Brass Stamped Parts, Brass Forging, Brass Forged Components , Hot Forging of Brass, Brass Hot Stamping

Precision Brass Forged Parts, Brass Forging, Brass Stamping & Brass Stamped Components

We are one of the leading manufacturers and exporters of precision Brass forged parts, Brass forging components, Brass stamping, and Brass stamped components from India. We have been supplying high-quality Brass forgings and precision-engineered Brass components to the world market for many decades. Our state-of-the-art manufacturing facility combines traditional forging expertise with modern CNC machining capabilities to deliver superior quality Brass forged parts that meet international standards including ASTM, BS, DIN, JIS, and IS specifications. With over three decades of experience in precision Brass forging and Brass stamping operations, we have established ourselves as a trusted partner for industries requiring complex geometries, tight tolerances, and consistent quality in their Brass components. Our comprehensive range includes custom Brass forged parts, precision Brass stamped components, hot forged Brass parts, and specialized Brass components for automotive, plumbing, electrical, and industrial applications. We maintain strict quality control protocols throughout our manufacturing process, ensuring that every Brass forged part and Brass stamped component meets or exceeds customer specifications and international quality standards.

Comprehensive Overview of Brass Forging and Stamping Services

Our comprehensive Brass forging and Brass stamping services encompass a wide range of manufacturing processes designed to transform raw Brass materials into precision-engineered components. Brass forging involves the plastic deformation of Brass alloys through controlled application of compressive forces, resulting in superior grain structure and enhanced mechanical properties compared to cast or machined alternatives. Our Brass stamping operations utilize progressive dies and precision tooling to create complex geometries with exceptional dimensional accuracy and surface finish quality.

The integration of traditional hot forging techniques with modern cold stamping processes allows us to optimize material utilization while achieving the specific mechanical properties required for diverse industrial applications. Our manufacturing capabilities include precision Brass hot forging for components requiring superior strength and durability, alongside high-volume Brass stamping for applications demanding consistent quality and cost-effectiveness.

Brass Forged Parts – Precision Engineering Excellence

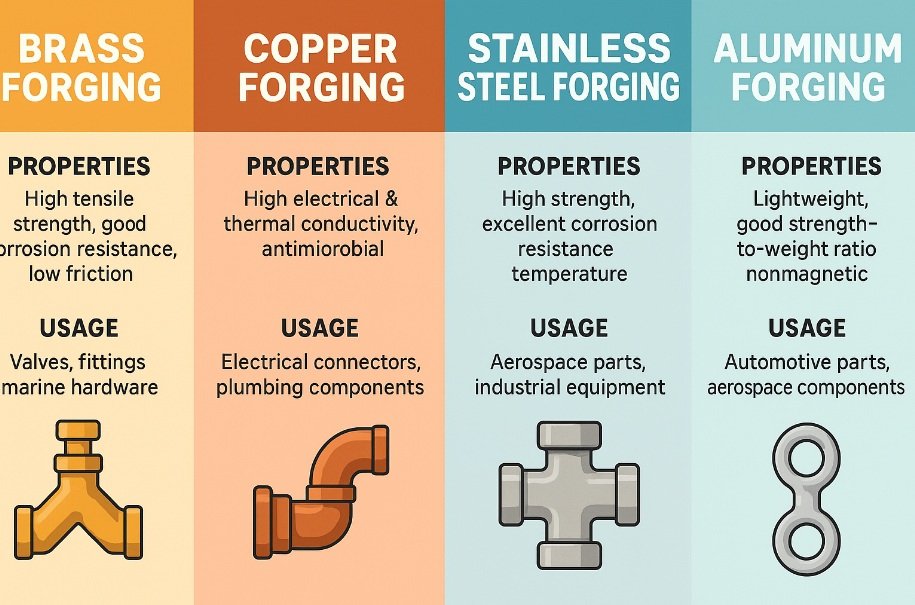

Brass forged parts represent the pinnacle of mechanical component manufacturing, where raw Brass billets undergo controlled plastic deformation to achieve superior grain structure and enhanced mechanical properties. Our precision Brass forged components are manufactured using advanced forging techniques that preserve the inherent corrosion resistance and electrical conductivity of Brass while significantly improving tensile strength, fatigue resistance, and overall durability. The forging process eliminates internal voids and creates a continuous grain flow pattern that follows the component’s geometry, resulting in high-strength Brass forged parts that outperform their cast or machined counterparts in demanding applications.

