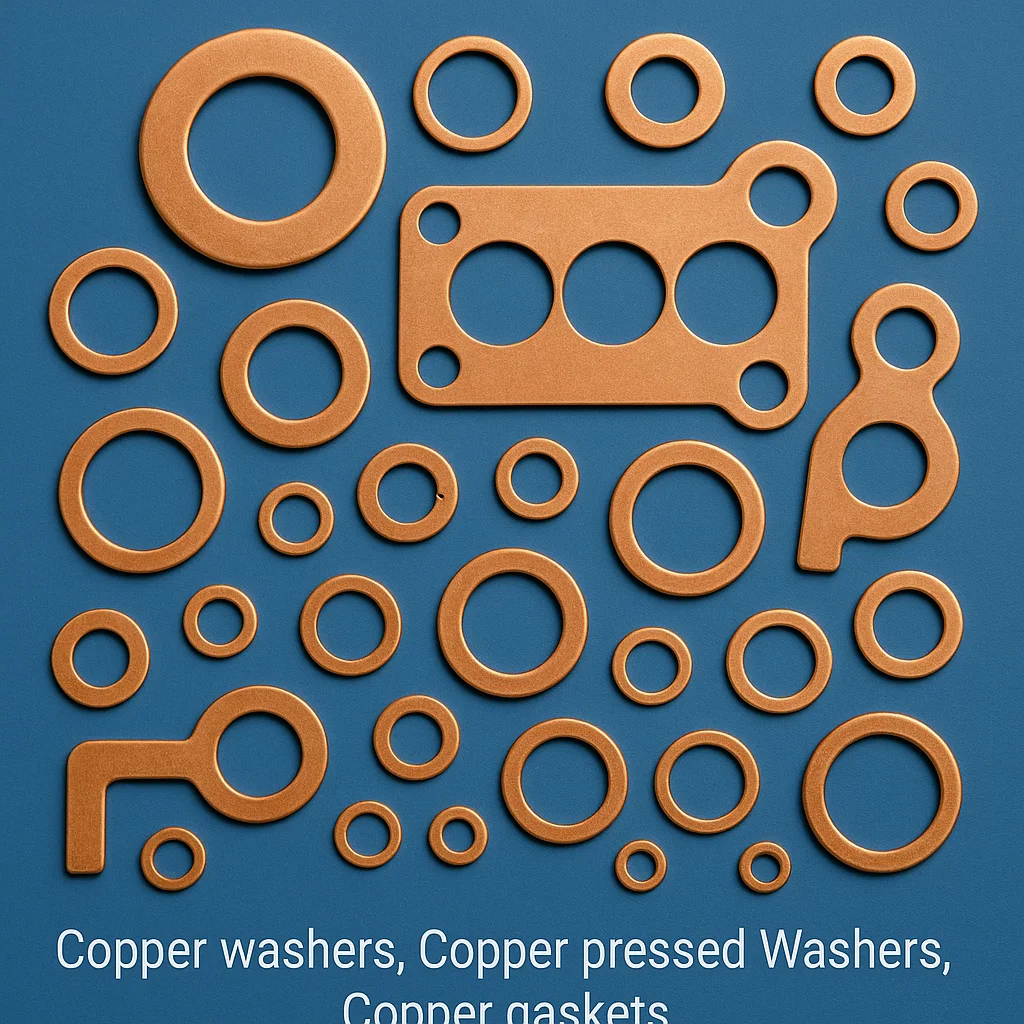

Copper Washers, Copper Pressed washers, Copper plain washers, Copper Tab Washers, Copper Sealing Washers, Copper Shims, Copper Gaskets

