Bronze Scoop Thru Hull Fittings, Bronze Marine Fittings

High-Performance Marine Water Intake Systems with Integrated Straining Technology

Rate: US$ 14.00/kilogram

Product Overview

Bronze Scoop Thru Hull fittings represent the pinnacle of marine water intake technology, combining the essential functions of raw water intake and debris straining in a single, robust bronze casting. These specialized marine fittings are engineered for high-speed water pickup applications, featuring a distinctive scooped design that optimizes water flow while preventing air locks and turbulence.

Manufactured from premium marine-grade Bronze alloy (typically 88% copper, 12% tin with aluminum additives for enhanced corrosion resistance), or LG2 or CDA 836 – C86000 Gunmetal bronze, these fittings deliver exceptional durability and reliability in harsh marine environments. The integrated strainer design serves as the first line of defense against debris, protecting downstream equipment and systems.

Key Features & Benefits

Integrated Strainer Design

Combines water intake and straining functions in a single fitting, eliminating the need for separate components and reducing installation complexity.

High-Speed Performance

Scooped profile directs water efficiently into the intake while preventing air lock formation at higher vessel speeds.

Premium Bronze Construction

Cast from marine-grade bronze with extra-sturdy wall thickness for maximum durability and corrosion resistance.

Versatile Applications

Suitable for engine cooling, air conditioning, bait tanks, washdown systems, and general raw water applications.

Easy Installation

Four mounting holes in strainer flange allow for secure attachment and enable single-person installation procedures.

Complete Assembly

Includes flanged jam nut for secure hull mounting and watertight seal integrity.

Technical Specifications & Sizing

Our Bronze Scoop Thru Hull fittings are available in five standard sizes to accommodate various flow requirements and vessel applications:

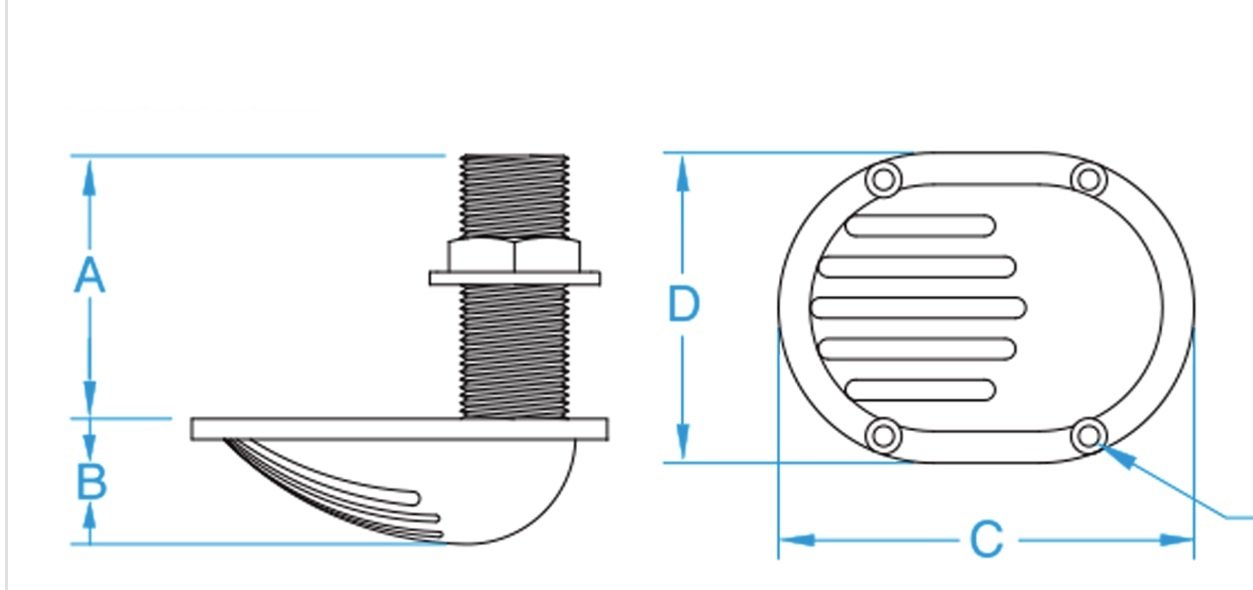

| Part Number | Thread Size (NPS) | Length A (in) | Hull Thickness B (in) | Overall Length C (in) | Flange Diameter D (in) |

|---|---|---|---|---|---|

| BST-500-W | 1/2″ | 2.20 | 1.05 | 3.28 | 2.55 |

| BST-750-W | 3/4″ | 2.20 | 1.05 | 4.00 | 3.05 |

| BST-1000-W | 1″ | 2.85 | 1.05 | 4.00 | 3.05 |

| BST-1250-W | 1-1/4″ | 2.90 | 1.20 | 4.30 | 3.35 |

| BST-2000-W | 2″ | 3.60 | 1.50 | 5.75 | 4.00 |

Material Specifications

- Alloy: Marine Grade Bronze (ASTM B62, DIN 1705, BS 1400 LG2)

- Composition: 88% Copper, 12% Tin with Aluminum additives

- Thread Standard: NPT (National Pipe Thread)