Our custom Brass forged parts manufacturing capabilities include both open-die and closed-die forging processes, enabling us to produce components ranging from simple geometric shapes to complex, near-net-shape forgings with intricate details. The controlled deformation process inherent in Brass forging operations results in components with superior mechanical properties, including enhanced yield strength, improved ductility, and excellent fatigue resistance, making our precision-engineered Brass forged parts ideal for critical applications in automotive, plumbing, electrical, and industrial sectors.

Brass Forging – Advanced Manufacturing Processes

Brass forging processes encompass a comprehensive range of manufacturing techniques designed to transform Brass alloys into precision components through controlled plastic deformation. Our advanced Brass forging capabilities include hot forging, warm forging, and precision forging operations, each optimized for specific component requirements and production volumes. Hot Brass forging is performed at elevated temperatures ranging from 700°C to 850°C, allowing for significant shape changes and excellent material flow characteristics, while our precision Brass forging operations utilize controlled temperature and pressure parameters to achieve tight tolerances and superior surface finish quality.

The Brass forging manufacturing process begins with careful material selection and preparation, followed by heating to optimal forging temperatures, precise forming operations using hydraulic or mechanical presses, and controlled cooling to achieve desired mechanical properties. Our multi-stage Brass forging processes can produce components with complex geometries, internal cavities, and near-net-shape profiles that minimize subsequent machining requirements, resulting in cost-effective production of high-quality Brass components with superior mechanical characteristics.

Brass Stamping – Precision Sheet Metal Forming

Brass stamping operations represent a highly efficient manufacturing process for producing precision Brass components from sheet and strip materials through controlled plastic deformation using specially designed dies and punches. Our progressive Brass stamping capabilities enable the production of complex components with multiple forming operations performed in a single press stroke, resulting in exceptional dimensional accuracy, consistent quality, and high production efficiency. Precision Brass stamping processes are particularly well-suited for manufacturing thin-walled components, intricate geometries, and high-volume production requirements where dimensional consistency and surface finish quality are critical.

Our advanced Brass stamping facilities feature high-speed mechanical and hydraulic presses ranging from 50 tons to 500 tons capacity, equipped with precision feed systems, progressive die sets, and automated quality control monitoring. The Brass stamping manufacturing process incorporates computer-aided die design, finite element analysis for optimal material flow prediction, and real-time process monitoring to ensure consistent production of high-quality Brass stamped components that meet or exceed customer specifications and international quality standards.

Brass Stamped Components – Precision Manufacturing Excellence

Brass stamped components are precision-engineered parts manufactured through controlled deformation of Brass sheet and strip materials using specialized tooling and press equipment. Our high-precision Brass stamped component manufacturing capabilities encompass a wide range of forming operations including blanking, piercing, bending, drawing, and forming, enabling the production of complex geometries with exceptional dimensional accuracy and surface finish quality. Custom Brass stamped components are designed and manufactured to meet specific customer requirements, incorporating features such as integral fastening elements, complex bend configurations, and precision-formed surfaces that eliminate the need for secondary operations.

The manufacturing of precision Brass stamped components involves careful material selection, optimized blank layout design, progressive die engineering, and controlled forming parameters to achieve consistent quality and dimensional accuracy. Our Brass stamped component production processes incorporate advanced quality control measures including statistical process control, coordinate measuring machine inspection, and real-time monitoring systems to ensure that every component meets stringent quality requirements and customer specifications.

Brass Hot Stamping – High-Temperature Forming Excellence

Brass hot stamping processes involve the formation of Brass components at elevated temperatures, typically ranging from 400°C to 600°C, enabling enhanced material formability and the production of complex geometries that would be difficult or impossible to achieve through conventional cold stamping operations. Our precision Brass hot stamping capabilities combine controlled heating systems, specialized tooling, and precise forming parameters to produce components with superior mechanical properties, excellent surface finish, and tight dimensional tolerances. High-temperature Brass forming operations are particularly beneficial for thick-section components, complex draw ratios, and applications requiring enhanced strength characteristics.

