Copper Gaskets , Copper Sealing Gaskets- Manufacturing Excellence

Price: US$ 12.30/kilogram

Professional Sealing Solutions for Industrial Applications

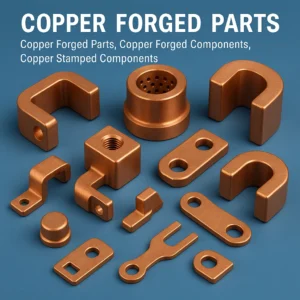

Overview – Copper Gaskets Manufacturing & Export

We are one of the leading manufacturers and exporters of Copper Gaskets from India. We have been supplying copper sealing solutions to the world market for many decades. Our comprehensive range of Copper Gaskets includes Pressed Copper Gaskets, Copper Engine Gaskets, Pure Copper Gaskets, Stamped Gaskets of Copper, Copper Ring Gaskets, and specialized Copper Sealing Gaskets designed for high-performance industrial applications. With over three decades of manufacturing expertise, we deliver precision-engineered copper gasket solutions that meet international quality standards including ASTM, DIN, BS, IS, and JIS specifications. Our state-of-the-art manufacturing facility in India combines traditional craftsmanship with modern technology to produce copper gaskets that excel in extreme temperature conditions, chemical resistance, and long-term reliability. From automotive engine applications to aerospace sealing requirements, our copper gaskets provide superior performance across diverse industries including petrochemical, power generation, marine, and heavy machinery sectors.

