substations, offshore platforms, chemical plants, and coastal installations.

Brass Grounding Tape Clamps combine the conductivity advantages of Brass with specialized designs for grounding grid applications, featuring enhanced clamping force distribution and optimized geometry for flat tape connections in high-voltage earthing systems.

Copper Tape Clamps in Brass and Bronze represent our premium range designed specifically for Copper earth tape connections, ensuring galvanic compatibility and eliminating electrochemical corrosion risks in critical safety applications.

Material Grades and International Standards

| Material | International Grade | USA Standard | European Standard | Chinese Standard | Japanese Standard | Composition | Conductivity (% IACS) |

|---|---|---|---|---|---|---|---|

| Brass | CuZn39Pb3 | ASTM B16 C36000 | EN CW614N | GB HPb59-1 | JIS C3604 | Cu 58-60%, Zn 38-40%, Pb 2.5-3.5% | 26-28 |

| Brass | CuZn37 | ASTM B36 C26000 | EN CW508L | GB H62 | JIS C2600 | Cu 62-64%, Zn 36-38% | 28-30 |

| Phosphor Bronze | CuSn8P | ASTM B139 C52100 | EN CW451K | GB QSn8-0.3 | JIS C5191 | Cu 91-93%, Sn 7.5-9%, P 0.15-0.35% | 15-18 |

| Gunmetal | CuSn10Zn2 | ASTM B62 C90500 | EN CC491K | GB ZCuSn10Zn2 | JIS CAC406 | Cu 86-89%, Sn 9-11%, Zn 1-3% | 12-15 |

| Aluminum Bronze | CuAl10Fe5Ni5 | ASTM B148 C95800 | EN CC333G | GB ZCuAl10Fe3 | JIS CAC703 | Cu 79-81%, Al 9-11%, Fe 3-5%, Ni 4-6% | 13-16 |

Manufacturing Processes and Machinery

Our manufacturing process combines traditional metallurgical expertise with advanced CNC machining technology. Hot forging and investment casting processes are employed for complex geometries, while CNC milling and turning operations ensure precise dimensional accuracy and surface finish. Key manufacturing processes include:

Sand Casting and Investment Casting: Utilized for complex Bronze clamp bodies using CO2 process and ceramic shell molding for superior surface finish and dimensional precision. Our foundry operations employ induction melting furnaces with precise temperature control (±5°C) ensuring consistent alloy composition.

CNC Machining Operations: 5-axis CNC milling centers (Haas VF-4SS, Mazak VTC-200B) and CNC turning centers (Okuma LB-300) with tolerance capabilities of ±0.05mm. Thread rolling operations using Fette thread rolling machines ensure superior thread strength and surface finish.

Heat Treatment and Surface Processing: Stress relieving operations at 350°C for Brass components, solution annealing for Bronze alloys, followed by controlled cooling. Surface treatments include passivation, electroplating (Nickel, Tin), and protective coating applications.

| Machinery Type | Model/Specifications | Capability | Tolerance Achieved |

|---|---|---|---|

| CNC Milling Center | Haas VF-4SS, Mazak VTC-200B | 5-axis simultaneous machining | ±0.05mm |

| CNC Turning Center | Okuma LB-300, Takisawa TC-200 | Live tooling, Sub-spindle | ±0.03mm |

| Thread Rolling Machine | Fette FR-16, Profiroll R42 | M6-M20 threads | ±0.02mm pitch accuracy |

| Investment Casting | Ceramic shell process | Complex geometries | ±0.1mm cast dimension |

Technical Dimensional Specifications

Technical Drawing: Square Tape Clamp Cross-Section

Copper Tape ChannelLength (L)H4-Point Secure Fastening System

| Product Code | Tape Size (mm) | Length (L) mm | Width (W) mm | Height (H) mm | Thread Size | Weight (kg) | Material Options |

|---|---|---|---|---|---|---|---|

| BCP -253-BR/BZ | 25 × 3 | 60 | 60 | 13 | M6 | 0.42/0.44 | Brass/Bronze |

| BCP -304-BR/BZ | 30 × 4 | 65 | 65 | 15 | M8 | 0.48/0.52 | Brass/Bronze |

| BCP -404-BR/BZ | 40 × 4 | 70 | 70 | 18 | M8 | 0.56/0.62 | Brass/Bronze |

| BCP 506-BR/BZ | 50 × 6 | 80 | 80 | 22 | M10 | 0.72/0.78 | Brass/Bronze |

| BCP -758-BR/BZ | 75 × 8 | 100 | 100 | 28 | M12 | 1.24/1.35 | Brass/Bronze |

Industries and Applications

Power Generation and Distribution: Thermal power plants, nuclear facilities, hydroelectric stations, and electrical substations utilize our Square Tape Clamps for main earthing grid connections, transformer neutral grounding, and switchyard earthing systems. High-voltage transmission lines and distribution networks require reliable grounding connections capable of handling fault currents up to 40kA.