Copper Washers, Copper Sealing Washers & Copper Gaskets

We are one of the leading manufacturers and exporters of Copper Washers, Copper Sealing Washers, and Copper Gaskets from India. We have been supplying premium quality copper sealing solutions to the world market for many decades. Our comprehensive range of copper sealing components includes flat washers, sealing washers, gaskets, tab washers, sealing rings, shims, punched washers, and precision machined washers designed for critical sealing applications across automotive, marine, aerospace, and industrial sectors. With over three decades of manufacturing excellence, we specialize in producing high-quality copper sealing solutions that meet stringent international standards including ASTM, DIN, BS, JIS, and IS specifications. Our state-of-the-art manufacturing facility in India combines traditional craftsmanship with modern precision machinery to deliver consistent quality and dimensional accuracy. We cater to diverse industry requirements from high-temperature automotive applications to corrosion-resistant marine environments, ensuring optimal sealing performance under extreme operating conditions. Our expertise extends to custom manufacturing capabilities, allowing us to produce specialized copper sealing components according to customer drawings and specifications with flexible turnaround times. Our deacdal experience of Copper pressed parts, Copper pressed components, Copper sheet metal parts and Components comes handy when it comes to churning out Copper washers in huge volumes.

Price: US$ 12.50/kilogram

Overview of Copper Sealing Solutions

Copper sealing washers and gaskets represent critical components in numerous industrial applications where reliable sealing performance is essential. The inherent properties of Copper, including excellent thermal conductivity, corrosion resistance, and malleability, make it the preferred material for sealing applications in high-temperature environments, automotive engines, hydraulic systems, and marine applications. Our manufacturing process encompasses various production techniques including stamping, punching, machining, and forming to create precision sealing components that meet exact dimensional requirements and performance specifications.

Copper Washers

Standard flat Copper washers are fundamental sealing components used to distribute load and prevent leakage in bolted joints. These washers are manufactured from high-purity Copper sheets through precision stamping and punching operations, ensuring consistent thickness and dimensional accuracy. Our Copper washers are available in various grades including C101, C110, C11000, and internationally equivalent materials conforming to ASTM B152, DIN 17670, BS 2870, and JIS H3100 standards. The manufacturing process involves blanking operations using progressive dies on high-speed stamping presses, followed by deburring and surface finishing. Typical applications include plumbing fittings, automotive brake systems, hydraulic connections, and general industrial sealing requirements where moderate sealing pressure is required.

Copper Gaskets

Copper gaskets are engineered sealing solutions designed for high-pressure and high-temperature applications requiring superior sealing performance. These gaskets are manufactured through precision cutting, forming, and machining processes to achieve exact dimensional tolerances and surface finish requirements. Our Copper gaskets utilize materials conforming to ASTM B152, ASTM B133, DIN 17670, BS 2870, and equivalent international standards including Chinese GB/T 4423 and Japanese JIS H3100 specifications. The manufacturing process involves water-jet cutting, laser cutting, or stamping operations depending on complexity, followed by annealing treatments to optimize sealing characteristics. Common applications include cylinder head gaskets, exhaust manifold gaskets, heat exchanger seals, and high-pressure vessel connections in automotive, marine, and industrial environments.

Copper Tab Washers

Copper tab washers serve dual functions as sealing components and mechanical retention devices, featuring extended tabs that can be bent to secure bolts and prevent loosening. These specialized washers are manufactured through precision stamping operations using progressive dies that form both the washer body and integral tabs in single operations. Material grades include oxygen-free Copper C101, electrolytic tough pitch Copper C110, and phosphorus deoxidized Copper C12200, conforming to ASTM B152, DIN 17670, and BS 2870 standards. Manufacturing involves blanking, forming, and tab creation using compound dies on mechanical or hydraulic presses, ensuring consistent tab dimensions and bend characteristics. Applications include automotive differential housings, transmission cases, marine propulsion systems, and industrial gearboxes where both sealing and mechanical retention are required.