Types of Copper Gaskets – Detailed Product Range

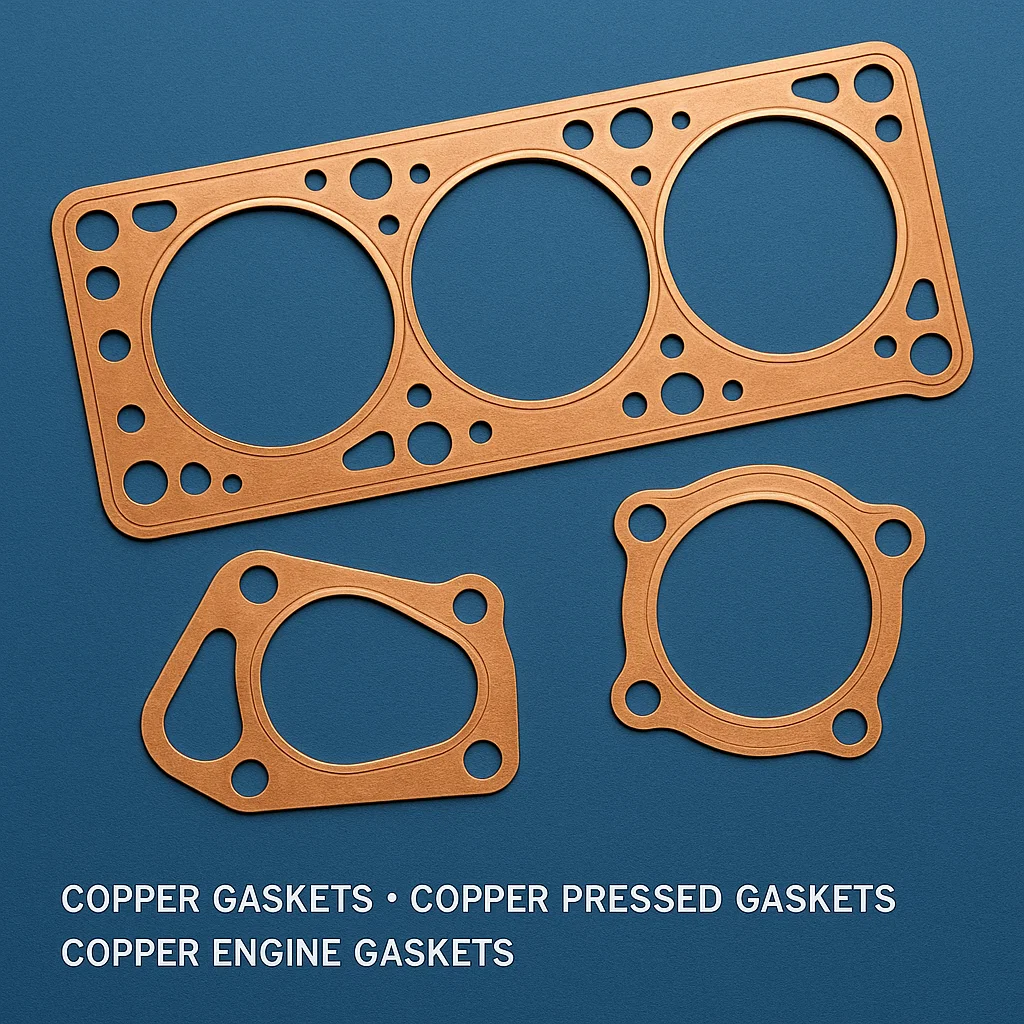

Standard Copper Gaskets

Our standard Copper Gaskets are manufactured from high-purity electrolytic Copper with excellent thermal conductivity and malleability properties. These gaskets are ideal for general sealing applications where moderate temperatures and pressures are encountered. The natural anti-seize properties of Copper make these gaskets perfect for applications requiring frequent assembly and disassembly. Standard Copper Gaskets are produced in various thicknesses ranging from 0.5mm to 6mm, with custom dimensions available to meet specific application requirements. These gaskets demonstrate excellent resistance to oxidation and provide reliable sealing performance in temperatures up to 250°C under normal atmospheric conditions.