Renewable Energy Sector: Solar photovoltaic installations, wind turbine farms, and energy storage systems depend on our grounding clamps for equipment bonding, lightning protection, and electrical safety compliance. Marine offshore wind platforms specifically benefit from our Bronze clamps’ superior corrosion resistance.

Telecommunications and Data Centers: Cell tower grounding systems, telecommunications central offices, and data center facilities require low-resistance earthing connections for equipment protection and signal integrity. Our Brass clamps provide excellent RF grounding characteristics.

Industrial and Petrochemical: Chemical processing plants, oil refineries, and manufacturing facilities in corrosive environments utilize Bronze tape clamps for intrinsic safety grounding, static electricity dissipation, and hazardous area electrical installations.

Transportation Infrastructure: Railway electrification systems, airport lighting, and highway infrastructure projects employ our grounding clamps for traction power return circuits, lightning protection, and electrical safety systems.

Performance Specifications and Standards Compliance

International Standards Compliance:

- IEC 62561-1: Lightning protection system components – Requirements for connection components

- IEEE 80: Guide for safety in AC substation grounding

- BS EN 62305: Protection against lightning

- UL 467: Grounding and bonding equipment

- ASTM B124: Standard specification for Copper and Copper alloy forging rod, bar, and shapes

- IS 5613: Code of practice for earthing

- DIN VDE 0185-305: Lightning protection systems

- JIS C 4431: Lightning protection systems for structures

| Performance Parameter | Brass Clamps | Bronze Clamps | Test Standard |

|---|---|---|---|

| Current Carrying Capacity | 800A continuous | 1000A continuous | IEC 62561-1 |

| Short Circuit Rating | 25kA (1 sec) | 40kA (1 sec) | IEEE 837 |

| Contact Resistance | < 50 microohms | < 40 microohms | ASTM B539 |

| Tensile Strength | 380-420 MPa | 450-550 MPa | ASTM E8 |

| Salt Spray Test | 500 hours | 1000+ hours | ASTM B117 |

| Operating Temperature | -40°C to +85°C | -50°C to +120°C | IEC 60068 |

Tolerances and Quality Control

Our precision manufacturing processes ensure consistent dimensional accuracy and reliable performance. All products undergo comprehensive quality testing including dimensional verification, material composition analysis, mechanical property testing, and electrical performance validation.

| Dimension Category | Standard Tolerance | Precision Tolerance | Measurement Method |

|---|---|---|---|

| Overall Dimensions (L×W×H) | ±0.2mm | ±0.1mm | CMM (Coordinate Measuring Machine) |

| Thread Pitch Accuracy | ±0.05mm | ±0.02mm | Thread Ring/Plug Gauges |

| Tape Channel Dimensions | ±0.1mm | ±0.05mm | Go/No-Go Gauges |

| Surface Finish | Ra 3.2 μm | Ra 1.6 μm | Surface Profilometer |

| Flatness/Squareness | ±0.1mm | ±0.05mm | Dial Indicators |

Comprehensive Q&A Section

A: Brass clamps offer excellent electrical conductivity (26-30% IACS) and good corrosion resistance, making them ideal for above-ground and moderate environmental conditions. Bronze clamps provide superior mechanical strength (450-550 MPa tensile) and exceptional corrosion resistance, particularly in marine, chemical, and underground environments. Bronze clamps typically last 2-3 times longer in harsh conditions.

A: Yes, our clamps are designed for lightning protection systems and can handle short-circuit currents up to 25kA (Brass) and 40kA (Bronze) for 1 second duration. They meet IEC 62561-1 requirements for lightning protection components and IEEE 80 standards for substation grounding.

A: We manufacture clamps for standard Copper tape sizes from 25×3mm to 100×10mm. Common sizes include 25×3, 30×4, 40×4, 50×6, and 75×8mm. Custom sizes can be manufactured with minimum order quantities of 500 pieces.

A: Bronze clamps are specifically recommended for underground installations due to superior soil corrosion resistance. They can withstand soil pH levels from 4.0 to 9.0 and resist sulfate attack. Brass clamps are suitable for above-ground and moderate underground conditions.

A: Our products are manufactured under ISO 9001:2015 quality management system and comply with IEC 62561-1, UL 467, IEEE 80, BS EN 62305, and ASTM B124 standards. We provide material certificates and test reports with each shipment.

A: We employ precision CNC machining for contact surfaces, maintaining flatness within ±0.05mm. Our 4-point fastening system ensures uniform pressure distribution. Contact resistance is tested on every batch and maintained below 50 microohms for Brass and 40 microohms for Bronze clamps.

A: Yes, we specialize in custom designs for specific applications. Our engineering team can modify dimensions, materials, fastening mechanisms, and surface treatments. Typical custom projects include special tape sizes, enhanced corrosion protection, and application-specific mounting configurations.

A: Standard products have minimum order quantities of 100 pieces for Brass and 50 pieces for Bronze clamps. Custom products typically require minimum 500 pieces. We offer flexible packaging options including customer-branded packaging.

A: Products are individually wrapped in VCI (Vapor Corrosion Inhibitor) paper, packed in moisture-resistant boxes with desiccant packets. Outer packaging uses export-grade wooden crates or cardboard cartons depending on destination. All packaging complies with ISPM-15 international standards.