Copper Sealing Rings

Copper sealing rings are precision-engineered circular sealing elements designed for applications requiring reliable radial or axial sealing in cylindrical assemblies. These rings are manufactured through various processes including machining from Copper bar stock, rolling from Copper strip, or forming through specialized ring-rolling operations. Material specifications encompass C101, C110, C11000, C12200 grades conforming to ASTM B124, ASTM B152, DIN 17670, BS 2870, JIS H3100, and Chinese GB/T 4423 standards. The manufacturing process varies based on ring size and application requirements, utilizing CNC machining centers, ring rolling mills, or progressive stamping operations for smaller rings. Surface treatments include annealing for improved sealing characteristics and dimensional stability under compression loading.

Copper Sealing Washers

Copper sealing washers are specialized flat washers designed specifically for sealing applications requiring superior conformability and leak-tight performance. These washers feature carefully controlled thickness tolerances, surface finish specifications, and edge conditions optimized for sealing effectiveness. Manufacturing utilizes high-purity Copper materials including C101 oxygen-free, C110 electrolytic tough pitch, and C12200 phosphorus deoxidized grades conforming to ASTM B152, DIN 17670, BS 2870, JIS H3100, and IS 407 standards. Production processes include precision blanking using compound dies, edge conditioning through tumbling or vibratory finishing, and controlled annealing for optimal sealing characteristics. Applications encompass automotive brake line connections, hydraulic fittings, pneumatic systems, and instrumentation connections requiring reliable low-pressure sealing performance.

Copper Shims

Copper shims are ultra-thin precision components used for dimensional adjustment, gap filling, and sealing applications requiring exact thickness control. These shims are manufactured from cold-rolled Copper strip materials through precision cutting operations maintaining tight thickness tolerances typically within ±0.001 inches. Material grades include C101, C110, C11000, and specialized alloys conforming to ASTM B152, ASTM B36, DIN 17670, BS 2870, and JIS H3100 standards. Manufacturing processes encompass precision shearing, water-jet cutting, laser cutting, and chemical etching depending on thickness requirements and complexity. Surface treatments include bright annealing for dimensional stability and improved surface finish. Applications include valve seat adjustments, bearing clearance control, heat exchanger applications, and precision mechanical assemblies requiring exact dimensional compensation.

Copper Punched Washers

Copper punched washers are cost-effective sealing solutions manufactured through high-speed punching operations using progressive dies and stamping presses. These washers are produced from Copper strip materials in continuous operations ensuring consistent quality and dimensional accuracy across large production runs. Material specifications include C101, C110, C11000, C12200, and specialized Copper alloys conforming to ASTM B152, DIN 17670, BS 2870, JIS H3100, and Chinese GB standards. The punching process utilizes progressive dies on high-speed mechanical presses capable of producing thousands of washers per hour with minimal material waste. Post-processing operations include deburring, surface treatment, and quality inspection to ensure dimensional compliance and surface quality standards.

Copper Machined Washers

Copper machined washers represent the highest precision sealing components manufactured through CNC machining operations from Copper bar stock or forged blanks. These washers are engineered for critical applications requiring exact dimensional tolerances, specific surface finishes, and consistent performance characteristics. Manufacturing utilizes advanced CNC turning and milling centers equipped with precision tooling and measurement systems ensuring dimensional accuracy within ±0.0005 inches. Material grades encompass oxygen-free Copper C101, electrolytic Copper C110, phosphorus deoxidized Copper C12200, and specialized alloys conforming to ASTM B124, ASTM B152, DIN 17670, BS 2870, and aerospace specifications. Applications include aerospace hydraulic systems, high-pressure instrumentation, precision mechanical assemblies, and specialized sealing applications requiring superior dimensional control and surface finish quality.

