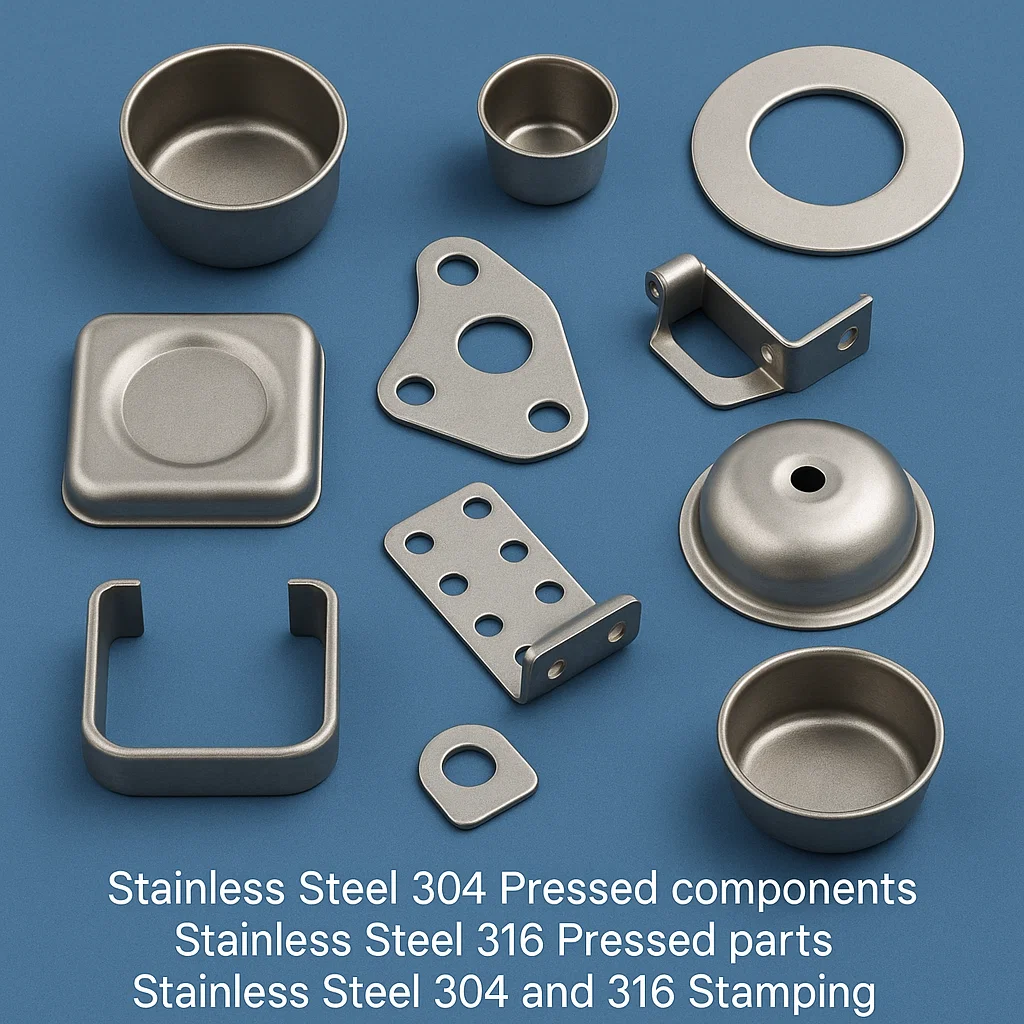

Stainless Steel Pressed Parts & Stainless Steel Sheet Metal Components, Stainless Steel Stamped Parts -Components, Stainless Steel Pressing Stamping

Price: US$8.30/kilogram

We are one of the leading manufacturers and exporters of precision Stainless Steel pressed parts and sheet metal components from India. We have been supplying high-quality Stainless Steel fabricated components to the world market for many decades. Our state-of-the-art manufacturing facility specializes in precision pressing, stamping, and forming of Stainless Steel grades including SS304, SS316, SS409, and SS430. With over three decades of expertise in metal forming technologies, we deliver custom-engineered solutions for automotive, aerospace, medical, electronics, and industrial applications. Our advanced progressive die stamping capabilities enable us to produce complex geometries with tight tolerances ranging from 0.05mm to 0.1mm. From prototype development to high-volume production runs, we maintain consistent quality standards certified under ISO 9001:2015. Our global clientele trusts us for reliable supply chain management, competitive pricing, and technical excellence in Stainless Steel component manufacturing.

