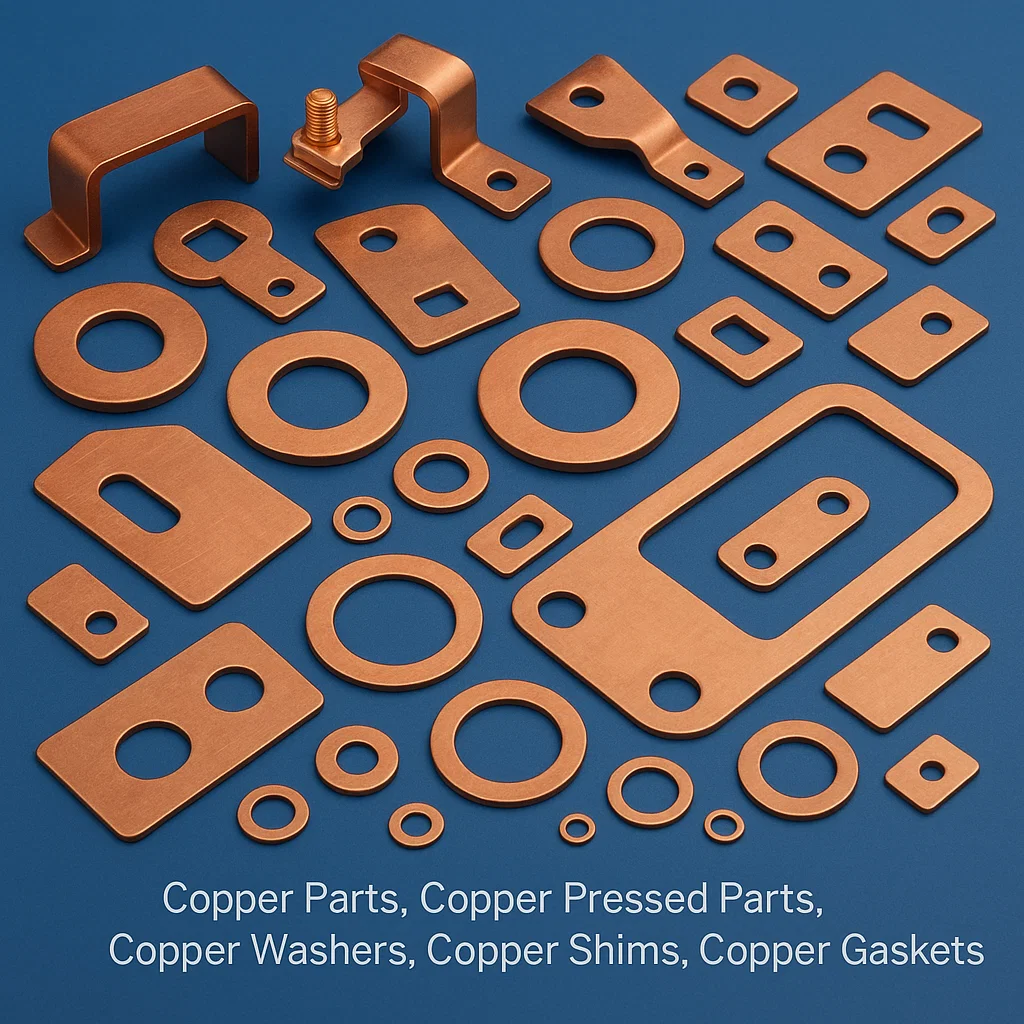

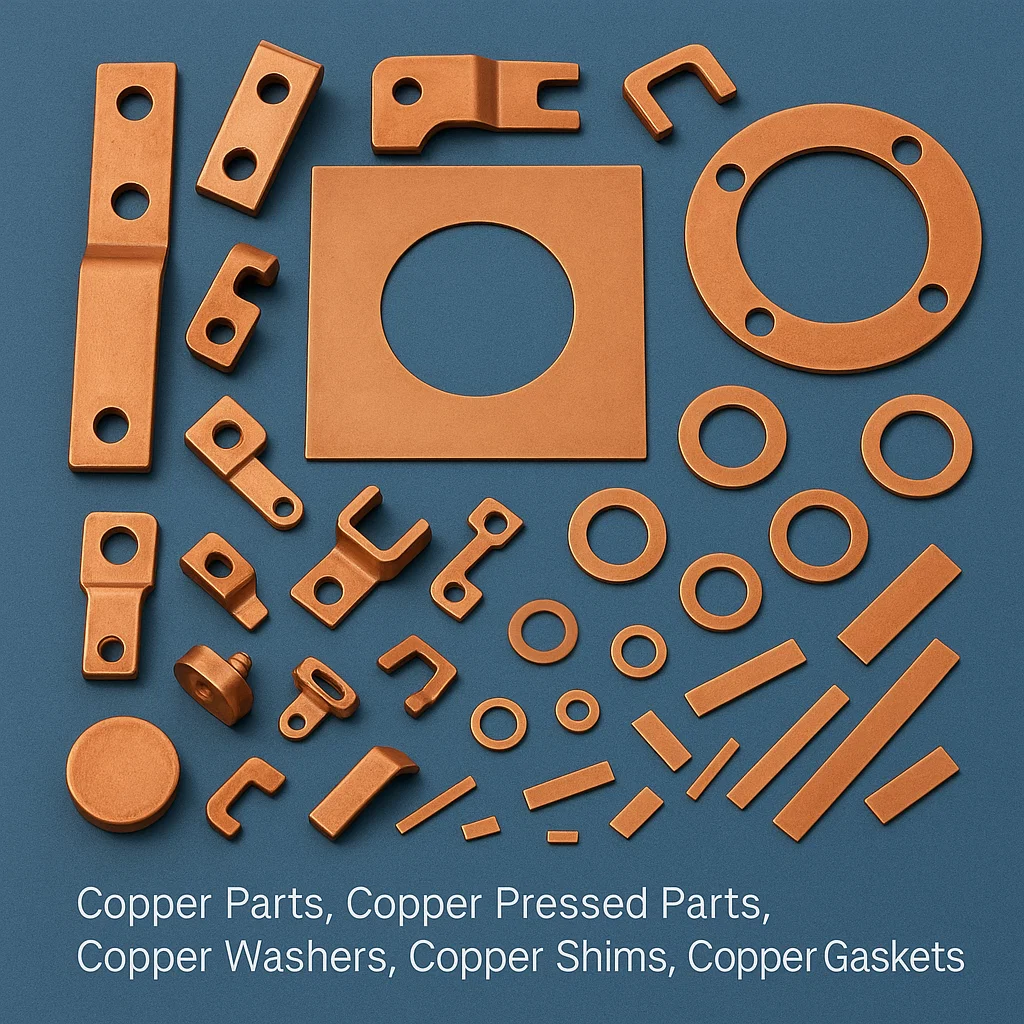

Copper Pressed Parts, Copper Sheet Metal Components – Precision Manufacturing Solutions

Price; US$ 13.30/Kilogram

Overview – Premium Copper Pressed Parts and Sheet Metal Components

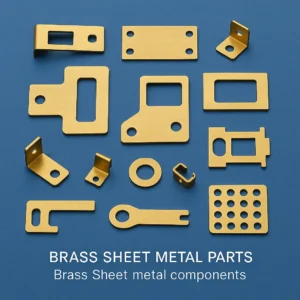

We are one of the leading manufacturers and exporters of Copper Pressed Parts, Copper Sheet Metal Components, and precision Copper fabricated products from India. We have been supplying high-quality Copper pressed components, Copper deep drawn parts, and custom Copper sheet metal solutions to the world market for many decades. Our state-of-the-art manufacturing facility specializes in producing precision Copper Pressed Parts including Copper gaskets, Copper washers, Copper shims, Copper brackets, Copper clamps, and Copper saddles for diverse industrial and electrical applications. With over three decades of expertise in Copper Sheet Metal Components manufacturing, we deliver superior quality products that meet international standards including ASTM, DIN, BS, JIS, and IS specifications. Our advanced pressing technology and deep drawing capabilities enable us to manufacture complex Copper Sheet Metal Parts with exceptional dimensional accuracy and surface finish. We also press Aluminum, Brass, and Stainless Steel and manufacture sheet metal components from these materials, providing comprehensive metal fabrication solutions under one roof.