Material Grades and International Standards

| Material Grade | ASTM Standard | DIN Standard | BS Standard | JIS Standard | Chinese Standard | Copper Content (%) | Key Properties |

|---|---|---|---|---|---|---|---|

| C101 (OF-Cu) | ASTM B152 | DIN 17670 Cu-OF | BS EN 13599 Cu-OF | JIS H3100 C1011 | GB/T 4423 T2 | 99.99 | Oxygen-free, high conductivity |

| C110 (ETP) | ASTM B152 | DIN 17670 Cu-ETP | BS EN 13599 Cu-ETP | JIS H3100 C1100 | GB/T 4423 T1 | 99.90 | Electrolytic tough pitch |

| C11000 | ASTM B152 | DIN 17670 | BS 2870 C101 | JIS H3100 | GB/T 4423 | 99.90 | Excellent formability |

| C12200 (DHP) | ASTM B152 | DIN 17670 Cu-DHP | BS EN 13599 Cu-DHP | JIS H3100 C1220 | GB/T 4423 TP2 | 99.90 | Phosphorus deoxidized |

| C14500 (Tellurium) | ASTM B301 | DIN 17670 | BS 2870 | JIS H3100 | GB/T 4423 | 99.50 | Free machining grade |

Manufacturing Processes and Machinery

Our comprehensive manufacturing capabilities encompass multiple production processes tailored to specific product requirements and quality standards. The primary manufacturing processes include precision stamping operations utilizing high-speed mechanical and hydraulic presses ranging from 50-ton to 500-ton capacity, equipped with progressive dies and compound tooling for complex geometries. CNC machining operations employ state-of-the-art turning centers, machining centers, and multi-axis equipment capable of maintaining tolerances within ±0.0005 inches for critical sealing applications.

| Manufacturing Process | Machinery Used | Capacity Range | Tolerance Capability | Typical Applications |

|---|---|---|---|---|

| Precision Stamping | Mechanical Presses 50-500 Ton | 0.5mm – 50mm thickness | ±0.02mm | Flat washers, punched washers |

| Progressive Die Stamping | High-Speed Stamping Lines | 0.1mm – 25mm thickness | ±0.015mm | Tab washers, complex shapes |

| CNC Machining | Multi-axis Turning Centers | 5mm – 500mm diameter | ±0.005mm | Precision sealing rings, machined washers |

| Water-Jet Cutting | 5-Axis Water-Jet Systems | 0.5mm – 200mm thickness | ±0.05mm | Complex gasket shapes, prototypes |

| Laser Cutting | Fiber Laser Cutting Systems | 0.1mm – 20mm thickness | ±0.02mm | Precision shims, thin washers |

🔧 Copper Washer Manufacturing Process Flow

Raw Material Inspection → Cutting/Blanking → Forming/Stamping → Secondary Operations → Heat Treatment → Quality Control → Packaging & Shipping

Each step incorporates rigorous quality control measures ensuring consistent product quality and dimensional accuracy

Technical Specifications and Dimensional Chart

| Product Type | Inside Diameter (mm) | Outside Diameter (mm) | Thickness Range (mm) | Standard Tolerances | Surface Finish (Ra µm) |

|---|---|---|---|---|---|

| Flat Copper Washers | M3-M100 (3.2-102) | 6-200 | 0.5-10.0 | ±0.05mm | 1.6-3.2 |

| Copper Sealing Washers | M4-M80 (4.3-82) | 8-160 | 0.8-8.0 | ±0.03mm | 0.8-1.6 |