Stainless Steel Pressed Parts

Stainless Steel pressed parts represent the cornerstone of precision metal forming technology, where raw Stainless Steel sheets undergo mechanical deformation through controlled pressure application. Our pressing operations utilize hydraulic and mechanical presses ranging from 25 tons to 800 tons capacity, enabling the formation of complex three-dimensional components from flat Stainless Steel blanks. The pressing process involves plastic deformation beyond the elastic limit, creating permanent shape changes while maintaining the inherent corrosion resistance and mechanical properties of Stainless Steel. Deep drawing, embossing, flanging, and coining operations are performed using precision-engineered dies and punches manufactured from hardened tool steels. Our pressed components exhibit excellent dimensional accuracy, superior surface finish, and consistent wall thickness distribution, making them ideal for critical applications in food processing equipment, pharmaceutical machinery, and architectural hardware.

Stainless Steel Sheet Metal Components

Stainless Steel sheet metal components encompass a comprehensive range of fabricated parts created through cutting, bending, forming, and joining processes. Our sheet metal fabrication capabilities include laser cutting with precision tolerances of ±0.1mm, CNC punching for high-speed hole patterns, and CNC press brake forming for accurate bend angles. Sheet thickness ranges from 0.3mm to 6.0mm, accommodating various application requirements from lightweight electronics enclosures to robust industrial housings. Advanced nesting software optimizes material utilization, reducing waste and ensuring cost-effective production. TIG and MIG welding processes create seamless joints with full penetration, while spot welding provides efficient assembly for multi-piece constructions. Surface treatments including passivation, electropolishing, and powder coating enhance appearance and performance characteristics of finished sheet metal components.

Stainless Steel 304 Pressed Parts

Stainless Steel 304 pressed parts leverage the exceptional formability and corrosion resistance of austenitic grade 304, containing 18-20% Chromium and 8-12% Nickel. The face-centered cubic crystal structure provides excellent ductility, enabling complex forming operations including deep drawing ratios exceeding 2.0:1. Work hardening characteristics allow progressive strengthening during forming, achieving ultimate tensile strengths up to 750 MPa in the formed condition. Our SS304 pressed components demonstrate superior performance in food contact applications, chemical processing equipment, and marine environments. Grain refinement during pressing enhances fatigue resistance and impact toughness, making these parts suitable for dynamic loading conditions. The non-magnetic properties in the annealed condition are particularly valuable for electronic applications, while the austenitic structure ensures excellent low-temperature toughness down to cryogenic temperatures.

Stainless Steel 316 Pressed Components

Stainless Steel 316 pressed components incorporate 2-3% Molybdenum addition, providing enhanced corrosion resistance in chloride-rich environments and elevated temperature applications. The superior pitting and crevice corrosion resistance makes SS316 pressed parts indispensable for marine hardware, chemical processing vessels, and pharmaceutical equipment. Our forming processes are optimized for the slightly higher work hardening rate of grade 316, requiring careful control of forming speeds and die lubrication. The enhanced creep resistance at temperatures up to 600°C enables applications in heat exchangers and exhaust systems. Biocompatibility certification to ASTM F138 standards makes our SS316 pressed components suitable for medical implants and surgical instruments. The austenitic microstructure remains stable under forming stresses, preventing martensitic transformation that could compromise corrosion resistance.

