Lead Free Brass Parts, Components, and Alloys

Lead Free Brass Components, Lead Free Machined Brass Parts, Brass Lead Free alloys– In today’s environmentally conscious manufacturing landscape, lead free brass parts and lead free brass components have become essential for industries prioritizing safety, sustainability, and regulatory compliance. As experienced manufacturers of high-quality lead free brass alloys, we understand the critical importance of providing solutions that meet stringent environmental standards without compromising performance.

Understanding Lead Free Brass: A Comprehensive Overview

Lead free brass represents a revolutionary advancement in metallurgy, eliminating the health and environmental concerns associated with traditional leaded brass alloys. These innovative lead free brass alloys maintain the excellent machinability, corrosion resistance, and mechanical properties that make brass indispensable across numerous industries.

What Makes Brass “Lead Free”?

The transition from traditional brass to lead free brass parts involves replacing lead content with alternative elements such as bismuth, silicon, or other eco-friendly additives. Our lead free brass components typically contain less than 0.25% lead by weight, meeting or exceeding the most stringent international standards.

Key Advantages of Lead Free Brass Parts

Environmental Benefits

Lead free brass alloys eliminate the environmental contamination risks associated with lead leaching, making them ideal for applications involving water contact or food processing. Our manufacturing processes for lead free brass parts align with sustainable practices and circular economy principles.

Health and Safety Compliance

Modern lead free brass components provide peace of mind for manufacturers and end-users alike. These materials eliminate lead exposure risks while maintaining the superior performance characteristics expected from premium brass alloys.

Regulatory Adherence

Our lead free brass parts comply with major international standards including:

- NSF/ANSI 61 for drinking water system components

- California AB1953 (lead-free plumbing requirements)

- European RoHS Directive for electronic components

- FDA regulations for food-contact applications

Types of Lead Free Brass Alloys

Silicon Brass Alloys

Our silicon-enhanced lead free brass alloys offer exceptional machinability and corrosion resistance. These lead free brass components are particularly suitable for plumbing fixtures, valve bodies, and marine applications.

Bismuth Brass Alloys

Bismuth-containing lead free brass parts provide excellent hot workability and superior surface finish. These alloys excel in applications requiring complex geometries and tight tolerances.

Copper-Zinc-Tin Alloys

Our specialized lead free brass alloys incorporating tin additions deliver enhanced strength and wear resistance, making them ideal for heavy-duty industrial lead free brass components.

Lead-Free Brass & Related Alloys (Categorized)

1. Silicon-Based Lead-Free Alloys

| Alloy Designation | Typical Composition (Approx. %) | Key Properties & Applications |

|---|---|---|

| C69300 (EcoBrass®) | Cu: 73–77, Zn: Balance, Si: 2.7–3.4, P: 0.04–0.15 | High strength, corrosion and dezincification resistance. Used in potable water fittings, valves, PEX systems. |

| C87850 (EnviroBrass III) | Cu: 75–80, Zn: Balance, Si: 2–3, Bi: 0.5–1.5, Se: 0.05–0.1 | Excellent machinability, NSF certified. Used for faucet bodies, valves, pump housings. |

| C87500 (Silicon Red Brass) | Cu: 80–85, Zn: 4–8, Si: 2–4, Sn: 3–5 | Excellent castability and corrosion resistance. Marine pumps, impellers, water fittings. |

| C87600 / C87800 | Cu: 60–70, Zn: Balance, Si: 2–4 | Good strength, dezincification resistance. Plumbing fixtures, water meters, valves. |

2. Bismuth & Selenium-Based Lead-Free Alloys

| Alloy Designation | Typical Composition (Approx. %) | Key Properties & Applications |

|---|---|---|

| C89510 / C89520 | Cu: 85–88, Zn: 4–6, Sn: 4–6, Bi: 0.5–2.2, Se: 0.35–1.1 | Machinability similar to leaded brass. Excellent corrosion resistance. Plumbing fittings, waterworks castings. |

| C89320 (SeBiLOY) | Cu: 86–89, Zn: 4–6, Sn: 4–6, Bi: 1.5–2.2, Se: 0.3–1.0 | Excellent machinability, potable water safe. Used in valves, meter bodies, pump parts. |

| Bismuth Brass | Cu: 58–62, Zn: 36–40, Bi: 0.5–2.0 | Forging and machining brass. Substitute for leaded C36000 in drinking water fittings. |