| Copper Gaskets | 10-500 | 20-800 | 0.5-25.0 | ±0.02mm | 0.4-1.6 |

| Copper Tab Washers | M6-M50 (6.4-52) | 12-100 | 1.0-6.0 | ±0.05mm | 1.6-3.2 |

| Copper Sealing Rings | 5-1000 | 15-1200 | 1.0-50.0 | ±0.01mm | 0.2-0.8 |

| Copper Shims | As Required | As Required | 0.05-5.0 | ±0.002mm | 0.1-0.4 |

Material Properties and Performance Metrics

| Property | C101 (OF-Cu) | C110 (ETP) | C12200 (DHP) | Units | Test Method |

|---|---|---|---|---|---|

| Density | 8.94 | 8.94 | 8.94 | g/cm³ | ASTM B311 |

| Electrical Conductivity | 101 | 101 | 85 | %IACS | ASTM B193 |

| Thermal Conductivity | 391 | 391 | 339 | W/m·K | ASTM E1461 |

| Tensile Strength (Annealed) | 220 | 220 | 220 | MPa | ASTM B557 |

| Yield Strength (0.2% offset) | 70 | 70 | 70 | MPa | ASTM B557 |

| Elongation | 45 | 45 | 45 | % | ASTM B557 |

| Hardness (Annealed) | 40-60 | 40-60 | 40-60 | HRB | ASTM E18 |

Industries and Applications

Our Copper sealing solutions serve diverse industrial sectors requiring reliable sealing performance under demanding operating conditions. The automotive industry represents our largest market segment, where Copper washers and gaskets are essential components in engine assemblies, brake systems, transmission units, and exhaust systems. Marine applications utilize our corrosion-resistant Copper sealing products in propulsion systems, hydraulic controls, and deck equipment exposed to saltwater environments.

Automotive Industry: Engine oil drain plugs, brake line connections, fuel system components, transmission seals, exhaust manifold gaskets, hydraulic brake systems, power steering assemblies, air conditioning connections, turbocharger seals, and diesel injection systems requiring high-temperature sealing performance and resistance to automotive fluids.

Marine and Offshore: Propeller shaft seals, hull through-hull fittings, hydraulic steering systems, winch assemblies, deck machinery, ballast systems, fuel transfer systems, and seawater cooling systems where corrosion resistance and reliable sealing under dynamic loading conditions are critical performance requirements.

Aerospace and Aviation: Hydraulic actuator seals, fuel system components, engine accessories, landing gear assemblies, environmental control systems, and avionics cooling systems requiring precision sealing solutions meeting stringent aerospace specifications and performance standards under extreme temperature variations.

Industrial Manufacturing: Hydraulic press systems, pneumatic equipment, process piping, heat exchangers, steam systems, chemical processing equipment, food processing machinery, and general industrial applications requiring reliable sealing performance in various process environments.

Why Choose Our Copper Sealing Solutions?

Three Decades of Manufacturing Excellence: Our extensive experience in Copper sealing component manufacturing ensures proven reliability and consistent quality across all product lines. Advanced Manufacturing Capabilities: State-of-the-art production facilities equipped with precision machinery enabling tight tolerance control and superior surface finish quality. Global Supply Chain Expertise: Established distribution network serving customers worldwide with reliable delivery schedules and comprehensive technical support. Custom Manufacturing Solutions: Flexible production capabilities accommodating customer-specific requirements, custom packaging with customer labels and logos, and rapid prototyping services. Quality Assurance Systems: ISO 9001:2015 certified quality management system ensuring consistent product quality and traceability throughout the manufacturing process. Competitive Turnaround Times: Standard delivery schedules of 4-6 weeks with expedited production capabilities for urgent requirements and emergency supply situations.

Quality Control and Testing Procedures

Our comprehensive quality control system encompasses incoming material inspection, in-process monitoring, and final product testing ensuring compliance with international standards and customer specifications. Material verification includes chemical composition analysis using X-ray fluorescence spectroscopy, mechanical property testing, and dimensional verification using coordinate measuring machines and precision gauging equipment.

| Test Parameter | Test Method | Frequency | Acceptance Criteria | Equipment Used |

|---|---|---|---|---|

| Dimensional Inspection | CMM Measurement | Every Batch | ±0.02mm tolerance | Zeiss CMM, Mitutoyo Calipers |

| Surface Finish | Profilometry | Sample Basis | Ra ≤ 3.2 µm | Mahr Surface Roughness Tester |

| Material Composition | XRF Analysis | Per Heat Lot | ASTM B152 Requirements | Bruker XRF Spectrometer |

| Hardness Testing | Rockwell B Scale | Sample Basis | 40-60 HRB (Annealed) | Wilson Hardness Tester |

| Visual Inspection | Optical Examination | 100% Inspection | No surface defects | Stereo Microscopes |

Frequently Asked Questions (Technical Q&A)

Q1: What is the maximum operating temperature for Copper sealing washers?

