Copper Parts, Copper Turned Components – Precision CNC Machined Copper Components

We are one of the leading manufacturers and exporters of precision Copper parts and Copper turned components from India. We have been supplying high-quality Copper CNC machined parts to the world market for many decades. Our state-of-the-art manufacturing facility specializes in producing custom Copper threaded components, precision Copper screw machine parts, and complex Copper milled components that meet the most stringent international quality standards. With over three decades of expertise in Copper machining and manufacturing, we have established ourselves as a trusted partner for industries requiring superior electrical conductivity, thermal management, and corrosion resistance properties. Our comprehensive range of Copper parts serves diverse applications across electrical, electronics, automotive, marine, and industrial sectors worldwide. We combine traditional craftsmanship with modern CNC technology to deliver precision-engineered Copper components that exceed customer expectations in terms of quality, dimensional accuracy, and delivery timelines.

Overview of Copper Parts and Components

Copper parts and components represent a critical segment of precision-engineered products that leverage Copper’s exceptional electrical conductivity (59.6 × 10⁶ S/m), thermal conductivity (401 W/m·K), and superior corrosion resistance properties. Our manufacturing expertise encompasses the complete spectrum of Copper component production, from simple turned parts to complex multi-axis CNC machined assemblies. The inherent malleability and ductility of Copper, combined with its antimicrobial properties, make it an ideal material choice for applications demanding reliability, longevity, and performance consistency across various environmental conditions.

Copper Manufacturing Process Flow

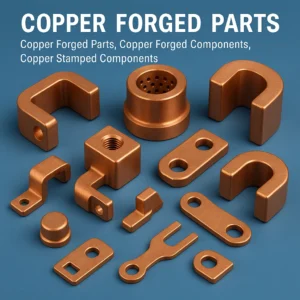

Copper Parts

Copper parts encompass a broad category of precision-manufactured components that utilize pure Copper or Copper alloys to achieve specific mechanical and electrical performance characteristics. Our manufacturing capability includes hot forged Copper parts, cold formed components, and precision stamped elements that maintain tight tolerances while preserving the material’s inherent properties. These parts are extensively used in electrical switchgear, power distribution systems, heat exchangers, and architectural applications where both functionality and aesthetic appeal are paramount. The manufacturing process involves careful material selection, precision machining operations, and comprehensive quality assurance protocols to ensure each part meets the specified dimensional accuracy and surface finish requirements.

Copper Turned Components

Copper turned components are precision-manufactured parts produced through advanced lathe machining operations that transform raw Copper stock into intricate cylindrical, conical, and complex geometric shapes. Our CNC turning centers are equipped with live tooling capabilities, enabling the production of components with multiple diameters, internal cavities, external grooves, and threaded sections in a single setup. The turning process maintains excellent concentricity and surface finish quality, typically achieving Ra values of 0.4 to 1.6 micrometers depending on application requirements. These components are widely utilized in electrical connector assemblies, valve stems, bearing bushings, and precision instrumentation where rotational symmetry and dimensional stability are critical performance factors.

Copper Milled Parts

Copper milled parts represent complex three-dimensional components manufactured using multi-axis CNC milling operations that create intricate geometries, pockets, slots, and contoured surfaces with exceptional precision. Our horizontal and vertical machining centers utilize advanced CAM programming to optimize tool paths, minimize cycle times, and maintain consistent surface quality across complex geometries. The milling process enables the production of heat sinks with optimized fin configurations, electrical bus bars with precise conductor pathways, and custom housings with integrated mounting features. Material removal rates are carefully controlled to prevent work hardening and maintain dimensional stability throughout the machining process.

Copper CNC Machined Parts

Copper CNC machined parts exemplify the pinnacle of precision manufacturing technology, combining computer-controlled machining operations with advanced tooling systems to produce components with tolerances as tight as ±0.005mm. Our CNC machining capabilities encompass 3-axis, 4-axis, and 5-axis operations, enabling the production of complex geometries that would be impossible to achieve through conventional machining methods. The integration of automated tool changers, in-process measurement systems, and adaptive machining strategies ensures consistent quality and optimal production efficiency. These parts are essential components in aerospace applications, medical devices, telecommunications equipment, and precision instrumentation where dimensional accuracy and surface integrity are non-negotiable requirements.

