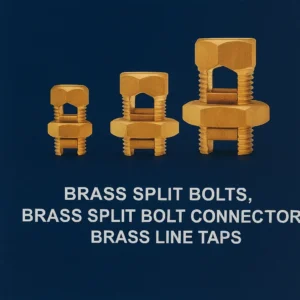

Bronze Bolted Lugs, Copper Bolted Lugs & Brass Bolted Lugs – Premium Electrical Cable Connectors

Price: US$ 11/Kilogram

We are one of the leading manufacturers and exporters of Bronze Bolted Lugs, Copper Bolted Lugs, and Brass Bolted Lugs from India. We have been supplying high-quality electrical cable connectors to the world market for many decades. Our comprehensive range of bolted lugs encompasses Bronze Electrical Lugs, Copper Terminal Lugs, Brass Compression Lugs, and specialized Bronze Bolt-on Connectors designed for diverse electrical applications. With over three decades of manufacturing excellence, we have established ourselves as a trusted partner for electrical infrastructure projects across continents. Our state-of-the-art manufacturing facility in India utilizes advanced precision machining and quality control systems to produce electrical connectors that meet international standards including ASTM, BS, DIN, JIS, and IS specifications. Our Bronze Bolted Lugs and Copper Bolted Lugs are engineered for superior conductivity, corrosion resistance, and mechanical strength, making them ideal for power transmission, distribution systems, renewable energy installations, and industrial electrical applications. We pride ourselves on delivering customized solutions with flexible production schedules, competitive pricing, and exceptional customer service that has made us a preferred supplier for electrical contractors, utilities, and OEMs worldwide.

Product Overview – Bolted Electrical Lugs

Bolted electrical lugs represent a critical component in electrical power systems, providing secure and reliable connections between cables and electrical equipment. Our comprehensive range includes Bronze Bolted Lugs, Copper Bolted Lugs, and Brass Bolted Lugs manufactured to exacting standards for optimal performance in demanding electrical environments. These electrical connectors feature precision-machined bolt holes, corrugated cable entry barrels, and high-conductivity alloy construction that ensures minimal voltage drop and maximum current carrying capacity. Our bolted lugs are designed for both temporary and permanent installations, offering exceptional reusability and maintenance accessibility compared to compression-type connectors.