| Grade | ASTM | EN/DIN | JIS | GB (China) | IS (India) | Composition (%) |

|---|---|---|---|---|---|---|

| SS304 | A240 Type 304 | 1.4301 | SUS304 | 0Cr18Ni9 | 304S31 | 18Cr-8Ni-0.08C max |

| SS304L | A240 Type 304L | 1.4307 | SUS304L | 00Cr18Ni9 | 304S11 | 18Cr-8Ni-0.03C max |

| SS316 | A240 Type 316 | 1.4401 | SUS316 | 0Cr17Ni12Mo2 | 316S31 | 16Cr-10Ni-2Mo-0.08C max |

| SS316L | A240 Type 316L | 1.4404 | SUS316L | 00Cr17Ni14Mo2 | 316S11 | 16Cr-10Ni-2Mo-0.03C max |

| SS409 | A240 Type 409 | 1.4512 | SUS409 | 00Cr11Ti | 409S19 | 11Cr-Ti stabilized |

| SS430 | A240 Type 430 | 1.4016 | SUS430 | 1Cr17 | 430S15 | 17Cr-0.12C max |

Stainless Steel Pressing Work

Stainless Steel pressing work encompasses specialized metal forming operations designed to transform flat sheet material into three-dimensional components through controlled plastic deformation. Our pressing operations utilize advanced servo-driven presses with programmable motion profiles, enabling precise control of forming velocity, dwell time, and pressure application. Force monitoring systems ensure consistent forming conditions across production batches, while adaptive control algorithms compensate for material property variations. Die temperature control systems maintain optimal forming temperatures, particularly critical for high-strength Stainless Steel grades requiring elevated temperature forming. Progressive hardening during pressing work increases yield strength by 150-300%, creating components with enhanced structural integrity. Lubrication systems using biodegradable forming fluids reduce die wear and improve surface finish quality.

Stainless Steel Stamping Work

Stainless Steel stamping work combines precision cutting and forming operations in single or multiple-stage processes, utilizing high-speed mechanical and servo presses for maximum productivity. Our stamping capabilities include blanking, piercing, drawing, embossing, and coining operations with cycle rates exceeding 200 strokes per minute for simple geometries. Progressive die designs enable complex part production through sequential forming stations, eliminating secondary operations and reducing manufacturing costs. Transfer press systems handle large components requiring multiple forming stages with automatic part handling between stations. Stamping work precision is maintained through real-time die monitoring, automatic strip feeding systems, and statistical process control methods. Carbide cutting edges and surface treatments extend die life beyond 500,000 cycles for high-volume production requirements.

| Process | Machinery | Capacity Range | Tolerance Achievable | Sheet Thickness |

|---|---|---|---|---|

| Deep Drawing | Hydraulic Press | 100-800 Tons | ±0.05mm | 0.5-3.0mm |

| Progressive Stamping | Mechanical Press | 25-400 Tons | ±0.08mm | 0.3-2.5mm |

| Fine Blanking | Fine Blanking Press | 160-630 Tons | ±0.02mm | 0.5-8.0mm |

| Hydroforming | Hydroform Press | 200-1000 bar | ±0.1mm | 0.8-4.0mm |

| Spinning | CNC Spinning Lathe | Ø50-1500mm | ±0.15mm | 0.5-6.0mm |

Stainless Steel Thin Sheet Stamped Parts and Components

Stainless Steel thin sheet stamped parts represent the pinnacle of precision metal forming for applications requiring minimal weight, maximum strength-to-weight ratios, and exceptional dimensional accuracy. Working with sheet thicknesses ranging from 0.1mm to 1.5mm demands specialized tooling designs, ultra-precise clearances, and advanced material handling systems to prevent buckling and distortion. Our thin sheet stamping processes incorporate micro-lubrication systems, climate-controlled forming environments, and vibration-isolated presses to achieve feature tolerances within ±0.02mm. Spring-back compensation algorithms account for elastic recovery in thin sections, ensuring final dimensions meet design specifications. Electronic components, medical devices, aerospace brackets, and automotive sensor housings represent typical applications for thin sheet Stainless Steel stamped components. Advanced nesting optimization maximizes material yield while maintaining grain direction alignment for optimal mechanical properties.

