Stainless Steel CNC Machined Parts & Components: Machined from AISI 316 and 304 for perfection

Stainless steel CNC machined parts are the cornerstone of modern precision manufacturing, offering an unparalleled combination of strength, corrosion resistance, and durability. Computer Numerical Control (CNC) machining transforms raw stainless steel stock into highly complex, tight-tolerance components essential for critical applications across aerospace, medical, automotive, and food processing industries. This process leverages advanced machining centers, including CNC milling services and CNC turning services, to produce parts with exceptional repeatability and geometric complexity.

Material Grades for Stainless Steel CNC Machining

The selection of the appropriate stainless steel grade is critical to the performance and longevity of the final component. Each grade offers a unique balance of machinability, strength, and corrosion resistance.

Austenitic Stainless Steels (Non-Magnetic)

304 / 304L Stainless Steel: The most common “18-8” (18% chromium, 8% nickel) grade. Excellent for general corrosion resistance, good formability, and weldability. 304L has a lower carbon content for improved welding. Ideal for food processing equipment, chemical containers, and architectural components.

316 / 316L Stainless Steel: The superior “marine grade” stainless. Enhanced corrosion resistance, particularly against chlorides and acids, due to the addition of molybdenum. Excellent for marine environments, pharmaceutical applications, chemical processing plants, and surgical instruments.

303 Stainless Steel: A free-machining variant of 304, with added sulfur or selenium. It offers significantly improved machinability and higher feed rates, making it a top choice for high-volume production of screws, nuts, bolts, and gears where corrosion resistance is secondary to ease of manufacturing.

Martensitic Stainless Steels (Magnetic)

410 Stainless Steel: A general-purpose, heat-treatable martensitic steel. It offers good strength, moderate corrosion resistance, and excellent wear resistance after heat treatment. Commonly used for valve components, pump shafts, and fasteners.

416 Stainless Steel: The premier free-machining martensitic stainless steel. It offers the highest machinability of all stainless grades, similar to 303, but can be heat treated to higher strengths. Perfect for parts requiring extensive machining like firearm components, gears, and fittings.

Precipitation-Hardening (PH) Stainless Steels

17-4 PH (Grade 630): The most widely used PH stainless steel. It can be supplied in a solution-treated state that is easy to machine and then age-hardened to achieve very high strength (up to H900 condition). Offers good corrosion resistance and is invaluable for aerospace components, nuclear waste casks, and high-stress turbine parts.

Duplex Stainless Steels

2205 (UNS S31803): Features a mixed microstructure of austenite and ferrite. It provides approximately twice the yield strength of standard austenitic grades and excellent resistance to stress corrosion cracking. Primarily used in demanding offshore oil & gas, chemical processing, and pressure vessel applications.

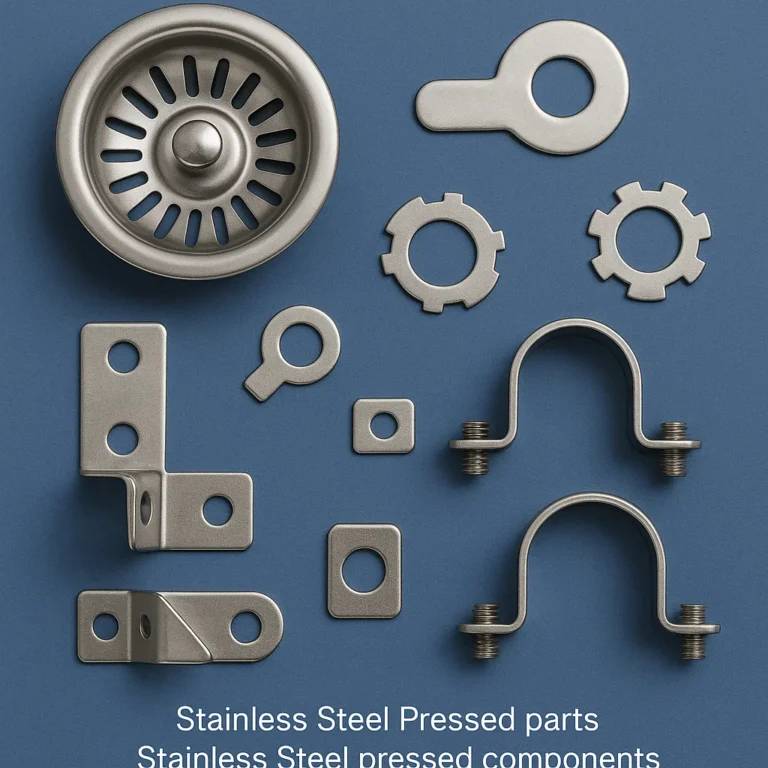

Typical Stainless Steel CNC Machined Parts & Components

CNC machining produces a vast array of stainless steel parts, from simple spacers to intricate housings. Common examples include:

Shafts and Pins: Precision-ground shafts for motors and assemblies.