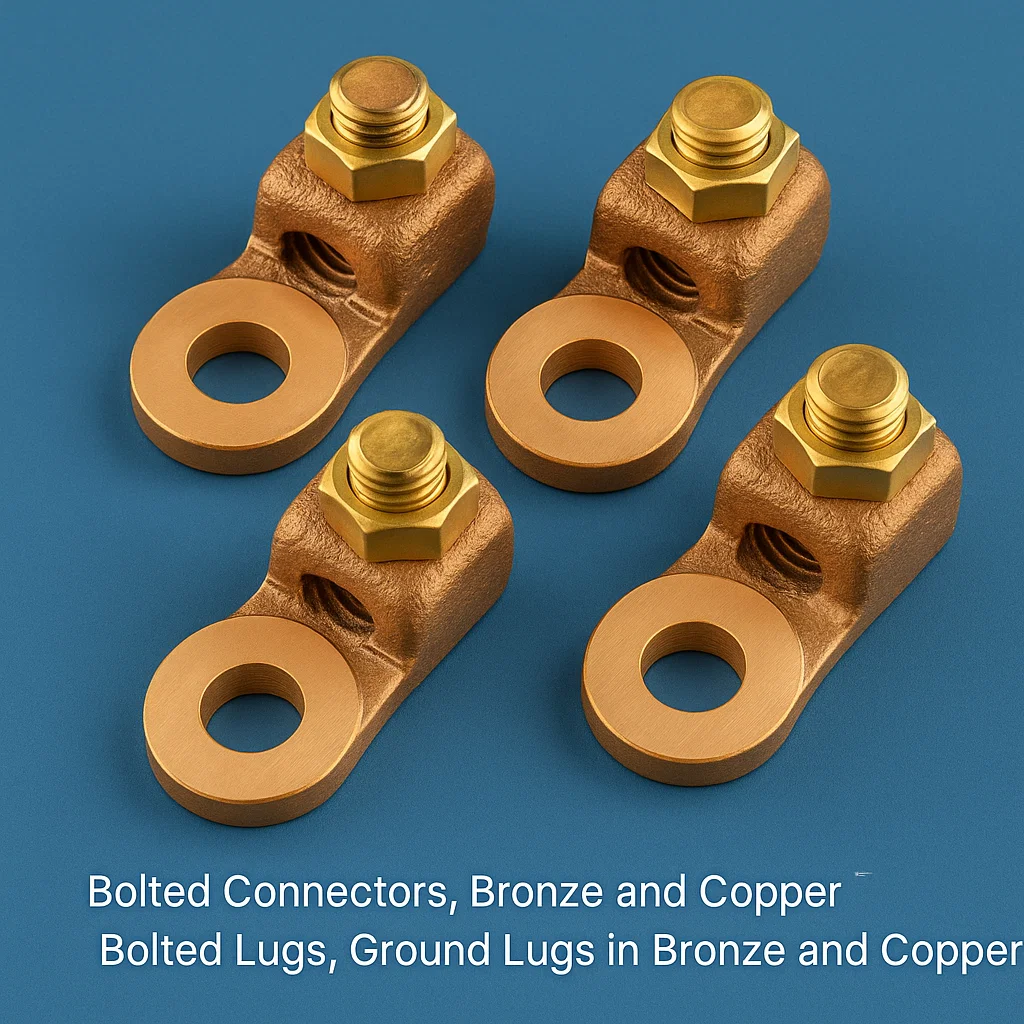

Bronze Bolted Lugs

Bronze Bolted Lugs manufactured from high-strength tin Bronze alloys offer exceptional corrosion resistance and mechanical durability for marine, coastal, and industrial applications. Our Bronze electrical connectors feature superior tensile strength compared to pure Copper alternatives while maintaining excellent electrical conductivity. These Bronze Terminal Lugs incorporate precision-machined palm surfaces with standardized bolt hole patterns for seamless integration with switchgear, transformers, and distribution equipment. The Bronze alloy composition typically includes 88-92% Copper with tin, phosphorus, and trace elements optimized for electrical applications, providing enhanced spring properties and reduced creep under mechanical stress.

Brass Bolted Lugs

Brass Bolted Lugs combine the conductivity of Copper with the strength and machinability of zinc alloys, creating electrical connectors ideal for instrumentation, control circuits, and medium-voltage applications. Our Brass electrical lugs feature enhanced antimicrobial properties and superior resistance to dezincification when manufactured from specialized leaded or unleaded Brass formulations. These Brass Terminal Lugs offer excellent dimensional stability and precise tolerances essential for automated installation processes. The zinc content in our Brass alloys ranges from 15-40% depending on application requirements, with alpha-beta Brass compositions providing optimal balance of conductivity and mechanical properties.

