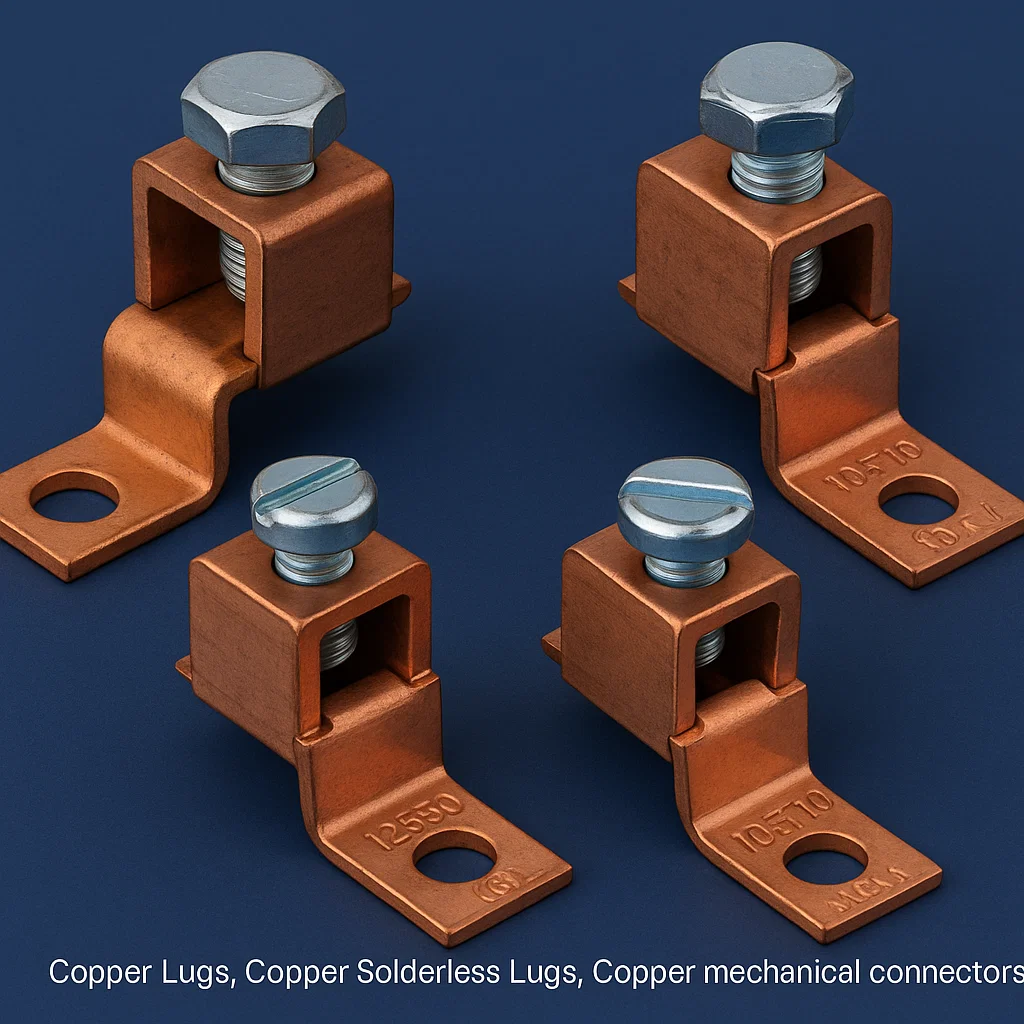

Copper Solderless Lugs, Copper Mechanical Connectors from India.

Copper Solderless Lugs & Copper Mechanical Connectors

We are one of the leading manufacturers and exporters of Copper Solderless Lugs, Copper Mechanical Connectors, and Electrical Terminals from India. We have been supplying premium quality copper electrical components to the world market for many decades. Our extensive range of copper solderless lugs and mechanical connectors caters to diverse industrial applications across electrical, power transmission, telecommunications, and infrastructure sectors. With state-of-the-art manufacturing facilities equipped with advanced machinery and stringent quality control processes, we ensure every product meets international standards including ASTM, DIN, BS, IS, and JIS specifications. Our copper electrical lugs are manufactured using high-grade Copper materials sourced from certified suppliers, ensuring superior conductivity, corrosion resistance, and mechanical strength. The company’s commitment to innovation, quality excellence, and customer satisfaction has established us as a trusted partner for electrical contractors, OEM manufacturers, and distributors worldwide. Our technical expertise spans over three decades, enabling us to provide customized solutions for specific voltage ratings, conductor sizes, and environmental conditions.