Copper Threaded Components

Copper threaded components are precision-manufactured parts featuring internal or external thread forms that provide secure mechanical connections while maintaining excellent electrical conductivity. Our thread manufacturing capabilities include single-point threading, thread milling, and thread rolling operations that produce threads conforming to ISO, ANSI, BSW, and metric standards. The threading process is carefully controlled to prevent galling and ensure proper thread engagement characteristics. These components include threaded rods, coupling nuts, electrical terminals, and custom fasteners used in electrical panel assemblies, grounding systems, and lightning protection installations where reliable electrical continuity and mechanical integrity are essential.

Precision Copper Components

Precision Copper components represent the highest echelon of manufactured Copper parts, featuring dimensional tolerances typically ranging from ±0.01mm to ±0.05mm and surface finishes achieving Ra values below 0.8 micrometers. These components undergo rigorous quality control procedures including coordinate measuring machine (CMM) inspection, surface roughness analysis, and electrical conductivity verification. The manufacturing process incorporates temperature-controlled environments, vibration-isolated machining centers, and precision fixturing systems to maintain dimensional stability throughout production. Applications include waveguide components, precision electrical contacts, calibration standards, and high-frequency electronic assemblies where performance depends critically on dimensional accuracy and surface quality.

Precision Copper Parts

Precision Copper parts are engineered components manufactured to exacting specifications that meet or exceed the demanding requirements of high-technology applications. Our manufacturing process incorporates statistical process control (SPC) methodologies, ensuring consistent part-to-part dimensional reproducibility and performance characteristics. These parts undergo comprehensive metallurgical analysis to verify material composition, grain structure, and mechanical properties. The production environment maintains ISO 9001:2015 quality standards with full traceability documentation for critical applications. Typical applications include semiconductor manufacturing equipment, precision measurement instruments, research laboratory components, and aerospace systems where material purity and dimensional precision directly impact operational performance.

Copper Screw Machine Parts

Copper screw machine parts are high-volume precision components manufactured using advanced CNC Swiss-type automatic lathes that combine turning, drilling, threading, and secondary operations in a continuous production process. These machines excel at producing small to medium-sized parts with complex geometries while maintaining tight tolerances and excellent surface finishes. The screw machine process is particularly well-suited for producing electrical terminals, connector pins, valve components, and instrumentation fittings where high production volumes and consistent quality are required. Our screw machine operations utilize bar feeding systems, programmable tool changers, and integrated quality monitoring systems to ensure optimal productivity and part quality consistency.

Material Grades and Specifications

International Standards

ISO Standards: ISO 1337, ISO 196, ISO 426

ASTM Standards: ASTM B152, B124, B133, B187, B188

DIN Standards: DIN 1787, DIN 17672, DIN 17660

JIS Standards: JIS H3100, H3110, H3130

BS Standards: BS 2870, BS 2871, BS 2872

USA Standards

UNS Designations: C10100, C10200, C10300, C10800, C11000

AISI Classifications: Pure Copper, Oxygen-Free Copper

SAE Standards: SAE J461, SAE J463

AWS Standards: AWS A5.6, A5.7 for welding

European Standards

EN Standards: EN 1172, EN 1173, EN 12163

CEN Classifications: CW003A, CW004A, CW008A

German DIN: Cu-ETP, Cu-OF, Cu-PHC

French NF: NF A51-101, NF A51-111

Asian Standards

Chinese GB: GB/T 5231, GB/T 2040, GB/T 13808

Japanese JIS: C1020, C1100, C1201, C1220

Korean KS: KS D 5101, KS D 5102

Indian IS: IS 407, IS 1897, IS 6912

Manufacturing Processes and Machinery

Our comprehensive manufacturing capabilities encompass multiple precision machining processes optimized for Copper component production. CNC turning operations utilize DMG Mori, Mazak, and Haas turning centers equipped with high-pressure coolant systems and live tooling capabilities. CNC milling processes employ Makino, Okuma, and Hermle machining centers featuring 5-axis simultaneous machining capabilities for complex geometries. Swiss-type screw machines from Citizen and Star provide high-volume production capabilities with excellent surface finish quality. EDM operations using Mitsubishi and Sodick equipment enable the production of intricate internal features and tight-tolerance cavities. Secondary operations include thread rolling, knurling, heat treatment, and various surface finishing processes to meet specific application requirements.

