Lead Free Brass Components, Lead Free Brass Parts, Lead Free Brass Precision Machining, Lead Free Brass Fittings

Premium Quality Lead free Brass Manufacturing & Export from India

Overview – Lead Free Brass Components Manufacturing

We are one of the leading manufacturers and exporters of Lead Free Brass Components from India. We have been supplying precision engineered lead free brass components, Lead Free Brass Fittings and Lead Free Brass parts to the world market for many decades. Our comprehensive range includes lead free brass turned parts, screw machine components, threaded fittings, and custom machined parts that meet the stringent requirements of plumbing, automotive, marine, and industrial applications. With over three decades of manufacturing excellence, we specialize in producing high-quality lead free brass alloys that comply with international standards including NSF-61, ASTM B124, and European EN 12164 specifications. Our state-of-the-art manufacturing facility in India is equipped with advanced CNC machining centers, multi-spindle automatic machines, and precision turning equipment to deliver components with exceptional dimensional accuracy and surface finish. We maintain strict quality control protocols throughout the manufacturing process, ensuring that every lead free brass component meets or exceeds customer specifications. Our expertise spans across various lead free brass grades including C89833 (Silicon Brass), C46400 (Naval Brass), and proprietary bismuth-bearing alloys that provide superior machinability while maintaining mechanical strength and corrosion resistance properties essential for critical applications.

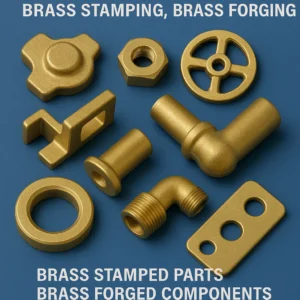

Lead Free Brass Components

Lead free brass components represent the next generation of brass manufacturing, designed to meet environmental regulations and health safety standards worldwide. These components are manufactured using advanced metallurgical techniques that eliminate lead content while maintaining the excellent machinability, corrosion resistance, and mechanical properties that traditional brass alloys offer. Our lead free brass components are produced using carefully controlled alloying processes that incorporate elements such as bismuth, silicon, and tin to achieve optimal performance characteristics. The manufacturing process involves precision melting, casting, and subsequent machining operations using specialized tooling designed for lead free alloys. These components find extensive applications in potable water systems, food processing equipment, marine hardware, and automotive components where lead content restrictions are mandatory. The dimensional stability and consistent material properties of our lead free brass components make them ideal for high-volume production applications requiring tight tolerances and reliable performance. Our quality assurance procedures include spectroscopic analysis to verify lead content compliance, mechanical testing for strength properties, and corrosion resistance evaluation to ensure long-term durability in service conditions.

| Component Type | Material Grade | Lead Content | Typical Applications | Size Range |

|---|---|---|---|---|

| Valve Bodies | C89833 Silicon Brass | <0.25% | Plumbing Fixtures | 1/4″ – 6″ |

| Pipe Fittings | C89836 Red Brass | <0.25% | Water Distribution | 1/8″ – 4″ |

| Marine Hardware | C46400 Naval Brass | Lead Free | Marine Applications | M6 – M50 |

| Automotive Parts | CuZn36Pb2As (Modified) | <0.1% | Fuel Systems | Custom Sizes |

Brass Lead Free Machining

Brass lead free machining requires specialized knowledge and expertise due to the unique characteristics of lead free alloys compared to traditional leaded brass materials. Our advanced machining capabilities encompass CNC turning, milling, drilling, threading, and finishing operations specifically optimized for lead free brass alloys. The machining parameters are carefully controlled to account for the different cutting characteristics of lead free materials, including adjusted cutting speeds, feed rates, and tool geometries to achieve optimal surface finish and dimensional accuracy. Our machine operators are trained in the specific requirements of lead free brass machining, understanding how the absence of lead affects chip formation, tool wear patterns, and surface finish quality. We utilize high-performance cutting tools with specialized coatings and geometries designed for lead free brass machining, ensuring consistent quality and extended tool life. The machining process includes proper coolant selection and application to manage heat generation and maintain dimensional stability during operations. Our quality control procedures for machined lead free brass components include dimensional inspection using coordinate measuring machines, surface roughness measurement, and visual inspection to ensure compliance with customer specifications and industry standards.