Price: US$ 12.50/kilogram

Copper Solderless Lugs Overview

Copper Solderless Lugs represent the pinnacle of electrical connection technology, designed for permanent and reliable termination of electrical conductors without the need for soldering processes. These precision-engineered components are manufactured from high-conductivity Copper alloys conforming to ASTM B152, DIN EN 13599, and JIS H3100 standards. The solderless design eliminates thermal stress on conductors while providing superior electrical and mechanical connection integrity. Our copper solderless lugs feature optimized barrel designs with controlled compression zones that ensure uniform current distribution and minimize hotspot formation. The lugs are available in various configurations including straight barrel, long barrel, and short barrel types to accommodate different cable sizes ranging from 14 AWG to 4/0 AWG and larger. Advanced manufacturing processes including precision forging, machining, and surface treatment ensure dimensional accuracy within ±0.05mm tolerances and consistent electrical performance across the entire product range.

Copper Mechanical Connectors

Copper Mechanical Connectors provide versatile solutions for joining electrical conductors through mechanical compression or bolted connections, eliminating the need for welding or chemical joining processes. These connectors utilize advanced mechanical designs including set screws, compression sleeves, and wedge mechanisms to achieve gas-tight connections with contact resistance values typically below 50 microhms. Our copper mechanical connectors are engineered for applications in power distribution systems, grounding networks, and electrical panels where reliable electrical continuity and ease of installation are paramount. The connectors feature corrosion-resistant tin plating or bare Copper finish options, with material specifications meeting ASTM B124 for forging quality Copper and ASTM B187 for Copper bus bar applications. Mechanical testing includes tensile strength verification, vibration resistance according to IEC 60068-2-6, and thermal cycling tests to ensure long-term reliability in demanding industrial environments.

Copper Mechanical Terminals

Copper Mechanical Terminals serve as critical interface components in electrical systems, providing secure mechanical and electrical connections between conductors and equipment terminals. These terminals incorporate sophisticated clamping mechanisms including spring-loaded contacts, cam-action levers, and torque-controlled screws to maintain consistent contact pressure under varying thermal and mechanical conditions. Our copper mechanical terminals are designed for quick installation and maintenance access while ensuring compliance with electrical safety standards including IEC 60947-7-1 and UL 486A/B specifications. The terminals feature modular designs accommodating wire sizes from 22 AWG to 500 MCM, with current carrying capacities ranging from 15 amperes to 1000 amperes depending on configuration and environmental conditions. Advanced materials including oxygen-free high-conductivity Copper (OFHC) and phosphor Bronze spring contacts ensure minimal electrical losses and extended service life even in harsh industrial environments.

Copper Electrical Lugs

Copper Electrical Lugs represent specialized termination devices engineered for high-performance electrical connections in power transmission, distribution, and control applications. These lugs combine advanced metallurgy with precision manufacturing to deliver superior electrical conductivity, mechanical strength, and environmental durability. Our copper electrical lugs are manufactured using controlled atmosphere forging processes that eliminate porosity and ensure uniform grain structure throughout the conductor interface areas. The lugs feature optimized palm and barrel geometries designed through finite element analysis to minimize stress concentrations and maximize current-carrying capacity. Surface treatments including electroplating with tin, nickel, or silver provide enhanced corrosion resistance and contact stability in diverse environmental conditions. Quality assurance processes include 100% dimensional inspection, electrical conductivity verification using four-wire Kelvin bridge measurements, and mechanical testing according to ANSI/IEEE C119.4 standards to ensure consistent performance and reliability.