The Brass hot stamping manufacturing process incorporates induction heating systems, temperature-controlled dies, and controlled cooling protocols to optimize material properties and dimensional stability. Our advanced hot stamping facilities feature precision temperature control systems, automated material handling equipment, and real-time process monitoring to ensure consistent production of high-quality Brass components with superior mechanical characteristics and exceptional dimensional accuracy.

Brass Hot Forging – Superior Strength and Durability

Brass hot forging operations represent the pinnacle of high-temperature forming processes, where Brass billets are heated to optimal forging temperatures and subjected to controlled compressive forces to achieve superior grain structure refinement and enhanced mechanical properties. Our precision Brass hot forging capabilities enable the production of components with exceptional strength-to-weight ratios, superior fatigue resistance, and excellent corrosion resistance characteristics. High-temperature Brass forging processes are specifically designed to optimize material flow, eliminate internal defects, and create components with continuous grain structure that follows the component geometry for maximum strength and durability.

Our advanced Brass hot forging facilities feature induction heating systems capable of achieving precise temperature control, hydraulic and mechanical presses with capacities ranging from 100 tons to 2000 tons, and controlled cooling systems to optimize material properties. The Brass hot forging manufacturing process incorporates computer-controlled heating cycles, precision die design, and real-time temperature monitoring to ensure consistent production of high-quality forgings that meet or exceed international standards for mechanical properties and dimensional accuracy.

Comprehensive Material Grades and International Standards

| Material Grade | International Standard | Chemical Composition | Typical Applications | Key Properties |

|---|---|---|---|---|

| CuZn37 (CZ108) | BS EN 12163, DIN 17660 | Cu: 62-64%, Zn: 36-38% | General engineering, decorative | Good formability, corrosion resistance |

| CuZn39Pb3 (CZ121) | BS EN 12164, ASTM B16 | Cu: 57-60%, Zn: 37-40%, Pb: 2.5-3.5% | Free-cutting applications, plumbing | Excellent machinability |

| C26000 (Cartridge Brass) | ASTM B19, JIS H3100 | Cu: 68.5-71.5%, Zn: 28.5-31.5% | Ammunition, electrical components | High strength, ductility |

| C36000 (Free-Cutting Brass) | ASTM B16, SAE 40 | Cu: 60.0-63.0%, Zn: 35.0-38.0%, Pb: 2.5-3.7% | Screw machine products | Superior machinability |

| Naval Brass C46400 | ASTM B21, JIS H3100 | Cu: 59-62%, Zn: 37.0-39.25%, Sn: 0.5-1.0% | Marine applications, valves | Excellent corrosion resistance |

| CuZn40 (MS58) | IS 319, BS 2874 | Cu: 57-61%, Zn: 39-43% | Hot forging, stamping | Good hot workability |

Advanced Manufacturing Processes and Machinery

Our comprehensive manufacturing processes integrate state-of-the-art equipment with proven metallurgical expertise to deliver superior quality Brass components. The manufacturing workflow begins with material inspection and preparation, utilizing spectrometric analysis and mechanical testing to verify material properties and composition compliance with specified standards.

| Process Stage | Equipment Used | Parameters | Quality Control |

|---|---|---|---|

| Material Preparation | Cut-to-length machines, Induction heating | Temperature: 750-850°C | Chemical analysis, dimensional inspection |

| Hot Forging | Hydraulic presses (100-2000T), Pneumatic hammers | Pressure: 50-200 MPa | Temperature monitoring, dimensional verification |

| Stamping Operations | Mechanical presses (50-500T), Progressive dies | Speed: 30-120 SPM | CMM inspection, surface finish verification |

| Heat Treatment | Controlled atmosphere furnaces | Temperature: 400-700°C | Hardness testing, microstructure analysis |

| Finishing Operations | CNC machining centers, Surface treatment | Tolerance: ±0.05mm | Final dimensional inspection, surface quality |

Typical Parts Produced and Applications

Our comprehensive manufacturing capabilities enable the production of diverse Brass forged and stamped components serving multiple industries and applications. Precision Brass forged parts include automotive components such as synchronizer rings, transmission parts, and engine components, while our Brass stamped components encompass electrical contacts, decorative hardware, and precision electronic housings.