| Manufacturing Process | Machinery Type | Tolerance Capability | Surface Finish (Ra) | Production Volume |

|---|---|---|---|---|

| CNC Turning | DMG Mori NLX, Mazak QTN | ±0.005mm | 0.4-1.6 μm | 1-10,000 pcs |

| CNC Milling | Makino a51nx, Hermle C30U | ±0.01mm | 0.6-3.2 μm | 1-5,000 pcs |

| Swiss Machining | Citizen L32, Star SV-32 | ±0.008mm | 0.8-2.5 μm | 100-100,000 pcs |

| Wire EDM | Mitsubishi MV2400R | ±0.003mm | 0.2-1.0 μm | 1-1,000 pcs |

| Sinker EDM | Sodick AQ327L | ±0.005mm | 0.4-1.8 μm | 1-500 pcs |

Typical Copper Industrial/Electrical/Threaded Parts

Our comprehensive product portfolio includes a diverse range of precision-engineered Copper components designed for specific industrial applications. Electrical components encompass bus bars, electrical terminals, connector housings, switch contacts, and circuit breaker components. Threaded fasteners include hex bolts, socket head cap screws, threaded rods, coupling nuts, and custom fastening solutions. Industrial components comprise heat exchanger tubes, valve stems, bearing bushings, pump components, and instrumentation fittings. Electronic parts feature waveguide sections, RF connectors, heat sinks, shielding enclosures, and precision calibration standards. Each component category is manufactured to meet specific industry standards while maintaining the superior material properties that make Copper an ideal choice for demanding applications.

| Component Category | Typical Parts | Key Applications | Critical Properties |

|---|---|---|---|

| Electrical Components | Bus bars, terminals, contacts, connectors | Power distribution, switchgear, control panels | High conductivity, low resistance |

| Threaded Fasteners | Hex bolts, cap screws, threaded rods, nuts | Electrical grounding, lightning protection | Corrosion resistance, conductivity |

| Heat Transfer Components | Heat sinks, exchanger tubes, cooling blocks | Electronics cooling, HVAC systems | Thermal conductivity, heat dissipation |

| Precision Instruments | Calibration standards, measurement fixtures | Metrology, testing equipment | Dimensional stability, precision |

| Marine Components | Propeller shafts, marine fittings, seawater valves | Ship building, offshore platforms | Corrosion resistance, antimicrobial |

Industries and Applications

Our Copper components serve critical functions across diverse industry sectors that demand superior material performance and reliability. Electrical and electronics industries utilize our components in power generation equipment, transmission systems, electronic devices, and telecommunications infrastructure. Automotive sector applications include electrical wiring systems, heat exchangers, brake lines, and engine components. Aerospace industry requires our precision components for avionics systems, heat management solutions, and electrical distribution networks. Marine applications leverage Copper’s corrosion resistance in seawater environments for propulsion systems, hull fittings, and navigation equipment. Medical device manufacturing benefits from Copper’s antimicrobial properties in surgical instruments, diagnostic equipment, and hospital infrastructure components.

Tolerances and Quality Standards

Our quality management system maintains strict adherence to international tolerance standards while providing customized precision levels based on specific application requirements. Standard tolerances for general applications range from ±0.1mm to ±0.05mm, while precision tolerances for critical applications achieve ±0.01mm to ±0.005mm accuracy. Geometric tolerances including straightness, flatness, roundness, and perpendicularity are maintained according to ISO 2768 and ASME Y14.5 standards. Surface finish specifications range from Ra 0.2 to Ra 6.3 micrometers depending on functional requirements. Our inspection capabilities include coordinate measuring machines (CMM), optical comparators, surface roughness testers, and hardness testing equipment to ensure complete dimensional verification and material property confirmation.

Standard Tolerance Chart

| Dimension Range (mm) | Standard Tolerance (±mm) | Precision Tolerance (±mm) | High Precision (±mm) | Surface Finish (Ra μm) |

|---|---|---|---|---|

| 0.5 – 3.0 | ±0.05 | ±0.02 | ±0.005 | 0.4 – 1.6 |

| 3.0 – 6.0 | ±0.08 | ±0.03 | ±0.008 | 0.6 – 2.5 |

| 6.0 – 30.0 | ±0.10 | ±0.05 | ±0.010 | 0.8 – 3.2 |

| 30.0 – 120.0 | ±0.15 | ±0.08 | ±0.015 | 1.6 – 6.3 |

| 120.0 – 400.0 | ±0.20 | ±0.10 | ±0.020 | 3.2 – 12.5 |

Material Properties and Performance Metrics

| Property | Pure Copper (C11000) | Oxygen-Free Copper (C10100) | Phosphorous Deoxidized (C12200) | Test Standard |