🔧 Manufacturing Process Flow

Raw Material → Forging → Machining → Surface Treatment → Quality Testing → Packaging

Each stage monitored with precision instruments ensuring ±0.02mm dimensional accuracy

Material Grades and Specifications

| Standard | Grade/Specification | Composition | Conductivity | Applications |

|---|---|---|---|---|

| ASTM B152 | C11000 (ETP Copper) | 99.90% Cu min | 101% IACS | General purpose electrical |

| DIN EN 13599 | Cu-ETP (E-Cu58) | 99.95% Cu min | 100% IACS | High conductivity applications |

| JIS H3100 | C1020 (Tough Pitch) | 99.96% Cu min | 102% IACS | Premium electrical connections |

| IS 407 | Grade 1 Copper | 99.90% Cu min | 100% IACS | Indian standard applications |

| BS EN 13599 | Cu-ETP1 | 99.95% Cu min | 101% IACS | European applications |

| GB/T 5231 | T2 Copper | 99.95% Cu min | 100% IACS | Chinese standard applications |

Manufacturing Processes and Machinery

Our advanced manufacturing facility employs cutting-edge technology and precision machinery to produce superior quality copper solderless lugs and mechanical connectors. The primary manufacturing process begins with hot forging operations using computer-controlled hydraulic presses capable of 500-ton capacity, ensuring uniform material flow and optimal grain structure. CNC machining centers equipped with carbide tooling and coolant systems maintain dimensional tolerances within ±0.05mm for critical surfaces and hole patterns. Progressive stamping operations utilize high-speed servo presses for volume production of standardized lug configurations, while maintaining consistent quality through real-time force monitoring and statistical process control.

Surface treatment processes include automated electroplating lines with precise chemistry control for tin, nickel, and silver plating applications. Heat treatment furnaces with controlled atmosphere capabilities provide stress relief and grain refinement for enhanced mechanical properties. Quality control equipment includes coordinate measuring machines (CMM), electrical conductivity meters, tensile testing machines, and metallographic analysis systems ensuring every product meets stringent international standards. The manufacturing process is supported by lean manufacturing principles and ISO 9001:2015 quality management systems, enabling consistent production schedules and rapid response to customer requirements.

Technical Specifications and Dimensions

| Part Number | Wire Size (AWG) | Stud Size | Length (mm) | Width (mm) | Thickness (mm) | Current Rating (A) |

|---|---|---|---|---|---|---|

| #DE704 | 6-14 | M8 | 45 | 12 | 3.2 | 85 |

| #DE713 | 3/0-4 | M12 | 75 | 18 | 6.0 | 350 |

| #DE711 | 4-14 | M10 | 52 | 14 | 4.0 | 120 |

| #DE705 | 2-8 | M10 | 58 | 16 | 4.5 | 180 |

| #DE703 | 10-14 | M8 | 42 | 11 | 3.0 | 65 |

| #DE706 | 1/0-6 | M12 | 68 | 17 | 5.5 | 280 |

Industries and Applications

Our copper solderless lugs and mechanical connectors serve diverse industries requiring reliable electrical connections and superior performance characteristics. Power generation facilities including thermal, nuclear, and renewable energy plants utilize our products for critical power transmission applications where safety and reliability are paramount. Electrical distribution networks incorporate our lugs in substations, switchgear, and distribution panels for voltage levels ranging from 480V to 35kV systems. Industrial manufacturing sectors including automotive, aerospace, chemical processing, and steel production rely on our copper electrical components for motor control centers, process control systems, and automation equipment.

Infrastructure projects such as railways, airports, hospitals, and commercial buildings specify our products for grounding systems, lightning protection, and electrical service entrances. Telecommunications and data centers utilize our precision-manufactured lugs for power distribution units, uninterruptible power supplies, and critical infrastructure applications. Marine and offshore applications benefit from our corrosion-resistant designs and environmental sealing capabilities in harsh saltwater environments. Mining and extraction industries depend on our robust mechanical connectors for heavy-duty applications in explosive atmospheres and extreme environmental conditions.

Quality Standards and Certifications

| ISO 9001:2015 | Quality Management System Certification |

| ISO 14001:2015 | Environmental Management System |

| ASTM B152/B124 | Copper Sheet, Strip, Plate and Bus Bar Standards |

| IEC 60068-2-6 | Environmental Testing – Vibration |

| UL 486A/B | Wire Connectors and Soldering Lugs |

| ANSI/IEEE C119.4 | Electrical Connection Testing |

| RoHS Compliance | Restriction of Hazardous Substances |

| CE Marking | European Conformity Declaration |

Performance Metrics and Testing Standards

Contact Resistance: < 50 microhms (ASTM B539) | Tensile Strength: > 200 MPa (ASTM E8) | Electrical Conductivity: > 100% IACS (ASTM E1004) | Corrosion Resistance: 1000+ hours salt spray (ASTM B117) | Temperature Cycling: -40°C to +150°C (IEC 60068-2-14) | Vibration Resistance: 10-2000 Hz, 20g acceleration (IEC 60068-2-6)

Frequently Asked Questions (Technical Q&A)

Q1: What is the difference between solderless lugs and traditional soldered connections?