Copper Parts – Precision Engineered Solutions

Copper Parts form the backbone of numerous industrial applications due to Copper’s exceptional electrical conductivity, thermal properties, and corrosion resistance. Our precision-engineered Copper Parts are manufactured using high-grade Copper alloys including C101, C110, C11000, and beryllium Copper variants. These Copper Parts find extensive applications in electrical switchgear, transformers, heat exchangers, and automotive components. Our manufacturing process ensures each Copper Part meets stringent quality standards with dimensional tolerances as tight as ±0.05mm. The surface finish of our Copper Parts ranges from mill finish to electroplated options including tin plating, nickel plating, and silver plating for enhanced performance in specific applications.

Copper Pressed Parts – Advanced Forming Technology

Copper Pressed Parts represent our core expertise in metal forming technology. Our Copper Pressed Parts are manufactured using high-tonnage hydraulic presses ranging from 25 tons to 400 tons capacity. The Copper Pressed Parts production process involves precision blanking, forming, drawing, and piercing operations to achieve complex geometries with excellent repeatability. Common Copper Pressed Parts include electrical terminals, contact springs, heat sink components, and decorative architectural elements. Our Copper Pressed Parts maintain excellent mechanical properties post-forming, with typical tensile strength ranging from 220-400 MPa depending on the Copper grade and work hardening achieved during the pressing operation.

Copper Sheet Metal Parts – Versatile Manufacturing Solutions

Copper Sheet Metal Parts encompass a wide range of fabricated components produced from Copper sheets ranging from 0.1mm to 6mm thickness. Our Copper Sheet Metal Parts manufacturing capabilities include laser cutting, CNC punching, bending, forming, and welding operations. These Copper Sheet Metal Parts are widely used in HVAC systems, electrical panels, roofing applications, and decorative elements. The Copper Sheet Metal Parts we produce demonstrate excellent formability characteristics, allowing for complex bends and curves without cracking or material failure. Surface treatments for Copper Sheet Metal Parts include passivation, patina finishing, and protective coatings to enhance durability and aesthetic appeal.

Copper Sheet Metal Components – Precision Assembly Solutions

Copper Sheet Metal Components represent sophisticated assemblies combining multiple fabrication processes to create functional units. Our Copper Sheet Metal Components integrate pressing, welding, and finishing operations to deliver ready-to-install solutions. These Copper Sheet Metal Components include enclosures, brackets, chassis, and complex multi-piece assemblies for electrical and electronic equipment. The design flexibility of Copper Sheet Metal Components allows for custom configurations meeting specific customer requirements while maintaining cost-effectiveness through optimized material utilization and efficient manufacturing processes.

Copper Pressing Work – Specialized Forming Operations

Copper Pressing Work involves sophisticated metal forming operations utilizing progressive dies, compound dies, and transfer dies to achieve precise component geometry. Our Copper Pressing Work capabilities include deep drawing operations achieving draw ratios up to 2.5:1, enabling production of cups, shells, and complex three-dimensional forms. The Copper Pressing Work process parameters are carefully controlled including blank holder pressure, drawing speed, and lubrication systems to prevent material defects such as wrinkling, tearing, or orange peel surface texture. Quality assurance in Copper Pressing Work includes dimensional inspection using coordinate measuring machines and surface finish verification using profilometers.

Copper Deep Drawn Parts – Advanced Forming Capabilities

Copper Deep Drawn Parts showcase our advanced forming capabilities for producing components with high depth-to-diameter ratios. Our Copper Deep Drawn Parts manufacturing process utilizes specialized drawing dies with optimized geometry to achieve uniform wall thickness and smooth surface finish. Common Copper Deep Drawn Parts include cylindrical shells, rectangular boxes, irregular shapes, and stepped components for automotive, electrical, and aerospace applications. The Copper Deep Drawn Parts production process involves multiple drawing stages with intermediate annealing treatments to restore material ductility and prevent work hardening that could lead to component failure.