A1: Copper sealing washers can operate effectively up to 250°C (482°F) in air environments and up to 150°C (302°F) in oxidizing atmospheres. For higher temperature applications, we recommend annealed Copper grades with optimized grain structure for enhanced thermal stability and creep resistance.

Q2: How do Copper washers compare to other sealing materials for automotive applications?

A2: Copper washers offer superior thermal conductivity, excellent conformability, and resistance to automotive fluids compared to steel or Aluminum alternatives. The malleability of Copper ensures effective sealing at lower bolt torques while maintaining long-term sealing integrity under thermal cycling conditions typical in automotive environments.

Q3: What tolerance capabilities can you achieve for precision Copper gaskets?

A3: Our CNC machining capabilities enable dimensional tolerances within ±0.005mm for critical sealing applications. For standard stamped components, we maintain ±0.02mm tolerances, while specialized shim applications can achieve ±0.002mm thickness control using precision rolling and laser cutting processes.

Q4: Are your Copper sealing products suitable for marine environments?

A4: Yes, Copper exhibits excellent corrosion resistance in seawater applications due to the formation of protective oxide layers. Our marine-grade Copper sealing products utilize C101 or C110 grades with appropriate surface treatments for enhanced performance in saltwater environments and resistance to marine organism fouling.

Q5: Can you manufacture custom Copper gaskets from customer drawings?

A5: Absolutely. Our engineering team specializes in custom gasket manufacturing from customer specifications, CAD drawings, or physical samples. We provide design review services, material recommendations, and prototype development with typical turnaround times of 2-3 weeks for custom tooling and initial samples.

Q6: What quality certifications do your Copper sealing products carry?

A6: Our products are manufactured under ISO 9001:2015 quality management system certification. Material certifications include mill test certificates tracing to original heat lot, dimensional inspection reports, and compliance certificates for ASTM, DIN, BS, JIS, and customer-specific standards as required.

Q7: How do you ensure consistent sealing performance across production batches?

A7: Our statistical process control system monitors critical parameters including dimensional accuracy, surface finish, hardness, and material properties throughout production. Each batch undergoes sample testing with documented results, ensuring consistent sealing performance and traceability for quality assurance requirements.

Q8: What is your minimum order quantity for Copper washers?

A8: Standard minimum order quantities vary by product type: 1,000 pieces for standard flat washers, 500 pieces for sealing washers, and 100 pieces for custom machined components. We accommodate smaller quantities for prototyping and evaluation purposes with adjusted pricing structures.

Q9: Do you provide technical support for sealing application design?

A9: Yes, our technical team offers comprehensive application support including sealing stress analysis, material selection guidance, bolt torque recommendations, and performance optimization for specific operating conditions. We maintain extensive application databases and testing capabilities for validation support.

Q10: What packaging options are available for international shipping?

A10: Standard packaging includes moisture-resistant bags, corrugated boxes, and palletized shipments for larger quantities. Custom packaging options include customer-labeled containers, vacuum-sealed packages, and specialized packaging for sensitive applications. Export documentation includes commercial invoices, packing lists, and certificates of origin.

Q11: Can you supply Copper washers with special surface treatments?

A11: We offer various surface treatments including bright annealing for improved surface finish, passivation for enhanced corrosion resistance, and specialized coatings for specific applications. Surface treatments are selected based on application requirements and compatibility with sealing performance objectives.

Q12: What testing capabilities do you have for validating sealing performance?

A12: Our testing laboratory includes pressure testing equipment for leak verification, thermal cycling chambers for temperature stability evaluation, and material testing capabilities for mechanical property validation. We can perform application-specific testing protocols to validate sealing performance under customer operating conditions.

