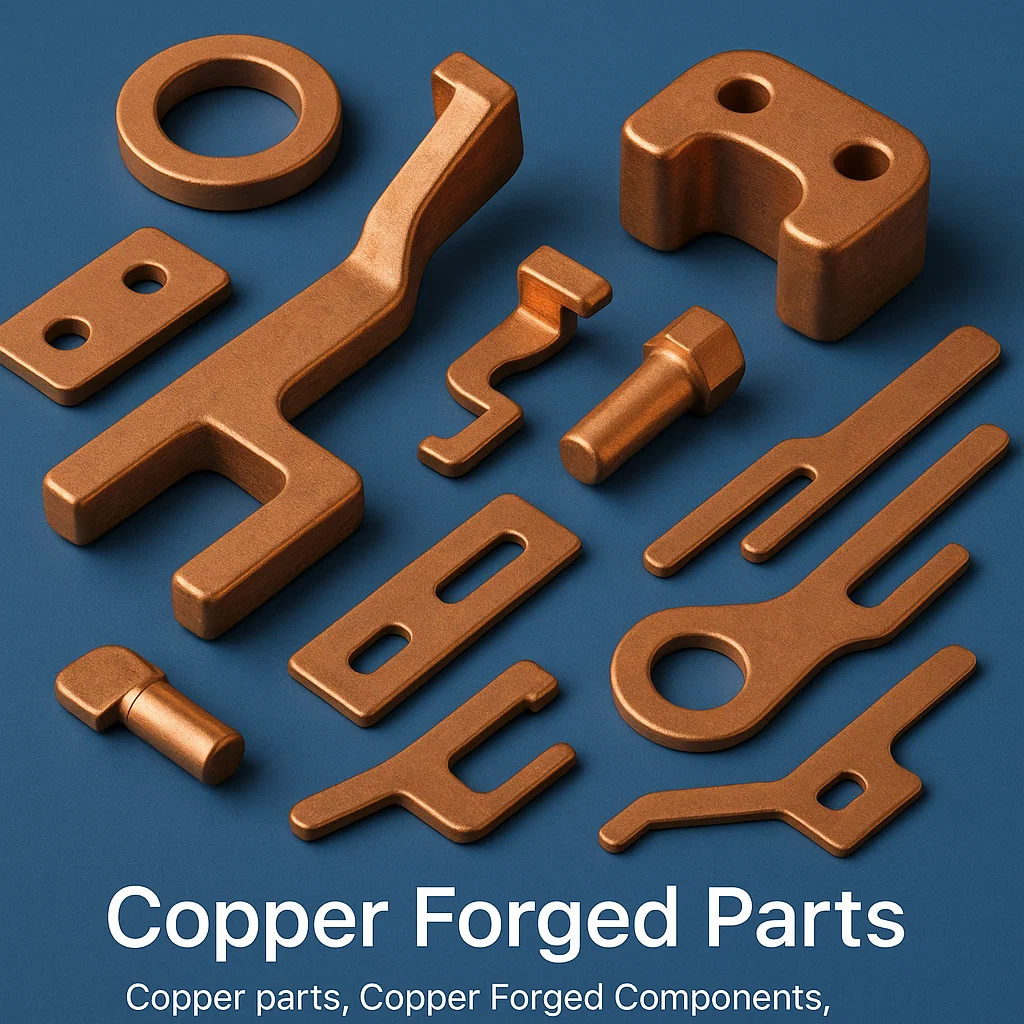

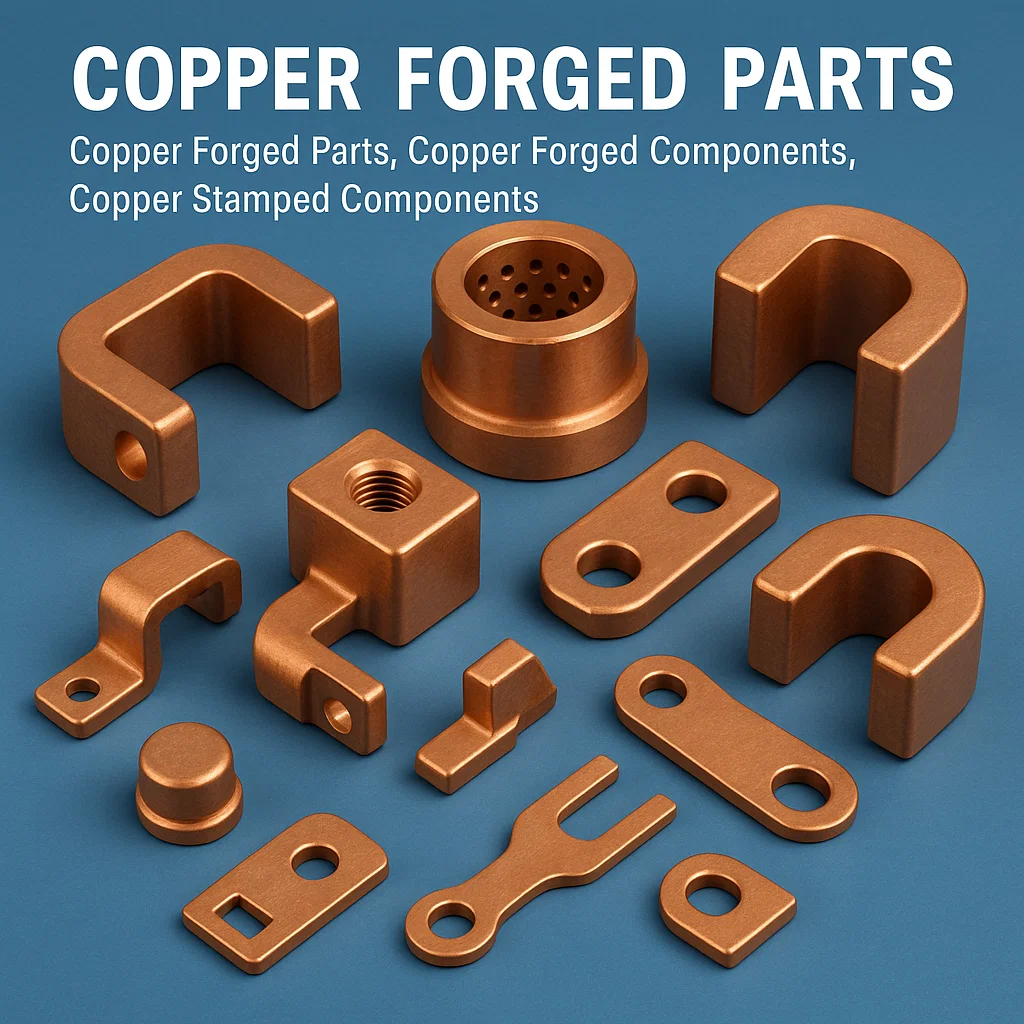

Copper Forging, Copper Forged Parts & Copper Stamped Components

Premium Copper Forging and Copper Stamping: Precision Copper Stamped Parts, Copper Forged parts

We are one of the leading manufacturers and exporters of Copper forging, Copper forged parts, and Copper stamped components from India. We have been supplying precision-engineered Copper components to the world market for many decades. Our comprehensive manufacturing capabilities encompass hot forging, cold forging, impact extrusion, progressive stamping, and CNC machining of Copper alloys. With state-of-the-art facilities and ISO 9001:2015 certification, we deliver high-quality Copper forged parts that meet stringent international standards including ASTM, DIN, JIS, and BS specifications. Our experienced engineering team specializes in custom Copper component design and manufacturing, serving diverse industries including electrical, plumbing, automotive, aerospace, and marine applications. Leveraging three decades of global manufacturing experience, we provide cost-effective solutions with exceptional dimensional accuracy and surface finish quality. Our advanced metallurgical processes ensure optimal material properties while maintaining competitive lead times and comprehensive quality assurance throughout the production cycle.