|---|---|---|---|---|

| Electrical Conductivity (%IACS) | 101 | 103 | 85 | ASTM B193 |

| Thermal Conductivity (W/m·K) | 401 | 403 | 359 | ASTM E1461 |

| Tensile Strength (MPa) | 220-380 | 220-275 | 200-310 | ASTM B557 |

| Yield Strength (MPa) | 70-345 | 69-275 | 69-275 | ASTM B557 |

| Elongation (%) | 45-4 | 45-5 | 45-8 | ASTM B557 |

| Hardness (HRB) | 40-95 | 40-85 | 40-85 | ASTM B294 |

| Density (g/cm³) | 8.89 | 8.89 | 8.89 | ASTM B311 |

| Melting Point (°C) | 1083 | 1083 | 1083 | ASTM E324 |

Turnaround Time and Production Scheduling

Our optimized production planning system ensures efficient delivery schedules that meet customer requirements while maintaining quality standards. Standard turnaround time for most Copper components ranges from 4-6 weeks from order confirmation, including material procurement, machining operations, quality inspection, and packaging. Express production capabilities enable delivery within 2-3 weeks for urgent requirements, subject to material availability and production capacity. Prototype development typically requires 1-2 weeks for initial samples and design verification. High-volume production runs may extend to 6-8 weeks depending on quantity requirements and complexity. Our production scheduling system provides real-time visibility into order status, enabling proactive communication regarding delivery expectations and any potential schedule adjustments.

Why Choose Our Copper Components

Three Decades of Manufacturing Excellence: Our extensive experience in Copper component manufacturing has established us as a trusted global supplier with deep understanding of material characteristics and application requirements. Advanced Manufacturing Technology: State-of-the-art CNC machining centers, Swiss-type screw machines, and EDM equipment ensure superior precision and surface quality. Global Export Experience: We have successfully supplied Copper components to customers across North America, Europe, Asia, and Australia, understanding diverse market requirements and quality expectations. Customization Flexibility: Our engineering team collaborates closely with customers to develop custom solutions tailored to specific application needs. Faster Turnaround Times: Optimized production processes and strategic inventory management enable competitive delivery schedules. Superior Customer Support: Dedicated project managers provide personalized attention and proactive communication throughout the project lifecycle. Quality Assurance: ISO 9001:2015 certified quality management system ensures consistent product quality and full traceability documentation.

Packaging and Shipping

Our comprehensive packaging and shipping services ensure product integrity throughout the global supply chain while accommodating specific customer requirements. Standard packaging utilizes anti-corrosive wrapping materials, moisture-resistant barriers, and cushioned containers to prevent damage during transportation. Customized packaging solutions include customer-branded labels, specific lot identification systems, and specialized protective packaging for sensitive components. Export documentation encompasses commercial invoices, packing lists, certificates of origin, material test certificates, and quality inspection reports. Shipping partnerships with leading logistics providers ensure reliable delivery through air freight, sea freight, and express courier services. Tracking systems provide real-time visibility into shipment status and delivery confirmation. International compliance includes adherence to ROHS, REACH, and other environmental regulations as required by destination markets.

Frequently Asked Questions (Q&A)

Q1: What Copper grades do you work with for electrical applications?

A: We primarily work with C11000 (ETP Copper), C10100 (Oxygen-Free Copper), and C12200 (Phosphorous Deoxidized Copper) for electrical applications. C10100 offers the highest electrical conductivity at 103% IACS, making it ideal for high-current applications, while C12200 provides excellent formability for complex geometries.

Q2: Can you achieve tolerances tighter than ±0.005mm on Copper components?

A: Yes, our precision machining capabilities can achieve tolerances as tight as ±0.002mm for critical dimensions using our Swiss-type screw machines and EDM equipment. However, such tight tolerances may impact production time and cost, requiring careful evaluation of functional requirements.

Q3: What surface treatments are available for Copper parts?

A: We offer various surface treatments including nickel plating, tin plating, silver plating, passivation, and protective lacquer coatings. The choice depends on application requirements such as corrosion resistance, solderability, and aesthetic considerations.

Q4: Do you provide material certificates and test reports?

A: Yes, we provide comprehensive material certificates including chemical composition analysis, mechanical property test results, electrical conductivity measurements, and dimensional inspection reports. All certificates are traceable to the original material source.

Q5: What is your minimum order quantity for custom Copper parts?

A: Our minimum order quantity varies depending on part complexity and machining requirements. For simple turned components, MOQ can be as low as 25 pieces, while complex milled parts may require 100 pieces minimum to optimize setup costs.