3. Tin-Based (Naval & Dezincification Resistant)

| Alloy Designation | Typical Composition (Approx. %) | Key Properties & Applications |

|---|---|---|

| C46400 (Naval Brass) | Cu: 59–62, Zn: Balance, Sn: 0.5–1.0 | Marine corrosion resistance. Propeller shafts, condenser plates, marine hardware. |

| C44300 (Admiralty Brass) | Cu: 70, Zn: 29, Sn: 1 | Excellent resistance to dezincification and biofouling. Tubes in heat exchangers, desalination plants. |

| C44500 (Arsenical Admiralty Brass) | Cu: 70, Zn: 29, As: 0.05–0.2, Sn: 0.8–1.0 | Improved dezincification resistance. Marine condenser tubes. |

| Tin Brass (Lead-Free) | Cu: 59–62, Zn: Balance, Sn: 0.5–1.0 | Waterworks, marine and architectural fittings. |

4. Dezincification-Resistant (DZR) Lead-Free Brasses

| Alloy Designation | Typical Composition (Approx. %) | Key Properties & Applications |

|---|---|---|

| C27450 | Cu: 60–63, Zn: Balance, As/Sn: trace | Substitute for C26000 Cartridge Brass. Tubes, plumbing, architecture. |

| DZR Brass (CW602N) | Cu: 61–63, Zn: Balance, As: 0.02–0.06 | Prevents zinc leaching. Widely used in plumbing valves/fittings. |

| C28000 (Muntz Metal) | Cu: 59, Zn: 40, As/Sn: trace | Strong, corrosion-resistant. Marine sheathing, condenser tubes, architecture. |

5. Manganese / Nickel Strengthened Lead-Free Alloys

| Alloy Designation | Typical Composition (Approx. %) | Key Properties & Applications |

|---|---|---|

| Manganese Brass | Cu: 77, Zn: 12, Mn: 7, Ni: 4 | High strength, toughness. Valves, marine service, bearings. |

| C99750 (Nickel-Silicon Brass) | Cu: 65–70, Zn: Balance, Ni: 2–5, Si: 0.5–1.5 | Very high strength, corrosion resistance. Aerospace fasteners, defense hardware. |

6. Aluminum & Specialty Lead-Free Alloys

| Alloy Designation | Typical Composition (Approx. %) | Key Properties & Applications |

|---|---|---|

| C95400 (Aluminum Bronze) | Cu: 83, Al: 10–11, Fe: 3–4, Ni: 1 | Very strong, excellent wear/corrosion resistance. Bearings, bushings, marine hardware. |

| C95500 / C95800 (Nickel-Aluminum Bronze) | Cu: 79–83, Al: 9–10, Ni: 4–5, Fe: 3–5 | Exceptional strength, seawater resistance. Ship propellers, pumps, aerospace. |

| C93700 (High-Tin Bronze) | Cu: 80–85, Sn: 7–10, Zn: Balance | Bearing alloy, wear resistant, potable water safe. |

Applications of Lead Free Brass Parts and Components

Plumbing and Water Systems

Water meter housings and internal components

Valve bodies and actuator assemblies

Pipe fittings and connection hardware

Faucet cartridges and control mechanisms

Backflow prevention devices

Electrical and Electronics

Our lead free brass components serve critical roles in:

- Electrical connectors and terminal blocks

- Switch components and contact assemblies

- Heat sinks and thermal management solutions

- EMI/RFI shielding applications

- Precision electronic housings

Automotive Industry

Lead free brass alloys support automotive innovation through:

- Fuel system components and injector parts

- Brake system fittings and hydraulic components

- Air conditioning fittings and manifolds

- Sensor housings and mounting brackets

- Decorative trim and interior hardware

Marine and Offshore

Salt-water resistant lead free brass parts include:

- Propeller shafts and bearing assemblies

- Through-hull fittings and seacocks

- Navigation equipment housings

- Corrosion-resistant fasteners

- Pump components and impellers

Manufacturing Excellence in Lead Free Brass

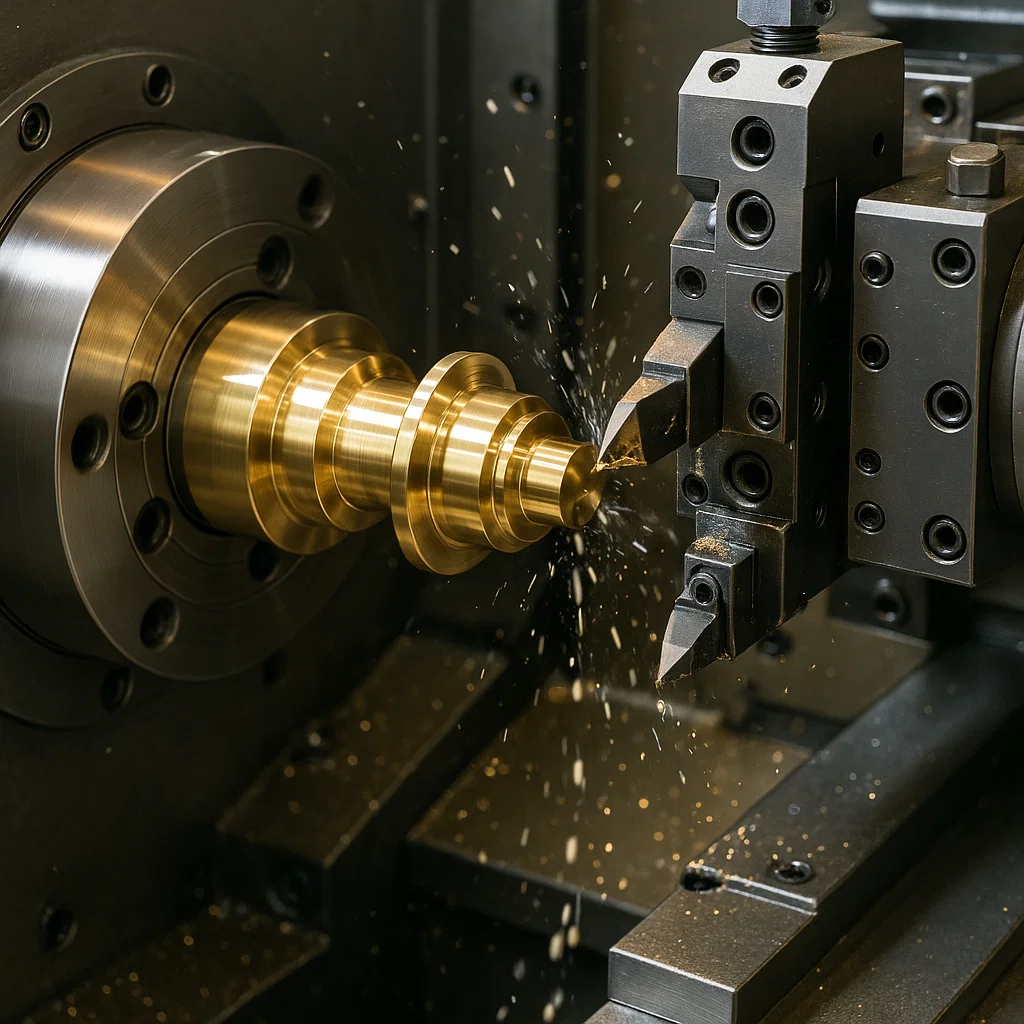

Precision Machining Capabilities

Our advanced manufacturing facilities specialize in producing lead free brass components with exceptional precision. We utilize state-of-the-art CNC machining centers, multi-axis turning equipment, and automated production systems to ensure consistent quality across all lead free brass parts.

Quality Assurance Standards

Every batch of lead free brass alloys undergoes comprehensive testing including:

- Chemical composition analysis using X-ray fluorescence spectroscopy

- Mechanical property testing for tensile strength and hardness

- Dimensional inspection using coordinate measuring machines

- Surface finish evaluation and coating adherence testing

- Corrosion resistance validation through salt spray testing

Custom Alloy Development

We collaborate with customers to develop specialized lead free brass alloys tailored to specific application requirements. Our metallurgical expertise enables the creation of custom lead free brass components optimizing performance, cost, and manufacturability.

Technical Properties of Lead Free Brass

Mechanical Characteristics

Lead free brass parts manufactured in our facilities exhibit:

- Tensile strength: 350-550 MPa depending on alloy composition

- Yield strength: 150-400 MPa across various grades

- Elongation: 15-45% providing excellent ductility

- Hardness: 70-160 HB suitable for diverse applications

- Fatigue resistance: Superior performance under cyclic loading

Thermal Properties

Our lead free brass alloys demonstrate:

- Thermal conductivity: 110-140 W/mK for efficient heat transfer

- Coefficient of expansion: 18-20 × 10⁻⁶/K for dimensional stability

- Melting point: 900-940°C enabling various processing methods

- Specific heat capacity: 380 J/kgK for thermal management applications

Electrical Properties

Lead free brass components provide:

- Electrical conductivity: 15-25% IACS for electrical applications

- Electrical resistivity: 6-12 µΩ⋅cm depending on alloy type

- Magnetic permeability: Non-magnetic characteristics for sensitive equipment

Surface Treatment and Finishing Options

Protective Coatings

Our lead free brass parts can be enhanced with various surface treatments:

- Nickel plating for enhanced corrosion resistance

- Chrome plating for decorative and functional applications

- Zinc plating for cost-effective protection

- Powder coating in custom colors and textures

- Anodizing treatments for specialized requirements

Polishing and Surface Preparation

We offer comprehensive finishing services for lead free brass components:

- Mirror polishing for aesthetic applications

- Brushed finishes for contemporary design elements

- Bead blasting for uniform matte appearances

- Tumbling operations for deburred, smooth surfaces

Industry Standards and Certifications

International Compliance

Our lead free brass alloys meet or exceed numerous international standards:

- ASTM B687 (UNS C89833) for unleaded brass

- ASTM B584 specifications for brass castings

- ISO 12165 for copper and copper alloy products

- EN 12164 European standards for brass applications

- JIS H3250 Japanese industrial standards

Quality Certifications

Our manufacturing facility maintains:

- ISO 9001:2015 quality management certification

- ISO 14001:2015 environmental management systems

- OHSAS 18001 occupational health and safety standards

- IATF 16949 automotive quality management

- AS9100 aerospace quality management systems

Economic Benefits of Lead Free Brass

Cost-Effectiveness

While lead free brass parts may have slightly higher raw material costs, they offer significant long-term value through:

- Reduced liability from environmental compliance

- Lower disposal costs due to non-hazardous classification

- Enhanced product life through superior corrosion resistance

- Premium market positioning for environmentally conscious brands

Supply Chain Advantages

Choosing lead free brass components provides:

- Regulatory future-proofing against evolving environmental standards

- Global market access without material restrictions

- Simplified documentation for international shipping

- Enhanced brand reputation through sustainable material choices

Innovation in Lead Free Brass Technology

Advanced Alloy Development

Our research and development initiatives focus on:

- Nano-enhanced brass alloys for superior properties

- Hybrid compositions combining multiple strengthening mechanisms

- Smart alloys with shape memory characteristics

- Antimicrobial brass formulations for healthcare applications

- High-temperature resistant grades for demanding environments

Manufacturing Process Innovation

We continuously improve our production of lead free brass parts through:

- Additive manufacturing for complex geometries

- Precision casting techniques for near-net-shape components

- Hot working optimization for improved grain structure

- Heat treatment innovations for enhanced properties

- Automated quality control systems for consistent results

Sustainability and Environmental Impact

Lifecycle Assessment

Our lead free brass alloys demonstrate superior environmental performance:

- 100% recyclable without performance degradation

- Lower energy consumption in secondary processing

- Reduced water treatment requirements in manufacturing

- Elimination of hazardous waste generation

- Carbon footprint reduction compared to alternative materials

Circular Economy Integration

Lead free brass components support circular economy principles through:

- Design for disassembly facilitating end-of-life recycling

- Material traceability systems for responsible sourcing

- Closed-loop recycling programs with customers

- Waste stream minimization in manufacturing processes

Future Trends in Lead Free Brass

Market Drivers

The demand for lead free brass parts continues growing due to:

- Stricter environmental regulations worldwide

- Increased consumer awareness of health impacts

- Corporate sustainability commitments across industries

- Green building standards requiring lead-free materials

- Insurance and liability considerations

Technological Advancements

Emerging trends in lead free brass technology include:

- AI-optimized alloy design for specific applications

- IoT-enabled manufacturing for real-time quality control

- Blockchain supply chain transparency for material provenance

- Digital twin modeling for predictive performance analysis

- Industry 4.0 integration for smart manufacturing

Choosing the Right Lead Free Brass Partner

Key Selection Criteria

When selecting a manufacturer for lead free brass components, consider:

- Technical expertise in alloy development and processing

- Quality certifications and compliance track record

- Manufacturing capabilities including precision and capacity

- Custom engineering support for specialized requirements

- Supply chain reliability and global reach

Our Commitment to Excellence

As leading manufacturers of lead free brass parts, we provide:

- Comprehensive technical support from design to delivery

- Rapid prototyping services for development projects

- Flexible production capabilities from prototype to high volume

- Global logistics network for timely delivery

- Continuous innovation in materials and processes

Conclusion

The transition to lead free brass parts and lead free brass components represents more than regulatory compliance—it embodies a commitment to sustainable manufacturing and responsible innovation. Our expertise in lead free brass alloys positions us as your ideal partner for current needs and future challenges.

Whether you require standard lead free brass components or custom-engineered solutions, our manufacturing capabilities and technical expertise ensure superior products that meet the highest standards for performance, quality, and environmental responsibility. Contact us today to discuss how our lead free brass parts can enhance your products and support your sustainability goals.

The future of brass manufacturing is lead-free, and we’re here to help you navigate this transition successfully. Trust in our proven experience with lead free brass alloys to deliver the components and parts that will drive your success in an increasingly environmentally conscious marketplace.