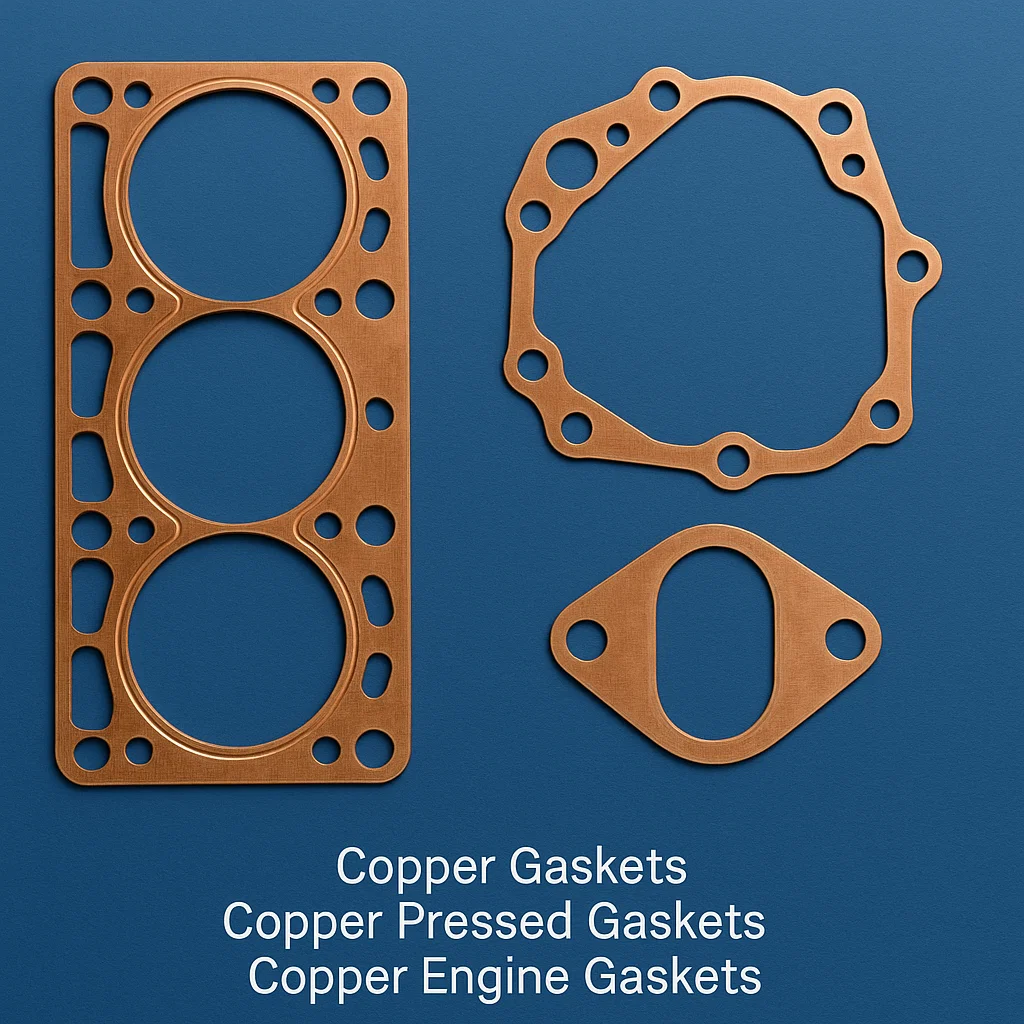

Pressed Copper Gaskets

Pressed Copper Gaskets are manufactured through precision hydraulic pressing operations that create uniform density and enhanced sealing characteristics. This manufacturing process eliminates internal voids and creates a homogeneous structure that improves the gasket’s ability to conform to mating surface irregularities. Our Pressed Copper Gaskets undergo controlled annealing processes to achieve optimal hardness levels between 40-60 HV, ensuring excellent sealing performance while maintaining sufficient flexibility for installation. These gaskets are extensively used in high-pressure hydraulic systems, steam applications, and industrial heat exchangers where consistent sealing performance is critical. The pressing process also enhances the gasket’s resistance to creep and relaxation under sustained loading conditions.

Copper Engine Gaskets

Specialized Copper Engine Gaskets are engineered specifically for automotive and marine engine applications where extreme temperature cycling and combustion pressures demand superior sealing performance. These gaskets are manufactured from high-purity Copper alloys with enhanced strength characteristics while maintaining excellent thermal conductivity for heat dissipation. Our Copper Engine Gaskets feature precision-machined sealing surfaces and are available with various edge treatments including rolled edges and reinforced borders for enhanced durability. These gaskets demonstrate exceptional resistance to combustion byproducts, coolant chemicals, and lubricating oils. Temperature resistance ranges from -40°C to 400°C, making them suitable for both gasoline and diesel engine applications across automotive, marine, and stationary power generation systems.