Lead Free Brass Machining Process Flow

Our streamlined 7-step process ensures consistent quality and timely delivery

| Machining Operation | Equipment Used | Tolerance Achievable | Surface Finish | Production Rate |

|---|---|---|---|---|

| CNC Turning | Multi-axis CNC Lathes | ±0.005mm (±0.0002″) | Ra 0.8–3.2μm | 500–2000 pcs/day |

| CNC Milling | Vertical Machining Centers | ±0.01mm (±0.0004″) | Ra 1.6–6.3μm | 200–1000 pcs/day |

| Thread Cutting | Thread Rolling Machines | Class 2A/2B | Ra 1.6μm | 1000–5000 pcs/day |

| Drilling Operations | Multi-spindle Drills | ±0.02mm (±0.0008″) | Ra 3.2μm | 2000–10000 pcs/day |

Lead Free Brass Alloys

Lead free brass alloys have been developed to replace traditional leaded brass materials while maintaining comparable mechanical properties and machinability characteristics. These advanced alloys utilize alternative alloying elements such as bismuth, silicon, tin, and antimony to achieve the desired properties without the environmental and health concerns associated with lead content. Our extensive range of lead free brass alloys includes both standard and proprietary compositions designed for specific applications and performance requirements. **EcoBrass® type alloys** represent the latest generation of environmentally friendly brass materials, featuring silicon-enhanced compositions that provide exceptional machinability ratings of 88-92% while maintaining NSF-61 compliance for potable water applications. These innovative alloys include CuZn21Si3P and CuZn35Ni2 variants that offer superior cutting characteristics, reduced tool wear, and excellent surface finish quality compared to traditional bismuth-bearing alternatives. The selection of appropriate lead free brass alloy depends on factors such as mechanical strength requirements, corrosion resistance needs, machinability considerations, and regulatory compliance standards. **Silicon-bearing EcoBrass equivalent alloys** demonstrate outstanding performance in high-speed machining operations, allowing increased cutting speeds and feed rates while maintaining dimensional accuracy and surface finish quality. Our metallurgical expertise enables us to provide technical guidance on alloy selection and processing parameters to ensure optimal performance and cost-effectiveness. The consistent quality and reliability of our lead free brass alloys, including specialized EcoBrass equivalent compositions, are maintained through rigorous incoming material inspection, process control monitoring, and finished product testing to verify compliance with specified chemical composition and mechanical properties.

| Alloy Designation | International Standards | Composition (%) | Tensile Strength (MPa) | Machinability Rating |

|---|---|---|---|---|

| C89833 (Silicon Brass) | ASTM B124, NSF-61 | Cu: 85–89, Zn: 10–14, Si: 3–4 | 380–450 | 85% (Free cutting) |

| C89836 (Red Brass LF) | ASTM B584, EN 12164 | Cu: 84–86, Zn: 14–16, Bi: 0.5–2.5 | 310–380 | 80% (Good) |

| EcoBrass® equivalent C89520 | ASTM B584, NSF-61, DVGW | Cu: 76–79, Zn: 20–23, Si: 1.5–2.5 | 340–420 | 88% (Excellent) |

| EcoBrass® equivalent C89510 | EN 12164, WRAS, NSF-61 | Cu: 85–87, Zn: 12–15, Si: 2.8–3.5 | 360–440 | 90% (Excellent) |

| CuZn21Si3P (EcoBrass equivalent) | EN 12164, DIN 17660 | Cu: 75–77, Zn: 20–22, Si: 2.8–3.2, P: 0.02–0.15 | 420–500 | 92% (Outstanding) |

| CuZn36Pb2As (Modified) | DIN 17660, BS EN 12164 | Cu: 61–63, Zn: 35–37, Bi: 1.5–2.5 | 450–520 | 90% (Excellent) |

| C46400 (Naval Brass LF) | ASTM B171, JIS H3250 | Cu: 59–62, Zn: 37–40, Sn: 0.7–1.2 | 340–410 | 75% (Fair) |

| C89831 (Bismuth Brass) | ASTM B584, NSF-61 | Cu: 81–84, Zn: 14–17, Bi: 1.8–2.5 | 350–420 | 87% (Very Good) |

| CuZn40Pb2 (BiSn Modified) | DIN 17660, EN 12164 | Cu: 57–60, Zn: 38–41, Bi: 1.2–2.0, Sn: 0.3–0.8 | 410–480 | 89% (Very Good) |

| IS 319 Grade A (EcoBrass equivalent) | IS 319, BIS Standards | Cu: 57–60, Zn: 38–42, Bi: 1.0–2.0 | 370–440 | 85% (Very Good) |