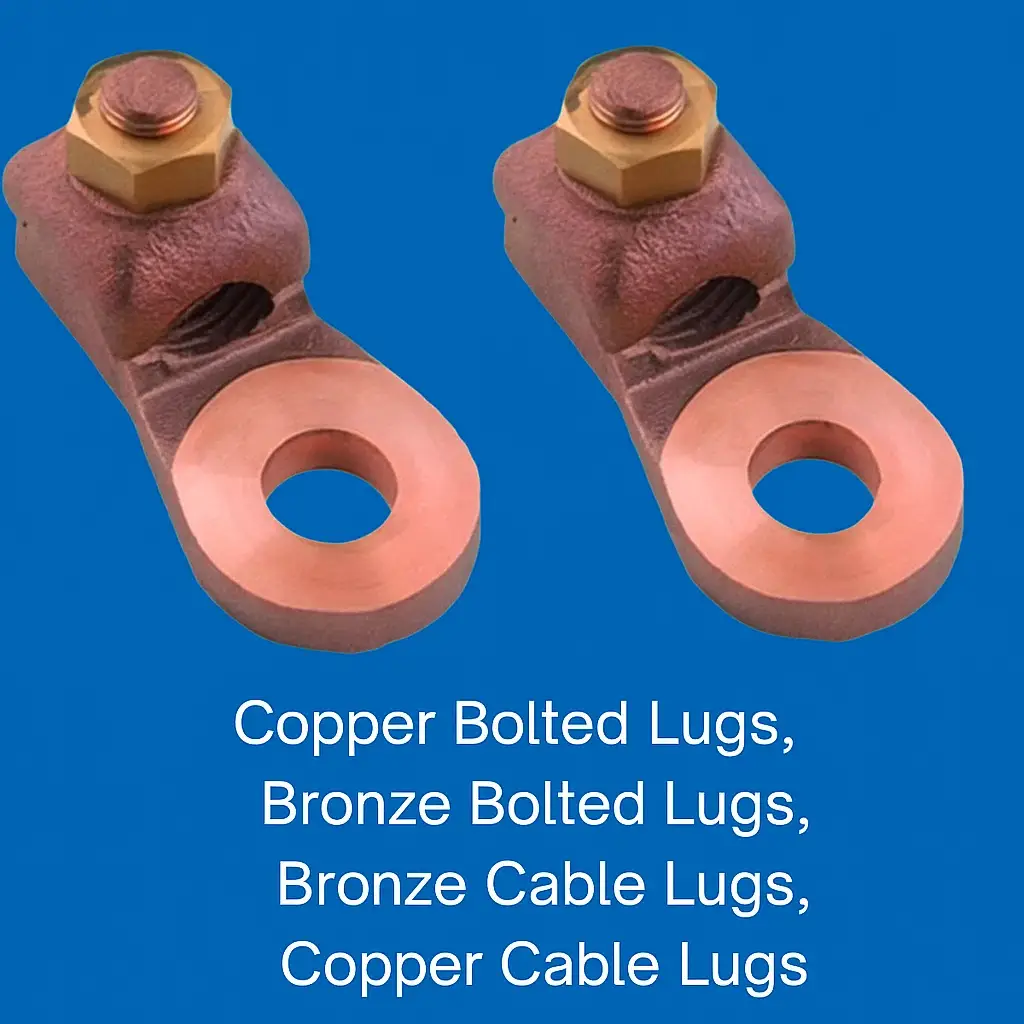

Copper Bolted Lugs

Copper Bolted Lugs represent the gold standard for electrical conductivity in cable termination applications, manufactured from high-purity electrolytic Copper meeting C11000 and C10100 specifications. Our Copper electrical connectors provide maximum current carrying capacity with minimal temperature rise, making them ideal for high-amperage power distribution systems. These Copper Cable Lugs feature precision-formed cable entry barrels with internal serrations that create multiple contact points for enhanced electrical contact and mechanical grip. The oxygen-free high-conductivity Copper construction ensures long-term reliability in power generation, transmission, and heavy industrial applications where electrical performance is paramount.

Bronze Electrical Lugs

Bronze Electrical Lugs engineered for high-voltage transmission and distribution applications where both electrical performance and mechanical strength are critical requirements. These specialized electrical connectors utilize phosphor Bronze and aluminum Bronze alloys that provide superior fatigue resistance and thermal cycling performance compared to standard Bronze formulations. Our Bronze Electrical Lugs incorporate advanced barrel designs with optimized compression zones that accommodate both stranded and solid conductors while maintaining consistent contact pressure over extended service life.

Bronze Mechanical Lugs

Bronze Mechanical Lugs designed for applications requiring exceptional mechanical strength and vibration resistance in addition to electrical conductivity. These robust connectors feature reinforced palm sections and heavy-duty bolt configurations capable of withstanding mechanical stress in mobile equipment, mining machinery, and transportation applications. Our Bronze Mechanical Lugs incorporate strain relief features and enhanced barrel wall thickness to prevent conductor pullout and maintain electrical integrity under dynamic loading conditions.

Bronze Terminal Lugs

Bronze Terminal Lugs specifically manufactured for control panel and switchboard termination applications where space constraints and aesthetic appearance are important considerations. These compact electrical connectors feature streamlined profiles and multiple palm configurations including straight, angled, and offset designs to accommodate various installation geometries. Our Bronze Terminal Lugs undergo precision machining and surface finishing processes that ensure consistent electrical contact and professional appearance in visible installations.

Bronze Cable Lugs

Bronze Cable Lugs engineered for heavy-duty cable termination in power cables, welding applications, and high-current DC systems. These robust electrical connectors feature extended barrel lengths and reinforced construction to accommodate large conductor sizes and multiple cable terminations. Our Bronze Cable Lugs incorporate advanced sealing features and corrosion-resistant finishes that provide reliable performance in outdoor and harsh environmental conditions where moisture and chemical exposure are concerns.

