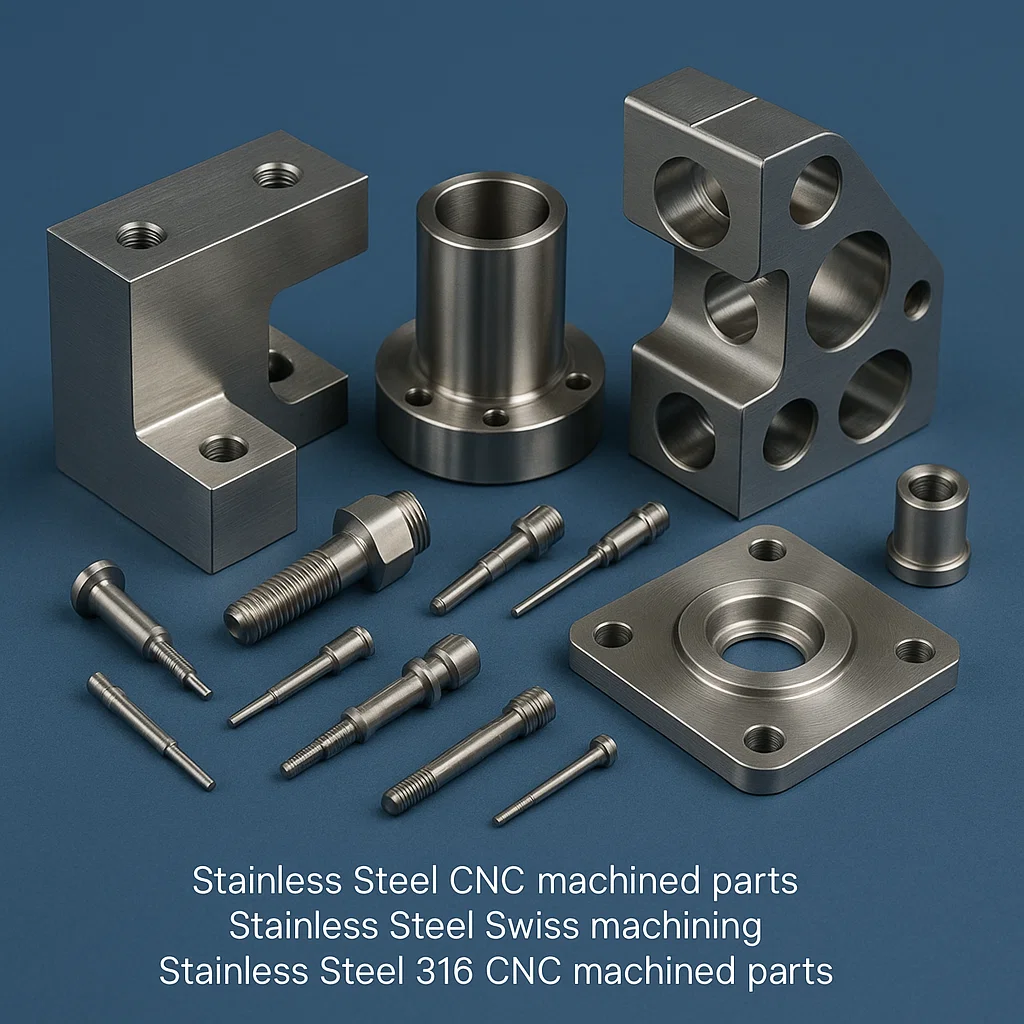

Stainless Steel CNC Parts, Stainless Steel CNC Machined Components-Parts

Price: US$ 11.80/Kilogram

Overview

We are one of the leading manufacturers and exporters of Stainless Steel CNC Parts and Stainless Steel CNC Machined Components from India. We have been supplying precision-engineered Stainless Steel components to the world market for many decades. Our state-of-the-art CNC machining facilities specialize in producing high-quality Stainless Steel parts that meet stringent international standards including ASTM, DIN, BS, IS, and JIS specifications. With over three decades of global exposure and experience, we have established ourselves as a trusted partner for industries requiring precision Stainless Steel CNC machined components. Our comprehensive manufacturing capabilities encompass everything from simple Stainless Steel CNC parts to complex multi-axis machined components, serving diverse industries including aerospace, automotive, medical devices, pharmaceutical, marine, and industrial equipment sectors. We maintain strict quality control protocols throughout our manufacturing process, ensuring each Stainless Steel CNC part meets exact customer specifications and tolerances. Our commitment to excellence, combined with competitive pricing and reliable delivery schedules, has made us a preferred choice for customers seeking high-quality Stainless Steel CNC machined components worldwide. we machine Stainless Steel parts from castings as well as Stainless Steel bars. We have Stainless Steel investment casting foundry that can cast intricate shapes.