| JIS H3250 C6782 (Modified) | JIS H3250, JIS H3270 | Cu: 59–62, Zn: 36–39, Si: 1.5–2.2, Bi: 0.8–1.5 | 390–460 | 86% (Very Good) |

| GB/T 4423 HPb59-3 (LF) | GB/T 4423, Chinese Standard | Cu: 57–60, Zn: 38–42, Bi: 1.5–2.8, Si: 0.5–1.2 | 380–450 | 88% (Excellent) |

| CuZn35Ni2 (EcoBrass equivalent Plus) | EN 12164, DIN 17660 | Cu: 62–65, Zn: 33–36, Ni: 1.8–2.5, Si: 0.8–1.5 | 480–550 | 82% (Good) |

Lead Free Brass Turned Parts

Lead free brass turned parts represent precision-engineered components manufactured using advanced CNC turning operations specifically optimized for lead free brass alloys. These components are produced on high-precision turning centers equipped with live tooling capabilities, sub-spindle operations, and advanced process monitoring systems to ensure consistent quality and dimensional accuracy. The turning process for lead free brass requires careful consideration of cutting parameters, tool selection, and workholding methods to achieve optimal results. Our experienced machinists utilize specialized cutting tools with optimized geometries and coatings designed for lead free brass materials, ensuring excellent surface finish and dimensional precision. The turned parts manufacturing process includes comprehensive programming using CAD/CAM software to optimize tool paths and minimize cycle times while maintaining quality standards. Quality control procedures for lead free brass turned parts include real-time dimensional monitoring during production, final inspection using precision measuring equipment, and statistical process control to ensure consistency across production batches. Our turned parts capabilities include complex geometries with multiple diameters, grooves, threads, and features that can be completed in single setups to minimize handling and maintain tight tolerances.

Typical Lead Free Brass Turned Part Dimensions

Length (L)DLead Free Brass Turned Component

| Dimension | Size Range | Tolerance | Standard Finishes |

|---|---|---|---|

| Outside Diameter (OD) | 3mm – 200mm | ±0.005mm to ±0.05mm | As Machined, Polished |

| Inside Diameter (ID) | 1mm – 180mm | ±0.01mm to ±0.05mm | Reamed, Honed |

| Length | 5mm – 500mm | ±0.02mm to ±0.1mm | Faced, Ground |

| Thread Pitch | M3 – M48, NPT, BSP | Class 2A/2B/3A/3B | Cut, Rolled |

Lead Free Brass Screw Machine Parts

Lead free brass screw machine parts are precision components manufactured using high-speed automatic screw machines designed to produce large quantities of small to medium-sized parts with excellent repeatability and cost-effectiveness. These specialized machines are particularly well-suited for lead free brass materials, utilizing their improved machinability characteristics while maintaining the productivity advantages of traditional screw machining operations. Our screw machine operations include both single-spindle and multi-spindle automatic machines capable of performing multiple operations simultaneously, including turning, drilling, threading, knurling, and cross-drilling in a single setup. The programming and setup of screw machines for lead free brass requires specialized knowledge of material flow characteristics, cutting tool selection, and process optimization to achieve maximum productivity while maintaining quality standards. Quality assurance for screw machine parts includes statistical process control monitoring, automated dimensional inspection systems, and regular sampling procedures to ensure consistent quality throughout production runs. The high-volume production capabilities of screw machine operations make them ideal for automotive, plumbing, electrical, and industrial applications requiring large quantities of precision lead free brass components at competitive pricing.

| Part Type | Machine Type | Production Rate | Size Range | Typical Applications |

|---|---|---|---|---|

| Connector Pins | 6-Spindle Automatic | 10,000-50,000/day | 2-20mm dia | Electrical Connectors |

| Valve Stems | 8-Spindle Automatic | 5,000-25,000/day | 5-25mm dia | Plumbing Valves |

| Threaded Inserts | Single Spindle | 2,000-10,000/day | M3-M20 | Automotive Applications |

| Precision Bushings | Swiss Type | 1,000-5,000/day | 3-50mm dia | Industrial Machinery |