| Component Category | Typical Parts | Manufacturing Process | Key Specifications | Tolerance Range |

|---|---|---|---|---|

| Automotive Components | Synchronizer rings, Gear components, Valve seats | Hot forging + CNC machining | Diameter: 25-200mm | ±0.05 to ±0.15mm |

| Plumbing Fittings | Valve bodies, Pipe fittings, Connectors | Hot forging + Threading | NPT/BSP threads | ±0.1 to ±0.2mm |

| Electrical Components | Terminal blocks, Switch parts, Contacts | Stamping + Plating | Thickness: 0.5-5mm | ±0.02 to ±0.08mm |

| Industrial Hardware | Fasteners, Brackets, Flanges | Forging + Heat treatment | Strength: 300-450 MPa | ±0.05 to ±0.12mm |

| Marine Components | Propeller parts, Shaft components | Hot forging + Corrosion treatment | Naval Brass specifications | ±0.08 to ±0.15mm |

🔧 BRASS FORGING PROCESS FLOW 🔧

Industries Served and Applications

Our precision Brass forged and stamped components serve diverse industries requiring superior quality, reliability, and performance. The automotive industry relies on our high-strength Brass forged parts for transmission components, synchronizer rings, and engine applications where durability and precision are critical. Plumbing and pipe fitting manufacturers utilize our corrosion-resistant Brass components for valve bodies, pipe connections, and water system components that must withstand high pressures and corrosive environments.

The electrical and electronics industry depends on our precision Brass stamped components for connectors, terminal blocks, and switch components that require excellent electrical conductivity and dimensional stability. Marine applications benefit from our specialized Naval Brass forgings that provide superior corrosion resistance in saltwater environments, while industrial machinery manufacturers rely on our custom Brass components for hydraulic systems, pneumatic equipment, and precision instrumentation applications.

Technical Specifications and Tolerances

| Specification Parameter | Forged Components | Stamped Components | Hot Forged Parts | Measurement Standard |

|---|---|---|---|---|

| Dimensional Tolerance | ±0.05 to ±0.15mm | ±0.02 to ±0.08mm | ±0.08 to ±0.20mm | ISO 2768-m |

| Surface Roughness | Ra 1.6 to 6.3 μm | Ra 0.8 to 3.2 μm | Ra 3.2 to 12.5 μm | ISO 4287 |

| Flatness | ±0.05mm per 100mm | ±0.02mm per 100mm | ±0.08mm per 100mm | ISO 1101 |

| Concentricity | ±0.05mm | ±0.03mm | ±0.08mm | ISO 1101 |

| Thread Accuracy | 6H/6g class | 6H/6g class | 6H/7g class | ISO 965 |

Performance Metrics and Quality Assurance

Our comprehensive quality assurance program ensures that every Brass forged part and stamped component meets or exceeds specified performance requirements. Mechanical property testing includes tensile strength verification (minimum 300 MPa for standard grades), yield strength confirmation, and elongation measurement to ensure compliance with material specifications. Dimensional accuracy verification is performed using coordinate measuring machines (CMM) with accuracy of ±0.002mm, ensuring that all critical dimensions meet specified tolerances.

| Performance Parameter | Standard Brass | High-Strength Brass | Naval Brass | Test Method |

|---|---|---|---|---|

| Tensile Strength | 300-380 MPa | 400-550 MPa | 380-480 MPa | ASTM E8 |

| Yield Strength | 120-180 MPa | 200-350 MPa | 150-220 MPa | ASTM E8 |

| Elongation | 35-45% | 20-35% | 30-40% | ASTM E8 |

| Hardness | 70-90 HRB | 85-105 HRB | 75-95 HRB | ASTM E18 |

| Fatigue Strength | 120-150 MPa | 180-220 MPa | 140-180 MPa | ASTM D7791 |

Comprehensive Q&A – Technical Information

Q1: What are the key advantages of Brass forged parts over cast or machined alternatives?

A: Brass forged parts offer superior mechanical properties including 25-30% higher tensile strength, improved fatigue resistance, and better grain structure integrity. The forging process eliminates internal voids and creates continuous grain flow, resulting in enhanced durability and reliability compared to cast components.

Q2: Can you produce complex geometries in Brass stamped components?

A: Yes, our progressive stamping capabilities enable production of highly complex Brass components with multiple bends, formed features, and tight tolerances. We utilize advanced die design and finite element analysis to optimize material flow and achieve intricate geometries with minimal secondary operations.