Progressive Pressing and Stamping in Stainless Steel

Progressive pressing and stamping in Stainless Steel represents the most efficient method for high-volume production of complex components requiring multiple forming operations. Our progressive die systems integrate up to 12 stations within single tooling assemblies, performing sequential operations including pilot hole punching, progressive drawing, trimming, piercing, and forming in continuous strip feed processes. Servo-driven press technology enables variable speed control throughout the stroke cycle, optimizing forming conditions for each station while maintaining overall cycle efficiency. Strip guidance systems utilizing carbide pilots and progressive carriers ensure precise registration between stations, maintaining cumulative tolerances within ±0.05mm across all operations. Automatic scrap handling and part ejection systems eliminate manual intervention, enabling lights-out production capabilities. Die protection sensors prevent damage from misfeeds or material variations, while force monitoring provides real-time process validation.

| Component Type | Thickness Range | Primary Industries | Key Features |

|---|---|---|---|

| Electronic Enclosures | 0.5-1.2mm | Electronics, Telecommunications | EMI Shielding, Precision Bends |

| Medical Device Components | 0.3-2.0mm | Medical, Pharmaceutical | Biocompatible, Sterilizable |

| Automotive Brackets | 1.0-3.0mm | Automotive, Heavy Equipment | High Strength, Corrosion Resistant |

| Aerospace Clips | 0.5-1.5mm | Aerospace, Defense | Lightweight, High Performance |

| Food Processing Parts | 0.8-4.0mm | Food & Beverage, Dairy | Hygienic Design, Easy Cleaning |

| Architectural Hardware | 1.5-6.0mm | Construction, Marine | Weather Resistant, Aesthetic |

| Heat Exchanger Components | 0.5-2.5mm | HVAC, Chemical Processing | Thermal Conductivity, Corrosion Resistance |

| Spring Elements | 0.2-3.0mm | Automotive, Industrial Machinery | High Fatigue Resistance, Precise Loading |

Material Properties and Performance Metrics

| Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness (HB) | Density (g/cm³) |

|---|---|---|---|---|---|

| SS304 | 205-310 | 515-620 | 40-60 | 150-200 | 8.00 |

| SS304L | 170-310 | 485-620 | 40-60 | 150-200 | 8.00 |

| SS316 | 205-310 | 515-620 | 40-60 | 150-217 | 8.03 |

| SS316L | 170-310 | 485-620 | 40-60 | 150-217 | 8.03 |

| SS409 | 205-275 | 380-515 | 20-25 | 150-200 | 7.80 |

| SS430 | 205-275 | 450-620 | 22-30 | 150-217 | 7.75 |

Dimensional Tolerances

Linear Dimensions: ±0.02mm to ±0.1mm depending on feature size and complexity

Angular Tolerances: ±0.5° for formed features

Flatness: 0.05mm per 100mm length

Surface Finish: Ra 0.4 to Ra 1.6 μm

Production Capabilities

Batch Size: 100 pieces to 1 million+ annually

Turnaround Time: 4-6 weeks for new tooling

Prototype Development: 1-2 weeks

Production Capacity: 2000+ tons/month

🔧 Stainless Steel Pressed & Stamped Parts with Industry Usage

1. Electrical & Electronics

Stainless Steel Terminal Lugs – Switchgear, transformers, control panels.

Busbar Links & Connectors – Power distribution, switchgear.

Shielding Covers & EMI Brackets – Electronics, telecom, defense.

Contact Plates – Relays, circuit breakers.

2. Automotive & Transportation

Stainless Steel Clips & Stainless Steel Brackets – Wiring harness, dashboards, seat assemblies.

Stainless Steel Washers, Stainless Steel Shims & Spacers – Engines and suspension.

Heat Shields & Exhaust Clamps – Automotive exhaust systems.

Retaining Plates & Spring Clips – Railways, trucks, buses.