Lead Free Brass Threaded Components

Lead free brass threaded components are precision-engineered fasteners and connecting elements that provide reliable mechanical joints in applications where lead content restrictions apply. These components are manufactured using advanced thread cutting and rolling techniques specifically optimized for lead free brass alloys to ensure proper thread form, surface finish, and dimensional accuracy. The threading process for lead free brass materials requires careful selection of cutting tools, thread forming methods, and process parameters to achieve optimal thread quality and production efficiency. Our threading capabilities include both cut threads and rolled threads, with each method offering specific advantages depending on the application requirements and production volumes. Cut threads provide precise dimensional control and are ideal for critical applications requiring exact thread specifications, while rolled threads offer superior strength characteristics and surface finish quality through the work-hardening effect of the rolling process. Quality control procedures for threaded components include thread gauge verification, dimensional inspection, and torque testing to ensure compliance with applicable thread standards including ISO metric, unified thread standard, and specialty thread forms. The consistent thread quality and reliability of our lead free brass threaded components make them suitable for demanding applications in plumbing systems, automotive assemblies, marine hardware, and industrial equipment.

| Thread Type | Size Range | Thread Class | Manufacturing Method | Typical Applications |

|---|---|---|---|---|

| ISO Metric | M3 – M48 | 4H/6H, 6G/8G | Cut/Rolled | General Purpose |

| NPT (National Pipe Thread) | 1/8″ – 4″ | Class A/B | Cut Threading | Plumbing Fittings |

| BSP (British Standard Pipe) | 1/8″ – 4″ | Class A/B | Cut Threading | European Market |

| UNC/UNF (Unified Thread) | #4-40 to 2″-4.5 | 1A/2A/3A | Cut/Rolled | North American Market |

| Custom Threads | Per Specification | Customer Defined | Cut Threading | Special Applications |

Lead Free Brass Fittings

Lead free brass fittings represent the cornerstone of modern plumbing and fluid handling systems, engineered to meet stringent environmental regulations while delivering superior performance in demanding applications. Our comprehensive range encompasses precision-manufactured tees, elbows, nipples, end caps, plugs, unions, couplings, reducers, and specialty fittings crafted from premium lead free brass alloys including Ecobrass type compositions and silicon-enhanced variants. These critical components are manufactured using advanced casting, hot forging, and precision machining techniques to achieve exceptional dimensional accuracy, optimal flow characteristics, and reliable long-term performance in service conditions ranging from residential water systems to industrial process applications.

The manufacturing excellence of our lead free brass fittings begins with careful alloy selection, utilizing C89833 silicon brass, EcoBrass ® equivalent C89520, and specialized bismuth-bearing compositions that provide superior machinability while maintaining NSF-61 compliance for potable water applications. Each fitting undergoes rigorous quality control procedures including hydrostatic pressure testing at 1.5 times working pressure, dimensional verification using coordinate measuring machines with ±0.005mm accuracy, and comprehensive chemical composition analysis to verify lead content below 0.25% (or 0.1% for NSF-61 applications). Our fittings are designed with optimized internal geometries to minimize pressure drop and turbulence while maximizing flow efficiency and system performance.

The extensive product line includes **NPT threaded fittings** for North American markets, **BSP threaded components** for European and Asian applications, **compression fittings** for easy installation without threading, **push-fit connectors** for rapid assembly systems, and **sweat fittings** for soldered copper tube connections. Specialized configurations include reducing fittings for different pipe sizes, street fittings with male-female combinations, close nipples for tight installations, and hex nipples for wrench access in confined spaces. Our lead free brass fittings comply with multiple international standards including ASTM B584, EN 12164, DIN 17660, JIS H3250, and regional plumbing codes, ensuring global market acceptance and regulatory compliance.

Surface finish options range from standard as-cast surfaces suitable for general applications to precision-machined finishes for critical installations, with optional protective coatings including nickel plating, chrome plating, and specialized corrosion-resistant treatments for marine and chemical processing environments. The fittings undergo comprehensive testing protocols including burst pressure verification, thread gauge inspection, dimensional compliance checking, and long-term durability assessment under accelerated aging conditions. Quality certifications include material test certificates, pressure test reports, NSF-61 compliance documentation, and dimensional inspection reports provided with every shipment to ensure complete traceability and customer confidence.