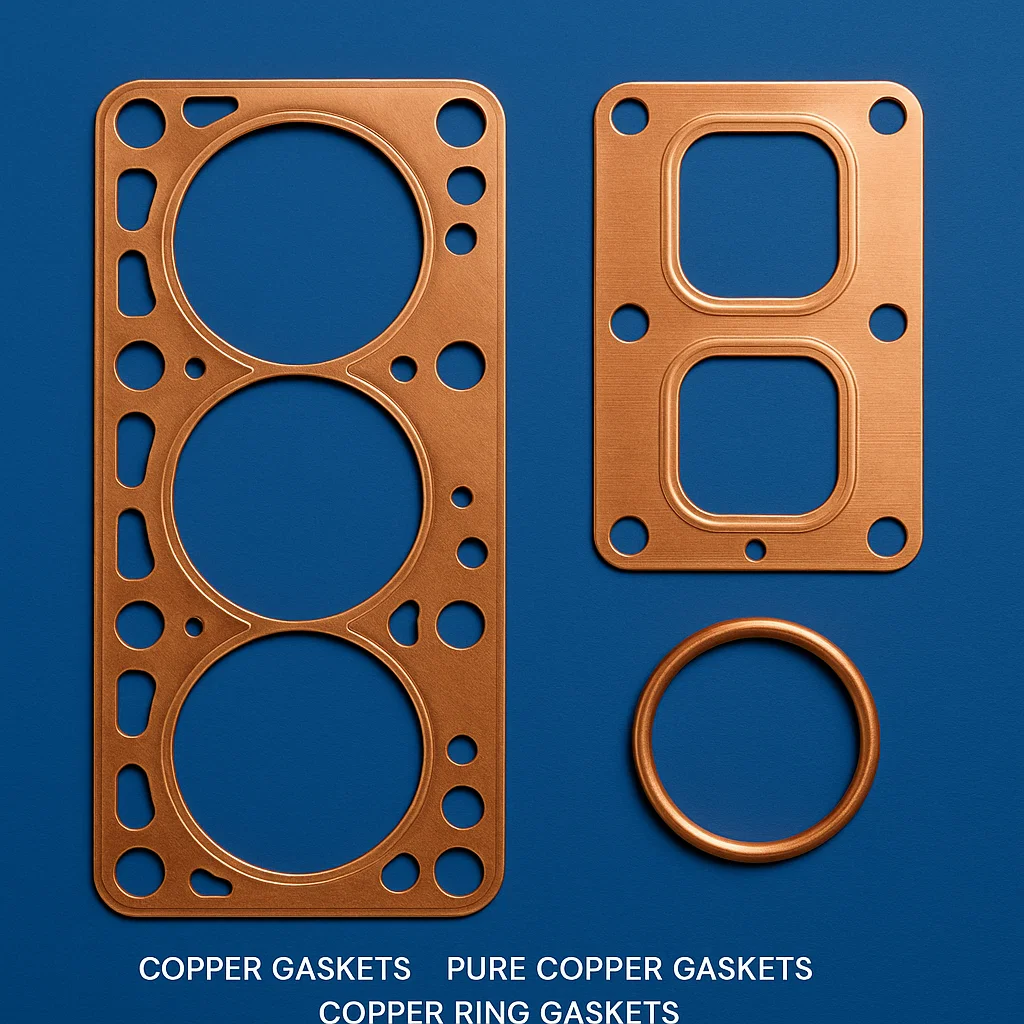

Pure Copper Gaskets

Pure Copper Gaskets manufactured from 99.9% electrolytic Copper offer the highest level of thermal and electrical conductivity available in copper sealing solutions. These gaskets are specifically designed for ultra-high vacuum applications, cryogenic systems, and precision instrumentation where contamination from alloying elements cannot be tolerated. Pure Copper Gaskets undergo specialized cleaning processes to remove all surface contaminants and are packaged in controlled environments to maintain purity levels. The exceptional malleability of pure Copper allows these gaskets to conform to extremely fine surface finishes, achieving vacuum levels below 10^-9 torr in properly designed systems. Applications include semiconductor manufacturing equipment, scientific instrumentation, and aerospace systems requiring absolute sealing integrity.

Stamped Gaskets of Copper

Stamped Gaskets of Copper are precision-manufactured through advanced progressive stamping operations using computer-controlled tooling systems. This manufacturing method ensures exceptional dimensional accuracy with tolerances as tight as ±0.05mm for critical dimensions. Our stamping capabilities include complex geometries, multiple hole patterns, and integrated sealing features such as embossed sealing beads and locating tabs. The stamping process work-hardens the Copper material, creating enhanced spring-back characteristics that improve sealing performance and gasket longevity. These gaskets are ideal for high-volume applications where consistent quality and cost-effectiveness are essential. Stamped Copper Gaskets are widely used in HVAC systems, plumbing applications, and industrial equipment where standardized sealing solutions provide optimal performance and reliability.