Customer Testimonial

“We have been sourcing Copper sealing washers from this manufacturer for over 8 years for our automotive brake system applications. Their consistent quality, competitive pricing, and reliable delivery schedules have made them our preferred supplier. The technical support team’s expertise in sealing applications has been invaluable in optimizing our assembly processes and improving product reliability. Their ability to accommodate custom specifications and urgent delivery requirements has exceeded our expectations consistently.”

– Robert Mitchell, Procurement Manager, Detroit Automotive Components

Packaging and Shipping

Our comprehensive packaging solutions are designed to protect product quality during transportation while providing convenient handling and inventory management for customers. Standard packaging utilizes anti-corrosion treatments, moisture-resistant materials, and protective cushioning appropriate for international shipping requirements. Custom packaging options include customer-branded labels, specialized container configurations, and consolidated shipments combining multiple product lines for supply chain efficiency.

Standard Packaging Options: Individual component packaging in sealed plastic bags with desiccant packets, bulk packaging in corrugated containers with foam cushioning, and palletized shipments for large quantities with weather-resistant covering and secure banding. Custom Packaging Services: Customer logo printing on packaging materials, specialized container sizes and configurations, vacuum-sealed packages for sensitive applications, and automated packaging integration compatible with customer assembly line requirements. International Shipping Capabilities: Complete export documentation preparation, freight forwarding services coordination, customs clearance assistance, and tracking information provision throughout delivery process with estimated transit times and delivery confirmation.

Turnaround Time and Production Scheduling

Our production scheduling system accommodates both standard delivery requirements and urgent supply situations through flexible manufacturing capabilities and strategic inventory management. Standard turnaround times of 4-6 weeks encompass material procurement, production scheduling, manufacturing operations, quality control testing, and packaging preparation. Expedited production capabilities enable 2-3 week delivery for urgent requirements through priority scheduling and overtime operations when necessary.

Glossary of Technical Terms

Annealing: Heat treatment process that softens Copper by relieving internal stresses and refining grain structure, improving formability and sealing characteristics for washer applications.

Electrolytic Tough Pitch Copper (ETP): High-purity Copper grade containing trace amounts of oxygen, offering excellent electrical conductivity and forming characteristics suitable for general sealing applications.

Oxygen-Free Copper (OF-Cu): Premium grade Copper with minimal oxygen content, providing superior thermal conductivity and corrosion resistance for demanding sealing applications.

Phosphorus Deoxidized Copper (DHP): Copper grade containing phosphorus additions for improved weldability and resistance to hydrogen embrittlement in high-temperature sealing applications.

Progressive Die Stamping: Manufacturing process utilizing sequential forming operations in a single press stroke, enabling efficient production of complex Copper washer geometries with consistent quality.

Sealing Stress: Compressive force applied to sealing washers during assembly, determining the effectiveness of the seal and preventing leakage under operating conditions.

Thermal Cycling: Repeated heating and cooling cycles that sealing components experience during service, testing the dimensional stability and sealing integrity of Copper washers.

Coordinate Measuring Machine (CMM): Precision measurement equipment used for dimensional verification of Copper sealing components, ensuring compliance with tolerance specifications.

Request Your Custom Quote Today

Ready to source premium quality Copper sealing solutions for your applications?

📧 Email us at: sales@brass-copper-parts. com for detailed product brochures and technical specifications

📱 WhatsApp/Call: +91-22-43449300 immediate technical consultation and pricing information

🌐 Visit our facility: Schedule a factory tour to witness our manufacturing capabilities and quality control processes

📋 Download our catalog: Comprehensive product portfolio with technical data sheets and application guides

Experience the difference that three decades of Copper washers and Copper pressed components , Copper sealing washer expertise can make for your critical applications. Contact us today for competitive pricing, technical support, and reliable delivery solutions tailored to your specific r