3. Aerospace & Defense

Lightweight Structural Stainless Steel Brackets – Aircraft interiors, UAVs.

Stainless Steel Gaskets & Seal Retainers – Jet engines, defense vehicles.

Spring Washers & Fastening Clips – Vibration-resistant assemblies.

4. HVAC & White Goods

Fan Guards & Motor Mounts – Air conditioners, refrigerators.

Stamped Housings & Covers – Compressors, washing machines.

Ventilation Louvers – HVAC ducts, chillers.

Stainless Steel Pipe Clamps – Chillers, ductwork, refrigeration piping.

5. Medical & Pharmaceutical

Surgical Tool Blanks – Scissors, clamps, blades.

Filter Screens & Mesh Supports – Sterilizers, IV sets, pharma processing.

Battery Contacts & Device Clips – Diagnostic equipment.

6. Construction, Plumbing & Architecture

Anchor Plates & Mounting Brackets – Facade systems, elevators.

Stamped Hinges & Latches – Doors, cabinets, enclosures.

Decorative Pressed Panels – Interiors, architectural trims.

Stainless Steel Brackets – Shelving, modular furniture, piping supports.

Pipe Clamps & Hangers – Plumbing, drainage, fire-fighting pipelines.

Sink Sieves / Sink Strainers – Kitchen sinks, hotel/restaurant plumbing.

7. Industrial Machinery

Bearing Retainers & Rings – Pumps, motors, turbines.

Coupling Plates & Spacer Discs – Gear assemblies.

Sealing Rings & Flanges – Valves, compressors.

8. Marine & Offshore

Deck Fittings (Clips, Cleats, Brackets) – Boats, offshore rigs.

Corrosion-Resistant Washers & Lugs – Marine electricals.

Hatch Hinges & Locking Plates – Ships, naval vessels.

Frequently Asked Questions (Technical Q&A)

Q1: What is the minimum thickness of Stainless Steel sheet that can be pressed effectively?

A: We can successfully press Stainless Steel sheets as thin as 0.1mm using specialized thin-gauge forming techniques. However, for optimal results and cost-effectiveness, we recommend minimum thicknesses of 0.3mm for SS304/316 and 0.5mm for ferritic grades like SS409/430.

Q2: How do you prevent cracking in deep-drawn Stainless Steel components?

A: Cracking prevention involves multiple strategies including optimized blank holder pressure, progressive forming stages, appropriate die radii (typically 4-6 times material thickness), proper lubrication with chlorine-free compounds, and controlled forming speeds. For severe draws, we employ intermediate annealing at 1050°C.

Q3: What tolerances can be achieved in progressive stamping operations?

A: Progressive stamping typically achieves ±0.05mm for critical dimensions, ±0.08mm for general features, and ±0.15mm for non-critical dimensions. Cumulative tolerances across multiple stations are controlled through precision pilot systems and statistical process control.

Q4: How do you ensure consistent material properties across different coil lots?

A: We maintain comprehensive incoming material inspection including chemical analysis, mechanical testing, grain size evaluation, and surface quality assessment. Each coil is certified with mill test certificates and undergoes batch sampling for tensile strength, yield strength, and elongation verification.

Q5: What is the maximum drawing ratio achievable for Stainless Steel deep drawing?

A: For SS304/316, we typically achieve drawing ratios up to 2.2:1 in single operations, and up to 4.0:1 through multi-stage progressive drawing. Ferritic grades like SS430 are limited to approximately 1.8:1 due to lower ductility characteristics.

Q6: How do you control spring-back in high-strength Stainless Steel grades?

A: Spring-back compensation involves over-bending calculations based on material properties, FEA simulation validation, and empirical adjustments. We typically over-bend by 2-5 degrees depending on bend radius, material thickness, and grain direction relative to bend axis.

Q7: What surface treatments are available for pressed Stainless Steel components?

A: Available treatments include passivation per ASTM A967, electropolishing for enhanced surface finish, pickling for scale removal, vibratory finishing for deburring, and various coating options including powder coating, PVD coating, and specialized anti-fingerprint treatments.