A1: Solderless lugs provide mechanical compression connections that eliminate thermal stress on conductors, offer faster installation, and enable reversible connections. They maintain consistent electrical performance without the risk of cold solder joints or flux contamination.

Q2: How do I select the correct lug size for my application?

A2: Lug selection depends on conductor size (AWG/MCM), current rating, voltage class, and environmental conditions. Our technical team provides application-specific recommendations based on NEC, IEC, and local electrical codes.

Q3: What torque specifications should be used for installation?

A3: Torque values vary by stud size and application. Typical ranges: M8 studs (8-12 Nm), M10 studs (15-20 Nm), M12 studs (25-35 Nm). Always follow manufacturer specifications and use calibrated torque tools.

Q4: Are your products suitable for aluminum conductors?

A4: Our copper lugs are primarily designed for Copper conductors. For aluminum applications, we recommend our specialized aluminum-to-copper transition lugs with anti-oxidant compounds to prevent galvanic corrosion.

Q5: What environmental conditions can these products withstand?

A5: Our lugs are rated for -40°C to +150°C operation, with optional high-temperature variants to +200°C. They pass 1000+ hour salt spray tests and are suitable for indoor/outdoor installations with appropriate sealing.

Q6: Do you provide custom designs for specific applications?

A6: Yes, we offer custom design services including modified dimensions, special platings, integrated insulators, and application-specific configurations. Our engineering team works closely with customers to develop optimized solutions.

Q7: What is the expected service life of your copper lugs?

A7: Under normal operating conditions, our lugs provide 25+ years of service life. Factors affecting longevity include environmental exposure, thermal cycling, mechanical stress, and maintenance practices.

Q8: How do you ensure consistent quality across production batches?

A8: We implement statistical process control with 100% dimensional inspection, batch-coded traceability, mechanical testing on representative samples, and continuous monitoring of electrical properties throughout production.

Q9: What shipping and packaging options are available?

A9: Standard packaging includes moisture-barrier bags with desiccants, protective foam inserts, and labeled cartons. Custom packaging with customer logos, part number labeling, and kit assembly services are available upon request.

Q10: Can these lugs be used in hazardous locations?

A10: Our standard lugs can be incorporated into hazardous location assemblies when properly installed according to NEC Articles 500-516. We also offer explosion-proof and intrinsically safe variants for specific applications.

Why Choose Our Copper Electrical Products

Our commitment to excellence spans over three decades of global manufacturing experience, establishing us as the preferred partner for discerning customers worldwide. We offer unmatched flexibility in production scheduling with standard lead times of 4-6 weeks and expedited delivery options for urgent requirements. Our technical expertise and engineering support ensures optimal product selection and application guidance, backed by comprehensive technical documentation and installation recommendations.

Customization capabilities include modified dimensions, special materials, unique plating options, and customer-specific packaging with branded labels and logos. Our advanced quality management systems provide full traceability from raw material sourcing through final inspection, ensuring consistent product performance and regulatory compliance. Competitive pricing strategies leverage our efficient manufacturing processes and strategic supplier relationships to deliver exceptional value without compromising quality.

Global market presence with established distribution networks ensures reliable supply chain management and localized customer support across major industrial regions. Our responsive customer service team provides technical assistance, application guidance, and rapid quotation responses, supported by multilingual communication capabilities and cultural awareness gained through decades of international business experience.

“We have been sourcing copper solderless lugs from this manufacturer for over 15 years for our power distribution projects across the United States. Their products consistently exceed our quality expectations, and their technical support team provides invaluable application guidance. The customization capabilities and flexible packaging options have streamlined our inventory management significantly. I highly recommend their products for any critical electrical infrastructure application.”