Price: US$ 13/Kilogram

Material Grades and International Standards

| Grade | ASTM | DIN | BS | JIS | Chinese | Composition | Applications |

|---|---|---|---|---|---|---|---|

| 304 | A240/A276 | 1.4301 | 304S15 | SUS304 | 0Cr18Ni9 | 18% Cr, 8% Ni | General purpose, food grade |

| 316 | A240/A276 | 1.4401 | 316S31 | SUS316 | 0Cr17Ni12Mo2 | 18% Cr, 10% Ni, 2% Mo | Marine, chemical resistance |

| 316L | A240/A276 | 1.4404 | 316S11 | SUS316L | 00Cr17Ni14Mo2 | Low carbon 316 | Welding applications |

| 321 | A240/A276 | 1.4541 | 321S31 | SUS321 | 0Cr18Ni10Ti | Titanium stabilized | High temperature |

| 310 | A240/A276 | 1.4845 | 310S24 | SUS310S | 0Cr25Ni20 | 25% Cr, 20% Ni | High temperature oxidation |

| 17-4 PH | A564 | 1.4542 | – | SUS630 | 0Cr17Ni4Cu4Nb | Precipitation hardening | Aerospace, medical |

| 2205 | A240 | 1.4462 | 318S13 | SUS329J3L | 00Cr22Ni5Mo3N | Duplex stainless | Oil & gas industry |

Stainless Steel CNC Components

Our Stainless Steel CNC Components represent the pinnacle of precision engineering, manufactured using advanced computer numerical control technology that ensures exceptional accuracy and repeatability. These components are produced from premium grades of Stainless Steel including 304, 316, 316L, 321, and specialty alloys, each selected based on specific application requirements and environmental conditions. Our CNC machining centers are equipped with multi-axis capabilities, allowing us to create complex geometries and intricate features that traditional machining methods cannot achieve. The Stainless Steel CNC Components we manufacture undergo rigorous quality inspection using coordinate measuring machines (CMM) and surface finish testing equipment to ensure they meet or exceed customer specifications. From simple bushings and spacers to complex valve bodies and pump housings, our Stainless Steel CNC Components are designed to withstand harsh operating conditions while maintaining dimensional stability and corrosion resistance. We specialize in both prototype and production runs, offering flexibility in quantities from single pieces to large-scale manufacturing volumes.

Stainless Steel CNC Parts

Stainless Steel CNC Parts manufactured in our facility encompass a broad spectrum of precision-machined components that serve critical functions across multiple industries. Our CNC turning and milling operations produce Stainless Steel parts with exceptional surface finishes ranging from as-machined to mirror polish, depending on application requirements. These parts are manufactured using state-of-the-art CNC lathes, machining centers, and specialized equipment that can handle complex programming and tight tolerances down to ±0.001 inches (±0.025mm). Our Stainless Steel CNC Parts include shafts, flanges, connectors, housings, brackets, and custom-designed components that require precise dimensional control and superior mechanical properties. The inherent corrosion resistance of Stainless Steel makes these CNC parts ideal for applications in food processing, pharmaceutical manufacturing, chemical processing, and marine environments where material integrity is paramount. Each Stainless Steel CNC part undergoes comprehensive testing including dimensional verification, surface roughness measurement, and material certification to ensure compliance with international quality standards.

CNC Machined Stainless Steel Parts and Fittings

CNC Machined Stainless Steel Parts and Fittings represent a specialized category of precision components designed for fluid handling, structural connections, and mechanical assemblies. Our manufacturing capabilities include threaded fittings, pipe connectors, valve components, pump parts, and custom-designed assemblies that require precise thread forms and sealing surfaces. These CNC machined parts are produced using advanced threading operations, boring cycles, and surface finishing techniques that ensure optimal performance in high-pressure and high-temperature applications. The Stainless Steel fittings we manufacture comply with industry standards such as ANSI, ASME, API, and DIN specifications, making them suitable for integration into existing systems without compatibility issues. Our CNC machining process for these parts includes specialized operations such as knurling, threading, chamfering, and precision drilling that create functional features essential for proper assembly and operation. Quality control measures for CNC Machined Stainless Steel Parts and Fittings include pressure testing, thread gauge verification, and leak testing to ensure they meet stringent performance requirements.