Valve Bodies and Housings: Complex internal passages for controlling flow in hydraulic and pneumatic systems.

Flanges and Fittings: Custom connectors for piping systems in chemical and processing plants.

Brackets and Mounts: Structural components that require strength and environmental resistance.

Gears and Pulleys: Wear-resistant components for power transmission.

Surgical Instruments and Implants: Biocompatible (e.g., 316L) parts for medical devices and orthopedic implants.

Fasteners: Custom screws, bolts, nuts, and studs.

Nozzles and Sprays: Components for high-pressure and corrosive environments.

Sensor Housings: Protects delicate electronics in harsh conditions.

Food Processing Parts: Mixer blades, conveyor components, and fittings that meet sanitary standards.

- Stainless Steel Hose barbs, stainless Steel Welding nipples,Stainless Steel Hose Couplings, Stainless Steel pipe fittings, Stainless Steel Nipples,

Key Standards and Specifications

Stainless steel CNC machining adheres to strict international standards to ensure quality, material composition, and performance.

ASTM Standards: Govern material properties (e.g., AISI 316 is covered under ASTM A276).

ASME Standards: Often adopted for pressure vessel and boiler components (e.g., ASME SA479).

ISO 9001: Quality management systems for manufacturing processes.

ISO 13485: Specific quality standard for medical device manufacturing.

AS9100: Aerospace industry quality management standard.

Material Certifications: Mill test reports (MTRs) or certificates of conformity (C of C) are provided to validate material grade and properties.

Industries Served by Stainless Steel CNC Components

The unique properties of machined stainless steel make it indispensable in these sectors:

Aerospace & Defense: High-strength, reliable components for landing gear, engine mounts, actuators, and avionics housings. Grades like 17-4 PH are prevalent.

Medical & Surgical: Biocompatible, sterilizable, and corrosion-resistant parts for surgical tools, robotic surgery arms, implants, and diagnostic equipment. 316LV is the grade of choice.

Oil & Gas: Parts that withstand extreme pressures, corrosive sour gas (H2S), and offshore environments. Duplex and super duplex stainless steels are commonly specified.

Marine & Offshore: Hardware, pump components, and fittings resistant to saltwater corrosion, primarily using 316/316L.

Automotive & Transportation: Fuel system components, sensors, and performance racing parts that demand durability under heat and stress.

Food & Beverage Processing: Equipment that must meet strict hygienic (FDA, 3-A) standards, be easy to clean, and resist corrosive food acids. 304 and 316 are standard.

Chemical Processing: Valves, pump housings, and reactor parts that handle aggressive acids and solvents.

Electronics: Shields, chassis, and connectors that provide EMI/RFI shielding and durability.

Why Choose CNC Machining for Stainless Parts?

Precision & Tight Tolerances: CNC technology consistently holds tolerances within +/- 0.001 inches or tighter.

Complex Geometries: 5-axis CNC machining can produce highly complex shapes, undercuts, and contours in a single setup.

Excellent Material Properties: Achieves superior surface finishes and maintains the inherent strength and corrosion resistance of the base material.

Repeatability & Volume: Ideal for both low-volume rapid prototyping and high-volume production runs with identical results.

Rapid Turnaround: Advanced CNC machining services, including online quoting, facilitate quick production from CAD model to finished part.

Conclusion

Stainless steel CNC machined components are a fundamental enabling technology for industries that cannot compromise on performance, reliability, or corrosion resistance. From common 304 brackets to mission-critical 17-4 PH aerospace fittings, the synergy of advanced CNC manufacturing techniques with the versatile family of stainless steel alloys continues to drive innovation and ensure safety in the most demanding applications worldwide. When sourcing, partnering with an experienced CNC machine shop that understands material selection, precision machining strategies, and industry-specific standards is paramount to project success.