Q6: Can you handle high-volume production requirements?

A: Absolutely. Our Swiss-type screw machines are specifically designed for high-volume production, capable of producing up to 100,000 pieces per month for suitable geometries. We also maintain strategic raw material inventory to support large-scale production schedules.

Q7: What quality standards do you follow for Copper component manufacturing?

A: We maintain ISO 9001:2015 quality certification and follow international standards including ASTM, DIN, JIS, and IS specifications. Our quality control procedures include incoming material inspection, in-process monitoring, and final dimensional verification using calibrated measuring equipment.

Q8: How do you ensure consistent material properties across production batches?

A: We source materials from certified suppliers with mill test certificates and conduct incoming inspection including spectrographic analysis, hardness testing, and electrical conductivity measurements. Statistical process control methods monitor key parameters throughout production to ensure consistency.

Q9: Can you provide design assistance for Copper component optimization?

A: Yes, our experienced engineering team provides design for manufacturability (DFM) analysis, suggesting modifications to optimize machinability, reduce production costs, and improve functional performance while maintaining design intent.

Q10: What are your capabilities for secondary operations on Copper components?

A: We provide comprehensive secondary operations including thread rolling, knurling, heat treatment, deburring, polishing, and various plating processes. Our integrated facility eliminates the need for external processing, ensuring better quality control and faster turnaround times.

Q11: How do you handle rush orders and expedited delivery requirements?

A: Our express production capability can accommodate rush orders within 2-3 weeks depending on part complexity and material availability. We maintain emergency stock of common Copper grades and can prioritize urgent orders through our flexible production scheduling system.

Q12: What inspection and testing equipment do you use for quality control?

A: Our quality laboratory includes coordinate measuring machines (CMM), optical comparators, surface roughness testers, hardness testing equipment, spectrographic analyzers, and electrical conductivity meters. All equipment is calibrated according to ISO 17025 standards.

Size and Dimensional Capabilities

| Component Type | Minimum Dimension | Maximum Dimension | Length Capability | Typical Applications |

|---|---|---|---|---|

| Turned Components | 0.5mm diameter | 400mm diameter | Up to 1500mm | Shafts, bushings, connectors |

| Milled Parts | 0.1mm feature size | 800 x 600 x 500mm | Variable geometry | Heat sinks, housings, brackets |

| Threaded Components | M1.0 thread size | M100 thread size | Up to 2000mm | Fasteners, coupling nuts |

| Swiss Machined Parts | 0.2mm diameter | 32mm diameter | Up to 300mm | Precision pins, terminals |

| EDM Components | 0.05mm slot width | 500 x 400 x 300mm | Complex cavities | Electrodes, precision tools |

Customer Testimonials

“We have been sourcing precision Copper electrical components from this manufacturer for over eight years, and their consistency in quality and delivery performance has been exceptional. Their technical expertise helped us optimize our connector designs, resulting in 15% improvement in electrical performance and 20% reduction in material costs. The customer service team is highly responsive and provides excellent communication throughout the project lifecycle. We particularly appreciate their ability to handle both prototype quantities and high-volume production runs with equal attention to detail.”

– Robert M. Johnson, Senior Procurement Manager, USA

Glossary of Technical Terms

| Term | Definition |

|---|---|

| IACS (International Annealed Copper Standard) | Standard reference for electrical conductivity measurement, with pure annealed Copper defined as 100% IACS |

| ETP Copper (Electrolytic Tough Pitch) | Standard grade Copper containing 99.90% minimum Copper with controlled oxygen content for electrical applications |

| OF Copper (Oxygen-Free) | High purity Copper with oxygen content below 10ppm, offering superior electrical conductivity and hydrogen embrittlement resistance |

| DHP Copper (Deoxidized High Phosphorous) | Copper deoxidized with phosphorous, providing excellent forming characteristics and corrosion resistance |

| CNC Machining | Computer Numerical Control machining process using pre-programmed computer software to control machine tool movement |

| Swiss Machining | Precision machining process using sliding headstock lathes for high-volume production of small, complex parts |

| EDM (Electrical Discharge Machining) | Manufacturing process using electrical discharges to remove material and create precise geometries |

| Ra (Surface Roughness Average) | Arithmetic average of surface profile deviations from the mean line, measured in micrometers |

| CMM (Coordinate Measuring Machine) | Precision measurement device used to verify dimensional accuracy and geometric tolerances |

| Thermal Conductivity | Material property measuring heat transfer capability, expressed in watts per meter-kelvin (W/m·K) |