Q8: How do you handle dimensional verification for complex pressed parts?

A: We employ coordinate measuring machines (CMM) with accuracy of ±0.002mm, laser scanning for complex geometries, optical comparators for profile verification, and functional gauging for assembly features. Statistical sampling plans follow military standards.

Q9: What is the typical tool life expectancy for Stainless Steel stamping dies?

A: Tool life varies significantly with part complexity and material grade. For SS304/316, we typically achieve 300,000-800,000 cycles, while ferritic grades may extend to 1,000,000+ cycles. Carbide inserts and proper maintenance can double these figures.

Q10: How do you ensure traceability for aerospace and medical applications?

A: Complete traceability includes material certifications, heat lot tracking, process parameter recording, dimensional inspection reports, and final certification packages. Each component is laser-marked with unique identification for full supply chain traceability.

Q11: What are your capabilities for prototype development and low-volume production?

A: Prototype development utilizes soft tooling, 3D-printed forming blocks, and universal dies for rapid turnaround within 1-2 weeks. Low-volume production (100-5000 pieces) can be accommodated using progressive dies or single-stage operations depending on complexity requirements.

Q12: How do you maintain quality consistency during high-volume production runs?

A: Quality consistency is maintained through automated process monitoring, real-time force feedback systems, statistical process control with control charts, regular preventive maintenance schedules, and continuous operator training programs following lean manufacturing principles.

Why Choose Our Stainless Steel Pressed Parts

Our three decades of specialized experience in Stainless Steel component manufacturing positions us as the preferred global supplier for critical applications across diverse industries. Advanced Manufacturing Technology forms the foundation of our competitive advantage, utilizing state-of-the-art servo-driven presses, progressive die systems, and computerized process control to deliver components with exceptional dimensional accuracy and surface finish quality. Our Technical Excellence is demonstrated through ISO 9001:2015 certification, AS9100 aerospace qualification, and FDA-registered medical device manufacturing capabilities, ensuring compliance with the most stringent international quality standards.

Flexibility and Customization represent core strengths of our operation, accommodating everything from prototype quantities of 10 pieces to high-volume production runs exceeding one million components annually. Our engineering team collaborates closely with customers during the design phase, providing Design for Manufacturing (DFM) recommendations, finite element analysis validation, and cost optimization strategies. Global Supply Chain Excellence ensures reliable delivery performance with standard turnaround times of 4-6 weeks for new tooling development and 2-3 weeks for repeat orders, supported by comprehensive export documentation and international logistics expertise.

Customer-Centric Service distinguishes our approach through dedicated technical support, multilingual communication capabilities, and customized packaging solutions including customer branding and labeling requirements. Our quality assurance program provides 100% dimensional inspection, material traceability documentation, and comprehensive certification packages meeting aerospace, medical, and automotive industry requirements.

Competitive Cost Structure leverages India’s manufacturing advantages while maintaining world-class quality standards, delivering 20-30% cost savings compared to traditional supply sources without compromising technical performance or delivery reliability.

“We have been sourcing precision Stainless Steel stamped components from this Indian manufacturer for over eight years, and their consistency in quality and delivery has been exceptional. Their technical team’s expertise in progressive die design helped us reduce our assembly costs by 25% through component consolidation. The dimensional accuracy of ±0.02mm on critical features and their proactive communication throughout the production process makes them our preferred supplier for all SS304 and SS316 requirements.”

– Michael Richardson, Senior Procurement Manager, Toronto, Canada

Packaging, Shipping, and Global Export Services

Our comprehensive packaging solutions are designed to ensure safe transit and customer convenience across international shipping routes. Standard packaging utilizes corrosion-resistant VCI (Vapor Corrosion Inhibitor) films, moisture-absorbing desiccants, and shock-resistant foam inserts within export-grade cardboard containers or wooden crates for heavy shipments. Custom packaging accommodates specific customer requirements including branded labeling, sequential part numbering, and specialized protective materials for sensitive electronic components or precision medical devices.