Bronze Compression Lugs

Bronze Compression Lugs combine the reliability of mechanical compression with the reusability advantages of bolted connections, featuring innovative hybrid designs for specialized applications. These unique electrical connectors incorporate compression-style barrel entry with bolt-secured palm connections, providing the benefits of both connection methods. Our Bronze Compression Lugs are particularly suited for applications requiring frequent maintenance access while maintaining the electrical performance characteristics of permanent compression connections.

Bronze Bolt-on Connectors

Bronze Bolt-on Connectors encompass a comprehensive range of electrical joining devices including parallel groove clamps, tap connectors, and splice connectors manufactured from corrosion-resistant Bronze alloys. These versatile electrical connectors feature multiple bolt configurations and conductor accommodation ranges suitable for overhead line construction, substation installations, and industrial power distribution systems. Our Bronze Bolt-on Connectors incorporate weather-resistant finishes and precision threading that ensures reliable mechanical and electrical connections throughout extended service life.

Bronze Stud Type Lugs

Bronze Stud Type Lugs feature integrated threaded studs and specialized mounting configurations for direct equipment termination and busbar connections. These precision-engineered electrical connectors eliminate the need for separate mounting hardware while providing secure mechanical attachment and optimal electrical contact. Our Bronze Stud Type Lugs are available in various stud lengths, thread pitches, and palm configurations to match specific equipment requirements and installation constraints in switchgear, motor control centers, and power distribution panels.

Material Grades and Specifications

Copper Alloy Grades

| Grade | Standard | Composition | Conductivity (%IACS) | Application |

|---|---|---|---|---|

| C11000 (ETP) | ASTM B152 | 99.90% Cu min | 101 | High conductivity applications |

| C10100 (OFE) | ASTM B152 | 99.99% Cu min | 103 | Premium electrical connectors |

| C10200 (OF) | ASTM B152 | 99.95% Cu min | 102 | Oxygen-free applications |

| CW004A | EN 13601 | 99.90% Cu min | 100 | European standard Copper |

| T2 | GB/T 5231 | 99.90% Cu min | 100 | Chinese standard Copper |

Bronze Alloy Grades

| Grade | Standard | Composition | Conductivity (%IACS) | Application |

|---|---|---|---|---|

| C51000 | ASTM B103 | Cu-5%Sn-0.2%P | 15 | Phosphor Bronze springs |

| C52100 | ASTM B103 | Cu-8%Sn-0.4%P | 12 | High strength Bronze lugs |

| C95400 | ASTM B505 | Cu-11%Al-4%Fe | 8 | Aluminum Bronze connectors |

| CAC703 | JIS H3250 | Cu-7%Sn-0.3%P | 13 | Japanese phosphor Bronze |

| CuSn8 | DIN 17662 | Cu-8%Sn | 11 | German tin Bronze standard |

Brass Alloy Grades

| Grade | Standard | Composition | Conductivity (%IACS) | Application |

|---|---|---|---|---|

| C26000 | ASTM B134 | Cu-30%Zn | 27 | Cartridge Brass lugs |

| C36000 | ASTM B16 | Cu-36%Zn-3%Pb | 26 | Free machining Brass |

| C46400 | ASTM B111 | Cu-40%Zn-1%Sn | 23 | Naval Brass connectors |

| CuZn37 | EN 12163 | Cu-37%Zn | 27 | European standard Brass |

| H62 | GB/T 4423 | Cu-38%Zn | 26 | Chinese standard Brass |

Manufacturing Processes and Machinery

Our advanced manufacturing facility employs multiple precision processes to produce high-quality Bronze Bolted Lugs and Copper Bolted Lugs that meet stringent electrical and mechanical specifications. The manufacturing process begins with hot forging operations using hydraulic presses ranging from 100-500 tons capacity to form the basic lug geometry from premium alloy billets. Subsequently, CNC machining centers including 4-axis and 5-axis equipment perform precision boring, drilling, and contouring operations to achieve exact dimensional tolerances and surface finishes required for electrical applications.

Progressive die stamping operations utilize custom tooling for high-volume production of standardized lug configurations, while investment casting processes enable complex geometries and specialized alloy compositions for custom Bronze Terminal Lugs and Copper Cable Lugs. Our barrel forming operations employ specialized mandrels and hydraulic expansion equipment to create the internal corrugations that enhance conductor grip and electrical contact area. Final machining operations include thread cutting, hole drilling, and surface preparation using precision equipment that maintains tolerances within ±0.05mm for critical dimensions.