316 Stainless Steel Parts

316 Stainless Steel Parts manufactured in our facility are specifically engineered for applications requiring superior corrosion resistance and enhanced mechanical properties. The addition of molybdenum in 316 Stainless Steel provides exceptional resistance to chloride corrosion, making these parts ideal for marine environments, chemical processing equipment, and medical devices. Our CNC machining operations for 316 Stainless Steel parts utilize specialized cutting tools and optimized machining parameters that account for the material’s work-hardening characteristics and heat generation during cutting. These parts undergo heat treatment processes when required to achieve specific mechanical properties and stress relief, ensuring dimensional stability and enhanced performance under load. The 316 Stainless Steel parts we produce include impellers, valve stems, surgical instruments, food processing equipment components, and architectural hardware that demand both aesthetic appeal and functional excellence. Our quality assurance program for 316 Stainless Steel parts includes material certification, mechanical testing, and corrosion resistance verification to ensure they meet the stringent requirements of critical applications.

Stainless Steel 304 Machined Parts

Stainless Steel 304 Machined Parts constitute the largest volume of our production, reflecting the versatility and widespread applicability of this austenitic Stainless Steel grade. Our CNC machining operations for 304 Stainless Steel are optimized to take advantage of the material’s excellent machinability while managing its tendency to work-harden during cutting operations. These machined parts are produced using carefully controlled cutting speeds, feed rates, and tool geometries that minimize work hardening and ensure consistent surface finishes. Stainless Steel 304 Machined Parts from our facility include kitchen equipment components, architectural hardware, automotive trim pieces, and industrial fasteners that require good corrosion resistance and attractive appearance. The non-magnetic nature of annealed 304 Stainless Steel makes these parts suitable for electronic applications and environments where magnetic interference must be minimized. Our manufacturing process for Stainless Steel 304 Machined Parts includes optional passivation treatments that enhance corrosion resistance and provide a clean, uniform surface finish suitable for food contact applications and pharmaceutical equipment.

Stainless Steel Screw Machine Parts

Stainless Steel Screw Machine Parts represent high-volume precision components manufactured using specialized CNC turning centers and multi-spindle screw machines designed for efficient production of cylindrical parts. Our screw machine operations are particularly well-suited for producing small to medium-sized Stainless Steel parts with complex turning profiles, multiple diameters, and intricate features that require precise dimensional control. These parts include screws, pins, bushings, spacers, and connector components that are used in automotive, electronics, medical device, and industrial equipment applications. The Stainless Steel Screw Machine Parts we manufacture benefit from the superior machinability of free-machining Stainless Steel grades such as 303 and 416, which allow for higher cutting speeds and improved surface finishes. Our screw machine operations incorporate automatic bar feeding systems, live tooling capabilities, and integrated quality monitoring systems that ensure consistent part quality and dimensional accuracy throughout production runs. Secondary operations for Stainless Steel Screw Machine Parts may include threading, knurling, drilling, and specialized surface treatments that enhance functionality and appearance.

Stainless Steel CNC Milled Parts

Stainless Steel CNC Milled Parts showcase our advanced milling capabilities and represent some of the most complex components in our manufacturing portfolio. Our CNC milling operations utilize 3-axis, 4-axis, and 5-axis machining centers equipped with high-speed spindles and advanced tool management systems that enable the production of intricate geometries and precise features. These milled parts include pump housings, valve bodies, manifolds, brackets, and custom-designed components that require complex pocketing, contouring, and surface machining operations. The Stainless Steel CNC Milled Parts we produce often incorporate multiple features such as threaded holes, seal grooves, mounting surfaces, and precision bores that must be held to tight positional tolerances. Our milling operations for Stainless Steel parts utilize flood coolant systems and specialized cutting tools designed for Stainless Steel machining, ensuring optimal tool life and surface finish quality. Quality control for Stainless Steel CNC Milled Parts includes comprehensive dimensional inspection using CMM equipment and surface finish verification to ensure all features meet specified requirements.