Export documentation includes commercial invoices, packing lists, certificate of origin, mill test certificates, dimensional inspection reports, and any required regulatory certifications such as FDA registration or CE marking. Our logistics partnerships with major international freight forwarders ensure competitive shipping rates and reliable transit times, with typical delivery schedules of 2-3 weeks to North American destinations, 1-2 weeks to European markets, and 3-5 days for express air shipment requirements.

| Feature Type | Minimum Size | Maximum Size | Tolerance | Remarks |

|---|---|---|---|---|

| Overall Part Dimensions | 5mm x 5mm | 800mm x 1200mm | ±0.05mm | Based on press bed size |

| Hole Diameter | 0.5mm | 200mm | ±0.02mm | Minimum 1.2x material thickness |

| Bend Radius | 0.5x thickness | 25mm | ±0.1mm | Material grade dependent |

| Flange Height | 2x thickness | 150mm | ±0.05mm | Progressive forming available |

| Wall Thickness | 0.3mm | 6.0mm | ±5% | Drawn component variation |

International Standards Compliance

Our manufacturing processes and quality systems maintain compliance with major international standards ensuring global acceptability and regulatory approval. ASTM Standards including A240 for Stainless Steel plate specifications, A480 for general requirements, and A967 for passivation treatments provide the foundation for material properties and processing parameters. European Standards compliance includes EN 10088 for Stainless Steel specifications, EN 10204 for inspection documents, and various DIN standards for dimensional tolerances and surface finish requirements.

Japanese Industrial Standards (JIS) particularly JIS G4305 for Stainless Steel plates and JIS G4321 for cold-rolled steel strips ensure compatibility with Asian market requirements. Chinese National Standards (GB) compliance facilitates supply to Chinese OEMs and joint ventures operating internationally. Indian Standards (IS) including IS 6911 for Stainless Steel specifications and IS 1848 for chemical composition requirements demonstrate domestic regulatory compliance while meeting export quality expectations.

Glossary of Technical Terms

Austenitic Stainless Steel: Non-magnetic Stainless Steel grades with face-centered cubic crystal structure, including SS304 and SS316, characterized by excellent formability and corrosion resistance.

Stainless Steel 304: A stainless Steel grade with- Fe (balance), Cr 18–20%, Ni 8–10.5%, C ≤0.08%, Mn ≤2.0%, Si ≤1.0%, P ≤0.045%, S ≤0.030%, N ≤0.10%

Stainless Steel 316 – A Stainless Steel material grade with Fe (balance), Cr 16–18%, Ni 10–14%, Mo 2–3%, C ≤0.08%, Mn ≤2.0%, Si ≤1.0%, P ≤0.045%, S ≤0.030%, N ≤0.10%

Blanking: Cutting operation that produces the external contour of a component, with the cut-out piece becoming the desired part rather than scrap material.

Deep Drawing: Metal forming process where flat sheet material is drawn into forming dies by mechanical action to create hollow, seamless components with significant depth-to-diameter ratios.

Drawing Ratio: Relationship between blank diameter and punch diameter in deep drawing operations, indicating the severity of deformation and material flow requirements.

Ferritic Stainless Steel: Magnetic Stainless Steel grades with body-centered cubic crystal structure, including SS409 and SS430, offering good corrosion resistance and lower cost compared to austenitic grades.

Forming Limit Diagram (FLD): Graphical representation showing the maximum strains a material can withstand before necking or fracture occurs during sheet metal forming operations.

Grain Direction: Orientation of metal crystals created during rolling operations, significantly affecting mechanical properties and forming behavior in directional applications.

Progressive Die: Multi-station tooling system that performs sequential operations on strip material, enabling complex part production through automatic advancement between forming stations.

Spring-back: Elastic recovery phenomenon where formed metal partially returns to its original shape after forming forces are removed, requiring compensation in die design.

