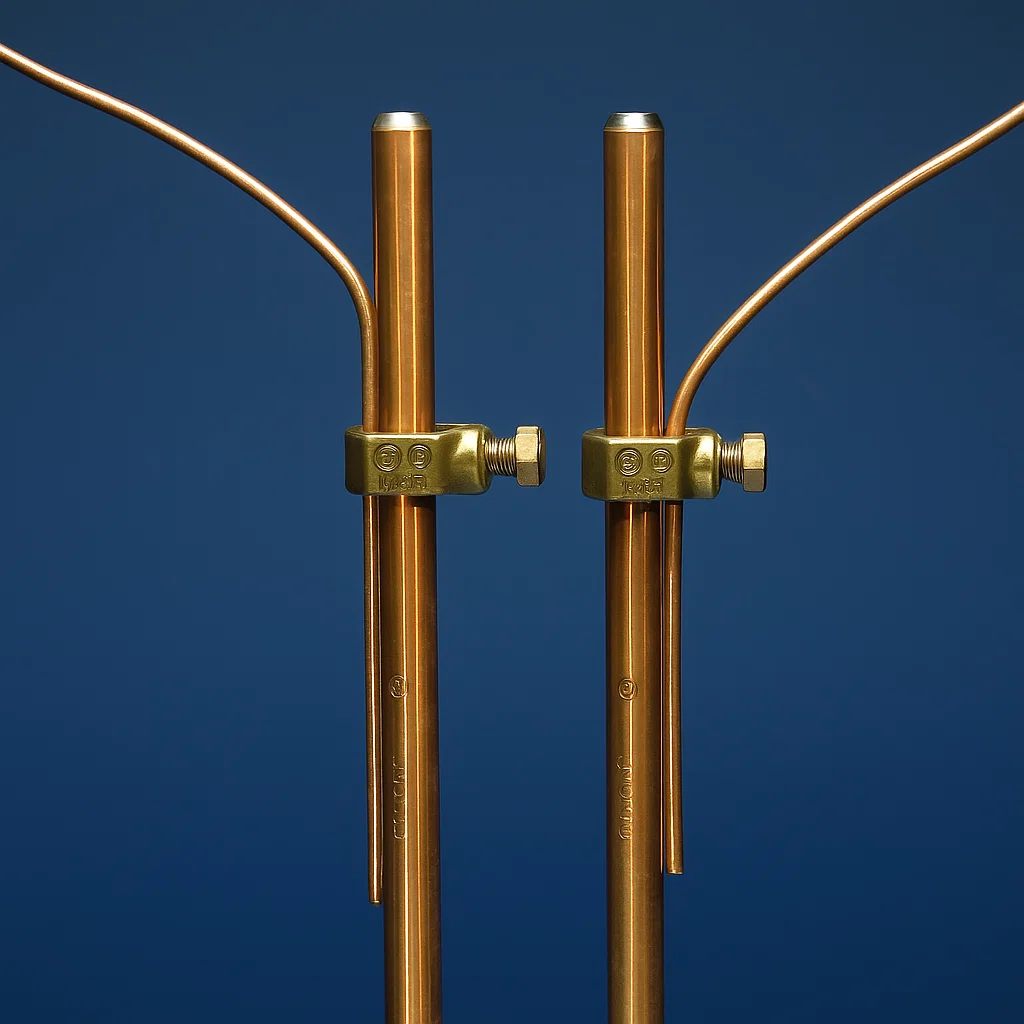

Bronze Ground Rod Clamps: Essential Components for Electrical Safety

In the world of electrical systems, safety is paramount. Among the critical components that ensure this safety are ground rod clamps – the unsung heroes that provide secure connections between grounding electrodes and electrical conductors. When it comes to durability, conductivity, and corrosion resistance, bronze ground rod clamps stand out as the premium choice for professionals worldwide. we also offer Brass Ground rod clamps along with bronze ground rod clamps. They are also called Acorn Clamps, Bronze Acorn clamps in certain markets.

Understanding Ground Rod Clamps: The Foundation of Electrical Safety

Ground rod clamps serve as the vital link in electrical grounding systems, creating secure mechanical and electrical connections between grounding electrodes and conductors. These essential components form the backbone of electrical safety systems, protecting both equipment and personnel from electrical faults and ensuring proper system operation.