Copper Shims – Precision Thickness Control

Copper Shims are precision-manufactured thin components designed for spacing, alignment, and adjustment applications. Our Copper Shims are available in thickness ranges from 0.025mm to 2mm with tolerance control of ±0.005mm. These Copper Shims demonstrate excellent dimensional stability under varying temperature conditions due to Copper’s low coefficient of thermal expansion. Copper Shims find extensive applications in motor assembly, gearbox adjustment, valve seating, and precision mechanical equipment where exact spacing is critical for optimal performance.

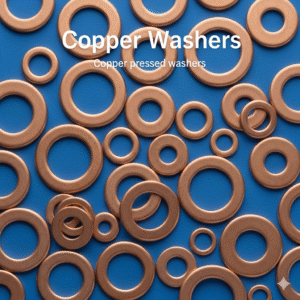

Copper Washers – Sealing and Distribution Solutions

Copper Washers serve dual functions as load distribution elements and sealing components in high-temperature applications. Our Copper Washers are manufactured from oxygen-free Copper grades ensuring consistent material properties and reliable performance. Copper Washers are available in standard sizes conforming to DIN 7603, BS 970, and ASTM specifications, with custom dimensions manufactured to customer drawings. The manufacturing process for Copper Washers includes precision blanking, edge finishing, and surface treatment options including annealing for enhanced formability in assembly applications.

Copper Sealing Washers – High-Performance Sealing Solutions

Copper Sealing Washers are engineered specifically for fluid sealing applications where high temperature and pressure conditions exist. Our Copper Sealing Washers feature precisely controlled dimensions and surface finish to ensure reliable sealing performance. These Copper Sealing Washers are commonly used in automotive drain plugs, hydraulic systems, and industrial piping applications. The material selection for Copper Sealing Washers includes phosphorus deoxidized Copper and oxygen-free Copper variants optimized for specific operating conditions and fluid compatibility requirements.

Copper Gaskets – Advanced Sealing Technology

Copper Gaskets represent sophisticated sealing solutions for extreme temperature and pressure applications including automotive exhaust systems and industrial process equipment. Our Copper Gaskets are manufactured using precision cutting, forming, and finishing processes to achieve optimal sealing surface geometry. Copper Gaskets demonstrate excellent thermal conductivity properties, making them ideal for applications requiring heat dissipation alongside sealing functionality. The manufacturing process includes stress-relief annealing and surface preparation to ensure consistent sealing performance across the entire gasket surface area.

Material Grades and International Standards

| Copper Grade | International Designation | Copper Content | Typical Applications |

|---|---|---|---|

| C101 | UNS C10100 / BS C101 | 99.99% Min | Electrical components, busbars |

| C110 | UNS C11000 / DIN CW024A | 99.90% Min | Heat exchangers, roofing |

| C102 | UNS C10200 / BS C102 | 99.95% Min | Electronic applications |

| C145 | UNS C14500 / DIN CW114C | 99.9% Cu + Te | Electrical contacts |

| C194 | UNS C19400 / JIS C1940 | Cu-Fe-P alloy | Springs, connectors |

Additional International Standards Coverage:

- ASTM Standards: B152, B187, B370, B103, B124

- DIN Standards: EN 1652, EN 1172, DIN 17670

- JIS Standards: H3100, H3110, H3250

- BS Standards: EN 1652, BS 2870

- Indian Standards: IS 407, IS 1545, IS 6912

Manufacturing Processes and Advanced Machinery

Our manufacturing facility utilizes cutting-edge equipment for precision Copper Pressed Parts production:

Progressive Die Stamping: High-speed progressive dies operating at speeds up to 300 strokes per minute for high-volume Copper Sheet Metal Components production.