| Fitting Type | Size Range | Connection Types | Pressure Rating | Standards Compliance |

|---|---|---|---|---|

| Tees (Equal/Reducing) | 1/8″ – 6″ | NPT, BSP, Sweat, Push-fit | 150-600 PSI | ASTM B584, NSF-61 |

| Elbows (90°/45°) | 1/8″ – 6″ | NPT, BSP, Sweat, Flare | 150-600 PSI | ASTM B584, EN 1254 |

| Nipples (Close/Long) | 1/8″ – 4″ | NPT Both Ends | 200-800 PSI | ASTM B687, NSF-61 |

| End Caps | 1/8″ – 4″ | NPT, BSP Internal | 150-600 PSI | ASTM B584, WRAS |

| Plugs (Square/Hex) | 1/8″ – 4″ | NPT, BSP External | 150-600 PSI | ASTM B687, CSA |

| Unions | 1/2″ – 2″ | NPT, BSP | 150-400 PSI | ASTM B584, NSF-61 |

Manufacturing Processes & Machinery

Our comprehensive manufacturing facility utilizes state-of-the-art machinery and advanced manufacturing processes specifically configured for lead free brass component production. The manufacturing process begins with careful material selection and incoming inspection to verify chemical composition and mechanical properties of lead free brass alloys. Primary forming operations include precision casting using permanent molds and investment casting techniques for complex geometries, hot forging for high-strength applications, and cold forming for dimensional accuracy and surface finish requirements. Secondary machining operations utilize CNC turning centers, multi-axis machining centers, and specialized equipment including Swiss-type lathes for precision components and multi-spindle automatic machines for high-volume production. Heat treatment facilities provide solution annealing, stress relieving, and aging treatments to optimize mechanical properties and dimensional stability. Surface finishing operations include mechanical polishing, electroplating, passivation treatments, and protective coatings to enhance corrosion resistance and aesthetic appearance. Quality control equipment includes coordinate measuring machines, optical measuring systems, spectroscopic analyzers, and mechanical testing equipment to ensure compliance with customer specifications and industry standards.

| Manufacturing Process | Equipment Details | Capacity | Tolerance Capability |

|---|---|---|---|

| CNC Turning | Haas ST-30, Mazak QTN-350, DMG CTX Beta | Ø3-200mm, Length 500mm | ±0.005mm |

| CNC Milling | Haas VF-4SS, Mazak VCN-530C | 530×410×460mm | ±0.01mm |

| Swiss Machining | Citizen L20, Star SR-20J | Ø20mm max, Length 300mm | ±0.002mm |

| Screw Machine | Brown & Sharpe 00G, Davenport 5/8″ | Ø20mm max, High Volume | ±0.02mm |

| Thread Rolling | Reed Rico TR-12, Perfmac TR-8 | M3-M30 threads | Class 2A/2B |

| Hot Forging | 500T Press, Induction Heating | Up to 5kg components | ±0.2mm |

Material Property Tables

| Property | C89833 Silicon Brass | EcoBrass® equivalent C89520 | CuZn21Si3P | C89831 Bismuth | Test Method |

|---|---|---|---|---|---|

| Tensile Strength (MPa) | 380-450 | 340-420 | 420-500 | 350-420 | ASTM B557 |

| Yield Strength (MPa) | 170-220 | 150-200 | 190-240 | 160-210 | ASTM B557 |

| Elongation (%) | 15-25 | 18-28 | 12-20 | 16-24 | ASTM B557 |

| Hardness (HB) | 90-120 | 85-110 | 105-135 | 88-115 | ASTM E10 |

| Density (g/cm³) | 8.4-8.6 | 8.2-8.4 | 8.3-8.5 | 8.5-8.7 | ASTM B311 |

| Thermal Conductivity (W/m·K) | 85-95 | 90-105 | 88-98 | 95-110 | ASTM E1461 |

| Corrosion Rate (mpy) | <0.5 | <0.3 | <0.4 | <0.4 | ASTM B117 |

| Machinability Index | 85% | 88% | 92% | 87% | Relative to C36000 |

Quality Standards & Tolerances

Our lead free brass components are manufactured to meet or exceed international quality standards and precision tolerance requirements. We maintain comprehensive quality management systems certified to ISO 9001:2015 standards, with specialized procedures for lead free brass manufacturing and testing. Standard manufacturing tolerances range from ±0.002mm for critical dimensions on precision Swiss-machined components to ±0.1mm for general tolerance features on forged and cast components. Surface finish specifications typically range from Ra 0.8μm for precision ground surfaces to Ra 6.3μm for as-machined surfaces, depending on application requirements and customer specifications. Thread tolerances are maintained according to ISO 965, ANSI B1.1, and DIN 13 standards, with typical thread classes of 2A/2B for general applications and 3A/3B for precision applications requiring tighter fits. Geometric tolerances including concentricity, perpendicularity, and cylindricity are controlled using statistical process control methods and verified using coordinate measuring machines with measurement uncertainties of ±0.001mm. All lead free brass materials undergo chemical composition verification using X-ray fluorescence spectroscopy to confirm lead content compliance, with typical lead content measurements of less than 0.1% for NSF-61 compliance and less than 0.25% for general lead free applications.