The importance of reliable grounding cannot be overstated. A properly installed grounding system with quality bronze ground rod clamps provides a safe path for electrical current to flow to earth, preventing dangerous voltage buildup and protecting sensitive equipment from electrical surges.

Why Choose Bronze for Ground Rod Clamps?

Bronze alloys offer an exceptional combination of properties that make them ideal for grounding applications:

Superior Corrosion Resistance: Bronze naturally resists corrosion, making it perfect for underground installations and harsh environmental conditions. Unlike other materials that may deteriorate over time, bronze maintains its integrity for decades.

Excellent Electrical Conductivity: With conductivity ranging from 12-15% IACS (International Annealed Copper Standard), bronze clamps ensure optimal electrical performance while maintaining mechanical strength.

Outstanding Mechanical Properties: Bronze alloys provide tensile strength ranging from 550-790 MPa, ensuring reliable mechanical connections that withstand thermal cycling and environmental stress.

Antimicrobial Properties: Aluminum bronze compositions offer inherent antimicrobial characteristics, preventing biological growth that could compromise electrical connections.

Comprehensive Range of Bronze Ground Rod Clamps

Bronze Ground Rod Clamps (Standard Series)

The flagship products in this category are manufactured from premium CDA 954, CDA 955, and CDA 956 aluminum bronze alloys. These high-grade bronze clamps feature:

- Dual-bolt compression mechanisms that distribute clamping force evenly

- Precision-machined contact surfaces for maximum surface area engagement

- Accommodation for rod sizes from 3/8″ to 3/4″ diameter

- Conductor compatibility ranging from 14 AWG to 4/0 AWG

Bronze Earth Rod Clamps

Specifically engineered for earth electrode systems, these clamps utilize specialized casting processes and incorporate:

- Corrosion-resistant surface treatments suitable for aggressive soil conditions

- Ergonomic design for easy installation

- Robust mechanical connections with optimal electrical performance

- Compliance with IS 318 and DIN 17662 standards

Brass Ground Earth Rod Clamps

Combining superior workability with exceptional conductivity, brass clamps offer:

- Innovative locking mechanisms preventing loosening under thermal cycling

- Optimized contact interface design maximizing current-carrying capacity

- Resistance to stress corrosion cracking

- Compliance with ASTM B16 and JIS H3250 specifications

Bronze Acorn Clamps

These compact, aesthetically pleasing clamps feature:

- Space-saving acorn-like profile ideal for residential applications

- Threaded cap compression system ensuring even force distribution

- Smooth exterior finish reducing installation injury risk

- Accommodation for conductors from 14 AWG to 2 AWG

Technical Excellence: Material Grades and Standards

CDA Bronze Alloy Specifications

CDA 954 Aluminum Bronze: Offers excellent balance of strength and conductivity, ideal for standard grounding applications with moderate environmental exposure.

CDA 955 Aluminum Bronze: Provides enhanced mechanical properties through optimized iron and nickel content, suitable for demanding industrial applications.

CDA 956 Nickel Aluminum Bronze: Represents the premium grade with maximum corrosion resistance and mechanical performance for harsh environmental conditions.

International Standards Compliance

Bronze ground rod clamps comply with multiple international standards:

- USA Standards: ASTM B62, ASTM B584

- European Standards: BS 2872, DIN 17662

- International Standards: ISO 5183, ISO 1338

- Indian Standards: IS 318, IS 6912

- Japanese Standards: JIS H5111, JIS H5120

Key Applications Across Industries

Power Generation and Distribution

- Substation grounding systems

- Transmission tower earthing

- Electrical equipment protection

Telecommunications Infrastructure

- Cell tower installations

- Data center grounding

- Communication equipment protection

Industrial Manufacturing

- Machinery grounding

- Static electricity dissipation

- Personnel safety systems

Construction and Building Systems

- Structural steelwork grounding

- Lightning protection systems

- Electrical service entrances

Oil and Gas Industry

- Pipeline cathodic protection

- Refinery grounding systems

- Hazardous area installations

Renewable Energy Systems

- Solar installation grounding

- Wind farm earthing

- Energy storage system protection

Performance Specifications and Features

Electrical Performance

- Contact Resistance: ≤50 microohms under standard conditions

- Current-Carrying Capacity: Validated through comprehensive testing

- Thermal Cycling: Maintains performance under temperature variations

Mechanical Properties

- Clamping Force: Consistent retention through thermal cycling

- Dimensional Tolerance: ±0.2mm for overall dimensions

- Surface Finish: Ra 1.6μm for optimal contact

Environmental Resistance

- Corrosion Rate: As low as 0.015 mm/year in seawater (CDA 956)