Precision Stainless Steel Machined Parts

Precision Stainless Steel Machined Parts represent the highest level of manufacturing accuracy and quality control in our production capabilities, with tolerances typically held to ±0.0005 inches (±0.013mm) or better depending on part geometry and features. These parts are manufactured using our most advanced CNC equipment, including machines with thermal compensation, precision spindles, and high-resolution feedback systems that ensure exceptional accuracy and repeatability. Our precision machining operations for Stainless Steel parts incorporate specialized fixturing, temperature-controlled environments, and rigorous process monitoring to maintain the tight tolerances required for critical applications. Precision Stainless Steel Machined Parts from our facility serve industries such as aerospace, medical devices, semiconductor equipment, and precision instrumentation where dimensional accuracy and surface finish quality are paramount. The manufacturing process for these parts includes multiple inspection points, statistical process control, and final verification using calibrated measuring equipment traceable to national standards. Our precision Stainless Steel parts often require specialized surface treatments such as electropolishing, passivation, or coating applications that enhance performance and extend service life in demanding applications.

Manufacturing Processes and Machinery

CNC Turning Operations:

- Multi-axis CNC lathes with live tooling capabilities

- Swiss-type automatic screw machines for high-precision cylindrical parts

- Vertical and horizontal turning centers for large diameter components

- Sub-spindle operations for complete part machining in single setup

CNC Milling Operations:

- 3-axis, 4-axis, and 5-axis machining centers

- High-speed machining capabilities for complex geometries

- Horizontal machining centers for heavy-duty cutting operations

- Multi-pallet systems for lights-out manufacturing

Secondary Operations:

- Thread rolling and cutting operations

- Drilling and tapping using precision tooling

- Surface grinding and finishing operations

- Heat treatment and stress relieving processes

Quality Control Equipment:

- Coordinate Measuring Machines (CMM) with touch probe technology

- Surface roughness testing equipment

- Optical comparators for profile verification

- Thread gauge and go/no-go testing equipment

Typical Parts Produced

| Part Category | Examples | Size Range | Tolerance | Surface Finish |

|---|---|---|---|---|

| Valve Components | Bodies, stems, seats | 0.5″ to 12″ | ±0.002″ | Ra 32-125 μin |

| Pump Parts | Impellers, housings, shafts | 1″ to 24″ | ±0.003″ | Ra 63-250 μin |

| Flanges | RF, RTJ, flat face | 0.5″ to 36″ | ±0.005″ | Ra 125-250 μin |

| Fasteners | Bolts, nuts, studs | M3 to M100 | ±0.001″ | Ra 32-125 μin |

| Bushings | Plain, flanged | 0.25″ to 6″ | ±0.0005″ | Ra 16-63 μin |

| Housings | Motor, gearbox, pump | 2″ to 48″ | ±0.005″ | Ra 125-500 μin |

Surface Finishes and Heat Treatment

Available Surface Finishes:

- As-machined (Ra 125-500 μin)

- Fine machined (Ra 32-125 μin)

- Ground finish (Ra 16-63 μin)

- Polished finish (Ra 8-32 μin)

- Mirror polish (Ra 4-16 μin)

- Electropolished (enhanced corrosion resistance)

- Passivated (ASTM A967 standards)

Heat Treatment Options:

- Solution annealing (stress relief)

- Precipitation hardening (17-4 PH grade)

- Cryogenic treatment (dimensional stability)

- Stress relieving (reducing residual stresses)

Industries and Applications

Aerospace Industry: Landing gear components, hydraulic fittings, structural brackets, engine parts requiring high strength-to-weight ratio and corrosion resistance in extreme environments.

Automotive Sector: Exhaust system components, fuel system parts, transmission components, and decorative trim pieces that demand durability and aesthetic appeal.

Medical Device Manufacturing: Surgical instruments, implantable device components, diagnostic equipment parts requiring biocompatibility and sterilization capability.

Food and Beverage Processing: Pump components, valve parts, conveyor elements, and processing equipment requiring FDA compliance and easy cleaning characteristics.

Chemical and Petrochemical: Process equipment components, piping systems, reactor parts, and instrumentation components for corrosive environments.