Work Hardening: Increase in material strength and hardness resulting from plastic deformation during forming operations, particularly significant in austenitic Stainless Steel grades.

Primary Terminology

- Stainless Steel Pressed Parts

- SS Pressed Components

- Stainless Steel Stamping

- Metal Pressed Parts

- Stainless Steel Fabrication

Manufacturing Terminology

- Stainless Steel Deep Drawing

- SS Progressive Stamping

- Stainless Steel Blanking

- Metal Forming Services

- Stainless Steel Punching

- SS Embossing Services

- Stainless Steel Coining

- Metal Pressing Technology

- Hydraulic Press Components

- Precision Metal Stamping

Grade-Specific Terms:

- 304 Stainless Steel Pressed Parts

- 316 Stainless Steel Components

- 410 SS Pressed Parts

- 430 Stainless Steel Stamping

- Duplex Steel Pressed Components

- Super Duplex Pressed Parts

- 17-4 PH Pressed Components

- 301 Stainless Steel Parts

Industry-Specific Applications

- Automotive Stainless Steel Parts

- Medical Device SS Components

- Food Grade Pressed Parts

- Pharmaceutical SS Components

- Electronics Stainless Steel Parts

- Aerospace SS Pressed Parts

- Marine Stainless Steel Components

- Chemical Industry SS Parts

Product-Specific Terms:

- SS Brackets and Mounting Parts

- Stainless Steel Housings

- SS Enclosures and Covers

- Stainless Steel Flanges

- SS Heat Shields

- Stainless Steel Gaskets

- SS Springs and Clips

- Stainless Steel Washers

- SS Diaphragms

- Stainless Steel Bezels

Technical Specifications

- Precision SS Pressed Parts

- High Tolerance Stainless Parts

- Custom SS Pressed Components

- Complex Stainless Steel Parts

- Thin Gauge SS Stamping

- Heavy Gauge SS Pressing

- Mirror Finish SS Parts

- Brushed Finish SS Components

Manufacturing Terms:

- Stainless Steel Pressed Parts India

- SS Components Manufacturer India

- Indian SS Pressing Services

- Stainless Steel Parts Exporter India

- SS Fabrication Company India

- Metal Pressing Services Mumbai

- Chennai SS Parts Manufacturer

- Pune Stainless Steel Components

- Custom Metal Stamping

- Sheet Metal Fabrication

- Precision Metal Components

- Industrial Metal Parts

- OEM Stainless Steel Parts

- Contract Manufacturing SS

- Metal Component Supplier

- SS Parts Prototype Services

Long-Tail terms:

- Small Batch Stainless Steel Pressing

- High Volume SS Component Production

- Rapid Prototyping SS Parts

- Custom Design SS Pressed Components

- Cost Effective SS Manufacturing

- Quick Turnaround SS Parts

- Precision Tooling SS Components

- Secondary Operations SS Parts

- Surface Treatment SS Components

- Assembly Services SS Parts

Technical Process Terms:

- Progressive Die SS Stamping

- Transfer Die SS Pressing

- Single Stage SS Stamping

- Multi-Stage Deep Drawing SS

- Hydroforming Stainless Steel

- Spin Forming SS Components

- Roll Forming SS Parts

- Stretch Forming SS Components

Request Your Custom Quote Today

Ready to partner with India’s leading Stainless Steel pressed parts manufacturer? Our technical team is standing by to discuss your specific requirements and provide comprehensive solutions for your next project.

📧 Email: sales@brass-copper-parts. com

📱 WhatsApp: +91-22-43449300

📞 Phone: +91-22-43449300

🌐 Website: www.brass-copper-parts.com

Request Your Free Technical Brochure – Comprehensive 50-page catalog featuring detailed specifications, material properties, case studies, and technical drawings for over 200 standard component designs.

Schedule a Virtual Factory Tour – Connect with our engineering team via video conference to discuss your specific requirements and see our manufacturing capabilities in real-time.

“Your Success is Our Commitment – Precision Engineered, Globally Delivered”