– Michael Thompson, Senior Electrical Engineer, Texas, USA

Packaging and Shipping Information

Standard packaging utilizes moisture-barrier polyethylene bags with silica gel desiccants to prevent oxidation during storage and transport. Products are individually wrapped or bulk-packed according to customer specifications, with protective foam inserts preventing mechanical damage during handling. Custom packaging solutions include customer-branded boxes, part number labels, barcode integration, and kit assembly services for project-specific requirements.

International shipping capabilities encompass air freight, ocean cargo, and expedited courier services with comprehensive export documentation including certificates of origin, material test certificates, and compliance declarations. Logistics partnerships with major freight forwarders ensure competitive shipping rates and reliable delivery schedules to destinations worldwide. Inventory management programs including vendor-managed inventory (VMI) and just-in-time (JIT) delivery options help customers optimize working capital and reduce storage costs.

Material Properties and Technical Data

| Property | Value | Test Method | Units |

|---|---|---|---|

| Electrical Conductivity | 100-102 | ASTM E1004 | % IACS |

| Thermal Conductivity | 385-400 | ASTM E1461 | W/m·K |

| Tensile Strength | 200-250 | ASTM E8 | MPa |

| Yield Strength | 70-100 | ASTM E8 | MPa |

| Elongation | 30-45 | ASTM E8 | % |

| Hardness | 50-70 | ASTM E18 | HRB |

| Density | 8.96 | ASTM B311 | g/cm³ |

| Melting Point | 1083 | ASTM E794 | °C |

Glossary of Technical Terms

IACS (International Annealed Copper Standard): Reference standard for electrical conductivity measurement, with pure annealed Copper defined as 100% IACS.

AWG (American Wire Gauge): Standardized wire gauge system used in North America for defining conductor cross-sectional area and current-carrying capacity.

MCM (Million Circular Mils): Unit of measurement for large conductor sizes, equivalent to 1000 kcmil or approximately 507 mm² cross-sectional area.

Contact Resistance: Electrical resistance at the interface between conductor and terminal, measured in microhms and critical for minimizing power losses.

Galvanic Corrosion: Electrochemical process occurring when dissimilar metals are in electrical contact within an electrolyte, prevented through proper material selection.

Crimping: Mechanical compression process used to permanently attach lugs to conductors, creating gas-tight electrical and mechanical connections.

Tin Plating: Electroplated coating applied to Copper surfaces to enhance corrosion resistance and improve contact reliability in electrical connections.

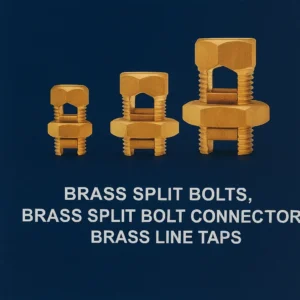

Related Parts:

Copper cable lugs, electrical terminal blocks, wire connectors, cable glands, busbars, grounding lugs, ring terminals, fork terminals, pin terminals, blade terminals, compression connectors, bolted connectors, electrical fittings, power distribution accessories, switchgear components, transformer terminals, motor connection terminals,

Contact Us for Expert Solutions

Ready to enhance your electrical systems with premium quality Copper solderless lugs and mechanical connectors? Our technical team is standing by to provide personalized recommendations and competitive quotations.

Turnaround Time: 4-6 weeks for standard products | Expedited delivery availableGlobal Shipping: Worldwide delivery with full export documentation

Technical Support: 24/7 engineering assistance and application guidance

Experience the difference of working with India’s leading Copper Lug, Copper Mechanical Connector manufacturer with over 30 years of global expertise.

📧 Email Us: sales@brass-copper-parts. com Send your detailed specifications, drawings, and quantity requirements to receive a comprehensive quotation within 24 hours. Our technical team reviews every inquiry personally to ensure accurate pricing and delivery schedules.

📱 WhatsApp/Phone Consultation: Connect directly with our technical specialists for immediate assistance with part design, material selection, and manufacturing recommendations. Our multilingual team provides support across global time zones.

📋 Request Technical Brochure: Download our comprehensive technical catalog featuring complete specifications, material properties, dimensional capabilities, and case studies from successful projects across diverse industries.

🎯 Get Instant Quote: Upload your drawings and specifications through our secure online portal for rapid quotation turnaround. Our automated systems provide preliminary pricing immediately with detailed quotes following within hours.

Special Offer: Mention this webpage for a 5% discount on your first order of Copper Lugs above 10,000 pieces!