Marine Applications: Propeller shafts, deck hardware, pump components, and structural elements requiring saltwater corrosion resistance.

Pharmaceutical Equipment: Clean room components, mixing vessel parts, filling equipment components requiring validation and documentation.

Tolerances and Quality Standards

| Dimension Range | Standard Tolerance | Precision Tolerance | Ultra-Precision |

|---|---|---|---|

| 0.000″ to 0.500″ | ±0.005″ | ±0.002″ | ±0.0005″ |

| 0.501″ to 2.000″ | ±0.007″ | ±0.003″ | ±0.001″ |

| 2.001″ to 6.000″ | ±0.010″ | ±0.005″ | ±0.002″ |

| 6.001″ to 12.000″ | ±0.015″ | ±0.007″ | ±0.003″ |

| Above 12.000″ | ±0.020″ | ±0.010″ | ±0.005″ |

Thread Tolerances: 2A/2B class for standard applications, 3A/3B class for precision applications Surface Finish: Ra 16 to 500 μin depending on application requirements Roundness: 0.0005″ TIR for precision applications Concentricity: 0.002″ TIR for critical components

Material Properties of Common Stainless Steel Grades

| Property | 304 | 316 | 316L | 321 | 17-4 PH |

|---|---|---|---|---|---|

| Tensile Strength (psi) | 75,000-85,000 | 75,000-85,000 | 70,000-80,000 | 75,000-85,000 | 190,000-200,000 |

| Yield Strength (psi) | 30,000-35,000 | 30,000-35,000 | 25,000-30,000 | 30,000-35,000 | 170,000-180,000 |

| Elongation (%) | 40-45 | 40-45 | 40-50 | 40-45 | 12-15 |

| Hardness (HRB) | 70-85 | 70-85 | 70-85 | 70-85 | 44-46 HRC |

| Density (lb/in³) | 0.290 | 0.290 | 0.290 | 0.290 | 0.280 |

| Melting Point (°F) | 2550-2650 | 2500-2550 | 2500-2550 | 2550-2650 | 2700-2790 |

| Thermal Conductivity | 9.4 | 9.4 | 9.4 | 9.4 | 11.2 |

Turnaround Time and Performance Metrics

Standard Turnaround Time: 4-6 weeks from order confirmation depending on part complexity and quantity requirements.

Expedited Services Available: Rush orders can be accommodated with 2-3 weeks delivery for standard parts with additional charges.

Performance Metrics:

- On-time delivery rate: 98.5%

- First-pass quality rate: 99.2%

- Customer satisfaction rating: 4.8/5.0

- Return rate: Less than 0.1%

- Process capability index (Cpk): 1.67 or higher

Production Capacity:

- Small parts (under 2″): 10,000-50,000 pieces per month

- Medium parts (2″-12″): 1,000-5,000 pieces per month

- Large parts (over 12″): 100-500 pieces per month

- Prototype quantities: 1-100 pieces within 1-2 weeks

Frequently Asked Questions (Q&A)

Q1: What is the minimum order quantity for Stainless Steel CNC parts? A: We accommodate orders from single prototype pieces to large production runs. There is no strict minimum order quantity, though small quantities may have higher per-piece pricing due to setup costs.

Q2: Can you machine exotic Stainless Steel grades like Duplex 2205 or Super Austenitic 254 SMO? A: Yes, we have experience machining a wide range of Stainless Steel grades including Duplex, Super Duplex, and Super Austenitic alloys. We adjust our machining parameters and tooling selection based on the specific grade requirements.

Q3: What documentation do you provide with Stainless Steel CNC parts? A: We provide material test certificates, dimensional inspection reports, surface finish verification, and certificates of compliance as required. For aerospace and medical applications, we can provide additional documentation including traceability records.

Q4: Do you offer secondary operations like passivation and electropolishing? A: Yes, we provide comprehensive secondary operations including passivation per ASTM A967, electropolishing, heat treatment, surface coating, and assembly services through our network of certified partners.

Q5: What is your capability for holding tight tolerances on Stainless Steel parts? A: We routinely hold tolerances of ±0.001″ (±0.025mm) on critical dimensions and can achieve ±0.0005″ (±0.013mm) on precision applications with appropriate part design and fixturing.