Technical Drawing – Bolted Lug Configuration

Cable Entry BarrelPalm SectionBolt ConnectionBolted Lug Cross-Section View

Dimensional Specifications and Tolerances

| Cable Size (mm²) | Stud Size (mm) | Dimension A (mm) | Dimension B (mm) | Dimension C (mm) | Dimension G (mm) | Tolerance |

|---|---|---|---|---|---|---|

| 16-25 | M8 | 45 | 25 | 6 | 30 | ±0.1 |

| 35-50 | M10 | 52 | 28 | 7 | 35 | ±0.1 |

| 70-95 | M12 | 58 | 32 | 8 | 38 | ±0.15 |

| 120-150 | M16 | 68 | 35 | 9 | 42 | ±0.15 |

| 185-240 | M16 | 76 | 38 | 10 | 45 | ±0.2 |

| 300-400 | M20 | 85 | 42 | 12 | 50 | ±0.2 |

International Standards Compliance

| Standard | Description | Application Region | Key Requirements |

|---|---|---|---|

| IS 5082 | Copper and Copper Alloy Lugs | India | Material composition, dimensions, testing |

| BS 4579 | Cable Lugs for Electrical Purposes | United Kingdom | Mechanical and electrical performance |

| ASTM B355 | Nickel and Nickel Alloy Bolting Materials | USA | Corrosion resistance, strength |

| DIN 46234 | Cable Lugs and Cable Connectors | Germany/Europe | Dimensional accuracy, conductivity |

| JIS C 2316 | Cable Connecting Hardware | Japan | Temperature cycling, vibration resistance |

| IEC 61238-1 | Compression and Mechanical Connectors | International | Type testing, performance verification |

Performance Metrics and Technical Parameters

| Parameter | Bronze Lugs | Copper Lugs | Brass Lugs | Test Method |

|---|---|---|---|---|

| Electrical Conductivity (%IACS) | 8-15 | 100-103 | 23-27 | ASTM B193 |

| Tensile Strength (MPa) | 400-600 | 220-240 | 300-450 | ASTM B557 |

| Operating Temperature (°C) | -55 to +150 | -55 to +100 | -55 to +120 | IEC 60068 |

| Contact Resistance (μΩ) | 15-25 | 5-10 | 10-20 | ASTM B539 |

| Corrosion Resistance | Excellent | Good | Very Good | ASTM B117 |

Industries and Applications

Our Bronze Bolted Lugs, Copper Bolted Lugs, and Brass Bolted Lugs serve critical applications across diverse industries requiring reliable electrical connections. The power generation sector utilizes our electrical connectors in thermal power plants, hydroelectric facilities, nuclear installations, and renewable energy systems including solar photovoltaic arrays and wind turbine installations. Transmission and distribution utilities rely on our bolted lugs for substation equipment, overhead line terminations, underground cable systems, and switchyard applications where long-term reliability and minimal maintenance requirements are essential.

The industrial manufacturing sector employs our electrical connectors in motor control centers, variable frequency drives, welding equipment, and heavy machinery where robust mechanical connections and high current carrying capacity are required. Marine and offshore applications benefit from the superior corrosion resistance of our Bronze alloy lugs in shipbuilding, offshore platforms, port facilities, and coastal infrastructure projects. Transportation infrastructure including railways, airports, and urban transit systems utilize our electrical connectors for traction power systems, signaling equipment, and ground support installations.

Manufacturing Excellence Infographic

Quality Control and Testing Procedures

Our comprehensive quality assurance program ensures every Bronze Bolted Lug and Copper Bolted Lug meets stringent performance standards before shipment. Incoming material inspection includes chemical composition analysis using X-ray fluorescence spectroscopy, mechanical property verification through tensile testing, and dimensional verification of raw material stock. In-process quality control involves coordinate measuring machine (CMM) inspection of critical dimensions, surface roughness measurement, and bolt hole concentricity verification using precision gauging equipment.

Final electrical testing encompasses contact resistance measurement, conductivity verification, and dielectric strength testing for all electrical connector variants. Mechanical testing protocols include bolt torque verification, pull-out strength testing, and vibration resistance evaluation according to relevant international standards. Our quality management system maintains full traceability from raw material lot numbers through final inspection records, ensuring complete documentation for critical electrical infrastructure applications.