Copper Ring Gaskets

Copper Ring Gaskets are specialized annular sealing components designed for flanged connections in high-pressure and high-temperature applications. These gaskets feature precisely machined sealing surfaces and are available in various cross-sectional profiles including rectangular, oval, and octagonal configurations to optimize sealing performance for specific flange designs. Our Copper Ring Gaskets are manufactured to international standards including API 6A, ASME B16.20, and DIN 7603, ensuring compatibility with global piping systems. The superior deformation characteristics of Copper allow these ring gaskets to create effective seals at relatively low bolt loads while maintaining sealing integrity under pressure cycling conditions. Applications include oil and gas production equipment, chemical processing systems, and power generation facilities where reliable sealing under extreme conditions is mandatory.

Copper Sealing Gaskets

Specialized Copper Sealing Gaskets encompass our premium range of application-specific sealing solutions engineered for the most demanding industrial environments. These gaskets incorporate advanced design features such as controlled compression zones, integrated backup rings, and specialized surface treatments to optimize sealing performance. Our engineering team collaborates closely with customers to develop custom Copper Sealing Gaskets that address unique application challenges including extreme temperature gradients, aggressive chemical environments, and dynamic sealing requirements. These gaskets undergo rigorous testing protocols including pressure cycling, temperature cycling, and chemical compatibility testing to ensure long-term reliability. Applications span across nuclear power systems, petrochemical refineries, aerospace propulsion systems, and specialized industrial processes where sealing failure is not acceptable.

Material Grades and International Specifications

| Grade/Standard | Designation | Purity (%) | Thermal Conductivity (W/m·K) | Applications |

|---|---|---|---|---|

| ASTM B152 | C11000, C10200 | 99.90-99.95 | 391-398 | Electronic, High-precision sealing |

| BS EN 13348 | CW004A, CW008A | 99.90 | 390 | General engineering, Automotive |

| DIN 17670 | E-Cu58, OF-Cu | 99.90 | 390-395 | Electrical, Heat transfer |

| JIS H3100 | C1020, C1011 | 99.90-99.96 | 393-398 | Electronics, Precision instruments |

| IS 407 | Cu-ETP, Cu-OF | 99.90 | 390 | General purpose, Industrial |

| GB/T 5231 | T2, TU1 | 99.90-99.95 | 390-395 | Industrial, Construction |

Manufacturing Processes and Advanced Machinery

Our copper gasket manufacturing facility employs state-of-the-art production technologies including precision hydraulic presses with capacities ranging from 50 to 500 tons, computer-controlled CNC stamping systems, and specialized annealing furnaces with atmosphere control capabilities. The manufacturing process begins with incoming material inspection using X-ray fluorescence spectrometers to verify chemical composition and purity levels. Progressive stamping operations utilize servo-electric press systems with position feedback control ensuring dimensional accuracy within ±0.025mm tolerances.

Our controlled atmosphere annealing process employs hydrogen-nitrogen gas mixtures to prevent oxidation while achieving optimal microstructure and hardness characteristics. Quality control procedures include coordinate measuring machines (CMM) for dimensional verification, universal testing machines for mechanical property evaluation, and leak testing equipment for sealing performance validation. Final inspection processes utilize automated optical inspection systems to detect surface defects and ensure consistent quality standards across all production batches.

Raw Material → Cutting → Stamping → Annealing → Inspection → Packaging

Dimensional Specifications and Technical Drawings

| Parameter | Range | Tolerance | Standard |

|---|---|---|---|

| Thickness | 0.5mm – 10mm | ±0.05mm | DIN 7603, ASTM F467 |

| Internal Diameter | 5mm – 2000mm | ±0.1mm | ISO 4762, BS 4504 |

| External Diameter | 10mm – 2500mm | ±0.15mm | ASME B16.20 |

| Surface Finish | Ra 0.8 – 3.2μm | ±0.2μm | ISO 4287 |

| Flatness | 0.05mm per 100mm | – | DIN 7603 |

Performance Characteristics and Technical Properties

| Property | Value | Test Method | Application Relevance |

|---|---|---|---|

| Operating Temperature | -200°C to +400°C | ASTM D1870 | Cryogenic to high-temperature applications |

| Pressure Rating | Up to 160 bar | ISO 1167 | High-pressure hydraulic systems |

| Hardness | 40-80 HV | ASTM E384 | Optimal sealing with conformability |

| Electrical Conductivity | 58-61 MS/m | ASTM B193 | EMI shielding applications |

| Corrosion Resistance | Excellent | ASTM G48 | Marine and chemical environments |