Overview of Copper Forging & Manufacturing

Copper forging represents a critical metalworking process that transforms raw Copper materials into complex geometries through controlled deformation under high pressure and temperature. This manufacturing technique enhances the mechanical properties of Copper alloys, improving grain structure, eliminating porosity, and achieving superior strength-to-weight ratios compared to cast alternatives. Our comprehensive Copper forging capabilities include upset forging, drop forging, press forging, and roll forging processes, each optimized for specific component geometries and production volumes.

The versatility of Copper forging extends across multiple industrial applications, from precision electrical components requiring excellent conductivity to corrosion-resistant marine hardware demanding superior durability. Advanced forging techniques enable the production of complex shapes with minimal material waste, reduced machining requirements, and enhanced metallurgical properties. Our integrated approach combines traditional forging expertise with modern computer-aided design and finite element analysis to optimize die design and process parameters.

Copper Forging

Copper forging involves the plastic deformation of Copper billets and bars under controlled temperature and pressure conditions to produce near-net-shape components. This process leverages Copper’s exceptional malleability and ductility, enabling the creation of complex geometries with superior mechanical properties. Hot forging temperatures typically range from 750°C to 950°C, optimizing material flow while preventing grain growth. Cold forging operations performed at ambient temperatures achieve exceptional surface finish and dimensional accuracy. Our forging capabilities include open-die forging for large components, closed-die forging for precision parts, and seamless forging for hollow components. Advanced process control systems monitor temperature, pressure, and deformation rates to ensure consistent quality and optimal material utilization throughout the forging cycle.

Copper Forged Parts

Copper forged parts demonstrate superior mechanical properties compared to machined or cast alternatives, featuring enhanced grain flow alignment, improved fatigue resistance, and elimination of internal porosity. Our comprehensive range includes valve bodies, pipe fittings, electrical terminals, heat exchanger components, and marine hardware. Precision forging operations achieve dimensional tolerances of ±0.1mm with surface roughness values as low as Ra 1.6μm. Multi-stage forging sequences enable complex geometries while maintaining material integrity and optimizing production efficiency. Secondary operations including heat treatment, machining, and surface finishing ensure final components meet exact customer specifications. Quality assurance protocols include dimensional inspection, material testing, and performance validation according to relevant international standards.

Copper Stamped Components

Copper stamped components encompass a wide range of precision-formed parts produced through progressive stamping, deep drawing, and blanking operations. High-speed stamping presses operating at speeds up to 800 strokes per minute enable cost-effective production of complex geometries with exceptional repeatability. Advanced die design incorporating carbide cutting edges and precision guide systems ensures consistent edge quality and dimensional accuracy. Progressive stamping operations combine multiple forming stages within a single press cycle, optimizing material utilization and production throughput. Our stamping capabilities include thickness ranges from 0.1mm to 10mm with forming depths up to 150mm for deep-drawn components. Specialized tooling for perforating, coining, and embossing operations expands the range of achievable features and surface textures.

Copper Hot Forging

Copper hot forging operations utilize elevated temperatures between 750°C and 950°C to enhance material plasticity and reduce forming forces. Induction heating systems provide precise temperature control with uniform heat distribution throughout the workpiece. Hot forging enables the production of large, complex components with significant cross-sectional changes while maintaining excellent material properties. Controlled atmosphere furnaces prevent oxidation and decarburization during heating cycles. Automated material handling systems ensure consistent heating times and optimal temperature uniformity. Post-forging cooling rates are carefully controlled to achieve desired microstructures and mechanical properties. Hot forging operations are particularly effective for high-volume production of components requiring extensive material flow and complex three-dimensional geometries.