Surface Finishes and Coatings

Our comprehensive surface finishing capabilities enhance the performance and longevity of Copper components across diverse applications. Electroplating options include nickel plating for corrosion resistance, tin plating for solderability, silver plating for enhanced conductivity, and gold plating for premium electrical contacts. Chemical treatments encompass passivation processes that improve corrosion resistance while maintaining electrical conductivity. Mechanical finishing includes polishing operations achieving mirror-like surface finishes, brushed finishes for aesthetic applications, and bead blasting for uniform matte appearances. Protective coatings feature clear lacquers that prevent oxidation while preserving the natural Copper appearance, and specialized anti-tarnish treatments for architectural applications.

| Finish Type | Process Description | Typical Thickness | Key Benefits | Applications |

|---|---|---|---|---|

| Nickel Plating | Electrochemical deposition of nickel | 5-25 μm | Corrosion resistance, hardness | Marine components, fasteners |

| Tin Plating | Electrodeposition of pure tin | 2-15 μm | Solderability, food safety | Electrical connectors, food equipment |

| Silver Plating | Electroplating with silver solution | 1-10 μm | Enhanced conductivity, low contact resistance | RF components, switch contacts |

| Passivation | Chemical surface treatment | Molecular layer | Oxidation resistance, maintained conductivity | Electronic assemblies, bus bars |

| Clear Lacquer | Protective coating application | 10-50 μm | Tarnish prevention, aesthetic preservation | Architectural hardware, decorative parts |

Related Terms

Copper parts manufacturer, Copper turned components, precision Copper machining, CNC Copper parts, Copper threaded components, Copper screw machine parts, custom Copper components, Copper electrical parts, Copper manufacturing India, Copper parts exporter

High precision Copper CNC machined parts manufacturer, custom Copper electrical connector components, precision Copper threaded fastener manufacturing, Copper heat sink components CNC machining, Swiss machined Copper electronic parts supplier, industrial Copper valve components manufacturer, marine grade Copper threaded parts exporter, aerospace Copper precision components manufacturer

Electrical conductivity Copper alloys, thermal management Copper components, corrosion resistant Copper parts, antimicrobial Copper applications, Copper brazing alloys, Copper welding electrodes, Copper pipe fittings, Copper heat exchanger tubes, Copper roofing components, Copper plumbing fittings

ASTM B152 Copper sheet specifications, DIN 17672 Copper alloy standards, JIS H3100 Copper material grades, ISO 1337 Copper conductivity standards, UNS C11000 Copper properties, oxygen-free Copper OFC specifications, phosphorous deoxidized Copper characteristics

Environmental Compliance and Sustainability

Our commitment to environmental responsibility encompasses comprehensive compliance with international environmental regulations and sustainable manufacturing practices.

ROHS compliance ensures our Copper components meet European Union restrictions on hazardous substances, making them suitable for electronic equipment applications.

REACH regulation compliance includes registration and safety documentation for chemical substances used in our manufacturing processes.

Conflict minerals compliance through responsible sourcing practices and supply chain transparency.

Recycling programs maximize material utilization efficiency, with Copper scrap generated during machining operations recycled back into the supply chain. Energy-efficient manufacturing through modern CNC equipment with optimized power consumption and waste heat recovery systems.

Water treatment systems ensure proper management of cutting fluids and cleaning solutions used in manufacturing processes.

Technical Support and Engineering Services

Our comprehensive technical support services provide customers with expert assistance throughout the entire project lifecycle, from initial concept development to final product delivery.

Design for Manufacturability (DFM) analysis helps optimize component designs for efficient production while maintaining functional requirements and cost effectiveness.

Material selection guidance ensures the most appropriate Copper grade is chosen based on application requirements, environmental conditions, and performance expectations.

Tolerance analysis and geometric dimensioning recommendations help achieve optimal functionality while maintaining manufacturing feasibility.

Prototype development services enable rapid design verification and testing before committing to full production volumes.

Value engineering consultations identify opportunities for cost reduction and performance enhancement through design modifications and manufacturing process optimization.

Get Your Custom Copper Components Quote Today

Ready to start your next project with precision-engineered Copper components?

📧 Email us your technical drawings and specifications for a detailed quotation sales@brass-copper-parts. com

📋 Request our comprehensive product brochure with detailed specifications and case studies

🔗 Upload your CAD files through our secure online portal for rapid quote processing

Experience the difference of working with India’s leading Copper components manufacturer – where precision meets excellence!