- Temperature Range: -40°C to +85°C operational range

- Service Life: 20-30 years in standard soil conditions

Installation Best Practices

Proper Size Selection

- Measure ground rod diameter accurately

- Determine conductor gauge requirements

- Select appropriate clamp size (3/8″, 1/2″, 5/8″, or 3/4″)

- Verify conductor range compatibility

Installation Guidelines

- Apply recommended torque specifications for optimal connection

- Ensure clean contact surfaces before installation

- Use anti-seize compounds where recommended

- Follow manufacturer’s installation instructions

Quality Assurance

- Verify material compliance through certification documentation

- Conduct resistance testing after installation

- Perform visual inspection for proper mechanical connection

- Document installation for maintenance records

Surface Treatment Options

Various surface treatments enhance performance and longevity:

- Natural Bronze Finish: Inherent corrosion resistance for standard conditions

- Tin Plating: Enhanced solderability and reduced contact resistance

- Nickel Plating: Superior corrosion protection and wear resistance

- Chemical Passivation: Improved corrosion resistance without dimensional changes

- Hot-Dip Galvanizing: Maximum protection for extreme environments

Quality Control and Testing

Manufacturing Excellence

- X-ray fluorescence spectrometry for material composition verification

- Coordinate measuring machines (CMM) for dimensional accuracy

- Electrical conductivity testing for performance validation

- Metallurgical analysis for material property confirmation

Testing Protocols

- Contact resistance measurement per IEC 61238 standards

- Current-carrying capacity validation under rated conditions

- Salt spray testing (ASTM B117) for corrosion resistance

- Temperature cycling (IEC 60068) for thermal performance

Choosing the Right Bronze Ground Rod Clamp

Application Considerations

- Environmental conditions (soil chemistry, moisture, temperature)

- Mechanical requirements (vibration, thermal cycling)

- Electrical specifications (current rating, conductor size)

- Installation constraints (space limitations, accessibility)

Material Selection

- Standard applications: CDA 954 Bronze for general-purpose use

- Industrial environments: CDA 955 Bronze for enhanced durability

- Harsh conditions: CDA 956 Bronze for maximum corrosion resistance

- High conductivity needs: Copper clamps for minimal resistance

Size and Configuration

- Rod diameter compatibility: Match clamp to ground rod size

- Conductor range: Ensure accommodation of required wire gauge

- Installation space: Consider clamp dimensions and clearance requirements

- Maintenance access: Plan for future inspection and maintenance

Future-Proofing Your Grounding System

Investing in high-quality bronze ground rod clamps ensures long-term reliability and performance. Consider these factors for future-proofing:

- Scalability: Choose clamps that accommodate system expansion

- Standards compliance: Ensure conformance with evolving regulations

- Environmental planning: Select materials for changing conditions

- Maintenance planning: Document specifications for future reference

Conclusion: Excellence in Electrical Safety

Bronze ground rod clamps represent a critical investment in electrical safety and system reliability. With their superior corrosion resistance, excellent electrical conductivity, and robust mechanical properties, these components provide decades of reliable service in demanding applications.

Whether you’re designing a new electrical system or upgrading existing infrastructure, choosing quality bronze ground rod clamps from experienced manufacturers ensures optimal performance and peace of mind. The combination of advanced materials, precision manufacturing, and comprehensive testing creates products that exceed industry standards and customer expectations.

For electrical contractors, utility companies, and industrial facilities worldwide, bronze ground rod clamps offer the perfect balance of performance, durability, and value. Invest in quality grounding components today and build electrical systems that stand the test of time.

Ready to enhance your grounding system with premium bronze ground rod clamps? Contact experienced manufacturers who combine three decades of expertise with state-of-the-art manufacturing capabilities to deliver superior grounding solutions for your specific requirements.