Q3: What tolerance ranges can you achieve for precision Brass forged parts?

A: Our standard tolerance ranges are ±0.05 to ±0.15mm for forged components, with tighter tolerances of ±0.02 to ±0.05mm achievable through secondary CNC machining operations. Specific tolerances depend on component geometry, size, and material grade.

Q4: Do you provide heat treatment services for Brass components?

A: Yes, we offer comprehensive heat treatment services including stress relieving, annealing, and solution treatment to optimize mechanical properties. Our controlled atmosphere furnaces ensure consistent results while preventing oxidation and maintaining surface quality.

Q5: What certifications and quality standards do you follow?

A: We maintain ISO 9001:2015 certification and comply with international standards including ASTM, BS, DIN, JIS, and IS specifications. All materials are traceable with mill test certificates, and we provide comprehensive inspection reports with each shipment.

Q6: Can you supply Brass components with special surface treatments?

A: Yes, we provide various surface treatments including nickel plating, Chrome plating, powder coating, and passivation. We also offer specialized treatments like anti-tarnish coatings and conductive platings for electrical applications.

Q7: What is your typical production capacity for Brass forged parts?

A: Our production capacity varies by component size and complexity, ranging from 500-2000 pieces per day for standard forged parts to 5000-15000 pieces per day for stamped components. We maintain flexible scheduling to accommodate both prototype and high-volume production requirements.

Q8: Do you provide design assistance for Brass component optimization?

A: Absolutely. Our engineering team provides comprehensive design support including material selection, process optimization, and cost reduction analysis. We utilize CAD modeling and simulation software to optimize component design for manufacturability and performance.

Q9: What inspection and testing procedures do you follow?

A: Our quality control program includes incoming material inspection, in-process monitoring, and final inspection using CMM, optical comparators, and mechanical testing equipment. We perform statistical process control and maintain detailed quality records for traceability.

Q10: Can you handle special packaging and labeling requirements?

A: Yes, we provide customized packaging solutions including anti-corrosion packaging, customer-specific labeling, and traceability marking. We can accommodate special shipping requirements and provide packaging that meets international shipping standards.

“We have been sourcing precision Brass forged components from this manufacturer for over 8 years, and their consistency in quality and delivery performance has been exceptional. Their technical expertise and ability to handle complex geometries with tight tolerances has made them our preferred partner for critical automotive applications. The team’s responsiveness and willingness to support our design optimization initiatives has resulted in significant cost savings while maintaining superior product quality.”

– R Thompson, Senior Procurement Manager, Michigan, USA

Why Choose Our Brass Forging and Stamping Services

Our commitment to excellence in Brass forging and stamping manufacturing sets us apart as the preferred partner for discerning customers worldwide. With over three decades of specialized experience in precision Brass component manufacturing, we have developed unmatched expertise in optimizing processes, material utilization, and quality control procedures. Our advanced manufacturing facility features state-of-the-art equipment including computer-controlled presses, induction heating systems, and precision measuring instruments that enable us to consistently deliver superior quality components.

Faster turnaround times are achieved through our streamlined production processes, optimized inventory management, and flexible scheduling capabilities that accommodate urgent delivery requirements without compromising quality. Our exceptional customer support team provides technical assistance, design consultation, and real-time project updates, ensuring transparent communication throughout the manufacturing process. Global exposure and experience gained through decades of international business enables us to understand diverse market requirements, quality standards, and customer expectations across different industries and geographical regions.

Our ability to customize extends beyond standard component specifications to include material grades, surface treatments, packaging, and documentation requirements tailored to specific customer needs. Flexibility in production planning allows us to accommodate varying batch sizes, delivery schedules, and specification changes while maintaining cost-effectiveness and quality standards. Comprehensive quality assurance programs ensure that every component meets or exceeds specified requirements, backed by detailed inspection reports and material certifications.

Packaging and Shipping Excellence

Our comprehensive packaging and shipping services are designed to ensure that Brass components reach customers in perfect condition while providing maximum protection against corrosion, damage, and contamination during transit. Anti-corrosion packaging utilizes VCI (Vapor Corrosion Inhibitor) papers, desiccant packs, and moisture barrier films to protect Brass components from oxidation and tarnishing during extended shipping periods.