- Finish: Natural bronze with protective coating

- Fasteners: Compatible with #8 stainless steel screws

Applications & Uses

Bronze Scoop Thru Hull fittings are engineered for demanding marine applications where reliable water intake and debris protection are critical:

Engine Cooling Systems

Raw water intake for inboard gasoline and diesel engine cooling circuits

Air Conditioning

Seawater intake for marine AC cooling systems and heat exchangers

Bait Tank Systems

Live well circulation and aeration system water supply

Washdown Systems

Deck wash and anchor washdown pump water intake

Bilge Pump Intake

Emergency and automatic bilge pump priming systems

Fire Suppression

Emergency fire pump raw water intake systems

Material Comparison

Understanding the advantages of bronze over other common thru-hull materials:

Bronze (Recommended)

Advantages:

• Superior corrosion resistance

• Excellent strength-to-weight ratio

• Time-tested marine reliability

• Compatible with most metals

Stainless Steel

Considerations:

• Higher cost

• Prone to crevice corrosion

• Requires oxygen for protection

• Limited marine applications

Plastic/Marelon

Limitations:

• Lower strength under stress

• UV degradation concerns

• Temperature limitations

• Conservative marine acceptance

Installation Guidelines

Critical Safety Notice

Installation of below-waterline fittings requires vessel hauling and should only be performed by qualified marine technicians. Improper installation can result in catastrophic flooding and vessel loss.

Pre-Installation Planning

Survey installation location, verify hull thickness, check for internal obstructions, and ensure adequate access for seacock installation. Plan the complete water system routing before cutting.

Hull Preparation

For fiberglass hulls, drill pilot hole and apply neat epoxy around the interior to seal laminate. For cored hulls, remove core material and fill with solid fiberglass before final drilling.

Hole Cutting

Use appropriate hole saw size for thread diameter plus clearance. Cut slowly to prevent gelcoat cracking. Test fit the thru-hull before proceeding.

Sealant Application

Apply marine-grade polysulfide or polyurethane sealant to both hull surfaces and fitting threads. Avoid silicone sealants which prevent proper adhesion.

Fitting Installation

Insert thru-hull from exterior, apply backing plate if required, and tighten jam nut gradually and evenly. Torque to manufacturer specifications.

System Connection

Install appropriate seacock, connect to water system with proper marine hose and clamps. Test system thoroughly before launching.

Maintenance & Service

Regular Inspection Schedule

- Monthly: Visual inspection of strainer for debris accumulation and cleaning as needed

- Quarterly: Check seacock operation and lubricate if required

- Semi-Annually: Inspect sealant integrity and fastener condition

- Annually: Complete haul-out inspection for corrosion, electrolysis, and structural integrity

Cleaning Procedures

Regular cleaning maintains optimal flow rates and prevents system contamination:

- Remove accumulated marine growth and debris from strainer slots

- Flush with fresh water to remove salt deposits

- Use soft bristle brush for stubborn deposits

- Avoid harsh chemicals that may damage bronze finish

- Inspect for physical damage during cleaning

Electrolysis Prevention

Monitor for signs of galvanic corrosion, particularly around dissimilar metals. Proper electrical bonding and zinc anode maintenance are essential for long-term durability. Consult marine electrical professionals for bonding system design.

Performance Characteristics

Flow Dynamics

The scooped design provides superior flow characteristics compared to standard thru-hulls:

- Reduced Turbulence: Streamlined water entry minimizes cavitation and air entrainment

- Self-Cleaning Action: Forward motion helps clear debris from strainer openings

- Pressure Recovery: Scoop design converts forward motion into positive intake pressure

- Air Lock Prevention: Eliminates dead air spaces that can form in conventional intakes

Sizing Guidelines

Proper sizing ensures adequate flow while preventing excessive stress on connected systems:

- 1/2″ & 3/4″: Small engines up to 50HP, bait tanks, washdown systems

- 1″: Medium engines 50-100HP, larger bait tanks, AC systems

- 1-1/4″: Larger engines 100-200HP, multiple system applications

- 2″: High-flow applications, large engines over 200HP, fire pumps

Troubleshooting Common Issues

| Problem | Probable Cause | Solution |

|---|---|---|

| Reduced flow rate | Strainer clogged with debris | Clean strainer openings, check for marine growth |

| Air in system | Loose connections or damaged seals | Inspect and tighten connections, replace seals |

| Leakage at hull | Deteriorated sealant or loose fitting | Re-seal with marine sealant, check fastener torque |

| Corrosion visible | Galvanic action or stray current | Check electrical bonding, inspect zinc anodes |

| Vibration or noise | Loose mounting or cavitation | Secure mounting, check for proper flow rates |

Compliance & Standards

Our Bronze Scoop Thru Hull fittings meet will comply to the following industry standards:

- ABYC Standards: American Boat & Yacht Council requirements for through-hull fittings

- ISO 9093-1: International standard for small craft seacocks and through-hull fittings

- ASTM B62: Standard specification for composition bronze or ounce metal castings

- UL Marine: Underwriters Laboratories marine equipment certification

- CE Marking: European conformity certification for marine equipment

Warranty & Liability

Professional installation and regular maintenance are required to maintain warranty coverage. Consult local marine authorities regarding installation regulations and requirements for your vessel classification and operating waters.