Industries and Applications

Automotive Industry: Copper Engine Gaskets are extensively used in cylinder head assemblies, exhaust manifolds, turbocharger connections, and transmission housings where high-temperature sealing and thermal conductivity are essential. The automotive sector demands gaskets that can withstand extreme temperature cycling, vibration, and exposure to various automotive fluids including engine oils, coolants, and fuel vapors.

Aerospace and Defense: Pure Copper Gaskets and specialized Copper Sealing Gaskets find critical applications in aerospace propulsion systems, satellite components, and defense equipment where reliability and performance under extreme conditions are paramount. These applications often require gaskets that can function in vacuum environments, extreme temperature ranges, and high-vibration conditions while maintaining absolute sealing integrity.

Oil and Gas Industry: Copper Ring Gaskets and high-pressure Copper Sealing Gaskets are essential components in wellhead equipment, pipeline connections, refinery systems, and petrochemical processing facilities. The oil and gas sector requires gaskets that can handle aggressive chemicals, high pressures, and wide temperature variations while providing long-term reliability in critical safety applications.

Power Generation: Steam turbine applications, nuclear reactor systems, and renewable energy installations utilize specialized Copper Gaskets designed for high-temperature steam environments, radiation exposure, and long-term operational reliability. Power generation applications demand gaskets with superior creep resistance and dimensional stability over extended operational periods.

Marine and Shipbuilding: Marine engine gaskets, seawater system connections, and shipboard equipment utilize Copper Gaskets for their superior corrosion resistance and reliability in marine environments. The combination of saltwater exposure, temperature cycling, and vibration requires gaskets with exceptional durability and sealing performance.

Comprehensive Technical Q&A Session

Q1: What is the maximum operating temperature for Copper Gaskets in oxidizing environments?

A: In oxidizing environments, our Copper Gaskets can operate reliably up to 250°C for extended periods. For higher temperatures up to 400°C, we recommend controlled atmosphere applications or protective coatings to prevent excessive oxidation while maintaining sealing performance.

Q2: How do Pressed Copper Gaskets compare to annealed copper gaskets in terms of spring-back characteristics?

A: Pressed Copper Gaskets exhibit superior spring-back characteristics due to work-hardening during the pressing process, resulting in 15-20% better recovery after compression compared to standard annealed gaskets. This enhanced spring-back improves long-term sealing performance under thermal cycling conditions.

Q3: What surface finish requirements are critical for optimal Copper Gasket performance?

A: For optimal sealing performance, mating surfaces should have a finish of Ra 1.6-3.2μm with minimal scratches perpendicular to the gasket sealing direction. Surfaces smoother than Ra 0.8μm may actually reduce sealing effectiveness by preventing proper gasket deformation and conformance.

Q4: Can Copper Gaskets be reused, and what are the inspection criteria?

A: Copper Gaskets can be reused if they show no visible cracks, maintain original thickness within 10%, and demonstrate uniform compression marks. However, for critical applications, we recommend single-use installation to ensure maximum reliability and sealing performance.

Q5: What are the recommended torque specifications for Copper Ring Gaskets?

A: Torque specifications vary by gasket size and application, but generally range from 40-80% of maximum recommended flange bolt torque. We provide detailed torque charts with each shipment, and recommend following a cross-pattern tightening sequence with multiple passes to ensure uniform compression.