Surface Finishes and Protective Coatings

Our comprehensive range of surface finishes for Bronze Bolted Lugs and Copper Bolted Lugs provides enhanced corrosion protection, improved electrical conductivity, and extended service life in demanding environmental conditions. Electroplating processes utilize advanced plating lines with precise current control, temperature regulation, and chemical composition monitoring to ensure uniform coating thickness and optimal adhesion characteristics across all product surfaces.

| Finish Type | Process | Thickness (μm) | Corrosion Resistance | Application |

|---|---|---|---|---|

| Natural Oxide | Atmospheric oxidation | 0.1-0.5 | Standard | Indoor electrical panels |

| Tin Plating | Electroplating | 5-15 | Enhanced | Outdoor applications |

| Nickel Plating | Electroplating | 10-25 | Superior | Marine environments |

| Silver Plating | Electroplating | 2-8 | Excellent conductivity | High-frequency applications |

| Passivation | Chemical treatment | 0.01-0.1 | Improved | Stainless steel compatibility |

| Chromate Conversion | Chemical treatment | 0.1-1.0 | Enhanced | Aluminum alloy compatibility |

Current Capacity Ratings and Temperature Derating

| Cable Size (mm²) | Copper Lugs (Amperes) | Bronze Lugs (Amperes) | Brass Lugs (Amperes) | Ambient Temp Rating |

|---|---|---|---|---|

| 16 | 85 | 65 | 70 | 30°C |

| 25 | 115 | 85 | 95 | 30°C |

| 35 | 140 | 105 | 120 | 30°C |

| 50 | 175 | 130 | 150 | 30°C |

| 70 | 225 | 170 | 190 | 30°C |

| 95 | 275 | 205 | 235 | 30°C |

| 120 | 320 | 240 | 275 | 30°C |

| 150 | 370 | 280 | 315 | 30°C |

| 185 | 425 | 320 | 365 | 30°C |

| 240 | 515 | 385 | 440 | 30°C |

Frequently Asked Questions – Technical Q&A

Q1: What is the difference between Bronze Bolted Lugs and Copper Bolted Lugs in terms of electrical performance?

A: Copper Bolted Lugs offer superior electrical conductivity (100-103% IACS) compared to Bronze Bolted Lugs (8-15% IACS), making Copper ideal for high-current applications. However, Bronze provides better mechanical strength and corrosion resistance, making it suitable for harsh environmental conditions where durability is more critical than maximum conductivity.

Q2: Can Bronze Bolted Lugs be used in marine applications?

A: Yes, Bronze Bolted Lugs are excellent for marine applications due to their superior corrosion resistance to saltwater environments. Aluminum Bronze and phosphor Bronze alloys provide exceptional performance in coastal and offshore installations where standard Copper connectors may experience accelerated corrosion.

Q3: What torque specifications should be used for installation of bolted lugs?

A: Torque specifications vary by stud size: M8 studs require 10-12 Nm, M10 studs require 18-22 Nm, M12 studs require 30-35 Nm, M16 studs require 60-70 Nm, and M20 studs require 95-110 Nm. Always use calibrated torque tools and apply thread-locking compound for permanent installations.

Q4: How do you determine the correct cable size range for specific lug models?

A: Cable size selection depends on conductor cross-sectional area, stranding configuration, and insulation thickness. Our Bronze Cable Lugs and Copper Cable Lugs accommodate ranges typically spanning 50-70% of the maximum rating to ensure proper compression and electrical contact without overstressing the barrel material.

Q5: What quality certifications do your bolted lugs carry?

A: Our electrical connectors are manufactured under ISO 9001:2015 quality management systems and comply with international standards including IS 5082, BS 4579, ASTM B355, DIN 46234, and JIS C 2316. Material certificates and test reports are provided with each shipment for traceability.

Q6: Can bolted lugs be reused after disconnection?

A: Yes, bolted lugs are designed for multiple use cycles. Bronze Bolted Lugs and Copper Bolted Lugs can typically be reused 15-20 times when properly installed and removed using correct procedures. Inspect barrel condition and bolt threads before reuse to ensure continued reliability.

Q7: What is the current carrying capacity of different alloy types?

A: Current capacity depends on cable size, ambient temperature, and installation method. Copper Bolted Lugs provide the highest capacity due to superior conductivity, while Bronze Bolted Lugs offer approximately 40-60% of Copper capacity but with enhanced mechanical properties for demanding applications.

Q8: How do you prevent galvanic corrosion when connecting dissimilar metals?