Deep Drawing Operations: Hydraulic deep drawing presses with tonnage ratings from 50-600 tons, capable of achieving draw ratios exceeding 2.8:1 for complex Copper Deep Drawn Parts.

CNC Machining Centers: 5-axis CNC machining centers for precision finishing operations on Copper Pressed Parts requiring tight tolerances.

Laser Cutting Systems: CO2 and fiber laser cutting systems capable of processing Copper sheets up to 12mm thickness with cutting accuracy of ±0.1mm.

Typical Components Produced

Our comprehensive product range includes specialized Copper Pressed Parts designed for various industrial applications:

Copper Clamps: Heavy-duty electrical connection clamps for power distribution systems, cable terminations, and grounding applications. Available in ratings from 10A to 1000A with appropriate certifications.

Copper Brackets: Structural support brackets for electrical panels, transformer mounting, and architectural applications. Custom designs accommodate specific load requirements and environmental conditions.

Copper Saddles: Cable support saddles and pipe mounting saddles manufactured to precise dimensional specifications for telecommunications and plumbing installations.

- Copper Lugs and Copper Terminals: Stamped and formed from Copper sheet, these are critical for terminating and joining electrical cables in high-current applications.

- Copper Connectors: A variety of stamped connectors, including crimp-style, spade connectors, battery terminals, and coaxial cable connectors.

- Busbars: Thick, stamped Copper strips used for power distribution within control panels, transformers, and battery systems.

- Internal Contacts: Small, precision-stamped contacts and clips for relays, switches, circuit breakers, and fuses.

- EMI/RFI Shields: Stamped Copper enclosures and shields to prevent electromagnetic interference in sensitive electronics.

- Copper Fuse Clips: Stamped and formed clips that hold fuses in place, providing a secure and conductive connection.

- Copper Fuse Holders, Copper Battery Caps and Anodes: Stamped components used in the construction of batteries.

- Motor and Generator Components: Stamped windings, terminals, and other internal parts for small motors and generators.

- Heat Sinks: Stamped Copper heat sinks and cooling fins used to dissipate heat from CPUs, power transistors, and other electronic components.

- Copper Gaskets for Thermal Pads: Precision-stamped Copper gaskets used in conjunction with thermal interface materials to improve heat transfer.

- Radiator Fins: Stamped and formed fins used in automotive and industrial radiators.

- Copper Washers: Stamped flat, lock, and crush washers for sealing, conductivity, and spacing applications.

- Gaskets: Precision-stamped Copper gaskets used for sealing applications in engines, pumps, and valves, valued for their thermal and corrosive resistance.

- Rivets and Eyelets: Small, stamped components for fastening and joining materials.

- Shims: Stamped shims for precise alignment, leveling, and gap-filling.

- Seals: Stamped and formed seals for hydraulic and pneumatic systems.

- Pneumatic and Hydraulic Valve Components: Small, stamped internal parts for valves and fluid control systems.

- Copper Battery Terminals and Clamps: Stamped terminals for car batteries and charging systems.

- Wiring Harness Components: A wide range of stamped Copper connectors, terminals, and splices used within a vehicle’s wiring loom.

- Brake System Components: Stamped washers, bushings, and seals for hydraulic braking systems.

- Exhaust Gaskets: Stamped Copper gaskets for exhaust manifolds and systems due to their ability to withstand high temperatures.

- Aerospace Electricals: Stamped components for aircraft wiring, avionics, and power distribution systems.

- Flashing: Stamped Copper flashing for roofing and waterproofing, valued for its malleability and corrosion resistance.

- Pipe Straps and Clamps: Stamped and formed Copper clamps for securing pipes in plumbing and HVAC systems.

- Fittings and Couplings: While many are cast, certain components like rings and seals for fittings are stamped from Copper.

- Faucet and Valve Components: Small, stamped internal parts for faucets and plumbing valves.