| Tolerance Class | Dimension Range | Tolerance (±mm) | Surface Finish (Ra μm) | Applications |

|---|---|---|---|---|

| Precision | Up to 50mm | 0.002-0.005 | 0.8-1.6 | Critical Components |

| Close | Up to 100mm | 0.005-0.02 | 1.6-3.2 | Precision Fittings |

| Standard | Up to 200mm | 0.02-0.05 | 3.2-6.3 | General Components |

| Commercial | Over 200mm | 0.05-0.1 | 6.3-12.5 | Standard Fittings |

Industries & Applications

Lead free brass components serve critical roles across diverse industries where environmental compliance, corrosion resistance, and mechanical reliability are essential requirements. The plumbing and water distribution industry represents the largest application segment, utilizing lead free brass fittings, valves, and connectors in residential and commercial building systems to ensure safe potable water delivery. Automotive applications include fuel system components, hydraulic fittings, and emission control parts where lead-free materials are mandated by environmental regulations. Marine hardware applications benefit from the excellent corrosion resistance of lead free brass alloys in saltwater environments, including propeller shafts, through-hull fittings, and deck hardware. Food processing and beverage industries require lead free materials for direct food contact applications, utilizing specialized components for processing equipment, dispensing systems, and packaging machinery. Oil and gas industry applications include wellhead components, valve trim parts, and instrumentation fittings designed for harsh operating conditions. Electrical and electronic industries utilize lead free brass components for connectors, terminals, and grounding hardware where conductivity and corrosion resistance are critical. Medical device manufacturing employs lead free brass components in surgical instruments, diagnostic equipment, and patient care devices where biocompatibility is essential.

Key Industry Applications

Plumbing & Water Systems: NSF-61 compliant fittings for potable water, irrigation systems, and commercial plumbing installations requiring zero lead content for health safety compliance.

Automotive Industry: Fuel injection components, brake system fittings, air conditioning parts, and emission control system components meeting OSHA and EPA environmental standards.

Marine & Offshore: Seawater-resistant components including propeller hardware, through-hull fittings, deck equipment, and offshore platform instrumentation requiring superior corrosion resistance.

Food & Beverage: FDA-compliant components for food processing equipment, brewing systems, dairy processing, and beverage dispensing applications requiring food-safe materials.

Turnaround Time & Production Scheduling

Our standard turnaround time for lead free brass components is 4-6 weeks from order confirmation to shipment, depending on part complexity, quantity requirements, and current production schedule. Rush orders can be accommodated with expedited processing in 2-3 weeks for standard components and existing tooling situations. New product development including prototyping, tooling design, and first article inspection typically requires 6-8 weeks for complex components and 3-4 weeks for simple turned parts. High-volume production runs are scheduled based on capacity planning and material availability, with typical lead times of 6-8 weeks for quantities exceeding 10,000 pieces. Our production planning system optimizes manufacturing schedules to minimize setup times and maximize equipment utilization while maintaining delivery commitments. Customers receive regular progress updates including order acknowledgment, material procurement status, production start notifications, and shipping confirmations. Emergency orders for critical applications can be processed with 48-hour turnaround for simple components from available stock materials, subject to manufacturing capacity and material availability. Long-term supply agreements provide guaranteed delivery schedules and priority production allocation for customers with recurring requirements and established volume commitments.

Performance Metrics & Testing

Our lead free brass components undergo comprehensive performance testing to verify compliance with specifications and ensure reliable service life in demanding applications. Mechanical testing includes tensile strength verification, yield strength measurement, elongation testing, and hardness evaluation according to ASTM standards. Corrosion resistance testing follows ASTM B117 salt spray procedures with minimum 240-hour exposure for standard applications and extended 1000-hour testing for marine applications. Pressure testing of fittings and threaded components includes hydrostatic testing at 1.5 times working pressure for 30 seconds minimum, with leak detection using helium mass spectrometry for critical applications. Dimensional verification utilizes coordinate measuring machines with documented measurement uncertainty and calibration traceability to NIST standards. Chemical composition analysis employs X-ray fluorescence spectroscopy for lead content verification and optical emission spectroscopy for complete elemental analysis. Fatigue testing simulates service conditions with cyclic loading and temperature variations to verify long-term reliability and service life expectations. Surface finish measurement uses calibrated profilometers to verify Ra values and ensure consistent surface quality across production batches.