A: Use appropriate plating finishes such as tin or nickel plating, apply joint compound specifically designed for electrical connections, and consider the galvanic series when selecting lug materials. Bronze lugs are particularly suitable for connections to aluminum conductors due to reduced galvanic potential difference.

Q9: What manufacturing lead times can you provide for custom specifications?

A: Standard Bronze Bolted Lugs and Copper Bolted Lugs ship within 4-6 weeks from order confirmation. Custom specifications including special alloys, dimensions, or plating finishes typically require 6-8 weeks. Rush orders can be accommodated with expedited processing for critical applications.

Q10: Do you provide material traceability documentation?

A: Yes, complete material traceability is provided including mill test certificates for base alloys, chemical composition analysis, mechanical property test results, and dimensional inspection reports. This documentation meets requirements for nuclear, aerospace, and other critical infrastructure applications.

Q11: What packaging options are available for international shipping?

A: We offer customized packaging with customer labels and logos, moisture-resistant packaging for marine shipments, and specialized protective packaging for delicate plated finishes. Standard packaging includes individual poly bags, corrugated cartons, and wooden crates for large quantities with complete export documentation.

Q12: Can you manufacture bolted lugs for high-temperature applications?

A: Yes, we manufacture specialized high-temperature Bronze Bolted Lugs using refractory alloys capable of operating at temperatures up to 300°C. These applications include furnace connections, industrial heating equipment, and high-temperature motor terminations requiring enhanced thermal stability.

Why Choose Our Bronze and Copper Bolted Lugs

Manufacturing Excellence

Our three decades of global manufacturing experience in electrical connectors ensures proven expertise in Bronze Bolted Lugs and Copper Bolted Lugs production. Advanced CNC machining capabilities and precision tooling deliver consistent dimensional accuracy and surface finishes that exceed industry standards. Our integrated manufacturing approach from alloy selection through final inspection guarantees superior quality control and traceability throughout the production process.

Customization Capabilities

We offer extensive customization options including special alloy compositions, unique dimensional requirements, custom plating finishes, and application-specific design modifications. Our engineering team works closely with customers to develop optimized solutions for specialized electrical connector requirements including extreme temperature, high-vibration, and corrosive environment applications.

Global Supply Chain Excellence

Our worldwide distribution network ensures reliable delivery of Bronze Terminal Lugs and Copper Cable Lugs to projects across six continents. Strategically located inventory centers reduce lead times while comprehensive export documentation and customs expertise streamline international shipping processes for electrical infrastructure projects.

Technical Support Services

Our experienced technical team provides comprehensive application engineering support including connector selection guidance, installation procedure development, and troubleshooting assistance. We offer on-site consultation services, training programs, and technical documentation customized for specific project requirements and industry applications.

Customer Testimonial

“We have been using Bronze Bolted Lugs and Copper Bolted Lugs from this manufacturer for our utility substation projects across the southeastern United States for over eight years. Their consistent quality, reliable delivery schedules, and exceptional technical support have made them our preferred supplier. The dimensional accuracy and finish quality of their electrical connectors consistently exceed our specifications, and their willingness to accommodate custom requirements has been invaluable for our specialized applications. We particularly appreciate their comprehensive material documentation and traceability records that meet our stringent quality requirements.”

– Michael Richardson, Senior Electrical Engineer, Autralia

Packaging and Shipping Solutions

Our comprehensive packaging solutions for Bronze Bolted Lugs and Copper Bolted Lugs are designed to protect electrical connectors during international transportation while providing convenient handling for installation teams. Individual component packaging utilizes anti-static poly bags with desiccant packets to prevent moisture absorption and oxidation during extended storage periods. Bulk packaging options include segregated compartment boxes with foam inserts that prevent component damage and facilitate organized inventory management at job sites.

Export packaging specifications comply with international shipping regulations including ISPM-15 heat-treated wooden crates for overseas shipments, corrosion-preventive packaging for marine environments, and specialized handling instructions for plated electrical connectors. We provide customized packaging with customer logos and labeling to support distributor requirements and project-specific identification needs. Complete export documentation includes commercial invoices, packing lists, certificates of origin, and material compliance declarations required for customs clearance and project documentation.