Technical Specifications and Dimensional Chart

| Component Type | Thickness Range | Maximum Dimensions | Tolerance Grade | Surface Finish |

|---|---|---|---|---|

| Pressed Parts | 0.5mm – 5mm | 300mm x 200mm | IT7 – IT9 | Ra 1.6 – Ra 3.2 |

| Deep Drawn Parts | 0.3mm – 3mm | Ø200mm x 150mm depth | IT8 – IT10 | Ra 1.6 – Ra 6.3 |

| Sheet Metal Components | 0.5mm – 6mm | 1000mm x 600mm | IT9 – IT11 | Ra 3.2 – Ra 6.3 |

| Shims | 0.025mm – 2mm | Ø200mm or 200x200mm | IT6 – IT8 | Ra 0.8 – Ra 1.6 |

Industries and Applications

Electrical and Electronics: Power distribution equipment, switchgear components, electrical terminals, and conductor assemblies requiring high conductivity Copper Pressed Parts.

Automotive Industry: Radiator components, electrical harness terminals, brake system components, and heat management solutions utilizing Copper Sheet Metal Components.

HVAC Systems: Heat exchanger components, air conditioning fittings, and thermal management solutions incorporating Copper Deep Drawn Parts.

Telecommunications: RF shielding components, connector assemblies, and grounding systems using precision Copper Sheet Metal Parts.

Marine Applications: Corrosion-resistant fittings, propeller components, and seawater system parts manufactured from marine-grade Copper alloys.

Surface Finishes and Treatment Options

| Finish Type | Process | Thickness | Applications |

|---|---|---|---|

| Mill Finish | As-manufactured | N/A | General industrial use |

| Electroplated Tin | Electrodeposition | 2-15 microns | Food industry, soldering |

| Electroplated Nickel | Electrodeposition | 5-25 microns | Corrosion protection |

| Silver Plating | Electrodeposition | 1-5 microns | Electrical contacts |

| Passivation | Chemical treatment | <1 micron | Corrosion resistance |

Quality Standards and Tolerances

Our quality management system complies with ISO 9001:2015 standards, ensuring consistent quality in all Copper Pressed Parts and Copper Sheet Metal Components. Dimensional tolerances achieved range from ±0.05mm for critical features to ±0.2mm for general dimensions. Surface roughness values typically range from Ra 0.8 to Ra 6.3 depending on the manufacturing process and application requirements.

Turnaround Time and Production Capacity

Standard production turnaround time for Copper Pressed Parts and Copper Sheet Metal Components ranges from 4-6 weeks depending on complexity and quantity. Rush orders can be accommodated with expedited processing for critical applications. Our production capacity includes capability for prototype quantities of 10-50 pieces up to high-volume production runs exceeding 100,000 pieces annually.

Performance Metrics and Testing Procedures

All Copper Pressed Parts undergo rigorous testing including dimensional inspection, material composition verification, and mechanical property testing. Typical performance metrics include tensile strength values ranging from 220-400 MPa, electrical conductivity exceeding 95% IACS, and thermal conductivity values of 350-400 W/m·K depending on the Copper grade utilized.

Frequently Asked Questions (Q&A)

Q1: What are the minimum order quantities for custom Copper Pressed Parts? A1: Our minimum order quantity for custom Copper Pressed Parts is typically 100 pieces for prototype orders and 500 pieces for production runs. However, we can accommodate smaller quantities for specialized applications with appropriate pricing adjustments.

Q2: Do you provide material certificates for Copper Sheet Metal Components? A2: Yes, we provide comprehensive material test certificates (MTC) with each shipment of Copper Sheet Metal Components, including chemical composition analysis, mechanical properties, and compliance with specified international standards.

Q3: Can you manufacture Copper Deep Drawn Parts with complex geometries? A3: Our advanced deep drawing capabilities enable production of Copper Deep Drawn Parts with complex geometries including stepped profiles, flanged edges, and irregular shapes. We utilize specialized tooling and multi-stage forming processes to achieve challenging designs.

Q4: What surface finishes are available for Copper Gaskets and sealing components? A4: Copper Gaskets can be supplied with various surface finishes including mill finish, electroplated tin, nickel plating, and specialized coatings for enhanced sealing performance and corrosion resistance in specific environments.