Q6: Can you machine Stainless Steel parts with complex geometries and undercuts? A: Our 5-axis machining capabilities allow us to produce complex parts with undercuts, angled features, and compound curves in single setups, reducing handling and improving accuracy.

Q7: What quality certifications do you maintain? A: We are ISO 9001:2015 certified and maintain AS9100D certification for aerospace applications. Our quality system includes statistical process control and continuous improvement programs.

Q8: Do you provide design assistance for Stainless Steel CNC parts? A: Yes, our engineering team provides design for manufacturability (DFM) reviews, suggests optimizations for cost reduction, and can recommend appropriate Stainless Steel grades for specific applications.

Q9: What file formats do you accept for CNC programming? A: We accept various formats including STEP, IGES, Parasolid, SolidWorks, AutoCAD, and PDF drawings. Our CAM programming team can work with 2D drawings or 3D models as needed.

Q10: Can you handle both metric and imperial specifications? A: Absolutely. We work with both metric and imperial measurements and can provide parts manufactured to either system with appropriate documentation and inspection reports.

Q11: What is your approach to cost optimization for Stainless Steel CNC parts? A: We focus on design optimization, material utilization efficiency, optimized machining strategies, and volume-based pricing to provide competitive costs while maintaining quality standards.

Q12: Do you provide packaging and shipping services worldwide? A: Yes, we offer customized packaging solutions including customer-branded packaging and handle worldwide shipping through established logistics partners with full documentation and tracking capabilities.

Why Choose Our Stainless Steel CNC Parts

Three Decades of Global Experience: Our 30+ years in precision machining has given us unparalleled expertise in working with various Stainless Steel grades and understanding the unique challenges each presents during CNC operations.

Advanced Manufacturing Technology: We continuously invest in state-of-the-art CNC equipment, measuring systems, and manufacturing technology to stay at the forefront of precision machining capabilities.

Flexible Production Scheduling: Unlike many manufacturers, we offer flexibility in production scheduling and can accommodate rush orders, prototype requirements, and just-in-time delivery schedules to meet your project timelines.

Superior Customer Communication: Our multilingual technical team provides clear communication throughout the project lifecycle, from initial quotation through final delivery, ensuring you’re always informed about your order status.

Comprehensive Quality Assurance: Our quality management system exceeds industry standards with multiple inspection points, statistical process control, and comprehensive documentation that provides complete traceability.

Customization Capabilities: We excel at producing custom Stainless Steel CNC parts according to your exact specifications, including specialized features, unique geometries, and application-specific requirements.

Global Supply Chain Integration: Our established relationships with material suppliers worldwide ensure consistent material quality and availability, while our logistics network enables efficient delivery to any global location.

Value Engineering Services: Our engineering team actively works with customers to optimize designs for manufacturability, cost-effectiveness, and performance, often resulting in significant cost savings without compromising quality.

Responsive Customer Support: Our dedicated customer service team provides rapid response to inquiries, technical support, and after-sales service to ensure your complete satisfaction with our Stainless Steel CNC parts.

Packaging and Shipping

Standard Packaging Methods:

- Individual part protection using VCI (Vapor Corrosion Inhibitor) materials

- Foam cushioning and custom-formed packaging for delicate components

- Cardboard boxes with moisture barrier protection

- Wooden crates for large or heavy components

- Anti-static packaging for electronic applications

Custom Packaging Options:

- Customer-branded packaging with logos and part numbers

- Special preservation methods for long-term storage

- Kitting and assembly packaging for multiple components

- Clean room packaging for medical and aerospace applications

- Export packaging compliant with international shipping requirements

Shipping and Logistics:

- Worldwide shipping through established courier and freight networks

- Express shipping options available for urgent requirements

- Full documentation including commercial invoices, packing lists, and certificates

- Tracking and monitoring throughout the shipping process

- Insurance coverage for high-value shipments

Our Unique Selling Propositions (USPs)

Customization Excellence: Our ability to customize every aspect of production, from material selection to final packaging, sets us apart in the industry. We work closely with customers to understand their specific requirements and deliver tailored solutions.

Production Flexibility: Unlike rigid production schedules of larger manufacturers, we offer flexible production timing that can accommodate changing customer requirements, urgent deadlines, and varying batch sizes.