Q6: How do you ensure dimensional accuracy in high-volume Stamped Copper Gasket and Copper sealing Gasket production?

A: Our quality assurance includes statistical process control with continuous monitoring of critical dimensions, automated inspection systems, and regular tooling maintenance. We maintain Cpk values above 1.33 for all critical dimensions and perform dimensional audits every 500 pieces during production runs.

Q7: What chemical compatibility testing do you perform on Pure Copper Gaskets?

A: We conduct comprehensive chemical compatibility testing including immersion testing per ASTM D543, stress crack resistance testing, and long-term aging studies in customer-specific media. Test reports include weight change, dimensional stability, and mechanical property retention data.

Q8: How do you address galvanic corrosion concerns when Copper Gaskets interface with dissimilar metals?

A: We provide galvanic compatibility charts and can supply gaskets with protective barrier coatings or recommend isolation techniques. For critical applications, we offer electroplated options with Nickel or Tin coatings to minimize galvanic potential differences.

Q9: What is the typical lead time for custom-designed Copper Sealing Gaskets?

A: Custom-designed Copper Sealing Gaskets typically require 2-3 weeks for engineering design and tooling development, followed by 4-6 weeks for production depending on quantity and complexity. Rush orders can be accommodated with expedited processing for critical applications.

Q10: Do you provide material certification and traceability documentation?

A: Yes, we provide comprehensive material test certificates (MTC) per EN 10204 3.1 standard, including chemical composition analysis, mechanical properties, and dimensional verification reports. Full traceability from raw material source through final inspection is maintained for all products.

Q11: What quality certifications does your manufacturing facility maintain?

A: Our facility is certified to ISO 9001:2015, ISO 14001:2015, and OHSAS 18001. We also maintain AS9100 certification for aerospace applications and API Q1 certification for oil and gas industry requirements, ensuring comprehensive quality management across all applications.

Q12: How do you handle special packaging requirements for international shipping?

A: We offer customized packaging solutions including vacuum sealing for purity preservation, individual gasket protection, custom labeling with customer logos, and export packaging compliant with international shipping regulations. Packaging can be optimized for specific shipping methods and destination requirements.

Why Choose Our Copper Gaskets – Competitive Advantages

Three Decades of Manufacturing Excellence: Our extensive experience spanning over 30 years in copper gasket manufacturing has established us as a trusted global supplier with deep understanding of diverse application requirements and industry standards. This experience translates into superior product knowledge, robust quality systems, and the ability to solve complex sealing challenges across multiple industries.

Advanced Customization Capabilities: Our engineering team collaborates closely with customers to develop application-specific solutions including non-standard dimensions, specialized alloy compositions, unique surface treatments, and integrated design features. We maintain flexibility to accommodate short-run custom orders and rapid prototype development to meet urgent customer requirements.

Superior Customer Communication and Support: We pride ourselves on exceptional customer service with dedicated technical support teams providing multilingual communication capabilities, rapid response times, and comprehensive technical documentation. Our customer support extends from initial design consultation through post-delivery technical assistance, ensuring complete customer satisfaction throughout the product lifecycle.

Flexible Production Scheduling and Fast Turnaround: Our manufacturing operations are designed for flexibility with standard delivery times of 4-6 weeks for most products, expedited production capabilities for urgent requirements, and the ability to accommodate varying order quantities from prototype quantities to high-volume production runs. We maintain strategic inventory levels of common sizes to enable immediate shipment for standard products.

Comprehensive Quality Assurance and Certification: Every gasket undergoes rigorous quality control procedures including dimensional verification, material composition analysis, surface finish inspection, and performance testing. We provide complete documentation packages including material certificates, inspection reports, and performance data to ensure full traceability and regulatory compliance for critical applications.