Q5: Do you offer custom packaging solutions for Copper Washers and small components? A5: We provide customized packaging solutions including customer-branded labels, protective packaging materials, and specialized packaging configurations to meet specific handling and storage requirements for Copper Washers and other small components.

Q6: What quality certifications do you maintain for Copper Pressed Parts manufacturing? A6: Our facility maintains ISO 9001:2015 certification along with AS9100D for aerospace applications. We also comply with RoHS directives and REACH regulations for European market requirements.

Q7: Can you provide technical support for Copper Sheet Metal Components design optimization? A7: Our experienced engineering team provides comprehensive technical support including design for manufacturability (DFM) analysis, material selection guidance, and cost optimization recommendations for Copper Sheet Metal Components projects.

Q8: What are the typical lead times for tooling development for new Copper Pressed Parts? A8: Tooling development for new Copper Pressed Parts typically requires 3-4 weeks for simple progressive dies and 6-8 weeks for complex deep drawing tools, depending on the component complexity and tooling requirements.

Q9: Do you offer secondary operations such as machining and assembly for Copper components? A9: We provide comprehensive secondary operations including CNC machining, drilling, tapping, welding, and assembly services to deliver complete Copper Sheet Metal Components ready for installation.

Q10: What testing and inspection capabilities do you have for dimensional verification? A10: Our quality laboratory includes coordinate measuring machines (CMM), optical comparators, micrometers, and specialized gauging for dimensional verification of all Copper Pressed Parts and Copper Sheet Metal Components.

Q11: Can you supply Copper Shims with custom hole patterns and configurations? A11: Yes, we manufacture Copper Shims with custom hole patterns, slots, and complex geometries using precision punching and laser cutting processes to meet specific application requirements.

Q12: What are your capabilities for high-volume production of Copper Washers? A12: Our high-speed progressive stamping equipment enables production of Copper Washers in volumes exceeding 50,000 pieces per day while maintaining consistent quality and dimensional accuracy.

Material Properties Table

| Property | Pure Copper (C101) | Phosphorus Copper (C110) | Beryllium Copper (C172) |

|---|---|---|---|

| Density (g/cm³) | 8.96 | 8.94 | 8.25 |

| Electrical Conductivity (%IACS) | 101 | 95 | 22-28 |

| Thermal Conductivity (W/m·K) | 391 | 355 | 115-200 |

| Melting Point (°C) | 1083 | 1083 | 980 |

| Tensile Strength (MPa) | 220-310 | 240-320 | 1100-1400 |

| Yield Strength (MPa) | 70-280 | 80-300 | 1000-1300 |

| Elongation (%) | 45-65 | 40-60 | 5-25 |

Why Choose Our Copper Pressed Parts and Sheet Metal Components

Three Decades of Global Experience: With over 30 years of experience in manufacturing Copper Pressed Parts and Copper Sheet Metal Components, we bring unparalleled expertise and proven track record to every project.

Advanced Manufacturing Technology: Our state-of-the-art facility utilizes the latest pressing technology, CNC machining centers, and quality control equipment to ensure superior product quality and consistency.

Faster Turnaround Times: Our streamlined production processes and efficient workflow management enable us to deliver Copper Pressed Parts with industry-leading turnaround times of 4-6 weeks without compromising quality.

Superior Customer Support: Our dedicated technical support team provides comprehensive assistance from initial design consultation through post-delivery support, ensuring seamless project execution.

Excellent Communication Skills: Our English-speaking technical team ensures clear communication throughout the project lifecycle, eliminating misunderstandings and ensuring precise execution of requirements.

Global Market Exposure: Having supplied Copper Sheet Metal Components to customers across North America, Europe, Asia, and other regions, we understand diverse market requirements and international quality standards.

Flexibility in Production Scheduling: We offer flexible production scheduling to accommodate urgent requirements and changing delivery schedules while maintaining quality standards.

Customized Packaging Solutions: Our packaging team provides customized packaging solutions including customer branding, protective materials, and specialized shipping configurations to ensure safe delivery.