Copper Hot Stamped Parts

Copper hot stamped parts combine the benefits of elevated temperature forming with precision stamping operations to achieve complex geometries with enhanced material properties. Hot stamping temperatures typically range from 400°C to 700°C, optimizing formability while maintaining dimensional stability. Heated die systems ensure uniform temperature distribution and prevent premature cooling during forming operations. This process is particularly effective for high-strength Copper alloys that require elevated temperatures for optimal formability. Integrated heating and forming systems minimize handling time and maintain consistent part quality. Hot stamped components exhibit improved grain structure, reduced residual stresses, and enhanced fatigue performance compared to cold-formed alternatives. Applications include automotive electrical components, aerospace fittings, and high-performance heat exchanger elements.

Copper Hot Stamped and CNC Machined Parts

Copper hot stamped and CNC machined parts represent the pinnacle of precision manufacturing, combining the enhanced material properties of hot forming with the dimensional accuracy of computer-controlled machining. Initial hot stamping operations create near-net-shape blanks with optimized grain structure and reduced material waste. Subsequent CNC machining operations achieve final dimensions with tolerances as tight as ±0.025mm and surface finishes up to Ra 0.4μm. Multi-axis machining centers enable complex feature geometry including threaded holes, precision bores, and intricate surface profiles. Integrated manufacturing cells combine hot stamping and machining operations to minimize handling and optimize production flow. Advanced programming techniques optimize tool paths and cutting parameters for maximum efficiency and surface quality. Quality control systems include in-process measurement and statistical process control to ensure consistent dimensional accuracy throughout production runs.

Copper Impact Extrusion Parts

Copper impact extrusion parts are manufactured through high-velocity forming operations that combine the benefits of forging and extrusion processes. Impact extrusion utilizes a punch traveling at speeds up to 10 m/s to force Copper material through a shaped die, creating hollow components with exceptional wall thickness uniformity. This cold-forming process achieves remarkable dimensional accuracy with typical tolerances of ±0.05mm and excellent surface finish quality. Impact extrusion is particularly effective for producing thin-walled cylindrical components, complex internal geometries, and parts requiring superior material properties. The rapid deformation rates result in fine grain structure and enhanced mechanical properties compared to conventional forming methods. Applications include electrical enclosures, heat sink components, and precision fittings requiring leak-tight performance and dimensional stability under thermal cycling conditions.

Copper Forged Transformer Spades

These are engineered for the most demanding high-current applications within power transformers and heavy electrical switchgear. Unlike stamped alternatives, these components are manufactured through a hot forging process that subjects high-purity Electrolytic Tough Pitch Copper (CDA 110) to extreme pressure, aligning the metal’s grain flow to the contour of the spade. This process eliminates porosity and creates a denser, more robust part with superior mechanical strength and electrical conductivity. The inherent grain flow resulting from forging provides exceptional resistance to fatigue and stress cracking, which is critical for handling the immense electromagnetic forces and thermal cycling experienced in transformer applications. These forged spades often feature a tin-plated finish to prevent oxidation and ensure a stable, low-resistance connection, making them the preferred choice for permanent, ultra-reliable power connections in the electrical utility sector.

Copper Stamped Electrical Terminals

They represent the most common and versatile manufacturing method for producing a wide array of connector types, including spade, ring, and hook terminals. This high-volume process utilizes precision progressive dies mounted in high-tonnage presses to blank, pierce, and form sheets of copper alloy, such as CDA 110 Copper or CDA 220 Commercial Bronze, into the final desired shape. Stamping allows for excellent dimensional consistency, complex features, and very high production rates, making it extremely cost-effective for large orders of standard components. While the grain structure is cut rather than formed, these terminals are perfectly suited for the vast majority of electrical wiring applications in control panels, automotive harnesses, and consumer appliances. They can be easily tin-plated or selectively plated to enhance solderability and corrosion resistance, offering a reliable and economical solution for secure electrical connections.