A: We provide comprehensive technical support including installation guides, CAD drawings, material certificates, and application engineering assistance. Our technical team offers phone/email support and can provide on-site consultation for major projects.

A: Yes, our Bronze clamps are specifically designed for marine environments. They resist seawater corrosion, salt spray, and marine atmosphere conditions. Aluminum Bronze grades (CuAl10Fe5Ni5) offer exceptional performance in offshore platforms and ship grounding systems.

A: We implement statistical process control (SPC) with real-time monitoring of critical dimensions, material composition verification using spectrometry, and batch testing of mechanical properties. Our quality system includes incoming material inspection, in-process monitoring, and final inspection protocols.

Why Choose Our Square Tape Clamps Over Competitors

Material Properties and Technical Data

| Property | Brass (CW614N) | Phosphor Bronze (CuSn8P) | Gunmetal (CuSn10Zn2) | Test Method |

|---|---|---|---|---|

| Density (g/cm³) | 8.5 | 8.8 | 8.7 | ASTM B311 |

| Electrical Conductivity (% IACS) | 26-28 | 15-18 | 12-15 | ASTM B193 |

| Thermal Conductivity (W/m·K) | 120 | 85 | 75 | ASTM E1461 |

| Coefficient of Expansion (×10⁻⁶/K) | 20.5 | 17.8 | 18.2 | ASTM E228 |

| Melting Point (°C) | 900-940 | 830-1050 | 830-900 | DSC Analysis |

| Hardness (HB) | 85-110 | 120-180 | 90-130 | ASTM E10 |

Packaging and Shipping Information

Standard Packaging: Individual VCI (Vapor Corrosion Inhibitor) wrapping prevents tarnishing during storage and transportation. Products are packed in moisture-resistant cartons with foam inserts for protection against impact damage. Each package includes product identification labels, material certificates, and installation instructions.

Export Packaging: Marine-grade packaging suitable for container shipping includes desiccant packets, moisture barrier films, and shock-absorbing materials. Wooden crates comply with ISPM-15 fumigation requirements. Packaging weight optimization reduces shipping costs while ensuring product protection.

Custom Packaging Options: Customer-branded packaging with company logos and identification labels available for OEM customers. Consignment packaging for direct customer delivery. Special packaging for hazardous transportation environments.

Shipping Methods: Air freight for urgent orders (3-5 days), sea freight for regular shipments (15-25 days depending on destination), and express courier services for samples and small quantities. Comprehensive shipment tracking and insurance coverage provided.

“We have been using BCP brand Bronze square tape clamps for our offshore wind farm projects for over 5 years. The quality consistency and corrosion resistance performance has been exceptional, even in harsh marine environments. Their technical support team helped us customize clamps for specific installation requirements, and delivery times are consistently met. The cost savings compared to European suppliers while maintaining superior quality makes them our preferred partner.”

– David Smith Senior Electrical Engineer, UK

Glossary of Technical Terms

| Term | Definition |

|---|---|

| Contact Resistance | Electrical resistance at the interface between conductor and clamp, measured in microohms |

| IACS (% International Annealed Copper Standard) | Standard measure of electrical conductivity relative to pure annealed Copper (100% IACS) |

| Galvanic Corrosion | Electrochemical corrosion occurring when dissimilar metals are in electrical contact |

| Earth Tape | Flat Copper conductor used in grounding systems, typically 25-100mm wide |

| Fault Current | Current flowing through grounding system during electrical fault conditions |

| Lightning Protection System (LPS) | System designed to protect structures from lightning damage through controlled discharge |

| Equipotential Bonding | Electrical connection maintaining same potential between conductive parts |

| Phosphor Bronze | Bronze alloy containing phosphorus for enhanced strength and corrosion resistance |

Related Search Terms

Brass square tape clamps, Bronze tape clamps, Square grounding clamps, Earth tape clamps, Lightning protection clamps

Brass square tape clamps manufacturer India, Bronze earth tape clamps exporter, Custom grounding tape clamps, Marine grade Bronze clamps, Copper tape connection clamps

Technical Terms: IEC 62561 compliant clamps, UL 467 listed grounding clamps, IEEE 80 substation grounding, ASTM B124 Bronze clamps, Phosphor Bronze tape clamps

Application-based Terms: Solar grounding clamps, Wind turbine earthing clamps, Substation grounding hardware, Telecommunications tower clamps, Marine grounding systems

Material-specific Terms: CW614N Brass clamps, CuSn8P Phosphor Bronze clamps, Gunmetal tape clamps, Naval Brass grounding hardware, Aluminum Bronze clamps

Get Your Custom Quote Today!

Ready to enhance your grounding system with premium quality Square Tape Clamps?

📧 Email us at: sales@brass-copper-parts. com for detailed quotations and technical specifications

📱 WhatsApp: +91-22-43449300 for instant communication and quick responses

📞 Call us: ++91-22-43449300 to speak with our technical experts

Experience the difference that three decades of manufacturing excellence makes!