Comprehensive Quality Assurance: Our ISO 9001:2015 certified quality management system ensures consistent quality and traceability for all Copper Pressed Parts and components.

Competitive Pricing Structure: Our efficient manufacturing processes and strategic material sourcing enable us to offer competitive pricing while maintaining superior quality standards.

Packaging and Shipping Solutions

Our comprehensive packaging and shipping services ensure safe delivery of Copper Pressed Parts and Copper Sheet Metal Components worldwide. Standard packaging includes protective wrapping, moisture barrier materials, and sturdy export-quality wooden boxes or cardboard cartons depending on component size and customer requirements.

Customized Packaging Options: We offer personalized packaging solutions featuring customer logos, part numbers, and specific handling instructions. Specialized packaging materials including anti-tarnish treatments and corrosion protection are available for sensitive applications.

International Shipping Experience: With extensive experience in international shipping, we handle all export documentation, customs requirements, and logistics coordination to ensure smooth delivery to customers worldwide.

Customer Testimonials

“We have been sourcing Copper Pressed Parts from this company for over 15 years and their quality consistency is exceptional. The engineering support provided during our product development phase was invaluable, and their ability to meet tight delivery schedules has made them our preferred supplier for all Copper Sheet Metal Components. The communication is always professional and clear, making project coordination seamless despite the geographical distance.” – Robert Johnson, Senior Procurement Manager, Michigan, USA

Glossary of Technical Terms

Copper Pressed Parts: Metal components manufactured through pressing operations using specialized dies and punches to form Copper sheets into desired shapes.

Deep Drawing: Manufacturing process where sheet metal is formed into cup-shaped or cylindrical components by drawing the material through a die using a punch.

Progressive Die: Specialized tooling system that performs multiple operations sequentially as the material advances through different stations.

Work Hardening: Increase in material strength and hardness resulting from plastic deformation during forming operations.

Draw Ratio: Relationship between the diameter of the initial blank and the diameter of the drawn component, indicating the severity of the forming operation.

Annealing: Heat treatment process used to restore ductility and relieve internal stresses in work-hardened materials.

Blanking: Cutting operation where the desired shape is punched out of sheet material, with the punched-out piece being the required component.

Forming: General term for manufacturing processes that shape materials through plastic deformation without removing material.

Tolerance: Allowable variation in dimensions or properties of manufactured components.

Surface Roughness: Measure of surface texture typically expressed as Ra (arithmetic average roughness) in micrometers.

Related Copper Parts:

Copper fabrication services, custom Copper pressing, Copper component manufacturing, electrical Copper parts, Copper deep drawing services, precision Copper stamping, Copper sheet fabrication, industrial Copper components, Copper gasket manufacturing, Copper washer production, Copper shim suppliers, Copper bracket fabrication, electrical Copper terminals, Copper heat sink components, Copper connector parts, automotive Copper components, marine Copper fittings, HVAC Copper parts, telecommunications Copper shielding, Copper alloy components, beryllium Copper parts, phosphorus Copper components, oxygen-free Copper parts, high-conductivity Copper components, corrosion-resistant Copper parts.

Technical Infographic Reference

Contact Information and Call-to-Action

Ready to discuss your Copper Pressed Parts and Copper Sheet Metal Components requirements? Our experienced technical team is standing by to provide expert consultation and competitive quotations for your specific applications.

Request a Detailed Quote: Email us your technical drawings and specifications for a comprehensive quotation including material recommendations, manufacturing feasibility analysis, and delivery scheduling.

Download Technical Brochure: Contact us to receive our complete technical brochure featuring detailed specifications, material property data, and case studies of successful Copper Pressed Parts applications.

Speak with Our Engineers: Call us directly at +91-22 43449300 or reach out via WhatsApp for immediate technical consultation and project discussion.

Email:sales@brass-copper-parts. com Phone: +91-22 43449300

Transform your design concepts into precision-manufactured Copper Pressed Parts and Copper Sheet Metal Components with our proven expertise and advanced manufacturing capabilities. Contact us today to experience the difference that three decades of specialized manufacturing experience can make for your next project.