Material Grades and Specifications

International Standards

ASTM: B124, B152, B187, B370, B624

DIN: 17670, 17672, 17850

BS: 2870, 2871, 2872, 2873, 2874

JIS: H3100, H3110, H3130

IS: 407, 410, 1545, 6912

USA Standards

UNS: C10100, C10200, C10300, C10400, C10500, C10700, C10800, C11000, C12000, C12200

ASTM B124: Grade ETP, DHP, FRHC

CDA: C101, C102, C103, C110, C120, C122

European Standards

EN: CW004A, CW008A, CW024A

DIN: CuETP, CuDHP, CuDLP

Material Numbers: 2.0040, 2.0060, 2.0070, 2.0080

Chinese Standards

GB/T: 5231, 13808, 17791

Grades: T1, T2, T3, TU0, TU1, TU2

YS: T/YS 683, T/YS 684

Japanese Standards

JIS H3100: C1020, C1100, C1201, C1220

JIS H3110: Tough pitch Copper grades

Special Grades: OFC (Oxygen-Free Copper)

Material Properties Table

| Property | Pure Copper (C10100) | ETP Copper (C11000) | DHP Copper (C12200) | Units |

|---|---|---|---|---|

| Density | 8.96 | 8.89 | 8.94 | g/cm³ |

| Melting Point | 1084 | 1083 | 1082 | °C |

| Electrical Conductivity | 101 | 101 | 85 | %IACS |

| Thermal Conductivity | 401 | 391 | 317 | W/m·K |

| Tensile Strength (Annealed) | 220 | 220 | 221 | MPa |

| Yield Strength (Annealed) | 69 | 69 | 69 | MPa |

| Elongation | 45 | 45 | 40 | % |

| Hardness (Vickers) | 45-50 | 40-80 | 40-85 | HV |

Manufacturing Processes and Machinery

Our state-of-the-art manufacturing facility incorporates advanced forging and stamping equipment designed for precision Copper component production. Primary manufacturing processes include mechanical press forging utilizing 500-ton to 2000-ton capacity hydraulic presses with precise load and position control. Screw press operations provide controlled energy delivery for complex forming operations, while hammer forging equipment enables rapid material deformation for specific component geometries.

| Equipment Type | Capacity Range | Precision Level | Applications |

|---|---|---|---|

| Hydraulic Press | 500-2000 tons | ±0.05mm | Precision forging, deep drawing |

| Mechanical Press | 100-800 tons | ±0.02mm | Progressive stamping, blanking |

| Screw Press | 200-1000 tons | ±0.1mm | Hot forging, upset operations |

| Impact Extrusion | 50-300 tons | ±0.03mm | Hollow components, thin walls |

| CNC Machining Centers | 5-axis capability | ±0.01mm | Secondary operations, finishing |

Typical Parts Produced

Our comprehensive manufacturing capabilities enable production of diverse Copper components across multiple industry sectors. Electrical applications include bus bars, terminals, connectors, and switch components requiring precise dimensional control and superior conductivity. Plumbing and HVAC applications encompass pipe fittings, valve bodies, heat exchanger tubes, and refrigeration components. Automotive applications include brake lines, electrical harnesses, radiator components, and heat sink assemblies.

Dimensional Capabilities Chart

| Component Type | Diameter Range (mm) | Length Range (mm) | Wall Thickness (mm) | Tolerance (±mm) |

|---|---|---|---|---|

| Forged Fittings | 10-300 | 15-500 | 2-50 | 0.1 |

| Stamped Terminals | 5-100 | 10-200 | 0.5-8 | 0.05 |

| Impact Extruded Parts | 8-150 | 20-300 | 0.8-5 | 0.03 |

| Hot Forged Components | 20-400 | 25-600 | 3-80 | 0.15 |

| CNC Machined Parts | 1-500 | 5-1000 | 0.2-100 | 0.01 |

Copper Manufacturing Process Flow

Raw Material → Heat Treatment → Forging/Stamping → Secondary Operations → Quality Control → Packaging → Shipping

Our integrated manufacturing process ensures optimal material utilization, consistent quality, and rapid turnaround times for all Copper component requirements.