Material Properties Comparison

| Property | Bronze Alloys | Copper Alloys | Brass Alloys | Units |

|---|---|---|---|---|

| Density | 8.7-8.9 | 8.9-8.96 | 8.4-8.7 | g/cm³ |

| Melting Point | 950-1050 | 1083 | 900-940 | °C |

| Thermal Conductivity | 25-85 | 390-401 | 100-120 | W/m·K |

| Coefficient of Expansion | 17-18 | 16.5 | 19-21 | ×10⁻⁶/°C |

| Elastic Modulus | 100-120 | 110-128 | 97-110 | GPa |

| Hardness (Brinell) | 150-200 | 45-85 | 60-150 | HB |

Unique Selling Propositions

Our competitive advantages in Bronze Bolted Lugs and Copper Bolted Lugs manufacturing stem from decades of specialized experience in electrical connector production combined with continuous investment in advanced manufacturing technology. Our flexibility in production scheduling allows accommodation of urgent project requirements and custom delivery schedules that align with construction timelines and maintenance windows. Comprehensive customization capabilities enable modifications to standard designs including special alloy compositions, unique dimensional requirements, and application-specific features not available from standard catalog suppliers.

Our global supply chain expertise ensures reliable delivery to international projects with comprehensive logistics support and expedited shipping options for critical applications. Technical engineering support provides customers with application-specific guidance, installation procedures, and troubleshooting assistance that reduces project risks and ensures optimal performance. Our commitment to sustainable manufacturing practices includes recycling programs for metal waste, energy-efficient production processes, and environmental management systems that support customer sustainability objectives.

Turnaround Time and Production Scheduling

Our standard production schedule for Bronze Bolted Lugs and Copper Bolted Lugs maintains a consistent 4-6 week turnaround time from order confirmation to shipment for catalog items and standard specifications. This timeline includes material procurement, manufacturing operations, quality inspection, surface finishing, and packaging processes optimized for reliability and efficiency. Expedited production options are available for urgent projects requiring accelerated delivery schedules, with rush orders typically completed within 2-3 weeks depending on quantity and specification complexity.

Custom Bronze Terminal Lugs and specialized Copper Cable Lugs requiring engineering design, tooling fabrication, or unique alloy compositions may extend lead times to 6-8 weeks to ensure proper development and testing procedures. Our production planning system maintains buffer inventory for common alloy grades and sizes, enabling faster response times for repeat orders and standard configurations. Blanket order programs provide customers with reserved production capacity and scheduled delivery releases that support annual procurement planning and inventory management requirements.

Glossary of Technical Terms

| Term | Definition |

|---|---|

| IACS (International Annealed Copper Standard) | Standard measurement for electrical conductivity where pure Copper = 100% |

| Bolted Lug | Electrical connector using mechanical bolt fastening for cable termination |

| Palm Section | Flat connection area of lug containing bolt hole for equipment attachment |

| Barrel Entry | Cylindrical section of lug that accepts and grips the cable conductor |

| Contact Resistance | Electrical resistance at the interface between connector and conductor |

| Corrugated Barrel | Internal surface texture providing enhanced grip and electrical contact |

| Galvanic Corrosion | Electrochemical corrosion between dissimilar metals in electrical contact |

| Tin Plating | Protective coating applied to prevent oxidation and improve conductivity |

Related Parts:

Electrical Connectors

Cable lugs, terminal lugs, compression lugs, mechanical lugs, electrical terminals, wire connectors, cable terminals, power connectors, electrical hardware, connector accessories

Materials and Alloys

Bronze alloys, Copper alloys, Brass alloys, phosphor Bronze, tin Bronze, aluminum Bronze, electrical Copper, high conductivity Copper, leaded Brass, naval Brass

Applications

Power distribution, electrical panels, switchgear connections, transformer terminals, motor connections, grounding lugs, busbar connectors, cable splicing, electrical maintenance

Request Your Custom Quote Today

Get expert consultation and competitive pricing for your Bronze Bolted Lugs and Copper Bolted Lugs requirements

📧 Email Quote Request

Send your specifications to:

sales@brass-copper-parts. com

📱 WhatsApp Inquiry

Quick response via:

+91-22-43449300

📋 Technical Brochure

Download complete specifications and technical data sheets

☎️ Direct Contact

Speak with our technical team:

+91-22-43449300

Our technical team responds to all inquiries within 24 hours with detailed quotations, technical recommendations, and delivery schedules tailored to your project requirements.

Manufactured in India | Exported Worldwide | ISO 9001:2015 Certified | 30+ Years Experience

Premium Bronze Bolted Lugs, Copper Bolted Lugs & Brass Bolted Lugs for Global Electrical Infrastructure