Global Logistics and Export Expertise: Our extensive export experience enables us to navigate international shipping requirements, customs documentation, and regulatory compliance across multiple countries. We offer comprehensive packaging solutions, competitive international shipping rates, and reliable delivery scheduling to ensure products arrive safely and on time regardless of destination.

International Standards and Certifications

Our Copper Gasket and Copper Sealing Gasket manufacturing processes and products comply with comprehensive international standards ensuring global compatibility and reliability. ASTM B152 and ASTM F467 standards govern our material specifications and dimensional tolerances, while DIN 7603 and ISO 4762 provide European standard compliance for metric applications. JIS H3100 certification ensures compatibility with Japanese industrial requirements, and BS EN 13348 addresses British and European market specifications.

Quality management systems are certified to ISO 9001:2015 for comprehensive quality assurance, AS9100 for aerospace applications, and API Q1 for oil and gas industry compliance. Environmental management follows ISO 14001:2015 standards, while occupational health and safety compliance meets OHSAS 18001 requirements. Additional certifications include CE marking for European markets and RoHS compliance for electronic applications requiring restriction of hazardous substances.

Customer Testimonial:

“We have been sourcing Copper Engine Gaskets from this Indian manufacturer for over five years, and their consistency in quality and delivery performance has been outstanding. The technical support team provided excellent guidance during our transition to higher-temperature applications, and their custom gasket solutions helped us resolve persistent sealing issues in our marine engine division. The combination of competitive pricing, superior product quality, and responsive customer service makes them our preferred supplier for all copper gasket requirements.”

– Daniel Marshman, Senior Procurement Engineer, Houston, Texas, USA

Material Properties and Technical Specifications

| Physical Property | Value | Units | Test Standard |

|---|---|---|---|

| Density | 8.96 | g/cm³ | ASTM B311 |

| Melting Point | 1085 | °C | ASTM E794 |

| Coefficient of Expansion | 16.5 | ×10⁻⁶/°C | ASTM E228 |

| Elastic Modulus | 110 | GPa | ASTM E111 |

| Poisson’s Ratio | 0.34 | – | ASTM E132 |

| Specific Heat | 385 | J/kg·K | ASTM C351 |

Packaging and Shipping Solutions

Standard Packaging: Our Copper Gaskets are individually wrapped in protective film to prevent oxidation and surface damage during storage and transportation. Small quantities are packaged in moisture-resistant plastic bags with desiccant packets, while larger quantities utilize corrugated cartons with foam inserts for protection against impact damage. Each package includes detailed product identification labels and handling instructions.

Custom Packaging Options: We offer specialized packaging solutions including vacuum-sealed pouches for ultra-pure applications, individual gasket containers for critical components, and custom labeling with customer logos and part numbers. Export packaging utilizes wooden crates or heavy-duty corrugated boxes with moisture barriers and shock-absorbing materials to ensure product integrity during international shipping.

Shipping and Logistics: Our global shipping capabilities include air freight for expedited delivery, ocean freight for cost-effective large shipments, and integrated door-to-door delivery services. We maintain partnerships with major international freight forwarders to ensure reliable delivery schedules and competitive shipping rates. Complete documentation packages include commercial invoices, packing lists, certificates of origin, and material test certificates to facilitate customs clearance processes.

Glossary of Technical Terms

Request Your Custom Copper Gasket Quote Today

Ready to experience the difference that three decades of manufacturing excellence makes? Our technical team is standing by to discuss your specific copper gasket requirements and provide detailed quotations with competitive pricing and fast delivery options.

Contact Options:

📧 Email: Send us your specifications at sales@brass-copper-parts. com for a detailed technical quote and product recommendations

📞 Phone: Call our technical support team at +91-22-43449300 for immediate assistance and expert guidance

📱 WhatsApp: Connect instantly via WhatsApp at +91-22-43449300 for quick responses and file sharing

📋 Request Brochure: Download our comprehensive product catalog with detailed technical specifications and application guides

Get your custom quote within 24 hours – Contact us now!