Industries and Applications

Copper forged and stamped components serve critical functions across diverse industrial sectors, leveraging the material’s exceptional electrical conductivity, thermal properties, and corrosion resistance. The electrical and electronics industry represents our largest market segment, utilizing precision Copper components in power distribution systems, renewable energy applications, and electronic devices. Automotive applications continue expanding with increasing electrification, requiring high-performance Copper components for battery systems, charging infrastructure, and power electronics.

Marine and offshore applications demand superior corrosion resistance, where Copper alloys provide exceptional performance in saltwater environments. HVAC and refrigeration systems utilize Copper components for optimal heat transfer efficiency and long-term reliability. Aerospace applications require lightweight, high-conductivity components meeting stringent quality and traceability requirements. Industrial machinery applications include hydraulic fittings, heat exchangers, and specialized tooling components.

Surface Finishes and Tolerances

| Finish Type | Surface Roughness (Ra) | Dimensional Tolerance | Applications |

|---|---|---|---|

| As-Forged | 3.2-6.3 μm | ±0.2mm | General applications, secondary machining |

| Machined | 0.4-1.6 μm | ±0.025mm | Precision assemblies, sealing surfaces |

| Polished | 0.1-0.4 μm | ±0.05mm | Electrical contacts, decorative applications |

| Pickled | 1.6-3.2 μm | ±0.1mm | Clean surface, oxide removal |

| Passivated | 0.8-1.6 μm | ±0.1mm | Corrosion protection, extended service life |

Performance Metrics and Quality Standards

Our comprehensive quality management system ensures consistent performance across all Copper forging and stamping operations. Statistical process control monitors critical parameters including dimensional accuracy, surface finish, mechanical properties, and material composition. Automated inspection systems utilize coordinate measuring machines, optical comparators, and digital micrometers to verify component conformance to specifications.

Material certification includes chemical analysis, mechanical testing, and metallurgical examination according to relevant international standards. Heat treatment processes are validated through hardness testing, microstructural analysis, and performance verification. Non-destructive testing methods including dye penetrant inspection and ultrasonic testing ensure component integrity for critical applications.

| Quality Parameter | Measurement Method | Acceptance Criteria | Frequency |

|---|---|---|---|

| Dimensional Accuracy | CMM, Optical measurement | Per drawing specification | 100% inspection |

| Surface Finish | Profilometer, Comparison samples | Ra ≤ specified value | Sample based |

| Chemical Composition | OES, XRF analysis | Per material standard | Per heat/batch |

| Mechanical Properties | Tensile testing, Hardness | Per specification | Statistical sampling |

| Visual Inspection | Trained inspector, Magnification | No defects per standard | 100% inspection |

Turnaround Time: 4-6 Weeks

Our streamlined manufacturing process delivers standard Copper forged and stamped components within 4-6 weeks from order confirmation. This timeline encompasses material procurement, production planning, manufacturing operations, quality inspection, and packaging preparation. Express delivery options are available for urgent requirements, with expedited processing reducing lead times to 2-3 weeks for standard component configurations.

Complex custom components requiring specialized tooling may extend lead times to 8-10 weeks, depending on design complexity and tooling requirements. Our production planning system optimizes scheduling to minimize delays and ensure on-time delivery performance exceeding 95%. Regular communication updates keep customers informed of production progress and any potential schedule adjustments.

Frequently Asked Questions

Why Choose Our Copper Forging Services

Competitive Advantages and Unique Value Proposition

Our three decades of global manufacturing experience in Copper component production provides unmatched expertise in complex geometry development and challenging application requirements. Superior customer communication capabilities ensure clear project understanding and seamless execution from initial inquiry through final delivery. Our flexibility in production scheduling accommodates urgent requirements and changing customer needs without compromising quality standards.

Comprehensive customization capabilities extend beyond standard component specifications to include specialized material grades, unique surface treatments, and application-specific testing requirements. Advanced engineering support services accelerate new product development through design optimization, manufacturability analysis, and cost reduction strategies. Our global supply chain network ensures reliable material availability and competitive pricing across international markets.