Customized packaging solutions include customer-specific labeling with logos, part numbers, and traceability information according to individual requirements. We provide flexible packaging options ranging from bulk containers for high-volume shipments to individual component packaging for precision parts requiring special handling. Our international shipping expertise ensures compliance with global shipping regulations, proper documentation, and optimized freight solutions to minimize delivery times and costs.

Material Property Reference Tables

| Property | CuZn37 | CuZn39Pb3 | C26000 | Naval Brass | Units |

|---|---|---|---|---|---|

| Density | 8.44 | 8.50 | 8.53 | 8.41 | g/cm³ |

| Melting Point | 905-932 | 885-900 | 900-940 | 880-920 | °C |

| Thermal Conductivity | 109 | 115 | 120 | 111 | W/m·K |

| Electrical Conductivity | 27-30 | 25-28 | 28-32 | 26-29 | %IACS |

| Coefficient of Expansion | 20.5 | 20.8 | 20.3 | 20.6 | μm/m·K |

| Elastic Modulus | 97-110 | 95-105 | 105-115 | 100-110 | GPa |

Glossary of Technical Terms

Brass Forging: A manufacturing process involving the plastic deformation of Brass alloys through controlled application of compressive forces to create components with superior mechanical properties and grain structure.

Hot Forging: A forging process performed at elevated temperatures (typically 700-850°C for Brass) to enhance material formability and achieve complex geometries with reduced forming forces.

Progressive Stamping: A metalworking process where multiple forming operations are performed sequentially in a single press using specially designed progressive dies to create complex components efficiently.

Grain Flow: The directional orientation of metal grain structure following the component geometry, achieved through forging processes to enhance mechanical properties and fatigue resistance.

Heat Treatment: Controlled heating and cooling processes applied to Brass components to optimize mechanical properties, relieve stresses, and achieve desired hardness levels.

Naval Brass: A specialized Brass alloy containing tin (typically 0.5-1.0%) for enhanced corrosion resistance in marine environments and high-stress applications.

Tolerance: The permissible deviation from specified dimensions, expressed as plus/minus values to define acceptable dimensional accuracy for manufactured components.

Coordinate Measuring Machine (CMM): Precision measurement equipment used for dimensional inspection and verification of complex geometries with high accuracy.

Related Search Terms and Keywords

Primary Brass forged parts, Brass forging, Brass stamping, Brass stamped components, precision Brass components, custom Brass forging, Brass hot forging, Brass manufacturing services

Industry-Specific Terms: Automotive Brass parts, plumbing Brass fittings, electrical Brass components, marine Brass parts, industrial Brass hardware, CNC machined Brass parts, Brass valve components

Process-Related s: Hot stamping Brass, cold forging Brass, progressive die stamping, precision forging services, Brass component manufacturing, metal forming services, custom metal stamping

Quality and Standards: ISO certified Brass parts, ASTM compliant Brass components, precision tolerance Brass parts, quality assured Brass forging, traceable Brass materials

Geographic : Brass forging India, Brass stamping manufacturer India, Indian Brass exporter, precision Brass parts supplier, Brass components from India

Get Your Custom Brass Components Quote Today!

Ready to experience the superior quality and precision of our Brass forged parts and stamped components? Our technical team is standing by to discuss your specific requirements and provide comprehensive solutions tailored to your needs.

📧 Email Us: sales@brass-copper-parts. com Send your detailed specifications, drawings, and quantity requirements to receive a comprehensive quotation within 24 hours. Our technical team reviews every inquiry personally to ensure accurate pricing and delivery schedules.

📱 WhatsApp/Phone Consultation: Connect directly with our technical specialists for immediate assistance with part design, material selection, and manufacturing recommendations. Our multilingual team provides support across global time zones.

📋 Request Technical Brochure: Download our comprehensive technical catalog featuring complete specifications, material properties, dimensional capabilities, and case studies from successful projects across diverse industries.

🎯 Get Instant Quote: Upload your drawings and specifications through our secure online portal for rapid quotation turnaround. Our automated systems provide preliminary pricing immediately with detailed quotes following within hours.

Special Offer: Mention this webpage for a 5% discount on your first order of Brass Forging, Brass Stamping above 10,000 pieces!

Turnaround Time: 4-6 weeks for custom orders | Worldwide shipping available | Technical support in multiple languages