| Test Parameter | Test Method | Acceptance Criteria | Frequency |

|---|---|---|---|

| Lead Content | XRF Spectroscopy | <0.25% (NSF-61: <0.1%) | Every Heat/Lot |

| Tensile Strength | ASTM B557 | Per Alloy Specification | Weekly/Process Change |

| Pressure Test | Hydrostatic Testing | 1.5x Working Pressure | 100% (Fittings) |

| Dimensional | CMM Inspection | Per Drawing/Specification | First Article + Sampling |

| Surface Finish | Profilometer | Ra per Specification | Process Control |

| Corrosion Resistance | ASTM B117 | No visible corrosion 240hrs | New Products/Annual |

Frequently Asked Questions (Q&A)

Q1: What makes lead free brass different from traditional brass alloys?

A: Lead free brass alloys eliminate or significantly reduce lead content (typically <0.25%) while maintaining comparable mechanical properties and machinability through alternative alloying elements like bismuth, silicon, and tin.

Q2: Are lead free brass components suitable for potable water applications?

A: Yes, our NSF-61 certified lead free brass components are specifically designed for potable water systems and comply with EPA Lead and Copper Rule requirements for safe drinking water delivery.

Q3: What tolerance levels can be achieved with lead free brass machining?

A: We routinely achieve tolerances of ±0.005mm (±0.0002″) on critical dimensions using precision CNC equipment, with even tighter tolerances possible for special applications using Swiss-type machines.

Q4: How does the machinability of lead free brass compare to leaded brass?

A: Modern lead free brass alloys like C89833 achieve 85-90% of traditional leaded brass machinability through optimized alloy chemistry and advanced cutting tool technology.

Q5: What surface finishes are available for lead free brass components?

A: Available finishes include as-machined (Ra 3.2-6.3μm), polished (Ra 0.8-1.6μm), passivated, nickel plated, chrome plated, and specialty coatings for specific applications.

Q6: Can you manufacture custom lead free brass components to customer specifications?

A: Yes, we specialize in custom manufacturing from customer drawings, specifications, or samples, with full engineering support for design optimization and material selection.

Q7: What quality certifications do your lead free brass components carry?

A: Our components are manufactured under ISO 9001:2015 quality systems with NSF-61, ASTM, DIN, and other relevant standard compliance certifications available upon request.

Q8: What is the typical lead time for lead free brass component orders?

A: Standard lead time is 4-6 weeks for production quantities, with expedited 2-3 week delivery available for urgent requirements and existing tooling situations.

Q9: Do you provide material certificates and test reports?

A: Yes, we provide comprehensive mill test certificates, chemical analysis reports, mechanical property verification, and dimensional inspection reports with every shipment.

Q10: What minimum order quantities do you require?

A: Minimum order quantities vary by component complexity and manufacturing method, typically ranging from 100 pieces for complex machined parts to 1000+ pieces for high-volume screw machine parts.

Q11: Can you supply components with special packaging requirements?

A: Yes, we offer customized packaging including customer-labeled boxes, anti-corrosion protection, controlled atmosphere packaging, and special handling for sensitive components.

Q12: What international shipping options are available?

A: We provide comprehensive international shipping via air freight, sea freight, and express courier services with full documentation support including certificates of origin and compliance documentation.

“We have been sourcing lead free brass components from this Indian manufacturer for over 8 years and their quality consistency in Lead Free Brass Machining is outstanding. Their technical support team helped us optimize our designs for better performance while reducing costs. The 4-week delivery schedule is reliable and their communication throughout the process is excellent. We particularly appreciate their ability to handle both prototype quantities and high-volume production runs with the same attention to detail.”

— Neil Hodson, Senior Procurement Manager , Ohio, USA

Why Choose Our Lead Free Brass Components

Our three decades of specialized experience in lead free brass manufacturing provides customers with unmatched expertise, quality assurance, and technical support for demanding applications. We maintain comprehensive inventory of lead free brass raw materials to ensure consistent availability and rapid response to customer requirements. Our engineering team provides technical consultation for material selection, design optimization, and manufacturing process development to ensure optimal component performance and cost-effectiveness. Advanced quality control systems including real-time process monitoring, statistical process control, and comprehensive inspection procedures guarantee consistent quality and dimensional accuracy across all production batches. Flexible production capabilities accommodate both prototype development and high-volume manufacturing requirements with scalable processes and equipment configurations. Competitive pricing structures benefit from efficient manufacturing operations, strategic raw material procurement, and optimized production scheduling to provide excellent value propositions. Global logistics capabilities ensure reliable delivery to international markets with comprehensive documentation support and regulatory compliance assistance. Customized packaging solutions include customer branding, special protection requirements, and logistics optimization to reduce shipping costs and ensure product integrity during transit.