Customized packaging solutions protect components during transit while incorporating customer branding and labeling requirements. Our quality management system exceeds industry standards with comprehensive traceability, documentation, and performance validation. Competitive pricing structures reflect efficient manufacturing processes and strategic material procurement advantages.

Packaging and Shipping

Professional packaging protocols ensure component protection throughout international shipping and handling operations. Standard packaging includes anti-corrosion treatments, moisture barriers, and cushioned containers designed for optimal protection during extended transit periods. Custom packaging solutions accommodate specific customer requirements including branded containers, specialized labeling, and unique identification systems.

Export documentation services include certificates of origin, material test reports, inspection certificates, and customs declarations prepared by experienced logistics personnel. Our freight forwarding partnerships provide competitive shipping rates and reliable delivery performance to destinations worldwide. Tracking systems enable real-time shipment monitoring and proactive communication of delivery schedules.

| Packaging Option | Protection Level | Suitable For | Additional Services |

|---|---|---|---|

| Standard Export Packaging | Moisture/corrosion protection | Most applications | Basic labeling, documentation |

| Premium Protection | Enhanced cushioning, climate control | Precision components | Insurance, tracking, expedited handling |

| Custom Branded | Customer-specific requirements | OEM applications | Customer logos, specialized labeling |

| Bulk Industrial | Cost-optimized protection | High-volume orders | Palletized, fork-lift ready |

Customer Testimonial

“Working with this Indian manufacturer for our Copper forged electrical components has been exceptional. Their technical expertise, consistent quality, and reliable delivery performance have made them our preferred supplier for over five years. The engineering support they provide during new product development is invaluable, and their ability to meet tight deadlines while maintaining quality standards is impressive. – Michael Richardson, Procurement Manager, USA

Glossary of Terms

| Term | Definition |

|---|---|

| Hot Forging | Metal forming process performed at elevated temperatures (750-950°C for Copper) to enhance material plasticity and reduce forming forces |

| Impact Extrusion | High-velocity forming process combining forging and extrusion to create hollow components with exceptional wall thickness uniformity |

| Progressive Stamping | Multi-stage stamping process combining multiple operations (blanking, forming, piercing) in a single press cycle |

| Upset Forging | Forging process that increases cross-sectional area by compressing material along its length |

| ETP Copper | Electrolytic Tough Pitch Copper containing controlled oxygen content for optimal electrical conductivity |

| DHP Copper | Deoxidized High Phosphorus Copper with improved formability and weldability characteristics |

| Grain Flow | Directional arrangement of material grain structure following component geometry for enhanced mechanical properties |

| Work Hardening | Strengthening mechanism resulting from plastic deformation that increases material hardness and strength |

| Annealing | Heat treatment process to restore ductility and reduce internal stresses in work-hardened material |

| IACS | International Annealed Copper Standard used for measuring electrical conductivity relative to pure Copper |

Related parts:

Copper forging services, custom Copper components, Copper stamping manufacturers, precision Copper parts, electrical Copper components, Copper alloy forging, hot forged Copper fittings, Copper impact extrusion, CNC machined Copper parts, Copper component suppliers, industrial Copper applications, automotive Copper parts, marine Copper fittings, HVAC Copper components, electrical Copper terminals, Copper heat exchangers, forged Copper valves, stamped Copper brackets, Copper tube fittings, electrical bus bars, Copper grounding components, power distribution parts, renewable energy components, battery system parts, charging infrastructure components.

Contact Us for Your Copper Forging and Copper Stamping Requirements

Ready to discuss your Copper forging and stamping needs? Our experienced engineering team is available to provide technical consultation, cost estimates, and delivery schedules tailored to your specific requirements of Copper forging, Copper stamping and precision Copper forged parts, Copper stamped parts.

Request a Quote: sales@brass-copper-parts. com