Technical Expertise: Our team of experienced engineers and machinists brings decades of specialized knowledge in Stainless Steel machining, enabling us to tackle challenging projects that others might decline.

Quality at Every Step: Our comprehensive quality management system ensures consistent results from first article to final delivery, with statistical process control and continuous improvement programs.

Global Reach with Personal Touch: While we serve customers worldwide, we maintain personal relationships and provide dedicated support that larger corporations often cannot match.

Competitive Pricing Structure: Our efficient operations and optimized processes allow us to offer competitive pricing without compromising on quality or service standards.

International Standards Compliance

ASTM Standards: A240, A276, A479, A564, A967 (passivation) DIN Standards: DIN 17440, DIN 17456, DIN 17458 BS Standards: BS EN 10088, BS EN 10095 JIS Standards: JIS G4303, JIS G4304, JIS G4305 IS Standards: IS 6911, IS 6912 (Indian Standards) ISO Standards: ISO 9001:2015 (Quality Management) AS Standards: AS9100D (Aerospace Quality)

Customer Testimonial

John Marshman, Procurement Manager, UK: “We have been sourcing precision Stainless Steel CNC components from this Indian manufacturer for over eight years, and they consistently exceed our expectations. Their attention to detail, quality control processes, and ability to meet our stringent aerospace requirements make them an invaluable partner. The 316L pump housing components they manufactured for our satellite propulsion systems performed flawlessly in space applications. What impressed us most was their proactive communication during a critical project timeline and their willingness to expedite production without compromising quality. Their technical team understood our complex specifications immediately and provided valuable suggestions that improved our design. We’ve never had a quality issue, and their delivery performance is outstanding. I would highly recommend them to any company seeking reliable, high-quality Stainless Steel CNC machining services.”

Glossary of Terms

Austenitic Stainless Steel: Non-magnetic Stainless Steel with face-centered cubic crystal structure, excellent corrosion resistance and formability.

CNC (Computer Numerical Control): Automated machining process controlled by programmed commands rather than manual operation.

Passivation: Chemical treatment that removes free iron and enhances the natural corrosion-resistant properties of Stainless Steel.

Work Hardening: Increase in material hardness during machining operations, particularly common in austenitic Stainless Steels.

Surface Roughness (Ra): Arithmetic average deviation of surface profile from mean line, measured in microinches or micrometers.

Precipitation Hardening: Heat treatment process that increases strength through formation of precipitates in the material matrix.

Duplex Stainless Steel: Two-phase microstructure containing both austenite and ferrite, providing enhanced strength and corrosion resistance.

Electropolishing: Electrochemical process that removes surface material to improve finish and corrosion resistance.

CMM (Coordinate Measuring Machine): Precision measuring device that determines dimensional accuracy of machined parts.

Feed Rate: Speed at which cutting tool advances through material during machining operations.

Related Parts:

Stainless Steel CNC machining services, custom Stainless Steel parts manufacturing, precision Stainless Steel components, CNC turned Stainless Steel parts, Stainless Steel CNC prototyping, medical grade Stainless Steel parts, aerospace Stainless Steel components, marine grade Stainless Steel parts, food grade Stainless Steel CNC parts,

Stainless Steel CNC Machining Process Flow

Raw Material → CNC Programming → Setup → Machining → Quality Control → Finishing → Packaging → Shipping

Contact Us for Your Stainless Steel CNC Parts Requirements

Ready to discuss your Stainless Steel CNC machining project? Our experienced engineering team is standing by to provide technical consultation, design recommendations, and competitive quotations for your specific requirements.

📧 Email us for a detailed brochure: sales@brass-copper-parts. com- Receive our comprehensive capabilities brochure with detailed specifications, case studies, and technical data sheets.

📞 Call us directly: +91-22-43449300 – Speak with our technical experts who can provide immediate assistance and project guidance.

💬 WhatsApp for quick response: +91-91-22-43449300- Get fast answers to your technical questions and preliminary quotations.

📋 Request a Quote: Submit your drawings, specifications, and requirements through our online quote system for a detailed proposal within 24 hours.

🏭 Schedule a Virtual Facility Tour: Experience our manufacturing capabilities through a virtual tour of our CNC machining facilities and quality control laboratories.

Let us be your trusted partner for precision Stainless Steel CNC parts and machined components. Contact us today to discover how our three decades of experience can benefit your next project.