Our Unique Selling Propositions (USPs)

Customization Capability: Complete engineering support from design concept through production implementation, including material selection optimization and manufacturing process development tailored to specific application requirements.

Flexible Production Scheduling: Adaptive manufacturing schedules accommodate urgent requirements, seasonal demands, and long-term supply agreements with guaranteed delivery commitments and priority allocation systems.

Custom Packaging Solutions: Comprehensive packaging options including customer logo labeling, anti-corrosion protection, controlled atmosphere packaging, and specialized handling for sensitive or precision components.

Global Experience: Three decades of international export experience serving customers across North America, Europe, Asia-Pacific, and Middle East markets with full regulatory compliance and documentation support.

Packaging & Shipping

Our comprehensive packaging and shipping services ensure product integrity and delivery reliability for international and domestic customers. Standard packaging utilizes corrosion-resistant materials including VCI (Volatile Corrosion Inhibitor) papers, desiccant packets, and moisture barrier films to protect lead free brass components during storage and transit. Custom packaging solutions accommodate specific customer requirements including branded labeling, specialized protective materials, and quantity-specific packaging configurations. Export packaging complies with international shipping regulations including ISPM-15 wooden packaging standards, hazardous materials classifications, and country-specific import requirements. Documentation services include commercial invoices, packing lists, certificates of origin, material certificates, inspection reports, and specialized compliance documentation for regulated industries. Shipping options encompass express courier services for urgent requirements, air freight for standard deliveries, and sea freight for large volume shipments with full container load and less-than-container load capabilities. Logistics partnerships with major international carriers provide competitive shipping rates, comprehensive tracking capabilities, and delivery confirmation services. Insurance coverage protects against loss or damage during transit with comprehensive claims support and replacement procedures to minimize customer disruption.

| Packaging Type | Application | Protection Level | Customization Options |

|---|---|---|---|

| Standard Industrial | General Components | Basic Corrosion Protection | Quantity Labels |

| Export Grade | International Shipping | Enhanced Protection | Customer Branding |

| Precision Component | Critical Parts | Individual Protection | Custom Foam Inserts |

| Controlled Atmosphere | Sensitive Applications | Maximum Protection | Vacuum/Gas Flushed |

Size & Dimensional Chart

| Component Category | Minimum Size | Maximum Size | Standard Increments | Custom Sizes Available |

|---|---|---|---|---|

| Turned Components – Diameter | 3mm (0.118″) | 200mm (7.87″) | 0.5mm (0.02″) | Yes |

| Turned Components – Length | 5mm (0.197″) | 500mm (19.69″) | 1mm (0.04″) | Yes |

| Threaded Parts – Metric | M3x0.5 | M48x5.0 | Standard Metric | Custom Pitch |

| Threaded Parts – Imperial | #4-40 UNC | 2″-4.5 UNC | Standard UNC/UNF | Special Threads |

| Pipe Fittings – NPT | 1/8″ NPT | 6″ NPT | Standard NPT Sizes | Limited |

| Pipe Fittings – BSP | 1/8″ BSP | 4″ BSP | Standard BSP Sizes | Limited |

| Screw Machine Parts | 2mm (0.079″) | 25mm (0.984″) | 0.1mm (0.004″) | Yes |

Related Items:

Glossary of Technical Terms

Thread Rolling: Cold forming process that creates threads through plastic deformation, resulting in superior strength and surface finish compared to cut threads.

Request Your Quote Today

Ready to source high-quality lead free Brass components or Lead Free Brass Fittings for your next project? Our expert team is standing by to provide technical consultation, material recommendations, and competitive pricing for your specific requirements.

Quick Response Guarantee: Technical inquiries answered within 4 hours | Quotes provided within 24 hours | Sample availability confirmed within 48 hours

Leading Manufacturer & Exporter of Lead Free Brass Components | ISO 9001:2015 Certified | NSF-61 Compliant | Serving Global Markets Since 32 yrs